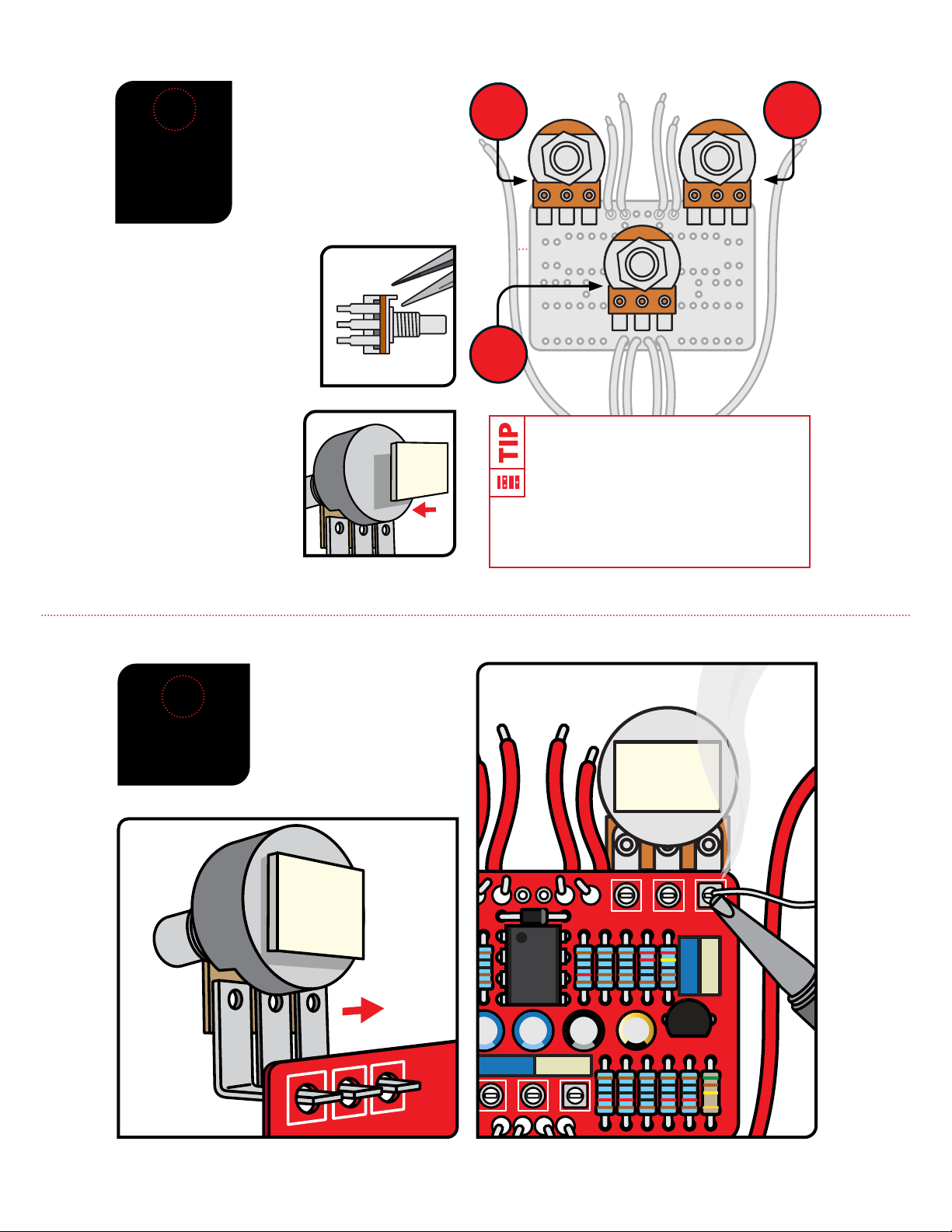

6

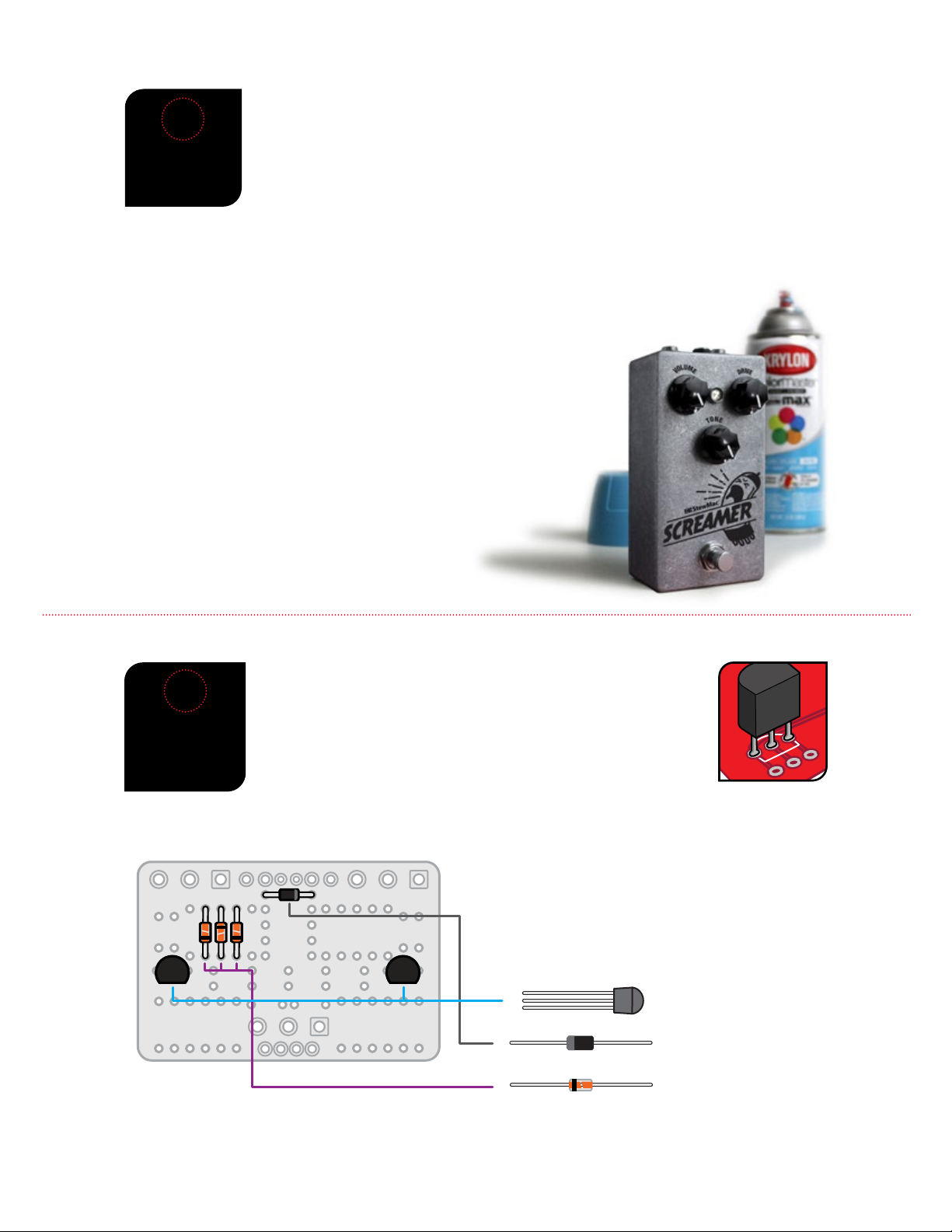

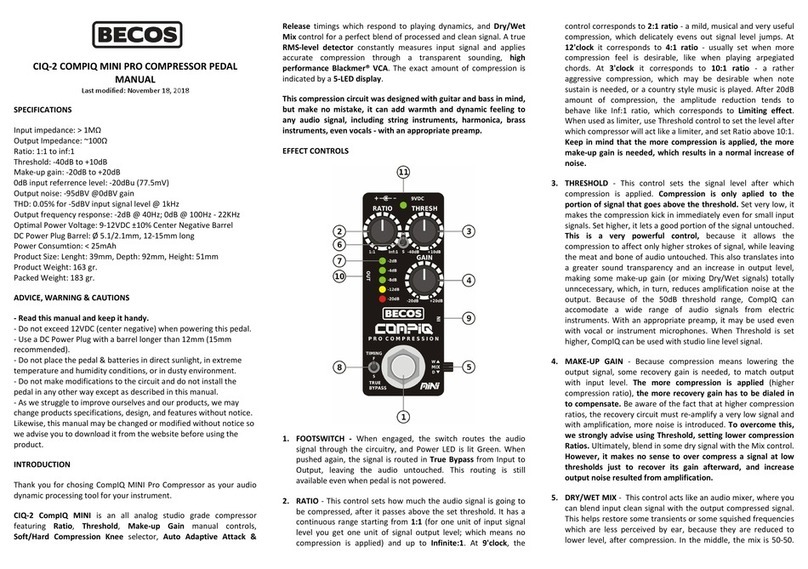

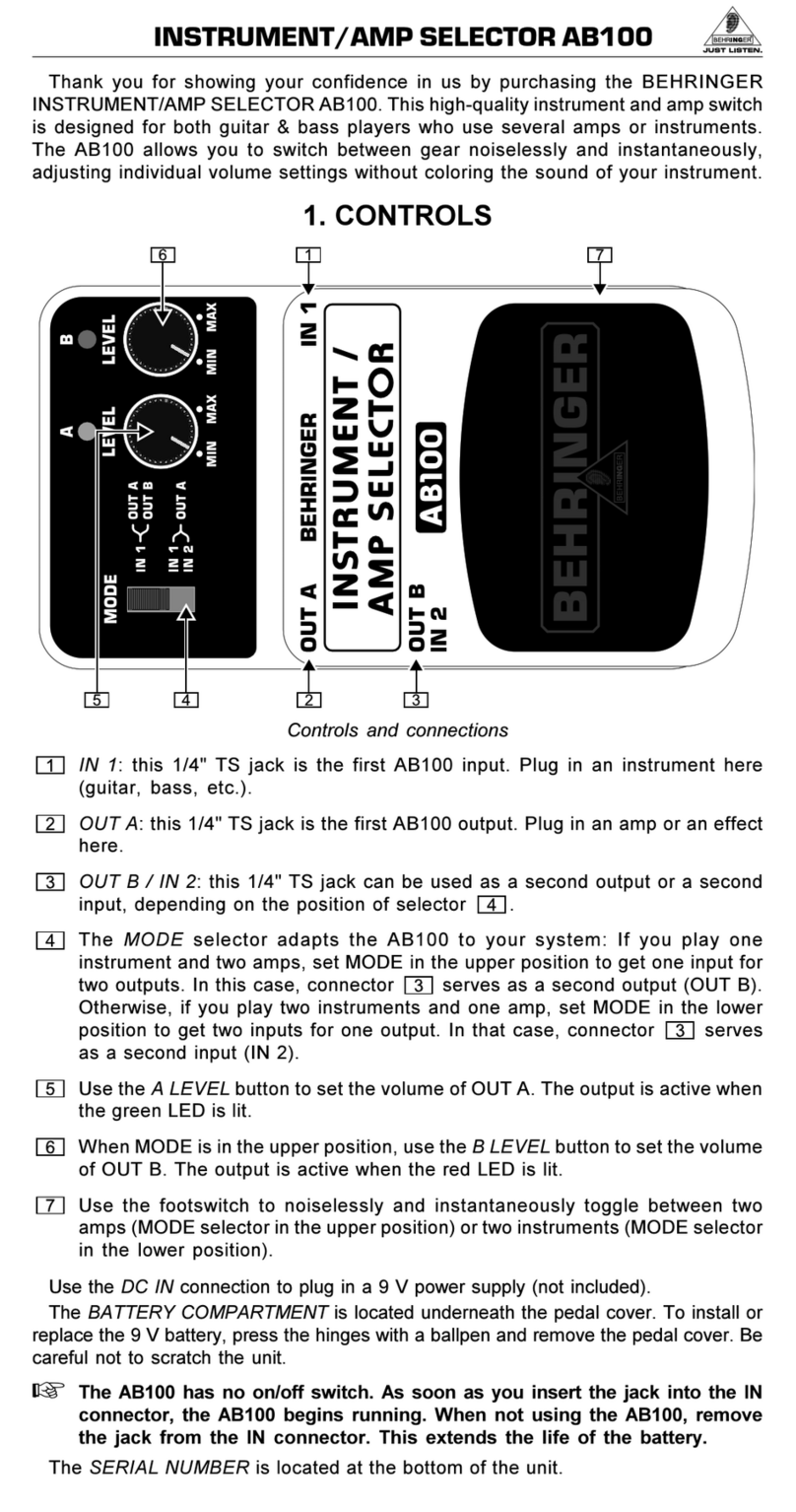

INTEGRATED CIRCUITS

Integrated circuits are tiny and

complex—complete circuits

containing many components.

Their connecting leads plug

into a socket, making them

easy to remove and replace for

experimenting with dierent

sounds. Various types of integrated circuits include

audio processors, voltage regulators, and operational

ampliers (op-amps), which multiply the input signal.

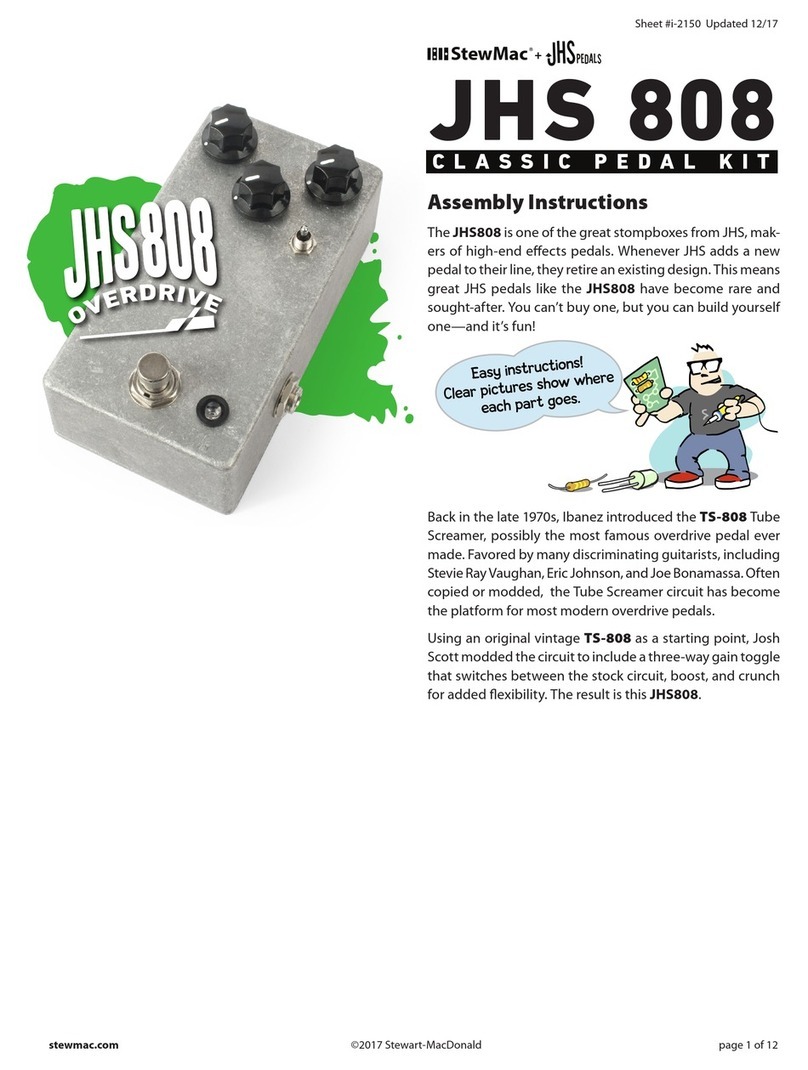

The integrated circuit in this pedal is a JRC4558D op-

amp as used in the original TS-808 Tube Screamer.

2n2J630

TL072

PT2399

PT2399

PT2399

PT2399

echo audio

processor (1) #7490

TL072CP TL072CP

low noise

op-amp (1) #7444

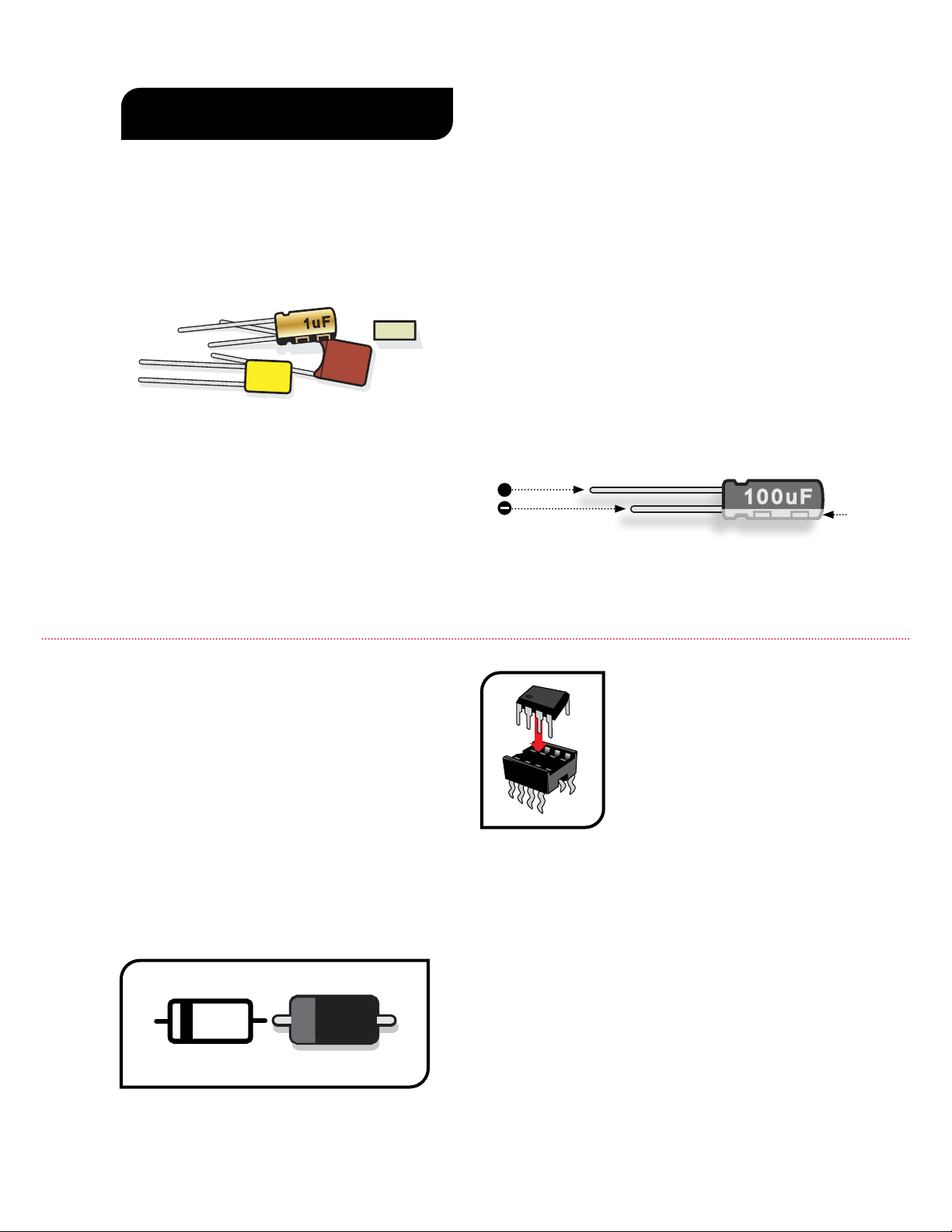

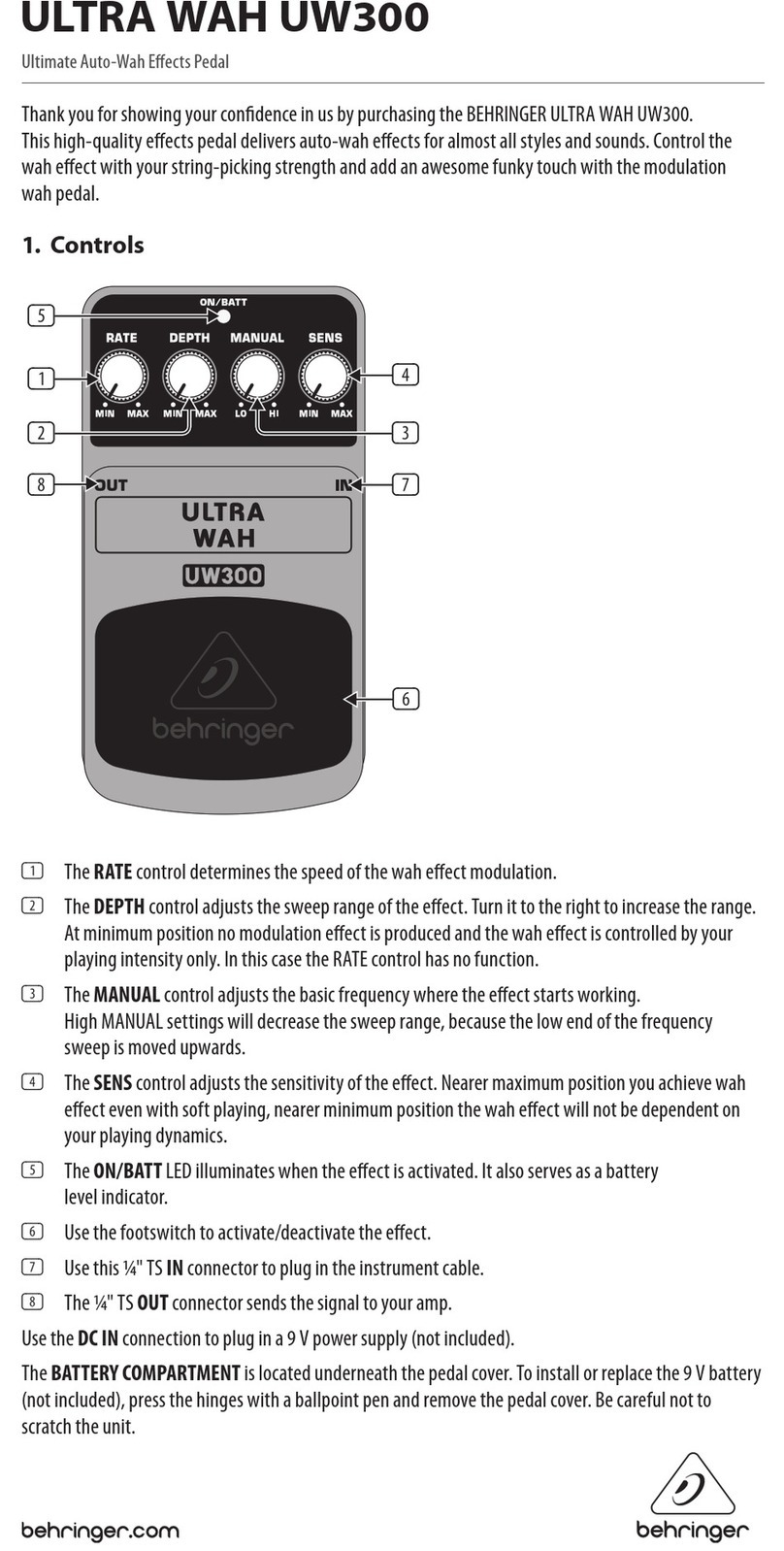

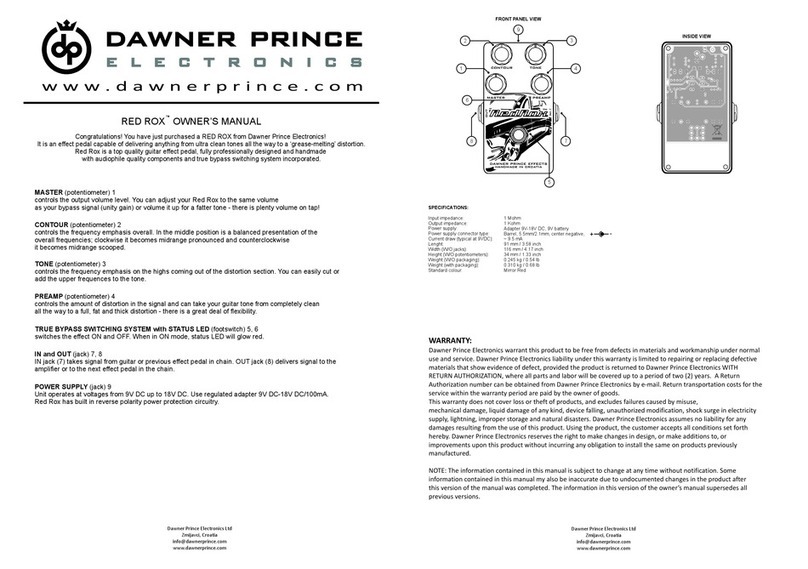

called nanofarads (nF), or trillionths of a farad, called

picofarads (pF). .001μF = 1nF = 1,000pF.

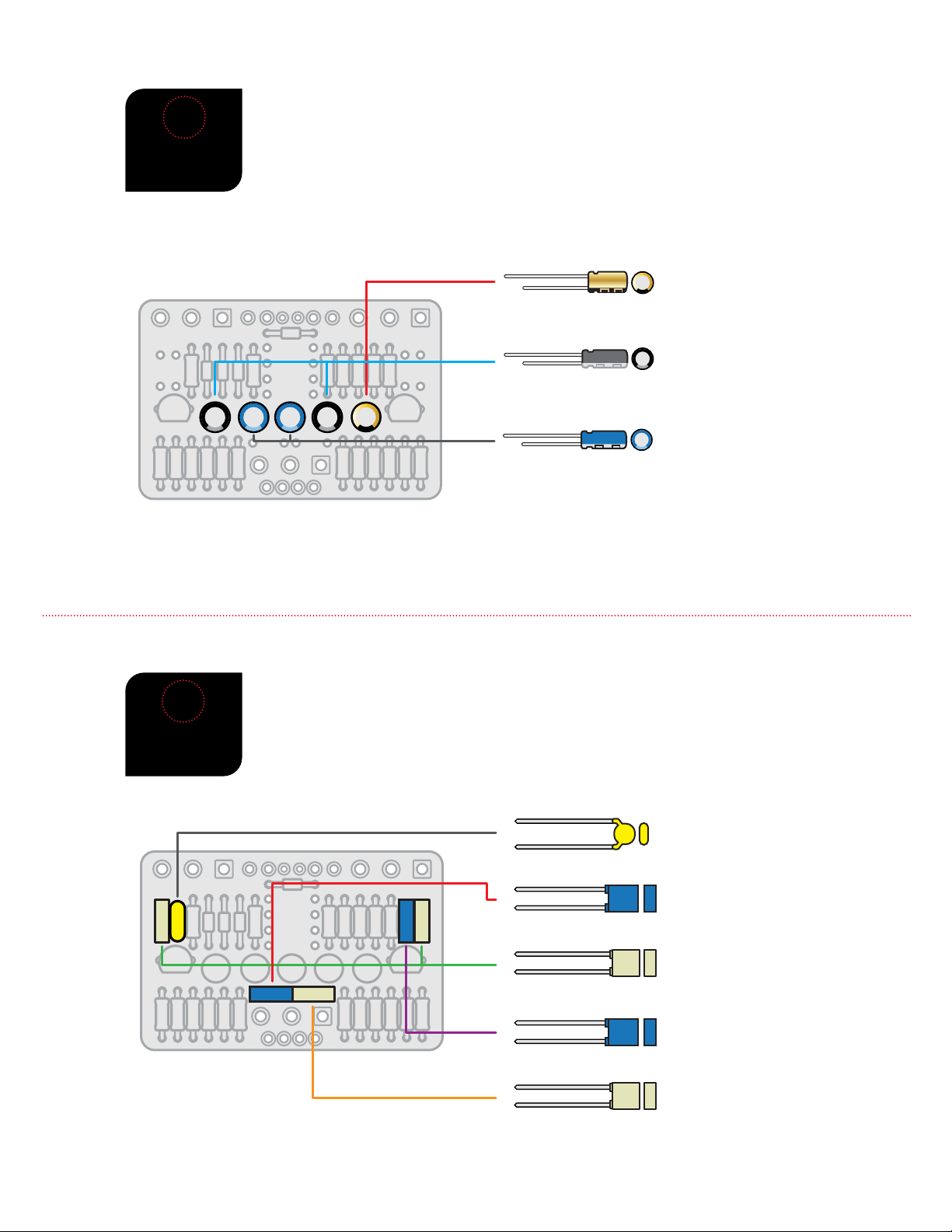

Resistors and capacitors may also be referred to with

shorthand notation on the printed circuit board

when there is a decimal in the value. For example,

the place on the printed circuit board for the 4.7K

resistor will read 4K7 and the spot for a 2.2nF

capacitor will read 2n2. This is done to save space on

the board and make the labels as clear as possible.

Some capacitors have polarity and some don’t.

It’s extremely important to install polarized caps

correctly in a circuit. The negative lead will often

be indicated by a stripe on the negative lead’s side

(often with arrows) and will be shorter than the

positive lead. The positive lead of an electrolytic cap

will be longer and won’t have the stripe on that side.

Installing capacitors with the polarity backwards will

make the circuit malfunction and quickly destroy the

capacitor—even causing it to explode.

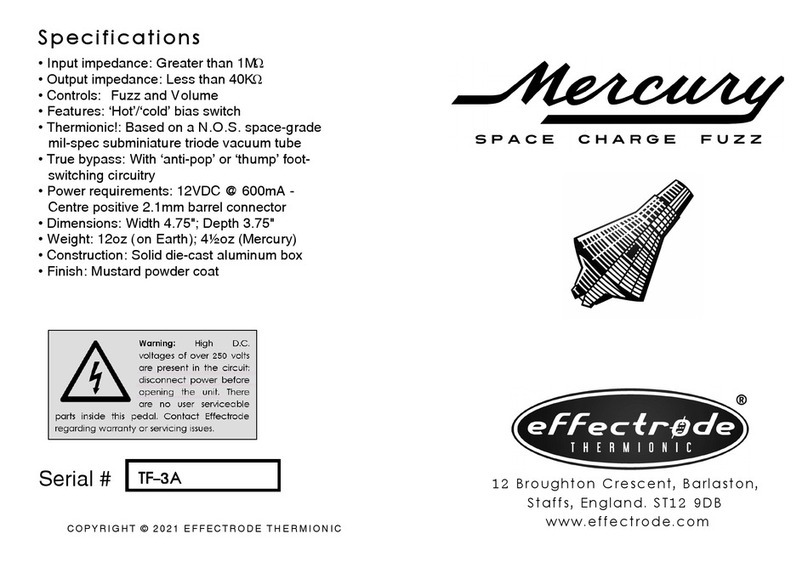

CAPACITORS

The two main uses of capacitors are to store

electricity and to block the ow of DC current.

Capacitor values are typically printed on the

component. The key values with caps are their

voltage and capacitance.

The voltage spec for a cap refers to how much DC

voltage it can handle at any given time. If this rating

is exceeded, the capacitor will fail.

Capacitance, measured in farads, refers to how

much electricity a capacitor can hold. One farad

(1F) would be much too large for use in a pedal.

Caps for pedals are rated between millionths of a

farad, called microfarads (F), billionths of a farad,

101J

100V

102J

1u F

.1J63

++

UNDERSTANDING ELECTRONIC

COMPONENTS

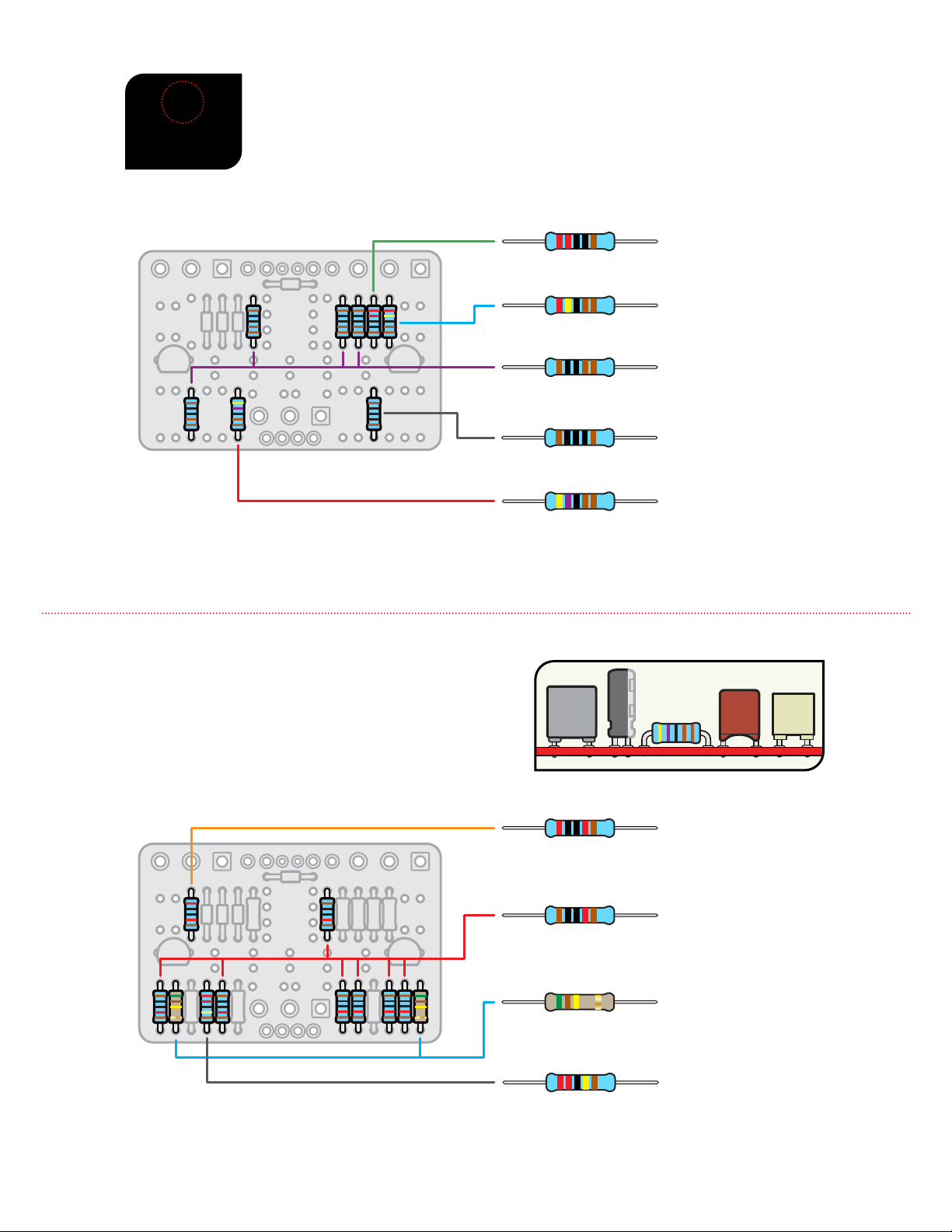

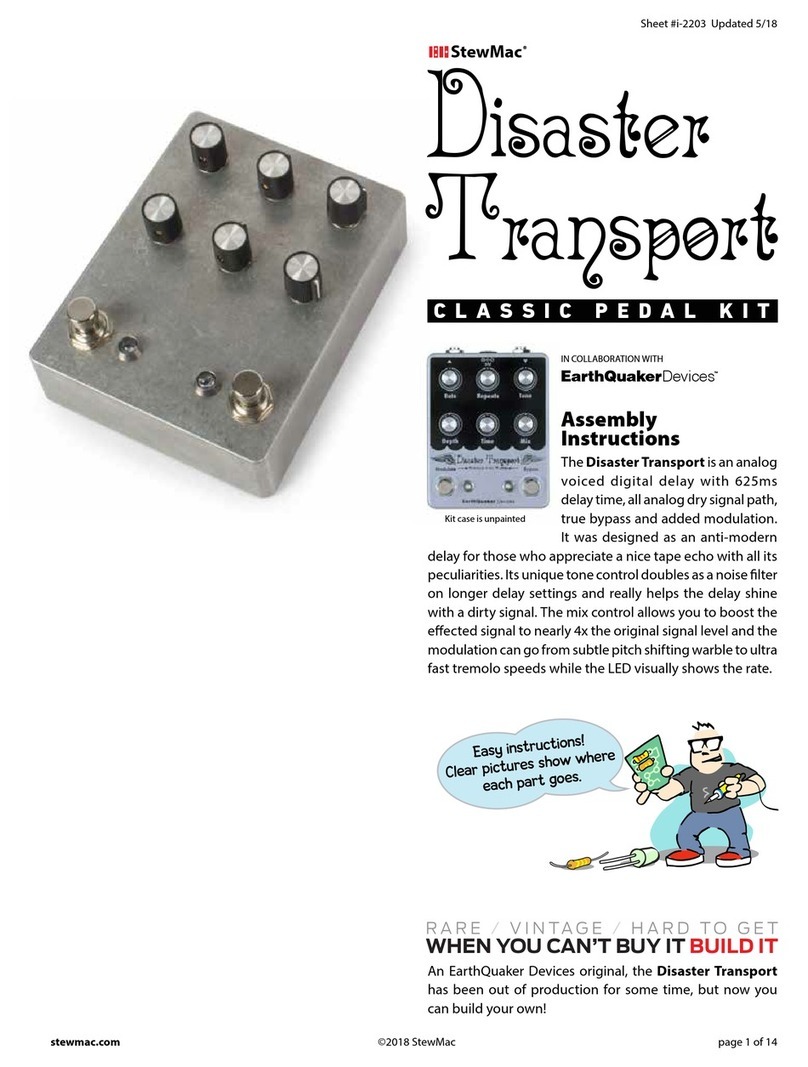

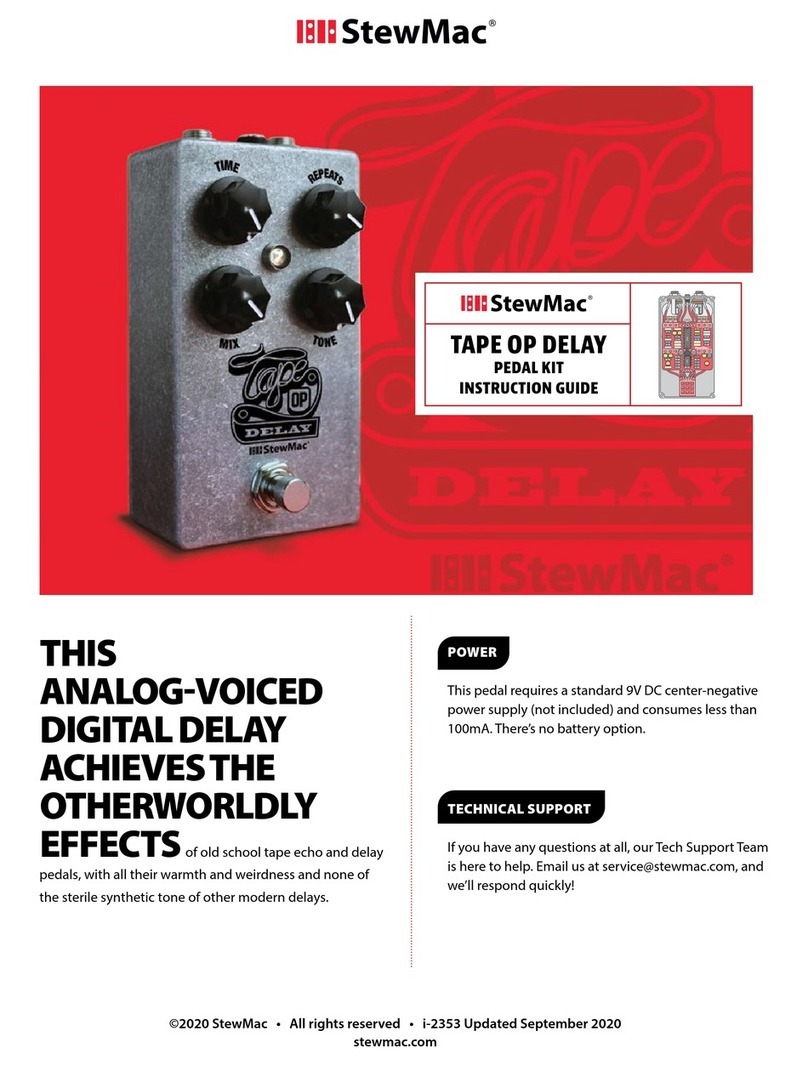

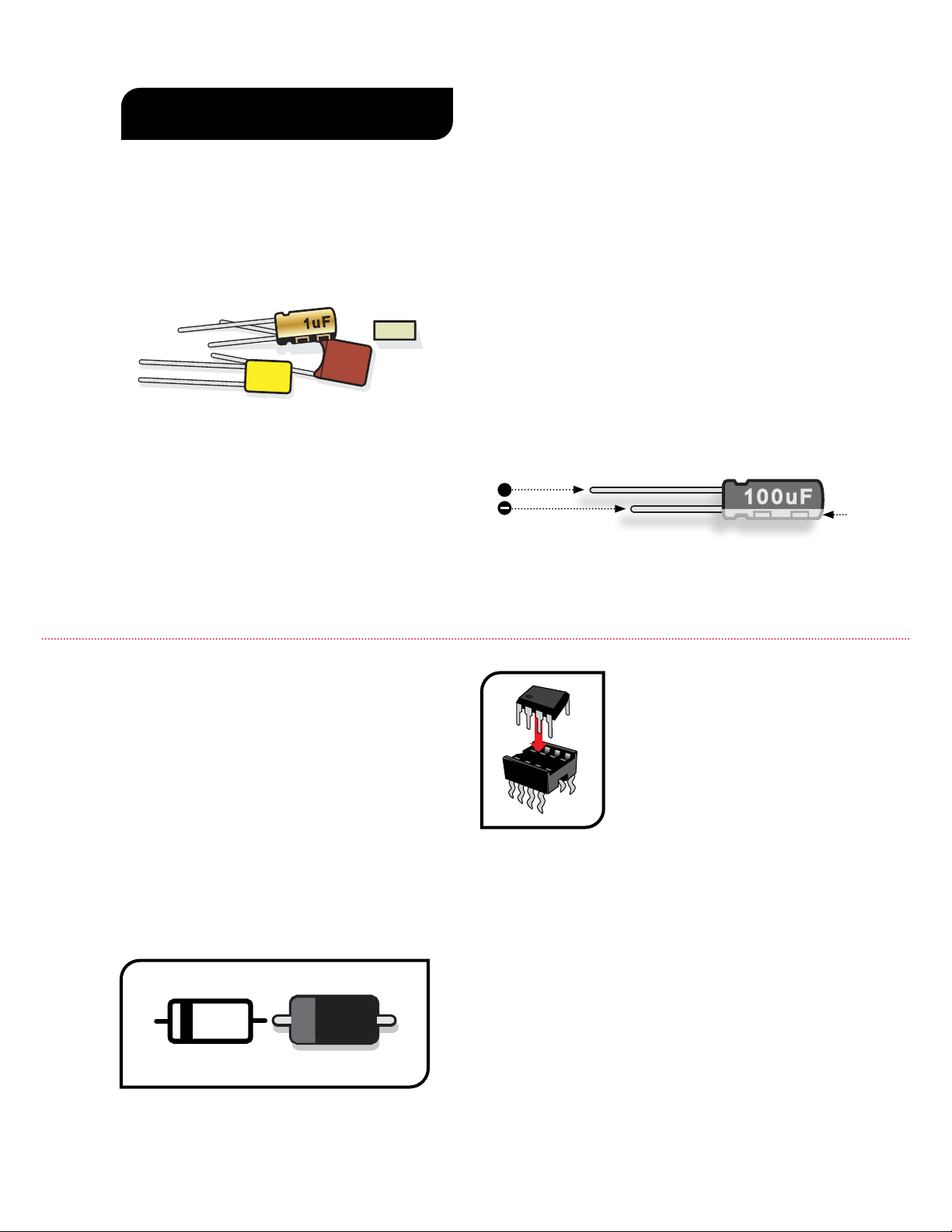

DIODES

Diodes are used where you want electricity to ow

in only one direction, such as power rectication,

and also to limit how much current can ow, to

create “clipping” distortion.

Diodes are also polarized, so they need to be

installed in the correct orientation. The stripe

around one end marks the negative (–) lead of the

diode. On the printed circuit board, the printed

outline of the diodes also shows this stripe. Install

each diode so that its stripe matches the direction

shown on the printed circuit board.