SteriFeed S180 User manual

Operating Manual

for S180 Pasteuriser

Serial No :

This Manuals belongs to

Mission Statement

Medicare Colgate Ltd continuously strives to meet the needs

of our customers by providing the latest technology in

pasteurisation equipment and consumables.

We aim to create value and make a difference.

We aim to remain the best in our field.

We aim to give more than expected.

We aim to deliver the highest level of service.

We aim to give commitment to quality.

Issue 5 4/12/2019

2

Operator Manual index

•Page 4 - Customer Specification

•Page 5 - Pasteuriser Times and Temperatures

•Page 6-7 -Do’s & Don’t’s

•Page 8-9 - Basket Options

•Page 10-13 - Bottle Options

•Page 14 - Waterproof Label for pasteuriser

•Page 15 - Pasteuriser Operation –Home Screen

•Page 16 - Pasteuriser Operation –Screen Icons

•Page 17 - Pasteuriser Operation –Bottle Probe Position

•Page 18 –SD Card Overview

•Page 19-22 - Pasteuriser Operating Sequence

•Page 23-29- Data logger Operation

•Page 30-37 - Engineer Fault finding

•Page 38 –Alarm reset instructions

•Page 39 - Cleaning Instructions

•Page 40-41 –Breakdown Form

•Page 42 –Pasteuriser sequence of events

•Page 43 - Graph

Issue 5 4/12/2019

3

Content List

Please Add Specification

Issue 5 4/12/2019

4

CYCLE TIME

Warm Up cycle is 30 minutes depending on incoming hot water temperature.

Total cycle time from start to finish is approximate 120 minutes

TIMES & TEMPERATURES

Heating Cycle :

62.5˚C (Tolerance +/- 0.5˚C) FOR 30 MINUTES ( Tolerance +5min)

Cooling:

from 62.5 ˚C to 25 ˚C – 10-12 minutes

Cooling to 4˚C for approximately 50minutes ( Tolerance + 0.5˚C)

PLEASE NOTE

Cycles 1 & 2: Have been set up for Breast Milk and are identical

The cooling time is based on the incoming cold water temperature not exceeding 20˚C and ambient room

temperature not exceeding 25˚C .

The pasteuriser program is based on incoming hot water temperature not exceeding 55C.

If temperatures exceed optimum settings cycles times can be slower.

temperature regulators can be fitted to control hot water temperatures.

Issue 5 4/12/2019

5

Times & Temperatures

✓The pasteuriser operating criteria have been set for ambient room temperature of

25 ˚C and incoming cold water from mains at 20 ˚C. Please ensure these criteria are

observed carefully as significantly higher temperatures will interfere with the

optimum running of the pasteuriser.

✓Always ensure that the content of the probe bottle matches the temperature of

the bottles to be pasteurised to get accurate results.

✓Only use waterproof labels suitable for prolonged exposure to hot & cold water.

✓If labels comes off this can damage the pasteuriser.

✓Please dry pasteuriser chamber after last cycle of the day.

Issue 5 4/12/2019

6

Do’s & Dont’s

XDo not open lid during the pasteurisation process.

XDo not forget to insert SD card at start of cycle.

XDo not remove SD card without being prompted by onscreen display.

XFor any changes to the pasteuriser factory setting please contact Sterifeed or

your local Sterifeed distributor

XDo not pasteurise frozen milk as the milk may not receive the required treatment.

When in doubt decant the milk to check for ice.

Issue 5 4/12/2019

7

Do’s & Dont’s

❑Combination Basket : This basket can be used for 130 & 250ml bottles. The

basket has spacer bars fitted. With spacer bars it is suitable for 130ml bottles

without spacer bars it is suitable for 250ml bottles.

❑Double Storey Basket : This basket is only suitable for 130ml bottles fitted

with foil seals as the bottles are totally submerged during heating & cooling. It

accommodates 144 x 130ml bottles

❑50ml Basket : this basket is only suitable for foil seal bottles and

accommodates 192 x 50ml bottles

❑100ml Basket : this is a single storey basket and accommodates 36 x 100ml

bottles

❑Special Baskets : we can provide tailor made baskets for customers who wish

to use different type bottles.

Basket Options

Issue 5 4/12/2019

8

Combination Basket

for 130ml / 250ml

130ml Double

Storey Basket

50ml Double

Storey Basket

Issue 5 4/12/2019

9

Basket Options

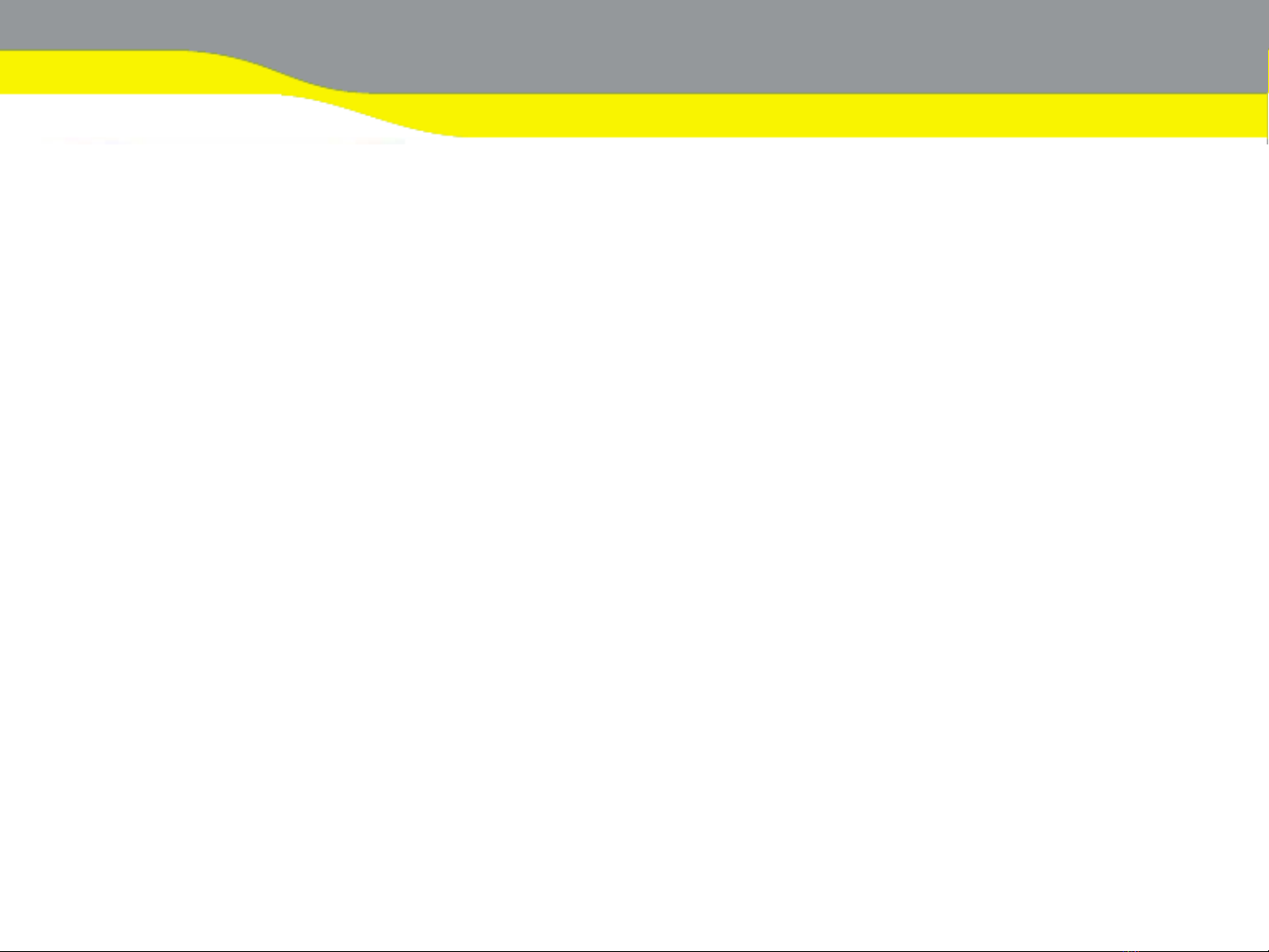

❑The Safety seal will prevent even minute volumes of water diluting the milking during

pasteurisation and cooling.

❑Tamper evident

❑The seals feature a tab to avoid touching the neck of the bottle when removing the tamper

evident foil seal.

❑The Safety seal method now answers many doctors apprehension regarding the professional

handling of pasteurised breast milk.

❑There is no additional operational cost only a marginal increase in the cost of containers. There

is a one off capital cost for the Sterifeed Induction sealer.

Sterifeed Foil Seal Bottles

Issue 5 4/12/2019

10

250ml 130ml 100ml 50ml

Issue 5 4/12/2019

11

BOTTLE CHOICES- Induction Sealer

BOTTLE CHOICES

250ml 130ml 100ml 50ml

Issue 5 4/12/2019

12

Pasteuriser Bottles

❑Water levels on the pasteuriser have been set for STERIFEED bottle

height

❑If the pasteuriser has been set for double storey baskets, only bottles

fitted with foil seals can be used.

❑If other bottles are used, please ensure that the bottles have been tested

with a leak tester to ensure no tank water can penetrate into the bottle.

Potential Hazard

❑Any change in bottle height will requires a water level adjustment and

need to be carried out by an engineer.

Bottle Specification for Pasteuriser

Issue 5 4/12/2019

13

Sterifeed Polyolefin Waterproof Easy Peel Labels

The Sterifeed label material has been specially formulated to withstand heating to

70C for 60 minutes and cooling to 4C. With a special adhesive to allow easy -peel

for when the bottles are discarded. (as per data protection act)

It is very important that the correct labels are used, as many labels classified as

waterproof are designed for water exposure but not for water immersion for any

length of time during heating and cooling conditions.

*Using the wrong labels can obstruct the pasteuriser drain & result in a malfunction*

Recommend Label Printer - ZEBRA DESK TOP PRINTER GK420T

Issue 5 4/12/2019

14

Waterproof Labels for Pasteuriser

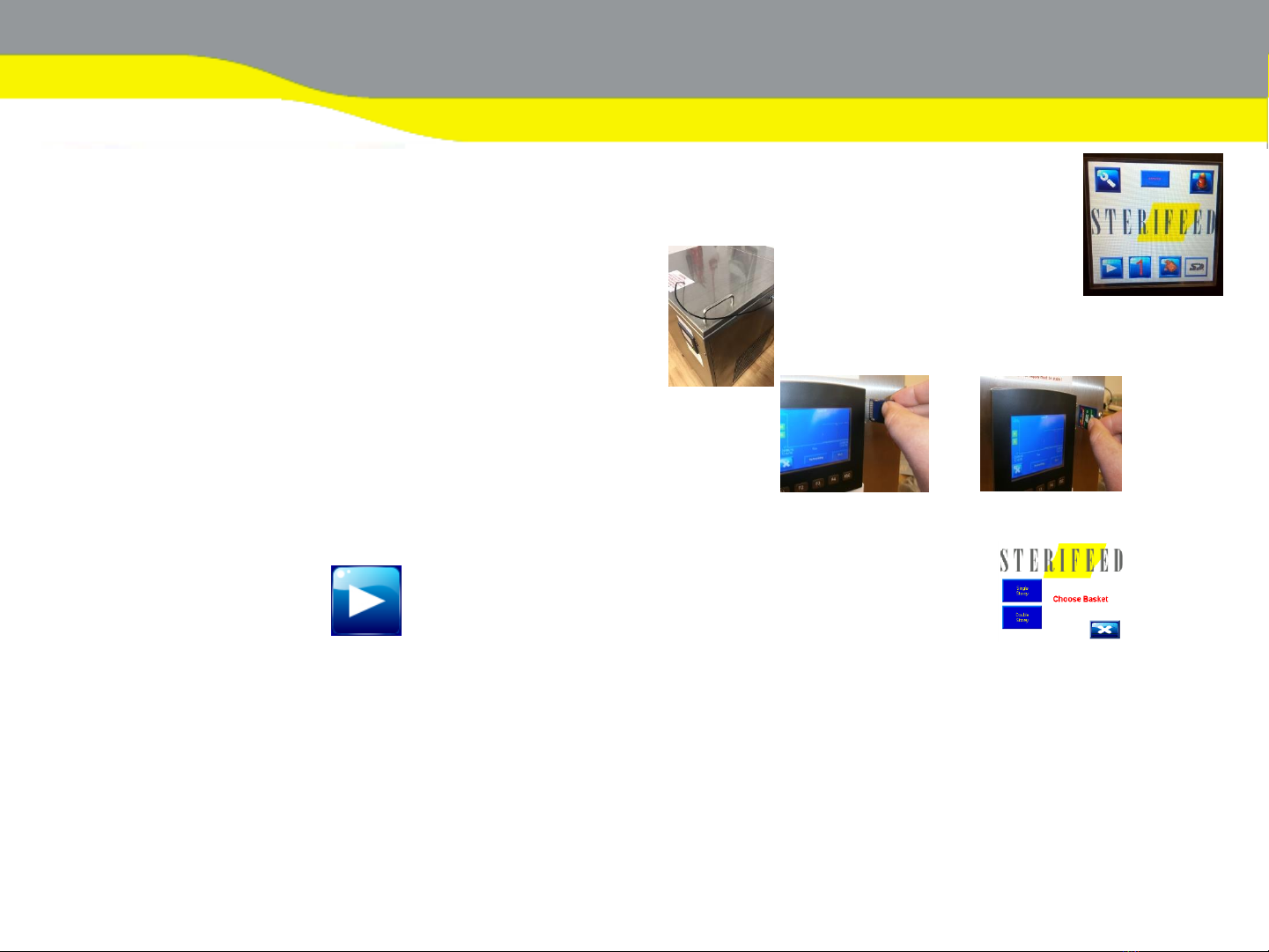

HOME SCREEN

Issue 5 4/12/2019

15

Pasteuriser Operation

SCREEN ICONS

Alarm

Issue 5 4/12/2019

16

Pasteuriser Operation

Settings Password for

settings page

Start Cycle

number Bottle

warmer

SD Card Cancel Ok

Bottle Probe Position

Issue 5 4/12/2019

17

Pasteuriser Operation

Issue 5 4/12/2019

18

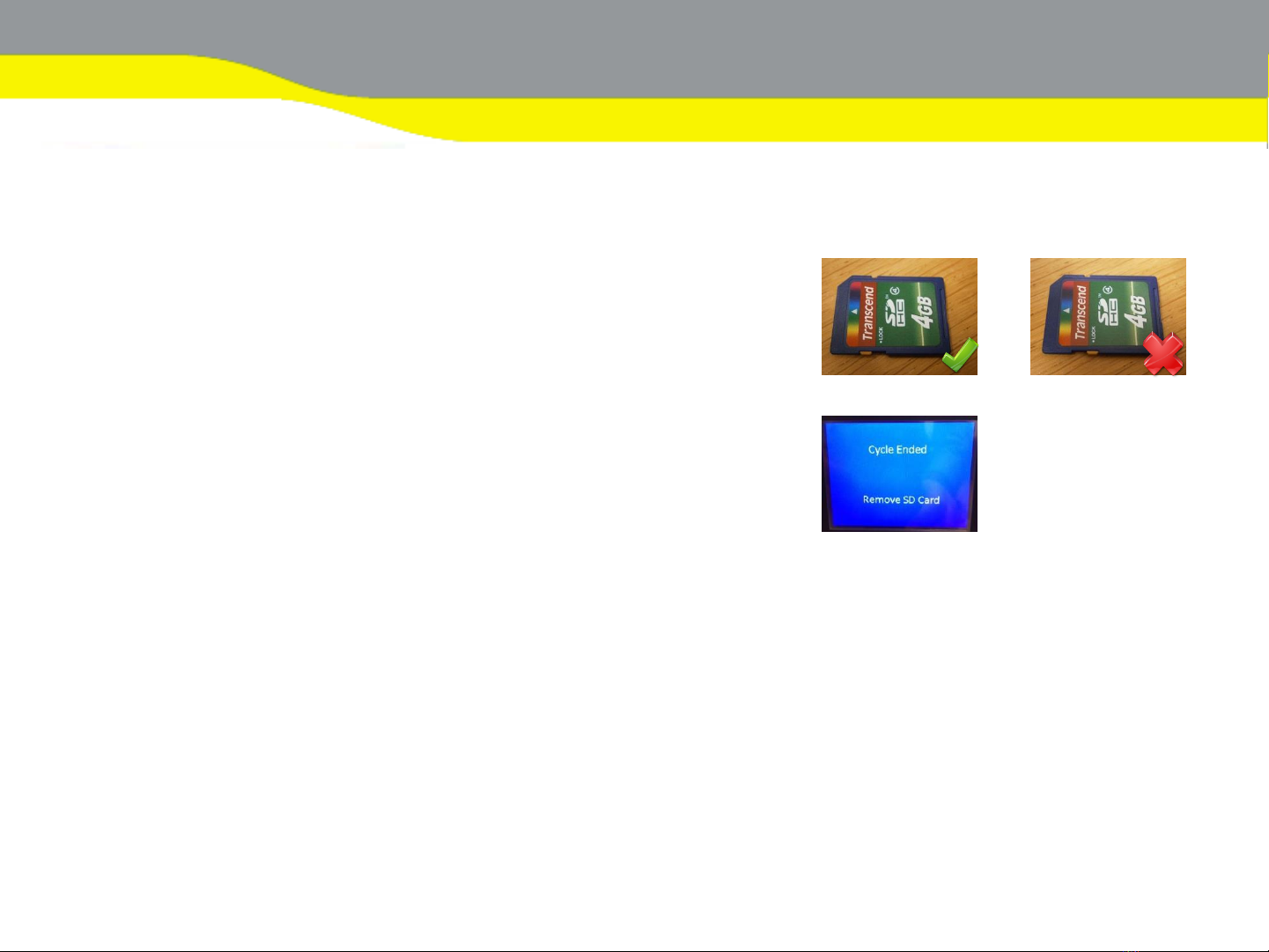

SD Card Overview

❑Please handle SD card carefully

❑Ensure the SD card lock has not been activated

❑Make sure the SD card is fully inserted into the slot

❑SD card must not be removed unless the screen

message advises you to do so

❑Only use Sterifeed pre-formatted SD cards on the Pasteuriser.

❑2 Spare SD cards are supplied with the Pasteuriser, new ones to be purchased

from Medicare Colgate Ltd.

❑With Machine On and displaying Home Screen.

❑Place probe into bath tank

❑Close Lid with No load.

❑Place SD card into the pasteuriser SD card slot.

Important -Do not remove SD Card until prompted at end of cycle

❑Press “Play” , then press on the basket you will be using.

Pasteuriser will not operate without lid closed and SD card in slot

❑Bath will now fill and Warm up.

Issue 5 4/12/2019

19

Pasteuriser Operating Sequence

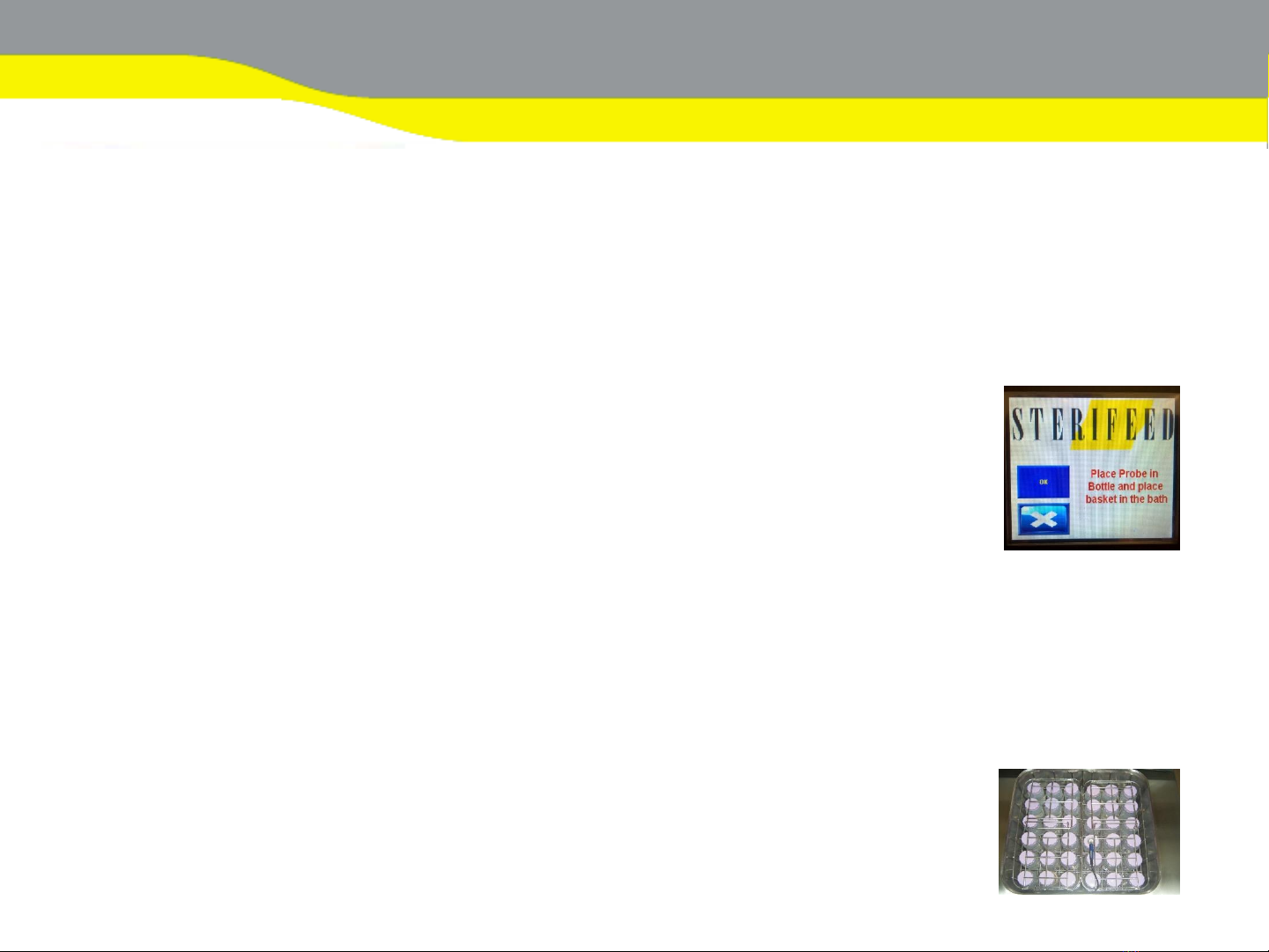

continued

❑Whilst pasteuriser is warming up prepare bottles including “ probe bottle”

and place into basket. Ensure probe bottle is the same temperature a

bottles to be pasteurised

❑When the bath has reached pasteurisation temperature the buzzer will

sound.

❑The screen display will show :

Place probe into probe bottle and place basket

with bottles into water bath.

❑Open Lid

❑Position probe into the probe bottle and then place basket into bath.

Ensure probe is not touching any part of the bottle and positioned centrally.

Pasteuriser Operating Sequence

Issue 5 4/12/2019

20

Table of contents

Other SteriFeed Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

IKA

IKA Big Squid operating instructions

Agilent Technologies

Agilent Technologies 979 Replacement manual

Gilson

Gilson DISTRIMAN user guide

IKA

IKA RET control operating instructions

Olympus

Olympus U-HGLGPS instruction manual

Chemglass Life Sciences

Chemglass Life Sciences JACKETED FILTER Assembly instructions