stertil DOCK products ED User manual

Dock Leveller

Dock Leveller

Überladebrücke

Dock Leveller

ED

Operation Manual

Gebruikshandleiding

Bedienungsanleitung

Manuel utilisateur

© 2016 Stertil B.V. Original manual no.

03200800

Operation Manual 2 Dock Leveller ED

Please read and understand the contents of this Operation Manual carefully.

Failure to read the manual can result in serious damage, injury or death.

Keep this manual. Make sure that all operators of the Dock Leveller have read

and understand the contents of this manual.

Copyright © 2016 Stertil B.V. All rights reserved worldwide.

This language version of the manual is verified by the manufacturer (Original manual).

No part of this publication, including drawings and diagrams, may be reproduced and/

or made public, whether by printing, photocopying, microfilm or by any other means

whatsoever, without the prior written permission of Stertil B.V..

Operation Manual 3 Dock Leveller ED

Contents

1 Preface 5

1.1 Storing the manual 5

1.2 Guarantee and liability 5

1.3 Recommissioning 5

1.4 Version history 6

1.5 Trademarks 6

1.6 EC Declaration Of Conformity Of The Machinery 7

2 Safety 8

2.1 Safety messages 8

2.2 Manufacturer details 9

2.3 General safety instructions 9

2.4 Safety signs 11

2.5 Safety features 11

2.5.1 Emergency stop switch 12

2.5.2 Automatic safety device 12

2.5.3 Lateral tilt torsion 12

2.5.4 Maintenance support 13

2.6 Lock-out/tag-out 14

2.6.1 Lock-out/tag-out procedure 14

2.6.2 Ending lock-out/tag-out procedure 15

2.7 Risks 15

2.8 Hazards 16

2.8.1 Electrical hazards 16

2.8.2 Mechanical hazards 16

2.9 Instructions to the owner and employer 16

2.10 Environmental aspects 17

2.10.1 Disposal 17

2.10.2 REACH declaration 17

3 Introduction 18

3.1 Requirements for operators 19

3.2 Training levels 19

3.3 Personal protection equipment 20

4 Description 21

4.1 Technical specifications 23

4.2 Product specification 24

5 Operation 25

5.1 Control components 25

5.2 Operation procedures 26

5.2.1 Switching on 26

5.2.2 Switching off 27

5.2.3 Running procedures 28

6 Inspection and maintenance 31

6.1 Aim of maintenance 31

6.2 When you carry out maintenance 31

6.2.1 Placing the maintenance support 32

6.2.2 Removing the maintenance support 33

6.3 Preventive maintenance schedule 33

6.3.1 Cleaning 34

6.3.2 Lubrication 34

6.3.3 Visual inspection 35

Operation Manual 5 Dock Leveller ED

1 Preface

This is the Operation Manual for the Dock Leveller ED. The manual is intended

for owners and operators. This manual contains important information and

instructions on safety, operation and use. Please read all information carefully

and follow the instructions and guidelines in this manual carefully. This ensures

that you will obtain long-term optimal performance and that possible accidents

and serious injury will be prevented.

In addition to this Operation Manual, you also received an installation manual.

That manual is intended for service mechanics and maintenance technicians

who install and maintain the Dock Leveller.

1.1 Storing the manual

The Operation Manual is a part of your machine. Store the manual in the

immediate vicinity of the machine. Always present a copy of the manual to

operators as they work with the Dock Leveller.

1.2 Guarantee and liability

Please refer to the order confirmation and the delivery terms and conditions for

the applicable guarantee and liability.

1.3 Recommissioning

In the event of a recommissioning (e.g. relocation of the machine or a transfer

of ownership), you MUST contact Stertil B.V. and representative subcontractor

to discuss the procedures, terms and conditions, service contract, etc., so that

the proper functioning and safety of the machine after recommissioning can be

guaranteed. This manual should always be relocated with the Dock Leveller.

If Stertil B.V. is not involved in a recommissioning, then Stertil B.V. is not liable

for any claims of third parties arising from that recommissioning.

Operation Manual 6 Dock Leveller ED

1.4 Version history

Every effort has been made to make this manual as accurate and complete as

possible. Should you discover any errors or omissions, please bring this to the

attention of your local Stertil B.V. service department or distributor, so that we

can make amendments. This will enable us to improve our documentation.

The instructions in this manual do not take into account different national

regulations and laws. When operating the Dock Leveller, it is the sole

responsibility of the operators to make sure that all applicable local laws and

regulations are obeyed.

During the lifetime of the Dock Leveller, engineering improvements may result

in the need to revise this manual. It is then at the discretion of Stertil B.V., if a

revision/new version of this manual is required

The following table describes the main changes for each document version of

this manual.

Version Date Changes

0 December 2016 Original edition

The information in this document concentrates solely on the installation, use

and maintenance of the Dock Leveller as intended by Stertil B.V.. In the event

that the products, parts or procedures are applied in any way other than that

described in this manual, then confirmation from Stertil B.V. must be obtained

as to the correctness and suitability of that use.

1.5 Trademarks

All trademarks stated in this manual are registered trademarks of Stertil B.V. or

her suppliers.

Operation Manual 7 Dock Leveller ED

1.6 EC Declaration Of Conformity Of The Machinery

Declaration according to Directive 2006/42/EC and EN 1398:2009, as amended (hereafter

called Machinery Directive). This language version of the declaration is verified by the

manufacturer (original declaration).

We (manufacturer):

Business name: Stertil B.V.

Address: Westkern 3 9288 CA, Kootstertille

Country: The Netherlands

declare for the product described below:

Generic denomination: Doc Leveller

Commercial name: Edge Dock

Model: ED

Type:

Serial Number:

Function: The Dock Leveller is designed for the loading and

unloading of trucks with the aid of vehicles such as forklifts

or electric pallet trucks.

that all the relevant provisions of the Machinery Directive are fulfilled;

that the product also complies with the provisions of the following European Directives:

the ‘Low Voltage Directive’ 2006/95/EC (applies to control box), and the ‘EMC Directive’

2004/108/EC (applies to control box).

that the product is designed and constructed in accordance with the system of full quality

assurance approved by:

Business name: C+ Certificering bv

Identification number: 11223/2

Address: Produktieweg 8, 9301 ZS Roden

Country: Netherlands

and that the following natural or legal person established in the Community is authorized to

compile the technical file:

Business name: Stertil Group

Name and position: U. Bijlsma, General Manager

Address: Westkern 3 9288 CA, Kootstertille

Country: The Netherlands

Done at Kootstertille, 01 November 2015.

U. Bijlsma

General Manager, Stertil Group

Operation Manual 8 Dock Leveller ED

2 Safety

If performing operation activities, always carry out these activities with the

greatest caution to avoid injuries or damage to the Dock Leveller. All operation

activities may only be performed by an authorised and sufficiently instructed

person. It is the responsibility of those in charge to ensure safe working

conditions.

Our safety requirements may under no circumstances conflict with the legal

ordinances and regulations that apply to the safety of the Dock Leveller. If any

one of the warnings or safety requirements should be in conflict with existing

local regulations, then the strictest regulation shall take precedence. The safety

instructions in this manual only serve as a guideline.

Always adhere to the local safety regulations. Stertil B.V. is not liable for

damage or physical injury due to ignoring the safety instructions.

2.1 Safety messages

This manual contains numerous warnings and safety notices.

Provides additional information that is helpful to do a task or to avoid problems.

Warns of a situation that may cause material damage if one does not follow the

safety instructions.

Operation Manual 9 Dock Leveller ED

Warns of a situation that may cause physical injury and/or material damage if

one does not obey the safety instructions.

Warns of a situation that will cause serious physical injury and/or heavy

material damage if one does not obey the safety instructions.

2.2 Manufacturer details

If you need any assistance, please contact your regional service centre. If

you still have questions after reading this manual, we would encourage you

to contact us. We appreciate all advice, feedback and suggestions from our

customers. Please contact:

Stertil B.V.

Address: P.O. Box 23, 9288 ZG Kootstertille

Westkern 3, 9288 CA Kootstertille

The Netherlands

Phone: +31 (0) 512 334 444

Fax: +31 (0) 512 332 638

E-mail: [email protected]

Internet: www.stertil.nl

2.3 General safety instructions

To safely work with the Dock Leveller, please follow the following safety

precautions carefully.

• Persons working with the machine must follow local safety and health

procedures, protocols and any additional local rules, laws and regulations

in addition to following the manufacturer's safety instructions. Additional

Operation Manual 10 Dock Leveller ED

rules and guidelines can be, but are not limited to local health and safety

regulations and the guidelines provided by professional associations.

• The machine manual must be available at the machine at all times.

• Read the operating instructions before you operate or maintain the machine.

• Make sure you have obtained, read and understood all instructions.

• Make sure you have obtained, read and understood any additional

instructions for special accessories for the machine.

• Carry out all work with and on the machine as described in the manual.

• Never start or operate a damaged machine.

• Always make sure that the machine is complete before operation. Operating

the machine with missing components can cause severe damage.

• Observe all signs with safety and danger notes. Replace warning and/or

safety signs immediately if they are missing or illegible.

• Do not perform any tasks for which you are not authorised. Only explicitly

qualified and authorised personnel may operate, maintain or repair the

machine.

• Personnel in training must be supervised at all times.

• Wear and use all needed personal protection equipment and safety gear

appropriate for the job.

• Keep a safe working environment.

• If necessary, make sure the machine complies with federal and local

standards before starting work.

• Do not use the machine for purposes other than those specified.

• All personnel working on or with the machine must be aware of possible

hazards.

• Never make any changes or additions to the machine, without obtaining

explicit written approval from the manufacturer/supplier. This also applies to

the installation and adjustment of safety devices.

Operation Manual 11 Dock Leveller ED

2.4 Safety signs

The Dock Leveller is provided with the following safety and protection signs.

Pictogram Description Location

Always use the

maintenance support

when servicing.

Underside of the deck

beam, on the right side

of the maintenance

support.

Operate according to

directions in manual.

Incorrect operation or

incorrect maintenance

can lead to personal

injury or damage to

goods.

On right side of the

Dock Leveller, on the left

top side of toe guard.

Make sure the labels are always legible. Replace the labels if they are damaged

or illegible.

2.5 Safety features

It is not allowed to bypass or switch off the safety systems.

Operation Manual 12 Dock Leveller ED

2.5.1 Emergency stop switch

The main switch of the Dock Leveller functions as an emergency stop switch.

Use the emergency stop switch only in case of emergencies.

Do not use this function during normal loading/unloading procedures. If you do,

the Dock Leveller is unable to follow the vertical movements of the truck, which

could lead to dangerous situations or damage.

2.5.2 Automatic safety device

If the truck drives off when loading or unloading with a forklift truck on the

Dock Leveller the automatic safety device is automatically activated. After the

load has been removed, reset the Dock Leveller by briefly pressing on the

control button.

The automatic safety device only activatees if the actual load on the

Dock Leveller exceeds 25% of the nominal load. If the automatic safety device

is activated in a panic stop situation, always have the Dock Leveller checked for

deformation by your supplier or dealer, before using it again.

2.5.3 Lateral tilt torsion

The torsion flexibility of the deck ensures that the lip of the Dock Leveller stays

in contact with the loading surface, even when the loading surface is not level.

The maximum lateral tilt torsion is 10 - 15mm: this depends on the type of

Dock Leveller.

Operation Manual 13 Dock Leveller ED

The maximum torsional flexibility is determined by the size of the Dock Leveller.

The lower value for the narrow Edge Dock 1830, the upper value for the widest

Edge Dock 2110.

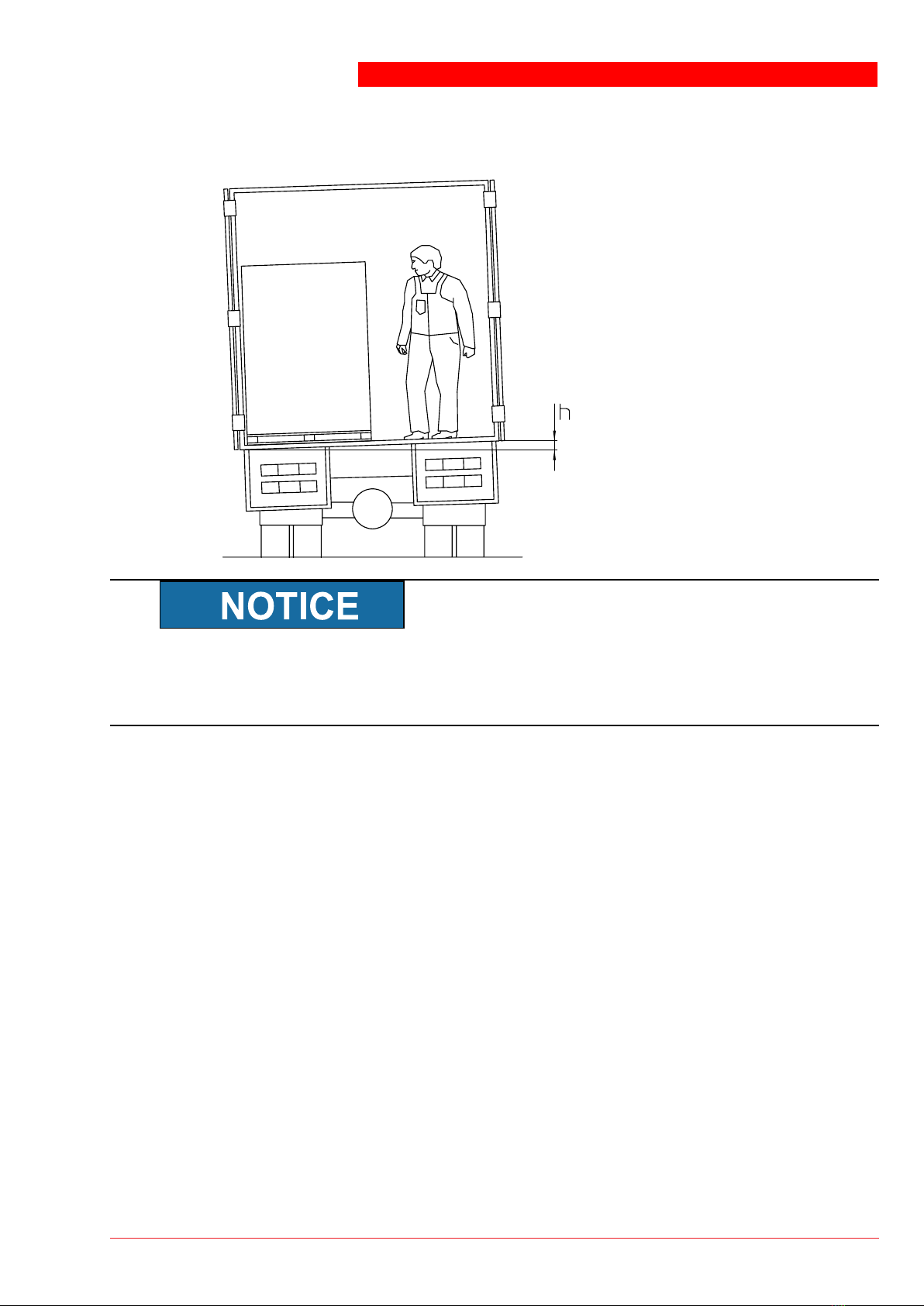

2.5.4 Maintenance support

During repairs, adjustments, maintenance or cleaning of the Dock Leveller

beneath the deck, a specific maintenance support must be placed. This

maintenance support prevents unexpected movements of the Dock Leveller

during activities beneath the deck.

Operation Manual 14 Dock Leveller ED

Operators strongly are advised not to go underneath the deck. If a situation

occurs that you must go underneath the deck, this must be done by qualified

personnel and always use the maintenance support

2.6 Lock-out/tag-out

Lock-out or tag-out procedures are safety measures, designed to prevent

application of power (energy) to the machine while it is being serviced. The

procedures for the application of energy control (the lock-out or tag-out

procedures) must be done in the prescribed sequence.

2.6.1 Lock-out/tag-out procedure

1. Notify all affected employees that service or maintenance is required on the

machine and that the machine must be shut down and locked out.

2. Preparation for shut-down. The machine may only be turned off by an

authorised employee. Before turning it off, the employee must know:

• The type and magnitude of the energy.

• The hazards of the energy to be controlled.

• The method or means to control the energy.

3. Shut-down. If the machine is in operation, shut it down by the normal shut-

down procedure.

Operation Manual 15 Dock Leveller ED

4. Machine isolation. Isolate the machine from the energy source(s). The

machine uses AC power. This is de-energized by removing the AC

connection to the machine.

5. Lock-out (or tag-out) device application. Lock out the energy isolating

device(s) with:

• An individual lock(s).

• A warning device on the main switch.

6. Remove residual or stored energy. Stored or residual energy (such as

that in capacitors, air pressure, etc.) must be dissipated or restrained by

methods such as grounding, bleeding down, etc.

7. Verification of isolation. Make sure that the machine is disconnected from

the energy source(s). First make sure that no persons are in or on the

machine. Test to verify the isolation of the machine. Make certain that the

machine will not operate (power cannot be turned on).

The machine is now locked out.

Return all operating control(s) to the OFF position after verifying the isolation of

the machine.

2.6.2 Ending lock-out/tag-out procedure

1. Make sure the service or maintenance is completed and the machine is

ready to return to normal operation.

2. Check the machine and the immediate area around to make sure that all

non-essential items have been removed.

3. Make sure that all components of the machine are operationally intact.

4. Make sure that all persons are at a safe distance from the machine.

5. Verify that the power switch is in the OFF position.

6. Remove the lockout devices.

7. Notify all personnel that the service or maintenance is completed and the

machine is ready for use.

2.7 Risks

The Dock Leveller has been carefully designed and expertly built for safe

operation. The European certifications confirm this. There are, however, still

Operation Manual 16 Dock Leveller ED

dangers and safety risks which cannot be ruled out. These risks are inherent to

operators using the machine.

It is therefore of utmost importance that precautions will be taken when working

with the Dock Leveller to exclude potential risks.

2.8 Hazards

2.8.1 Electrical hazards

Precautions to be taken when working with electrical equipment:

• Consider all circuits live until you have personally turned off the main switch.

Also tag the main switch with a safety sign.

• Keep your clothing, hands and feet dry.

• Do not wear rings, watches, metal-rimmed glasses or jewellery when working

around electrical circuits.

• Static electricity can harm electronic parts. Always make sure that you are

earthed when working on electronic parts.

• Maintenance and repair activities on the electrical system of the machine

may only be performed by special trained electricians which are familiar with

the common and local electrical regulations in charge.

2.8.2 Mechanical hazards

Precautions to be taken when working with mechanical equipment:

• Do not wear rings, watches, jewellery, ties or loose sleeves when working

around moving mechanical parts.

• Keep long hair covered when working around moving mechanical parts.

• Stay away from moving machine parts.

• Always use spare parts of a type and part number recommended by

Stertil B.V..

2.9 Instructions to the owner and employer

The owner/employer shall:

• Ensure that operators are qualified and that they are trained in the safe

use and operation of the Dock Leveller using the manufacturers operating

instructions.

• Establish procedures to periodically inspect the Dock Leveller in accordance

with the manufacturer's instructions.

• Ensure that Dock Leveller inspectors are qualified and that they are

adequately trained in the inspection of the Dock Leveller.

• Display the manufacturers operating instructions in a conspicuous location in

the machine area convenient to the operators.

Operation Manual 17 Dock Leveller ED

• Not modify the Dock Leveller in any manner without the prior written consent

of the manufacturer.

2.10 Environmental aspects

2.10.1 Disposal

When the machine has reached the end of its useful life, the owner and/or user

is responsible for the safe disassembly of the machine and for the disposal of

the components, in accordance with the local laws or regulations.

2.10.2 REACH declaration

The REACH regulation became effective on 1st June 2007. The aim of the

REACH regulation is to ensure a high level of protection of human health and

the environment from chemical substances.

Stertil B.V. manufactures articles in compliance with current revision of the

REACH regulation, and is downstream-user of chemical substances.

Stertil B.V. has the intention to fully comply to REACH regulation and has

checked its suppliers to make sure they comply with REACH requirements for

all materials and substances used in our products.

Stertil B.V. will provide relevant information e.g. Material Safety Data Sheet

(MSDS) on request.

Operation Manual 18 Dock Leveller ED

3 Introduction

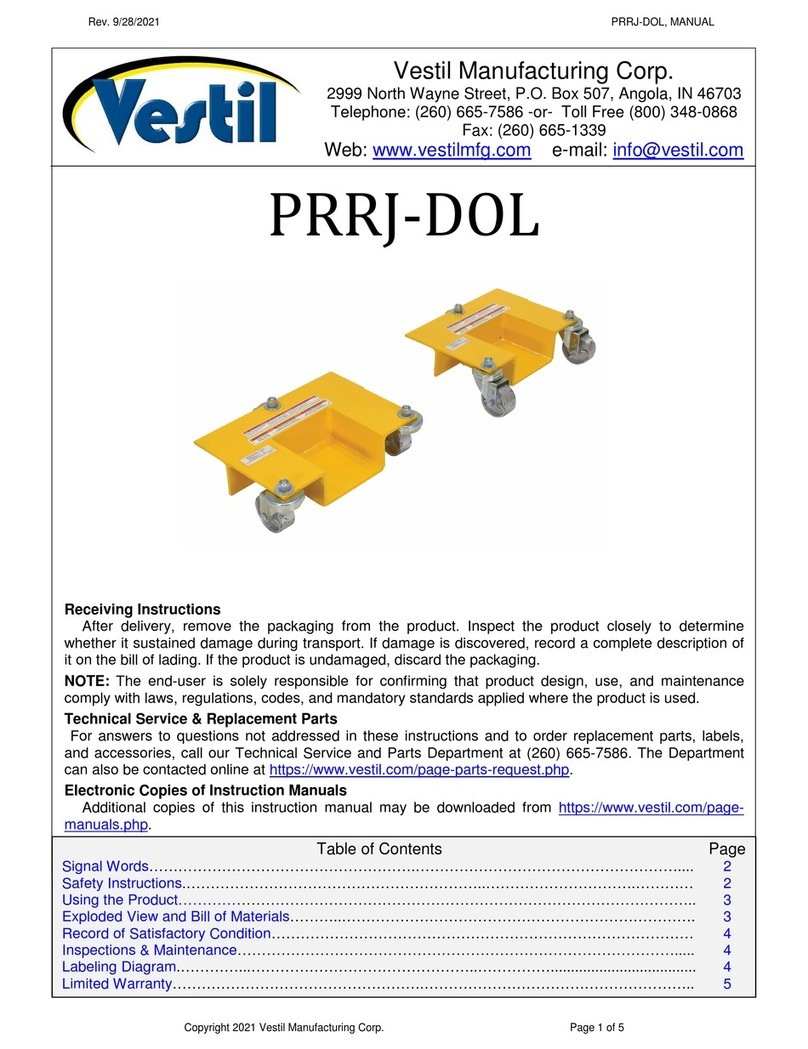

The Dock Leveller is designed for the loading and unloading of trucks with the

aid of vehicles such as forklifts or electric pallet trucks.

Do not use the Dock Leveller for purposes other than for which it is

intended. This is not allowed and can be very dangerous.

The Dock Leveller may never be operated above its rated load and

permitted gradient of 12,5%.

Operation Manual 19 Dock Leveller ED

In this manual is commonly referred to trucks as the vehicle to be loaded or

unloaded. When truck is written all common means of road transport equipment

such as trucks, (semi-)trailers, swap bodies and containers are intended.

3.1 Requirements for operators

Normal operation of the Dock Leveller requires that operators:

• have enough technical knowledge and experience to carry out the assigned

tasks,

• can recognize and prevent hazards,

• have read this manual and understand the contents,

• have been adequately trained,

• are able to follow the procedures in this manual.

The owner must ensure that employees are qualified and trained to perform all

activities involved. The owner also must ensure that all persons working on the

Dock Leveller have free access to the instruction manuals.

3.2 Training levels

Stertil B.V. recommends the following training levels:

• Operator:

Lower vocational education or intermediate vocational education level and

trained by the supervisor.

• Supervisor:

Intermediate vocational education level and trained after the installation of

the machine by the installation personnel and service engineers.

Please contact the service department of the manufacturer or dealer for more

information about possible training and education.

Operation Manual 20 Dock Leveller ED

Persons under 16 years of age are prohibited from working on this

Dock Leveller in any way whatsoever. Children under 14 years of age are not

allowed in the immediate vicinity of the Dock Leveller.

3.3 Personal protection equipment

The following personal protection equipment is recommended for operators:

• Protective clothing

• Gloves

• Ear protection

• Safety shoes

Table of contents

Languages:

Other stertil Lifting System manuals

Popular Lifting System manuals by other brands

John Bean

John Bean EELR529A Installation and operating manual

THIEMAN

THIEMAN TopLifter TT-15 manual

EKKO

EKKO EB12EA Series manual

Snorkel

Snorkel MHP 13/35 Mark II Maintenance and repair parts manual

Pro-Lift

Pro-Lift C-2036 Operating instructions & parts manual

Genie

Genie Load Lifter 5.5 Operator's manual