Operating instructions (Version 0) 9 ST 1075

Preface

Prior to the operation of your Stertil Koni mobile lift, make sure that you read the

instructions thoroughly. These instructions are found in this manual. Please note that

your warranty can be voided if you do not read the manual and understand its

contents

If you have any questions concerning operation, safety or application of your mobile

lift, please contact Stertil Koni USA at the following toll free number:

800 336 6637 or call 410 643 9001.

The address for Stertil Koni USA Inc. is 200 Log Canoe Circle, Stevensville,

Maryland 21666.

The operator shall have certain qualifications before he/she can safely operate a

Stertil Koni mobile lift and these include ability in written or oral communications as

demonstrated by either a high school diploma or certificate of equivalency, aptitude

test or job experience. He/she must also have the ability to understand the

mathematical, mechanical and electrical principles of automotive lifts as

demonstrated by one of, or a combination of aptitude test, training program,

technical vocational school or job experience.

The owner/employer of the Stertil Koni mobile lift must ensure that the operator of

the mobile lift must be instructed and trained in the safe use and operation of the lift

using the manufacturer provided instructions and warning labels and the Automotive

Lift Institute Publications, "Lifting It Right" and "Safety Tips".

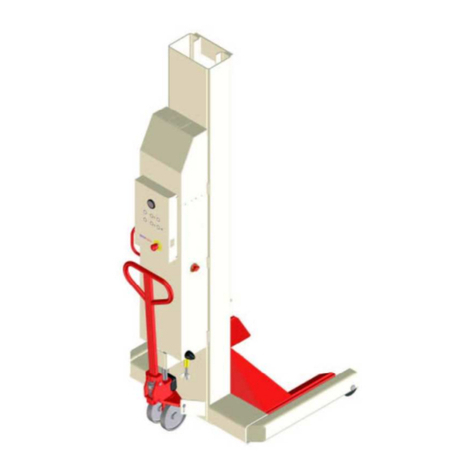

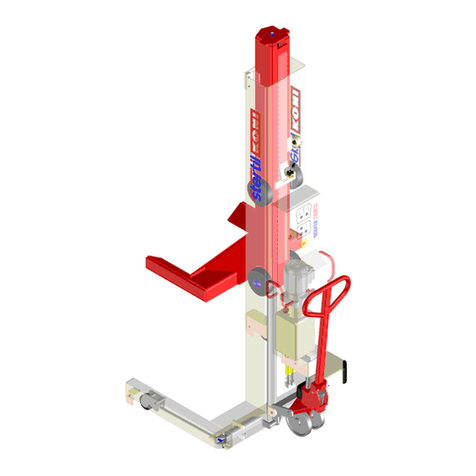

The lift that has been delivered to you contains the supply of operating instructions,

general safety information, safety tips and warning labels on the control post. As an

owner, or employer, it is requested that you display these materials in a conspicuous

location in the lift operating area.

The owner or employer shall appropriately document operator training by

completing an operator-training log, which shall be part of the management

documentation.

The operator shall operate the automotive lift only after being properly instructed or

trained in accordance with manufacturer supplied instructions found in the this

manual.

The operator shall use all applicable safety features provided on the automotive lift

and operate the lift in accordance with the instructions provided by Stertil Koni.

The lift operator or employer shall take all appropriate steps to follow the

recommended inspection procedures of the lift manufacturer but in no event shall

the lift operator fail to inspect or take notice of the following features on a daily basis.

1. Accessibility and readability of the operating procedures, safety tips and generic

safety material.

2. Accessibility and readability of safety warning labels.

3. Readability of the rated load capacity of the lift.

4. Proper operation of the lift controls, restraints and locking devices.