CONTENTS

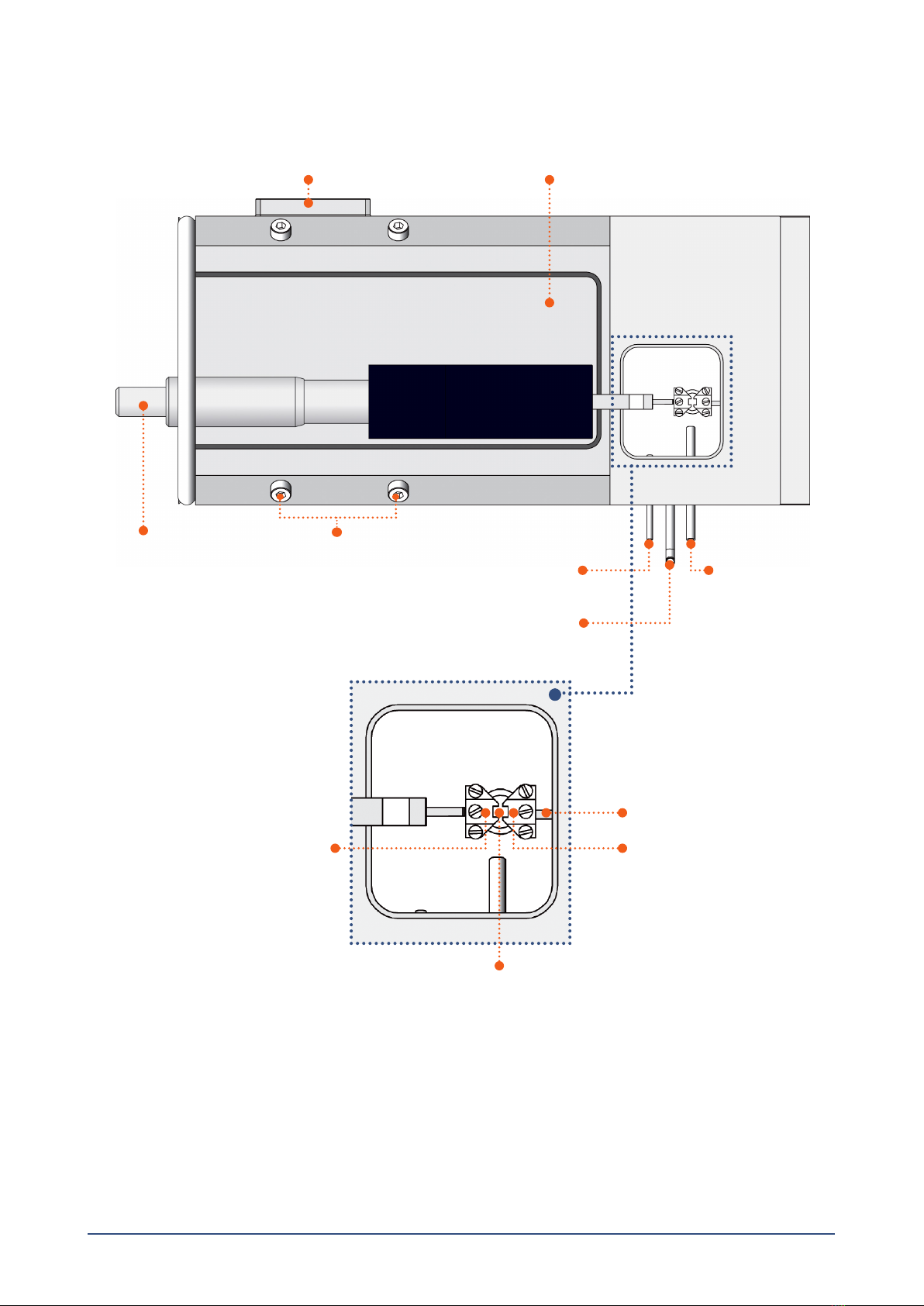

Chapter 1 - Single Wire Myograph overview........................................................................................................................................................................3

Chapter 2 - Setting up the Single Wire Myograph .............................................................................................................................................................4

2.1 Adjustment of supports.....................................................................................................................................................................4

2.2 Force transducer calibration.............................................................................................................................................................5

Chapter 3 - Experimental set-up ..............................................................................................................................................................................................6

3.1 Mounting protocol for small arteries................................................................................................................................................6

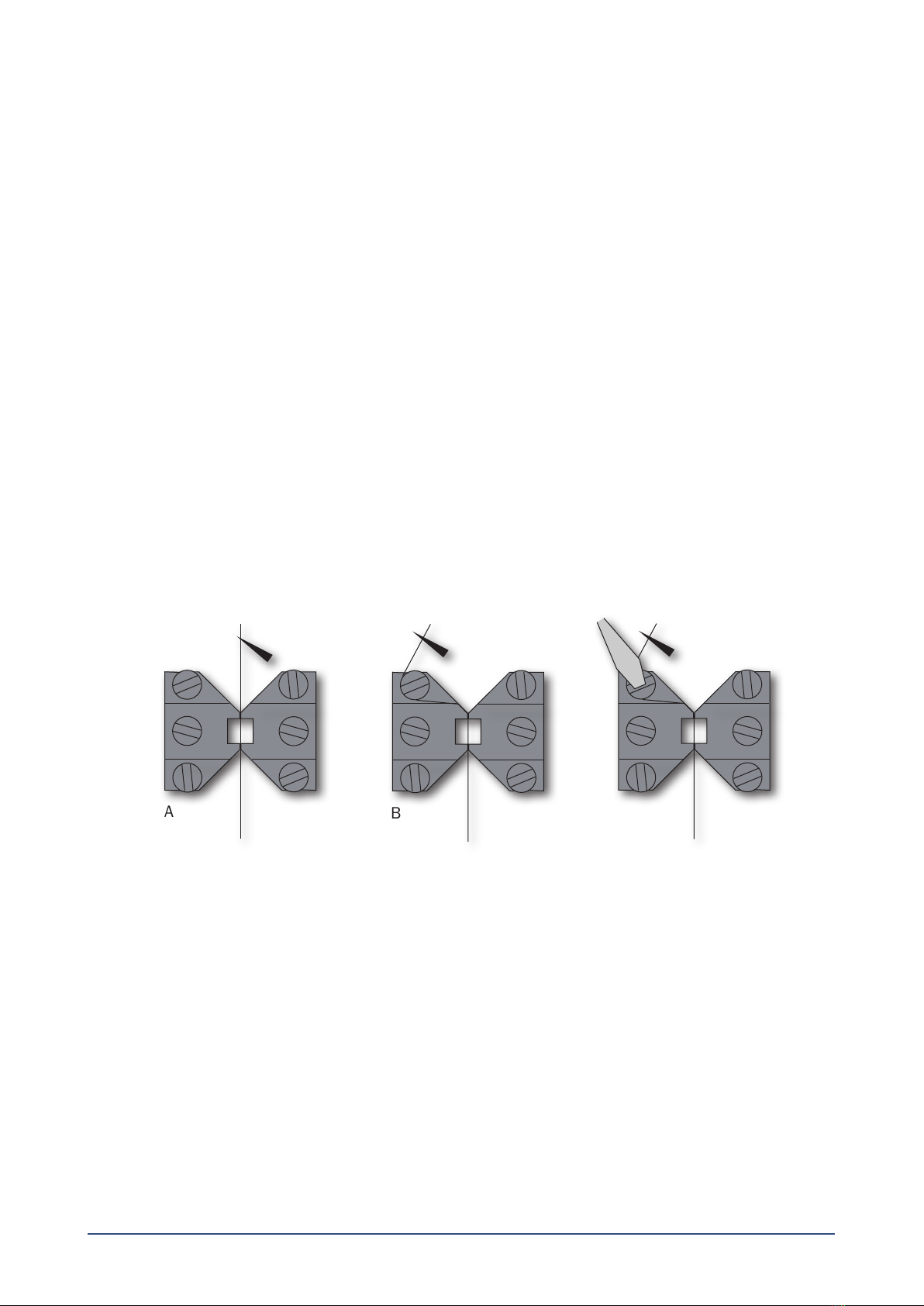

3.1.1 Mounting step one ......................................................................................................................................................................6

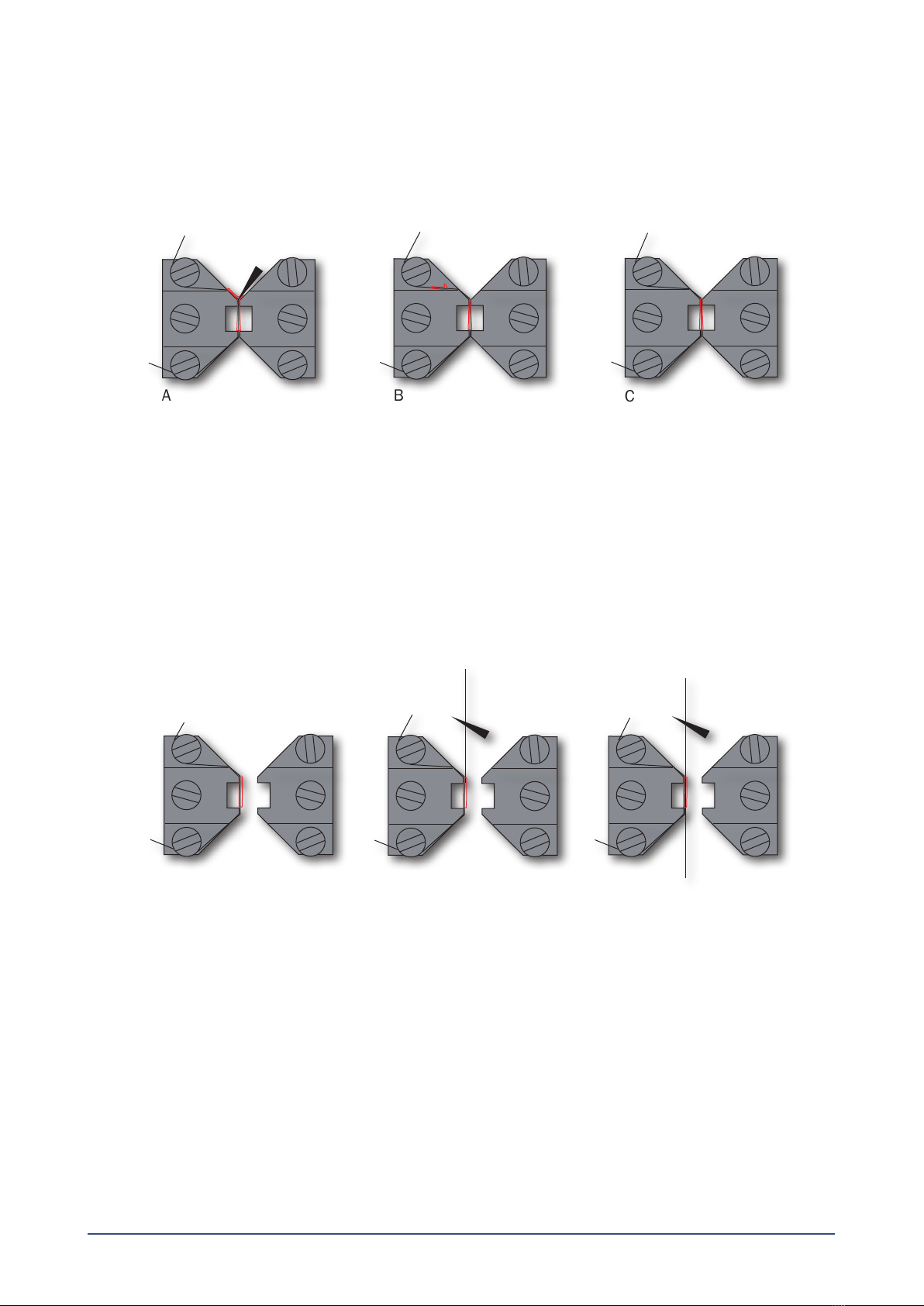

3.1.2 Mounting step two ......................................................................................................................................................................7

3.1.3 Mounting step three ...................................................................................................................................................................7

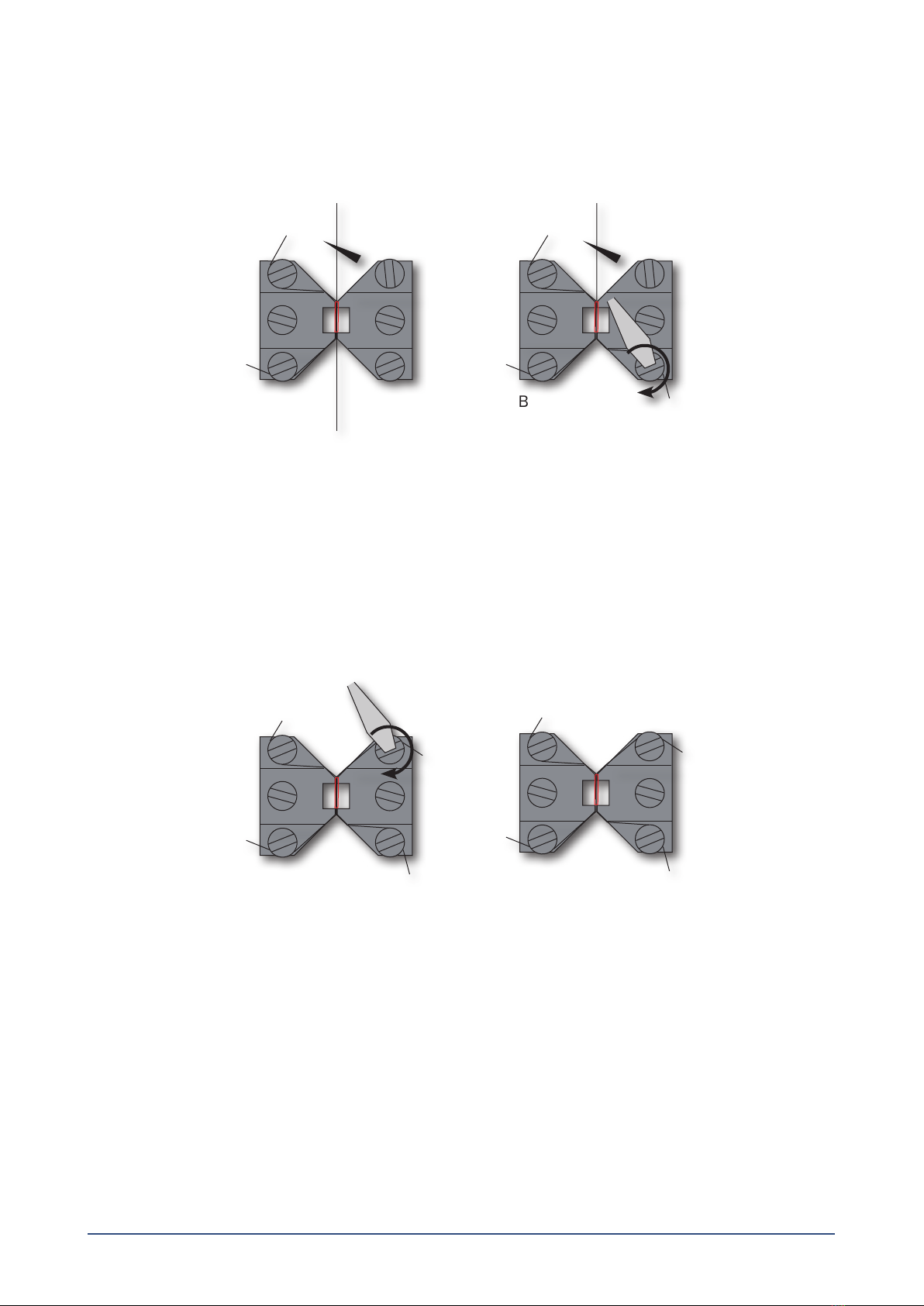

3.1.4 Mounting step four......................................................................................................................................................................8

3.1.5 Mounting step ve.......................................................................................................................................................................8

3.1.6 Mounting step six........................................................................................................................................................................9

3.1.7 Mounting step seven...................................................................................................................................................................9

3.2 Normalization ....................................................................................................................................................................................9

3.2.1 Principles of the normalization procedure ............................................................................................................................. 10

3.3 Standard start................................................................................................................................................................................. 10

3.3.1 Principles of the standard start procedure ............................................................................................................................ 10

3.4 Endothelium function..................................................................................................................................................................... 11

3.4.1 Principles of checking endothelium function......................................................................................................................... 11

3.5 In vitro experiment 1: Noradrenaline contractile response......................................................................................................... 12

3.5.1 Background .............................................................................................................................................................................. 12

3.5.2 Protocol..................................................................................................................................................................................... 12

3.6 In vitro experiment 2: Acetylcholine relaxation curve .................................................................................................................. 13

3.6.1 Background .............................................................................................................................................................................. 13

3.6.2 Protocol..................................................................................................................................................................................... 13

Chapter 4 - Cleaning and Maintenance .............................................................................................................................................................................. 14

4.1 Cleaning the Single Wire Myograph .............................................................................................................................................. 14

4.2 Maintenance of the force transducer ........................................................................................................................................... 15

4.2.1 Checking force transducer ...................................................................................................................................................... 15

4.2.2 Force transducer replacement................................................................................................................................................ 16

4.4 Maintenhance of the linear slide .................................................................................................................................................. 17

4.3 Changing the Single Wire Myograph window glass...................................................................................................................... 17

Appendix 1 - Buer recipes ..................................................................................................................................................................................................... 18

Appendix 2 - Normalization theory ...................................................................................................................................................................................... 20

Appendix 3 - Reading a millimetre micrometer............................................................................................................................................................... 22

Notes................................................................................................................................................................................................................................................ 23