StewMac FAN TREMOLO Manual

FAN TREMOLO

PEDAL KIT

INSTRUCTION GUIDE

.22 J63

1J63

.1J63

IN GND SW OUT

FROM

VINTAGE

WARBLE

TO CHOPPY

HELICOPTER

LIKE SOUNDS,

this one tremolo can do it all. With three adjustable

speed ranges, this pedal runs the gamut from

slow swamp like pulses to speedy envelope-like

weirdness.

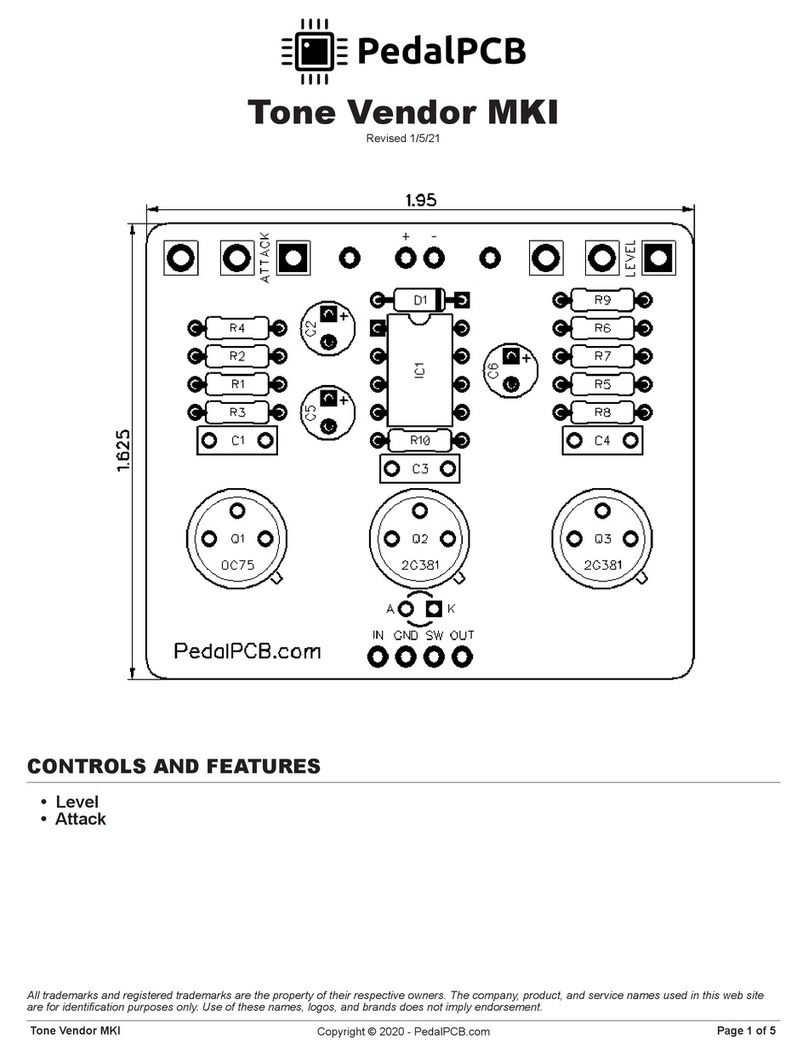

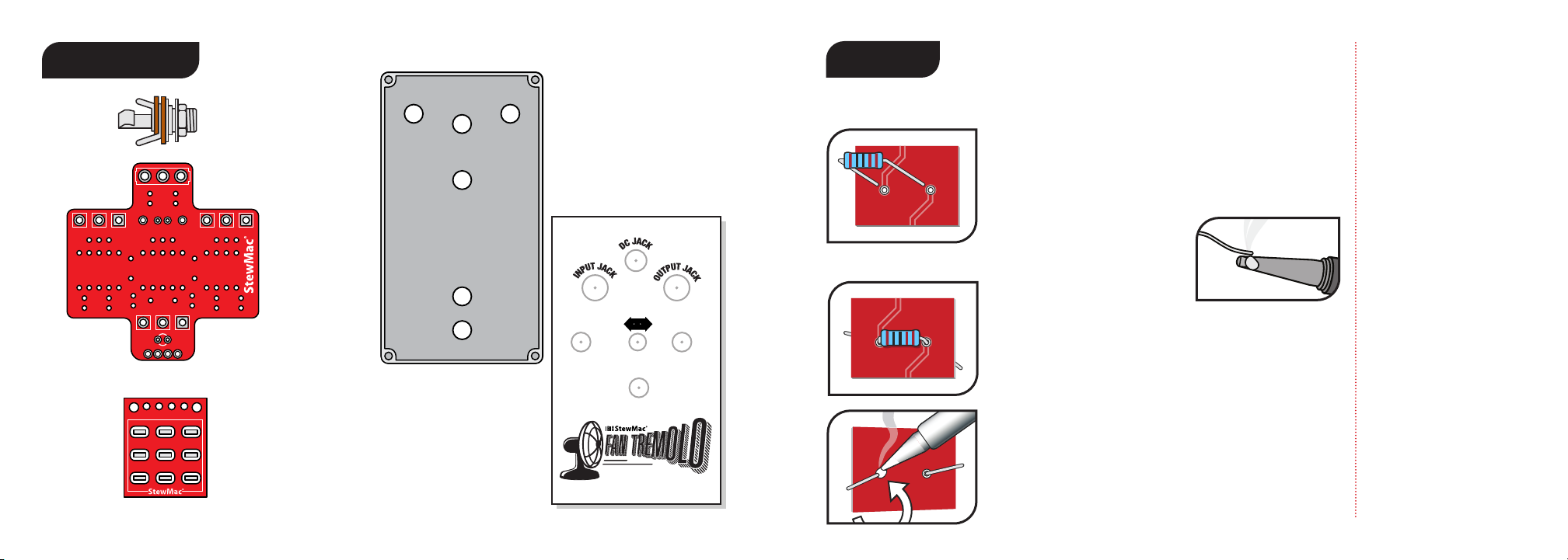

PARTS LIST

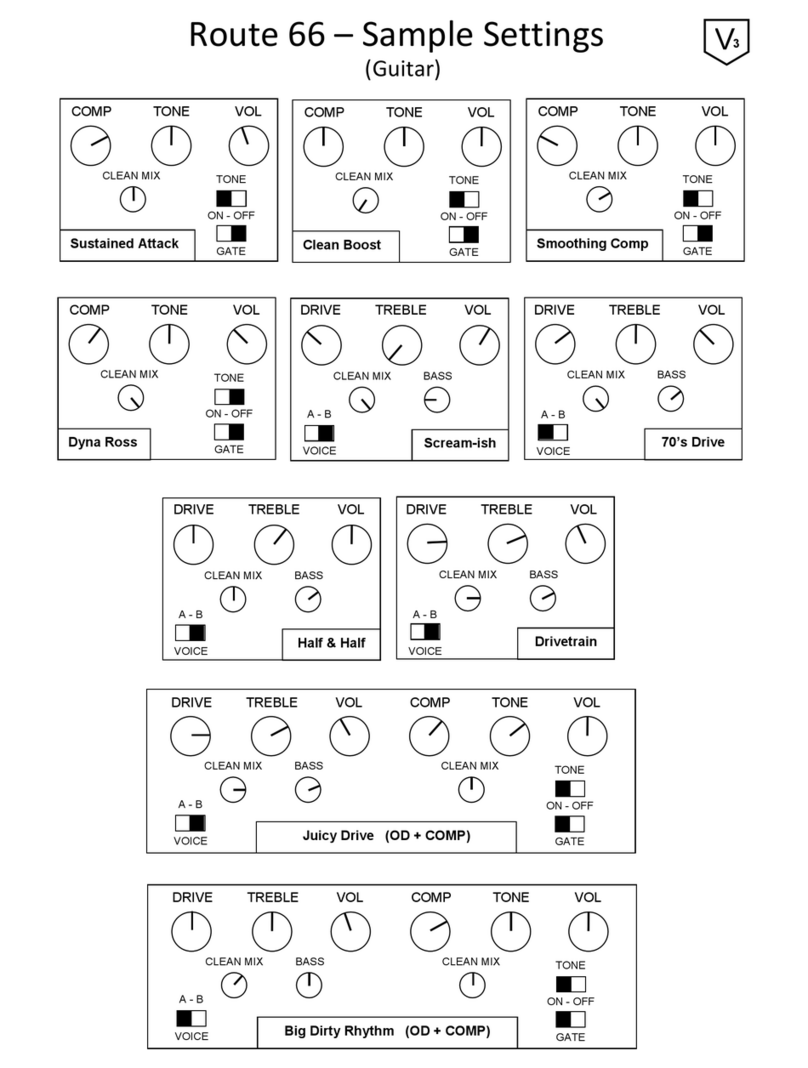

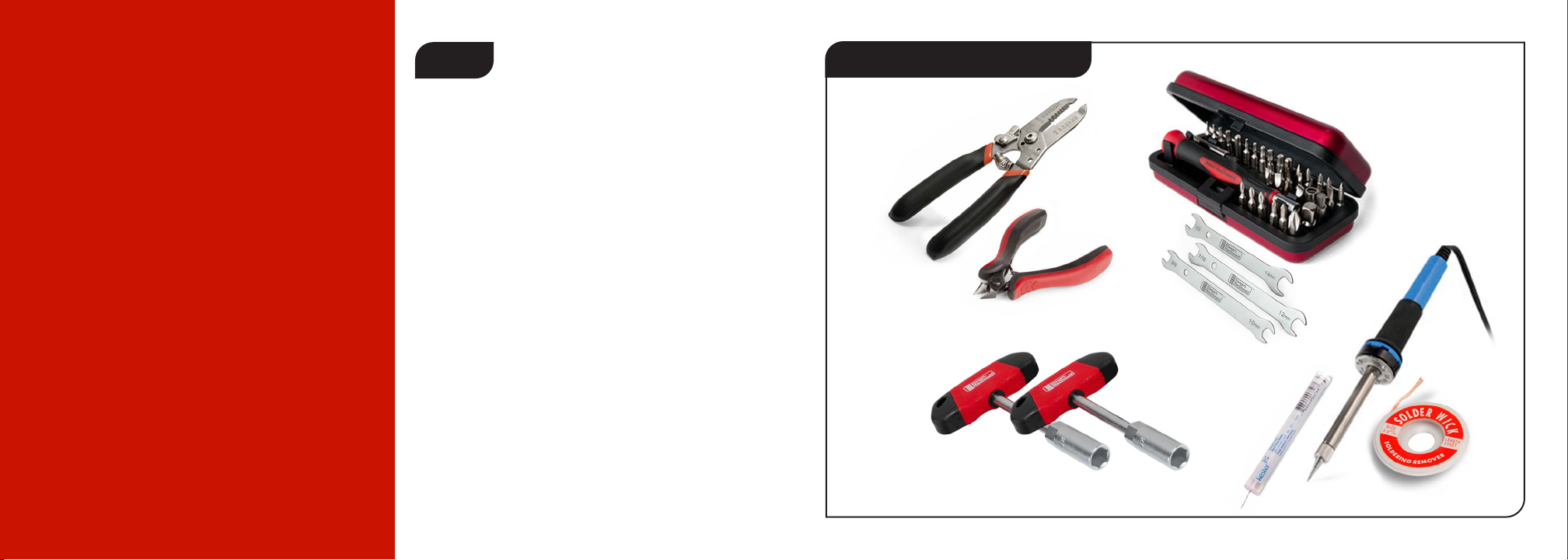

TOOLS AND SUPPLIES REQUIRED

REQUIRED

POWER

This pedal requires a standard 9V DC center-

negative power supply (not included) and

consumes less than 100mA. There’s no battery

option. Soldering Iron #0502

Solder Wick #0504

Solder #0505

Wire Cutter #1607

Wire Stripper #1606

Guitar Nutdrivers #5890

Guitar Tech Screwdriver

and Wrench Set #3696

Resistor values are indicated by colored bands, read from left to right. The rst

color in the code is usually the one painted closest to a lead wire. When a gold

or silver band is present, it’s always one of the last colors in the code.

Brown Black Black Yellow Brown

Red Red Black Red Brown

Red Red Black Brown Brown

Red Purple Black Red Brown

Brown Red Black Red Brown

Yellow Purple Black Red Brown

Red Red Black Orange Brown

1M resistor (1) #7367

22K resistor (1) #7379

2.2K resistor (2) #7376

27K resistor (1) #7398

12K resistor (1) #7392

47K resistor (2) #7369

220K resistor (1) #7381

Yellow Purple Black Black Brown

470Ω resistor (2) #7355

Yellow Purple Black Brown Brown

4.7K resistor (1) #7359

Brown Black Black Black Brown

100Ω resistor (1) #7352

PARTS LIST

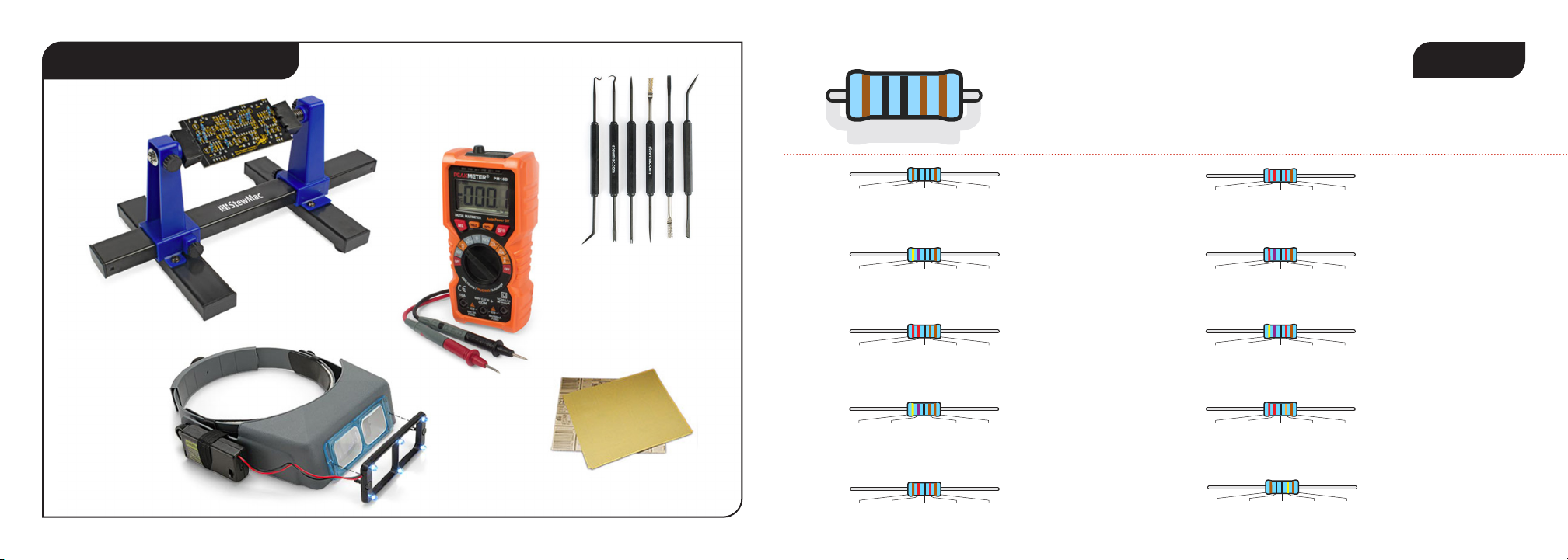

TOOLS AND SUPPLIES HELPFUL

*Not pictured:

Clear silicone adhesive and spray nish

PC Board Holder #0500

Magnifying glass or

OptiVISOR #1685

Soldering Aids #0521

Multimeter #3607

3M Gold Fre-Cut

Sandpaper #5097

220nF capacitor (1)

#7305

100nF capacitor (1)

#7304

10µF capacitor (1)

#7338

100µF capacitor (2)

#7312

10uF

1µF capacitor (2)

#7337

1uF

100uF

2.2µF capacitor (2)

#7315

2.2uF

4.7µF capacitor (1)

#7316

4.7uF

1N5817 rectier diode (1)

#7522

.22J63

1µF capacitor (1)

#7308

1J63

1uF

10uF

.1J63

5mm white LED (1)

#7422

PARTS LIST CONT

3PDT latching footswitch (1)

#1611

3-way toggle switch (1)

#7465

B10K linear taper pot (1)

#7532

B100K linear taper pot (2)

#7453

24" of lead wire (1)

#5960

Adhesive foam tape square (4)

#7560

Control knob (3)

#7501

5mm LED mounting bezel (1)

#7432

PF5102 transistor (1)

#7518

2N5089 transistor (1)

#7514

FKH09

PF

5102

CEN

2N5

089

2N6027 transistor (1)

#7515

2N

6027

C45

2.1mm DC power connector (1)

#7468

PARTS LIST CONT

D

E

P

T

H

R

A

T

E

132

L

E

V

E

L

1/4" mono jack (2)

#4652

Circuit Board (1)

StickerSheet (1)

Pre-drilled enclosure (1)

Breakout Board (1)

IN GND SW OUT

PARTS LIST CONT SOLDERING MORE HELPFUL

SOLDERING TIPS

AND TRICKS

•Keep your soldering tip

clean by wiping it often

on a damp sponge.

• Also keep it tinned by

occasionally melting

a little solder onto it.

•Don’t blow on the

hot solder or touch

anything until the joint

has cooled completely.

A good solder joint

is shiny—a sign that

it was left to cool

undisturbed.

• Plan so each joint is

only soldered once.

Resoldered joints are

messy and more likely

to fail.

The solder joints you’ll make on the circuit boards are very

small, and too much heat can damage the board. The idea is to make joints

quickly, without scorching the eyelets.

1. Hold components in place for soldering by

threading the leads through the board and bending

them apart on the reverse side. You will be making

your solder joints on the reverse side of the board.

2. Melt a small amount of

solder onto the tip of

the iron (“tinning”the iron).

3. Insert the tip into the eyelet and let it heat for 4-5

seconds before touching it with solder. This heats the

contact enough for the solder to ow nicely without

damage. Feed the solder to the eyelet, not the iron,

and you don’t need much solder, just enough to ll

the eyelet. Keep the iron on the connection for a

second longer; this pause gives time for all of the ux

to cook out of the joint. After the joint has cooled,

trim away the excess lead wire.

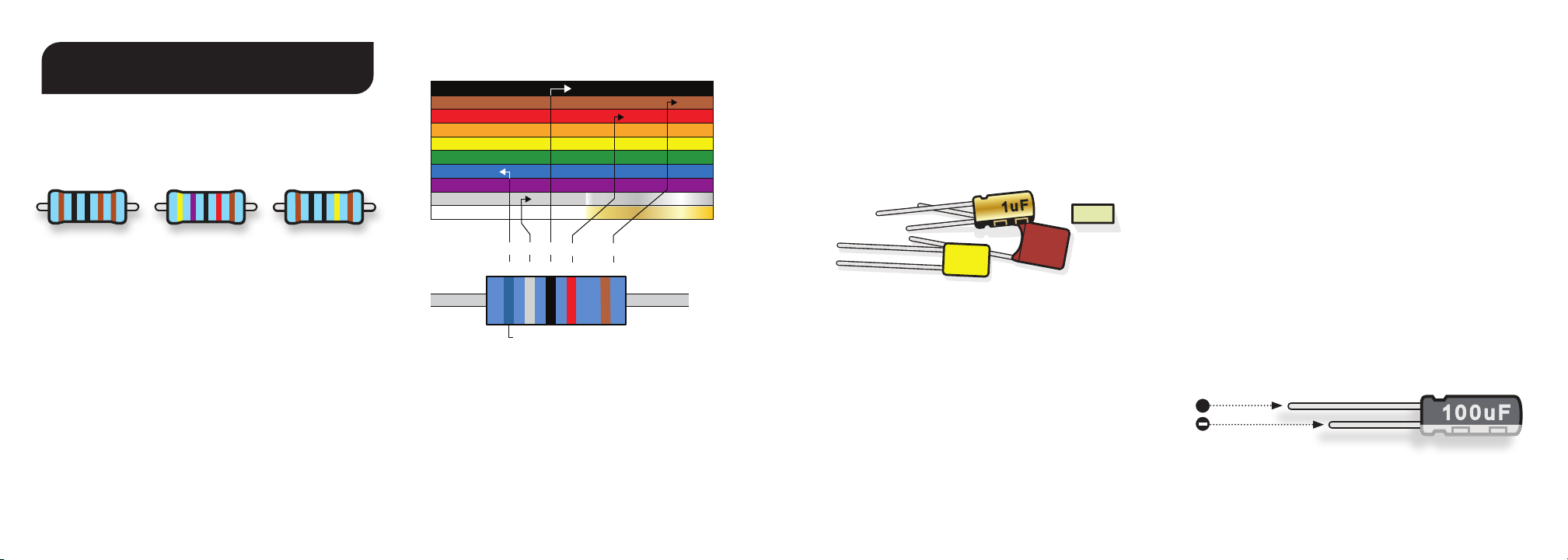

Resistor values are indicated by colored bands, read

from left to right. The rst color in the code is usually

the one painted closest to a lead wire. When a gold

or silver band is present, it’s always one of the last

colors in the code. If you’re having trouble reading

the color bands, try using a multimeter to read a

resistor’s value. Just set your multimeter to ohms and

connect the test leads on each side of the resistor.

A number of dierent components are used to make

an eects pedal. The ones used in this pedal are

resistors, capacitors, diodes, and integrated circuits.

RESISTORS

Resistors are used in electrical circuits to direct

or reduce current ow and adjust signal levels.

In layman’s terms a resistor does exactly that,

resists the ow of current. The value of the resistor

determines how much eect the resistor will have

on the ow of electrons.

A resistor’s value—the amount of resistance it

creates—is rated in ohms (). Larger ohm values

mean more resistance. For example, a 100

resistor creates ten times as much resistance

as a 10 resistor.

UNDERSTANDING ELECTRONIC

COMPONENTS

Band 1 Band 2 Band 3 Band 4 Band 4

1st Digit 2nd Digit 3rd Digit Multiplier Tolerance

6 8 x100 +/- 1%

68K +/- 1%

K=1,000

Blue

Read this band rst (closest to an end)

Gray Black Red Brown

BLACK 0 0 0 1

BROWN 1 1 1 10 +/- 1%

RED 2 2 2 100 +/- 2%

ORANGE 3 3 3 1,000

YELLOW 4 4 4 10,000

GREEN 5 5 5 100,000 +/- .5%

BLUE 6 6 6 1,000,000 +/- .25%

VIOLET 7 7 7 10M +/- .1%

GRAY 8 8 8 .01 SILVER

WHITE 9 9 9 .1 GOLD

0

Resistors and capacitors may also be referred to with

shorthand notation on the printed circuit board

when there is a decimal in the value. For example,

the place on the board for the 4.7K resistor will read

4K7 and the spot for a 2.2nF capacitor will read 2n2.

This is done to save space on the board and make

the labels as clear as possible.

Some capacitors have polarity and some don’t.

It’s extremely important to install polarized caps

correctly in a circuit. The negative lead will often

be indicated by a band of arrows pointing to the

negative lead and will be shorter than the positive

lead. The positive lead of an electrolytic cap will be

longer and won’t have any arrows pointing to it.

Installing capacitors with the polarity backwards will

make the circuit malfunction and quickly destroy the

capacitor— even causing it to explode.

CAPACITORS

The two main uses of capacitors are to store

electricity and to block the ow of DC current.

Capacitor values are typically printed on the

component. The key values with caps are their

voltage and capacitance.

The voltage spec for a cap refers to how much DC

voltage it can handle at any given time. If this rating

is exceeded, the capacitor will fail.

Capacitance, measured in farads, refers to how

much electricity a capacitor can hold. One farad (1F)

would be much too large for use in a pedal. Caps

for pedals are rated between millionths of a farad,

called microfarads (F), billionths of a farad, called

nanofarads (nF), or trillionths of a farad: picofarads

(pF). .001μF = 1nF = 1,000pF.

101J

100V

102J

1u F

.1J63

++

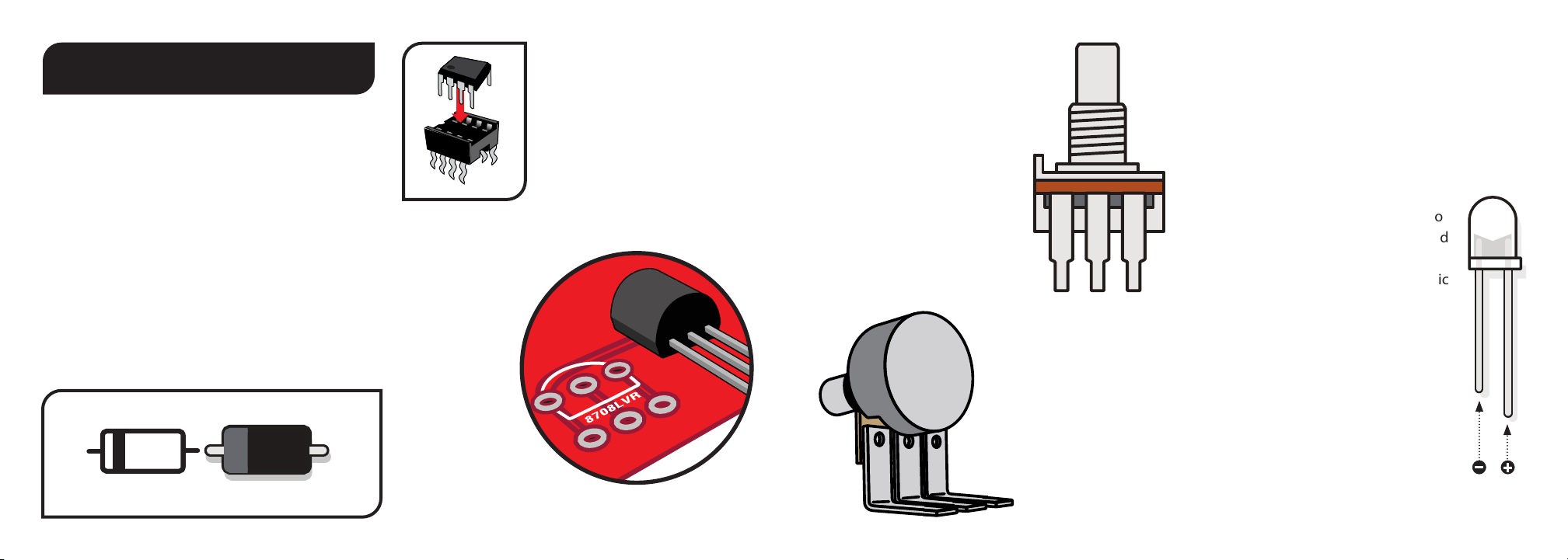

INTEGRATED CIRCUITS

Integrated circuits are complex,

tiny, self-contained collections

of components that contain

a complete circuit. Op-amps,

audio processors, and linear

voltage regulators are three

kinds of integrated circuits.

TRANSISTORS

Transistors are

used to amplify

electrical signals.

The have a at

side and a round

side. The location

on the circuit

board also has a

round side and a at

side. Match the orientation

of the component to this outline.

UNDERSTANDING ELECTRONIC

COMPONENTS

DIODES

Diodes are used where you want electricity to ow

in only one direction, such as power rectication,

and also to limit how much current can ow, to

create “clipping” distortion.

Diodes are also polarized, so they need to be

installed in the correct orientation. The stripe

around one end marks the negative (minus) lead of

the diode. On the circuit board, the printed outline

of the diodes also shows this stripe. Install each

diode so that its stripe matches the direction shown

on the circuit board.

2n2J630

TL072

PT2399

PT2399

PT2399

PT2399

echo audio

processor (1) #7490

TL072CP TL072CP

low noise

op-amp (1) #7444

POTENTIOMETER

A potentiometer, or pot, is a variable

resistor. This means as the knob

shaft is rotated, the DC resistance

will change. There are three lugs

or soldering terminals on a

conventional potentiometer.

The outside two are the ends

of the resistive strip, and the

center lug is connected to the

“sweeper.” The sweeper allows

you to vary the DC resistance

relative to its position along the

resistive strip, or relative to the

outer two lugs.

Potentiometers come in

two varieties, linear-taper

and audio-taper. The linear-

taper pot’s taper works at a 1:1

ratio. Audio taper, has a special

logarithmic ratio.

Audio taper is used because our ears don’t hear

changes in volume in a linear fashion as you might

expect. As the volume increases, a greater change

in signal or sound-pressure is required to perceive

a smooth transition.

LED

LED stands for Light Emitting Diode,

and functionally LEDs are very similar to

regular diodes. LEDs are most often used

as indicator lights in pedals. They are

polarized just like diodes and electrolytic

capacitors and must be installed in the

correct orientation to work. The positive

(anode) lead of the LED will be longer and

the anode side of the LED housing will be

round. The negative (cathode) lead of the

LED will be shorter and the cathode side

of the LED housing will be at. LEDs are

mounted inside of a bezel, which protects

the LED and insulates the leads from

shorting against the enclosure or any

internal components.

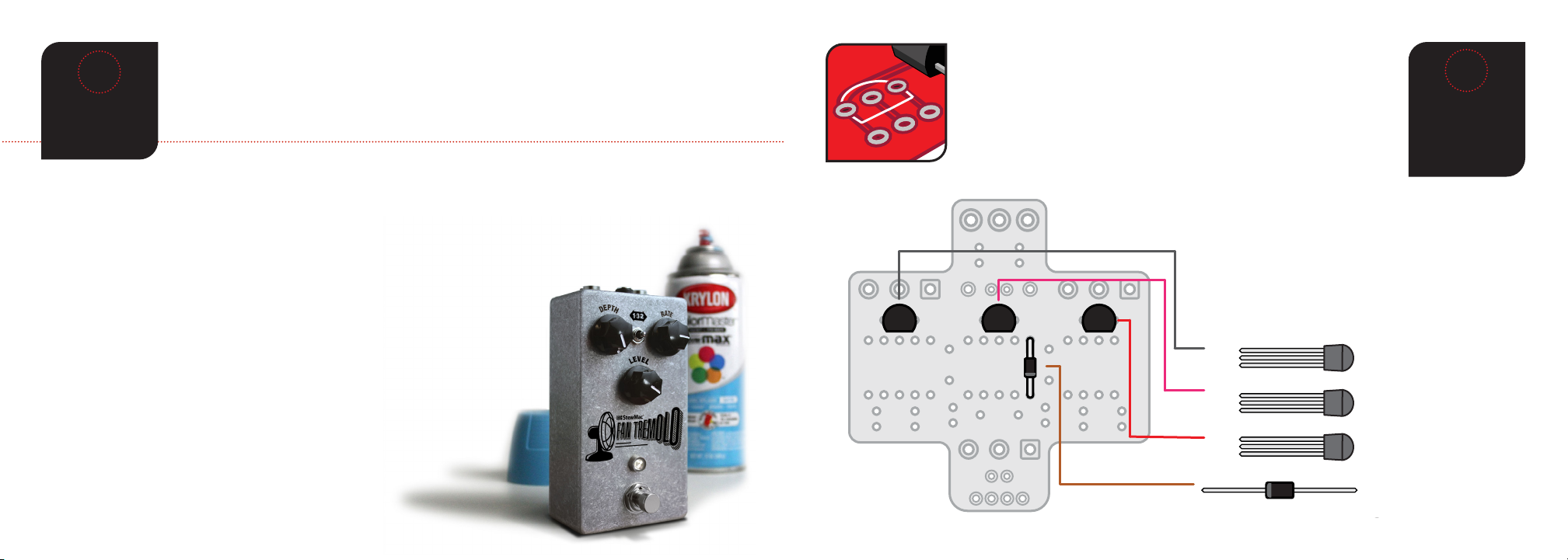

It’s time to install your parts! Before soldering the diode and

transistors to your Printed Circuit Board (PCB), make sure you thread

the legs through the correct side. The side of the PCB that has white

values and outlines of the components is the correct side. In some

cases, components must be inserted into the PCB in a specic

direction due to their polarity, so follow the graphics carefully.

INSTALL

1 DIODES

AND 3

TRANSISTORS

2

1N5817 rectifier diode (1)

#7522

1N4148 rectifier diode (2)

#7470

Linear voltage

regulator (1) #7508

1N5817 rectifier diode (1)

#7522

1N4148 rectifier diode (2)

#7470

Linear voltage

regulator (1) #7508

2N6027

Note the stripe around one end of the diode. This marks

the negative (minus) lead. On the PCB, the printed

outline of the diodes also shows this stripe. Install each

diode to match the direction shown. Similarly, the

transistors are directional, and must be installed in a

specic orientation. Match the at side of the

transistors to the outline printed on the PCB.

FKH09

PF

5102

CEN

2N5

089

2N6027 transistor (1)

#7515

2N

6027

C45

PF5102 transistor (1)

#7518

2N5089 transistor (1)

#7514

1N5817 rectifier diode (1)

#7522

Note the stripe around one end of the diode. This

marks the negative (minus) lead. On the PCB, the

printed outline of the diodes also shows this stripe.

Install the diode to match the direction shown.

Similarly, the transistors are directional, and must be

installed in a specic orientation. Match the at side

of the transistors to the outline printed on the PCB.

1. To minimize redoing steps,

make sure you have a solid idea of

the look and feel you’re going for.

2. Lightly sand housing with a 220

grit sandpaper and wipe clean any

debris.

3. Cover the holes from the

inside with masking tape.

4. On a large piece of cardboard,

elevate the housing top and

bottom on a couple of small

blocks of wood.

5. With long, slow strokes, spray

1 light coat of primer or primer/

paint on top and bottom. Allow

45 mins of drying time between

next two to three coats.

6. If you’re using primer followed

by paint method, paint 3 coats

with 45 mins between coats.

7. Now, add your Fan Tremolo

sticker and any other desired

decoration (paint pens, acrylic

paint, Sharpie etc.).

Allow drying time.

8. Add 3 coats of clear coat glaze

with 45 mins between coats.

Wait at least 2 hours

before adding parts.

You’re about to create a pedal from the ground up, so why not give your pedal a custom

paint job? Painting your pedal and adding the sticker provided in this kit (or custom

decals that you can create on your own) in advance is not only fun, but it’s much easier

than disassembling the pedal to paint it once you put it together.

PAINTING

YOUR PEDAL

HOUSING

1

Next, we’re going to add a bunch of resisitors to our PCB. Like in the previous step, you’ll

nd an outline of each resistor and its value printed in their proper location on the PCB.

Match resistors to the values on the PCB and solder in place.

Resistors are not polarized, so it doesn’t matter which lead goes in which eyelet.

INSTALL 13

RESISTORS

3

Red Red Black Brown Brown

Brown Red Black Red Brown

2.2K resistor (2) #7376

12K resistor (1) #7392

Yellow Purple Black Black Brown

470Ω resistor (2) #7355

Yellow Purple Black Brown Brown

4.7K resistor (1) #7359

Brown Black Black Black Brown

100Ω resistor (1) #7352

Resistors have a low prole, sitting closer to the board

than taller components, so installing these now will make

installing other parts easier later on.

Brown Black Black Yellow Brown

Red Red Black Red Brown

Red Purple Black Red Brown

Yellow Purple Black Red Brown

Red Red Black Orange Brown

1M resistor (1) #7367

22K resistor (1) #7379

27K resistor (1) #7398

47K resistor (2) #7369

220K resistor (1) #7381

101J

100V

100uF

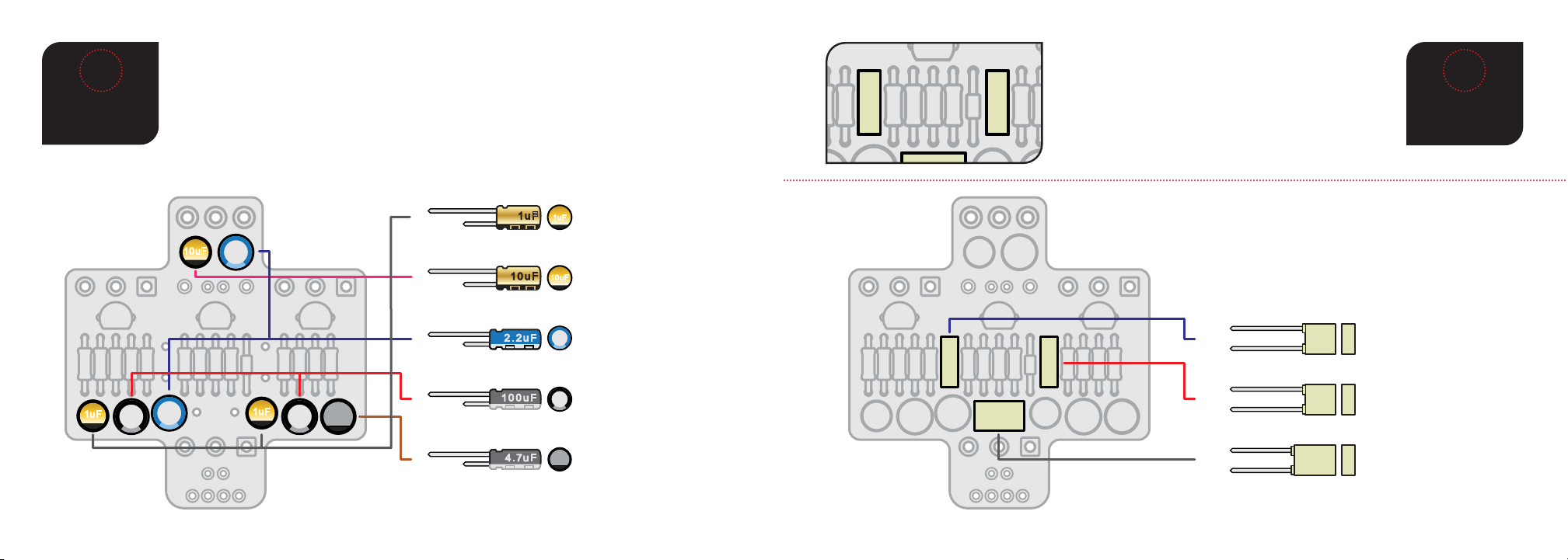

INSTALL11

CAPACITORS

4

The three types of capacitors shown below are polarized and have to be installed in

the correct orientation. Note the stripe running the length of each cap; this identies

the negative (minus) lead. On the circuit board, the circle for this cap’s location has a

round through hole on one side, and a square through hole on the other: insert the

capacitors with their stripe facing the round hole side. (On polarized caps of this type,

there’s a second way to identify the negative lead: it is the shorter of the two leads).

1uF

1uF

10uF

10µF capacitor (1)

#7338

100µF capacitor (2)

#7312

10uF

1µF capacitor (2)

#7337

1uF

100uF

4.7µF capacitor (1)

#7316

4.7uF

2.2µF capacitor (2)

#7315

2.2uF

1uF

10uF

.22J63

1J63

.1J63

220nF capacitor (1)

#7305

100nF capacitor (1)

#7304

.22J63

1µF capacitor (1)

#7308

1J63 .1J63

INSTALL3

CAPACITORS

5

The remaining capacitors below are not polarized.

However, best practice is to solder these caps in

place all facing the same direction.

.22J63

1J63

.1J63

220nF capacitor (1)

#7305

100nF capacitor (1)

#7304

.22J63

1µF capacitor (1)

#7308

1J63 .1J63

One 3-way toggle switch is included with the kit. Slide the switch lugs through the back

of the the three PCB holes at the top of the board and solder them.

You can use the pedal enclosure as a mount for the toggle switch while you solder the

PCB board to it. Just lay the enclosure face-up and drop the switch in its hole, you don’t

even need to fasten it with a nut from the back if you don’t want to.

INSTALL 1

SWITCH

6

.22J63

1J63

.1J63

.22J63

1J63

.1J63

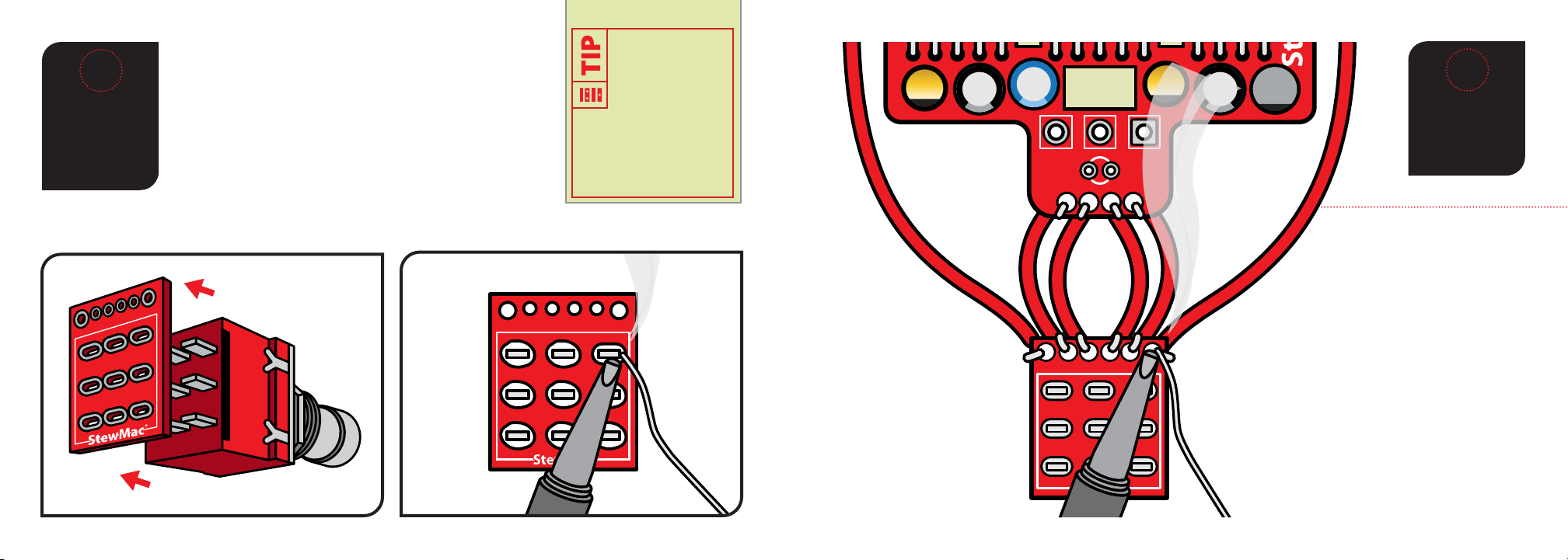

The kit comes with 24" of lead wire.

Cut the wire into eight 2" sections and two 4" pieces.

Strip around 3/32" o both ends of all wires.

Solder the eight 2" leads on to main board in the

locations shown in the diagram.

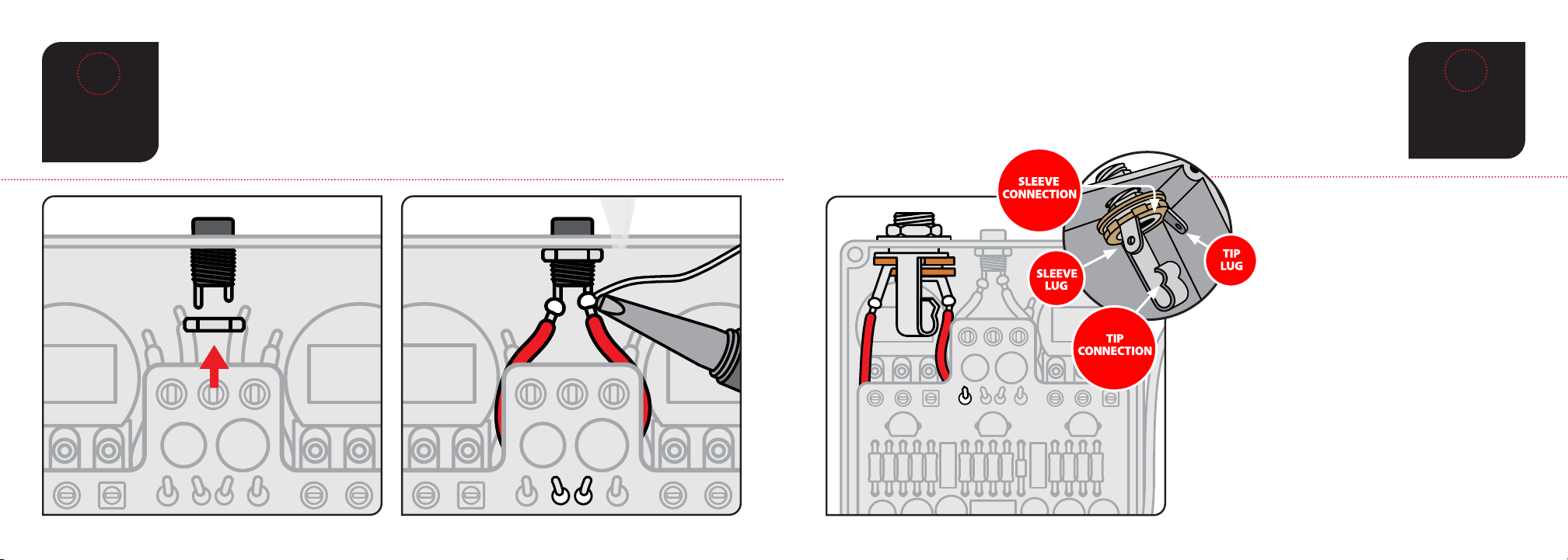

INSTALL 8

LEAD WIRES

7

We nd it easiest to feed the free end of

each lead through the bottom of the PCB

and solder it on the top of the board.

TIP

INSTALL

FOOTSWITCH

INTO

BREAKOUT

BOARD

8

Orient the breakout board with the text facing up,

reading left to right, and slide the lugs of the footswitch

up through the bottom of the board.

Solder each lug to the breakout board around it. If the

lugs of the footswitch don’t quite t in the breakout

board, use a pair of pliers to gently bend the lugs of the

footswitch until the breakout board will slide over the lugs.

IN GND SW OUT

IN G NDSW OUT

Just like the toggle

switch and the

PCB, you can use

the pedal enclosure

as a mount for the

footswitch while you

solder the breakout

board to it.

9

ATTACH 6

WIRES TO

BREAKOUT

BOARD

.22J63

1J63

.1J63

IN GND SW OUT

Solder the four wires from the bottom of the

main board to their corresponding holes in

the breakout board.

Solder the one free end of each 4" wire to the

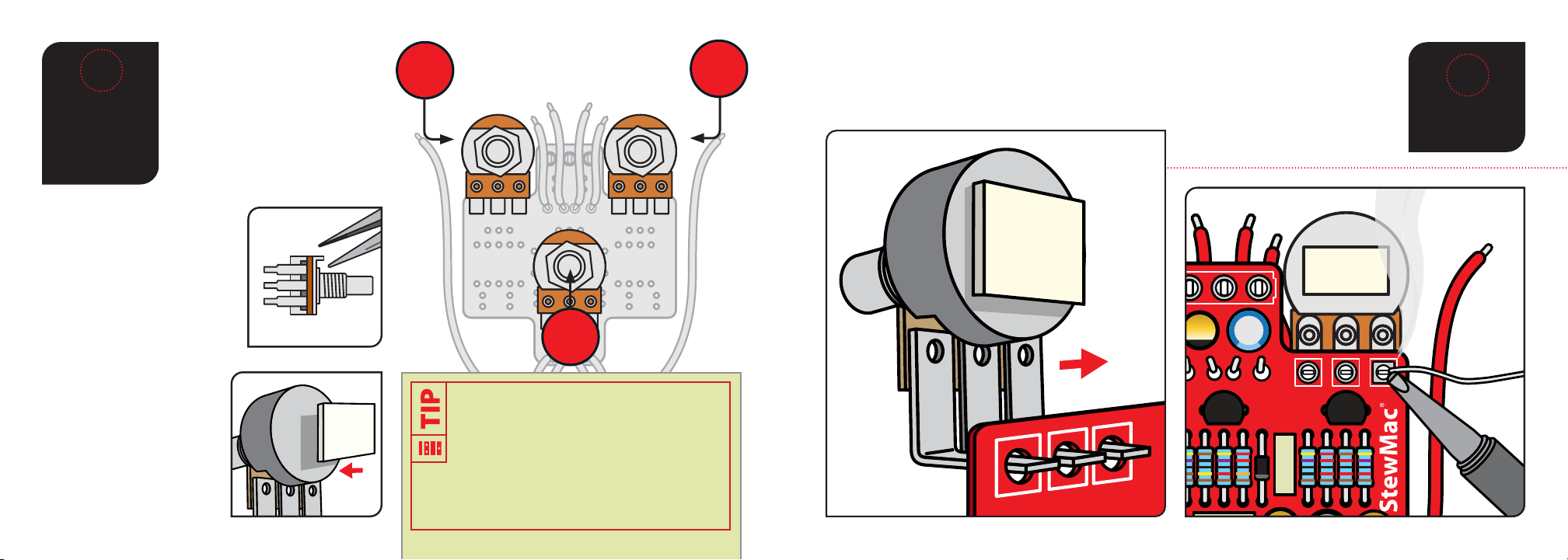

last two holes on the breakout board.

LEVEL

(B100K)

10

If any pot has an index pin

protruding from the case,

break it o before installation,

so the pot will mount ush

against the pedal case.

Needle nose pliers work well

for removing the pins.

The last components to go onto

the circuit board are the three

control pots. They install on the

back of the board. Each pot has

three connecting lugs. Note

orientation of each pot.

INSTALL

POTS AND

ATTACH

FOAM TAPE

TIME

Once you’ve removed any index pins and

added the foam tape to the back of each pot,

use the pedal enclosure as a mount for the

control pots while you solder the PCB to them.

Just lay the enclosure face-up and arrange the pots

in their holes, you don’t even need to fasten them

with a nut from the back if you don’t want to.

Use the adhesive foam tape

to insulate the back of the

pots from the soldered

leads of the other parts on

the circuit board. This is

especially important on the

“level” pot.

DEPTH

(B10K)

RATE

(B100K)

SOLDER

POTS TO PCB

11

Solder the pots in place, making sure the foam back stays on the back of the pot.

This insulates the solder joints on the PCB from shorting to the housing of the pot.

.22J63

1J63

.1J63

IN GND SW OUT

case

5mm LED mounting bezel (1) #7432

5mm white LED (1) #7422

case

The LED mounting bezel consists of two main parts: a

ring that the LED ts into, and a plastic plug that goes

over the LED from the back side to keep it in place.

Install the mounting bezel through the front of the

enclosure. From the inside, slip a lock washer and nut

on and tighten it up using a 3/8" socket. Insert the LED

into the bezel so the at side (the shorter lead) faces to

the right side of the case when looking from the back.

Feed the leads through the plastic plug, press the plug

down until it’s tight in the bezel. The LED will be held

in place when you solder the leads to the switches and

circuit board. For a more secure mount, you can run a

bead of clear silicone adhesive around the plastic plug.

12

INSTALL 1

LED

INDICATOR

LIGHT

Like some of the caps and diodes,

the LED is polarized and has to be

installed in a specic direction. The

negative lead of the diode has a at

edge and is shorter than the positive.

++

.22J63

1J63

.1J63

IN GND SW OUT

The circuit board is held in place by the

control pots, but the LED leads need to

pass through their eyelets in the PCB

before the pots will pass through the

enclosure. Pass the longer

positive lead through

the hole marked “A”

and the shorter negative lead through

the hole marked “K”. Once the pots are

secured to the enclosure, solder these

leads in place.Install their shafts through

the top of the case, and thread washers onto them on

the outside. Using a 10mm wrench, install the mounting

nuts so they are good and snug, but take care not to

overtighten.

Install the footswitch through the top of the case and

thread a washer onto it from the outside. Use a 14mm

wrench to tighten it up. The footswitch is the eect bypass

switch that turns the pedal on.

Do not connect any of the lead wires at this point. Once all

of the pots are tightened down, twist the pot shafts all the

way counter-clockwise and install the knobs pointing at “7

o’clock” indicating a the “zero” position.

Insert the DC jack into the top of the housing making sure the longer of the two lugs

is on the left. Using a 14mm wrench and 14mm nut, secure jack into housing.

Solder the inside left wire to the longer lug of the DC jack.

Solder the inside right wire to the shorter lug of the DC jack.

14

INSTALL

DC JACK

INSTALL

THE INPUT

JACK

15

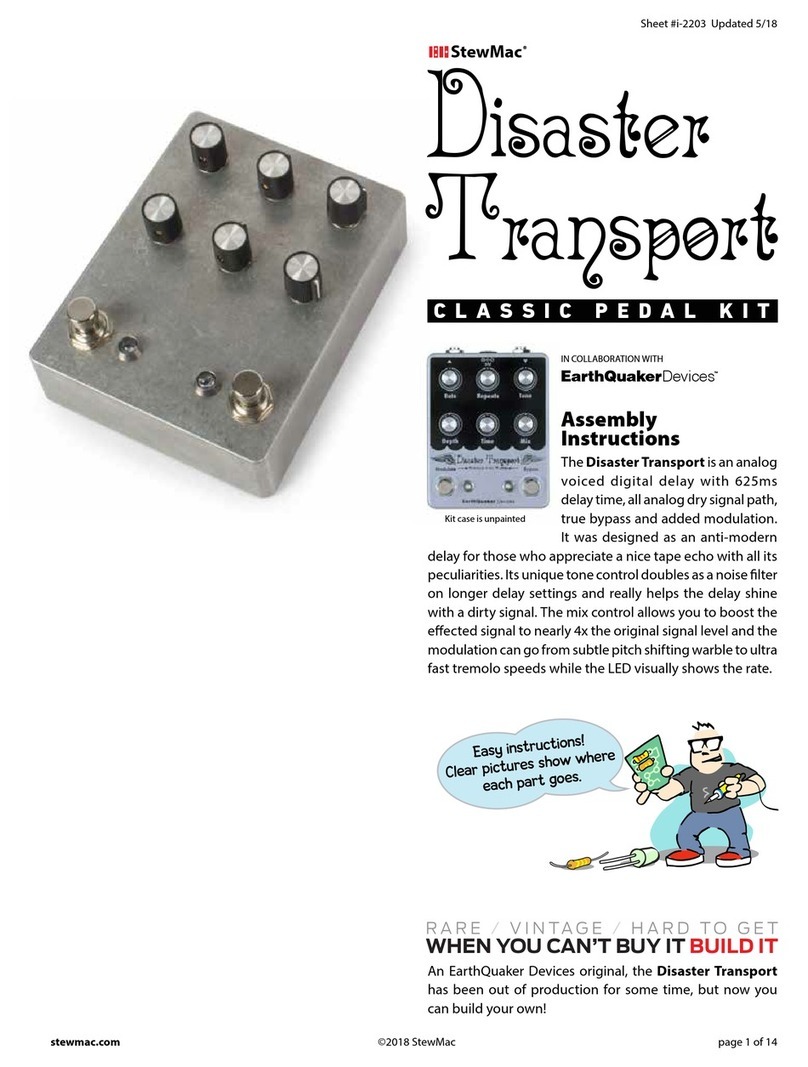

Insert the input jack into the left side of the housing with the tip connection facing

down, as shown in the diagram. Add the washer and thread the nut on to the shaft

enough so that the pot can rotate freely. You may need to rotate the jack to provide

easier access to setting the solder joints.

Solder the left most wire at the top of the

board to the input jack lug that corresponds

with the sleeve connection. The sleeve

connection lug should be the one

closest to the DC jack.

Solder the 4" wire on the left side of the

footswitch board to the lug of the input jack that

corresponds with the tip connection. The tip

connection lug should be the one closest to the

outside wall of the enclosure.

Once the solder has cooled, orient the jack as

shown in the diagram, make sure none of the

connections on the jack are shorting to any other

components, and tighten the nut on the jack.

Shield lug Tip connection

Tip lugShield connection

16

INSTALL

THE OUTPUT

JACK

Insert the output jack into the right side of the housing with the tip connection facing

up, as shown in the diagram. Add the washer and thread the nut on to the shaft

enough so that the pot can rotate freely. You may need to rotate the jack to provide

easier access to setting the solder joints.

Solder the right most wire at the top

of the board to the output jack lug that

corresponds with the sleeve connection.

The sleeve connection lug should be the

one closest to the DC jack.

Solder the 4" wire on the right side of the

breakout board to the lug of the output jack that

corresponds with the tip connection. The tip

connection lug should be the one closest to the

outside wall of the enclosure.

Once the solder has cooled, orient the jack as

shown in the diagram, make sure none of the

connections on the jack are shorting to any other

components, and tighten the nut on the jack.

Shield lug Tip connection

Tip lugShield connection

COMPLETED

VIEW

17

.22 J 63

1J63

.1J63

IN GND SW OUT

With the output jack secured, this is what your pedal

should look like.

Congrats on a job well done.

Now, simply attach the back of the pedal, pop on the

knobs, plug this thing in and bend some tone!

POWER: Use a standard 9 volt DC power

supply with a 2.1mm negative-center barrel (not

included). We always recommend pedal-specic,

transformer-isolated wall-wart power supplies or

supplies with separate isolated outputs. Pedals

will make extra noise if there is ripple or unclean

power. Switching-type power supplies, daisy

chains, and non-pedal specic power supplies

do not lter dirty power as well and let through

unwanted noise. Do not run at higher voltages!

Current draw is 25 mA.

DEPTH: This control could also be labeled Mix or

Intensity. A low setting will have a very low eect

on the signal and the more you turn the knob the

more intense or“deep”the tremolo eect will be.

HERE’S HOW THE CONTROLS WORK INPUT

OUTPUT 9V DC

BYPASS

D

E

P

T

H

R

A

T

E

132

L

E

V

E

L

NOTES

MODE: This 3-way toggle switch selects which

type of oscillation you would like. All the way left

is a subtle, early 60’s style oscillation. All the way

right is a slightly faster and heavier“opto-isolator”

style tremolo, more like the eect found in amps

in the late 60’s and 70’s. The middle position is a

very modern, almost digital style oscillation that

can easily achieve ring-mod style tremolo.

RATE: This adjusts the speed of the oscillations.

LEVEL: There is a slight boost in the circuit to

help compensate for the perceived volume drop

associated with tremolo eects. A lower setting

means a lower output, and a higher setting

results in, you guessed it, a higher output. We’re

guilty of sometimes turning the depth very low

and the level up higher and using this pedal as a

clean boost with a touch of shimmer.

TL072 PT2399

IN GND SW OUT

NOTES

THE STEWMAC

FAN TREMOLO

TECHNICAL SUPPORT:

If you have any questions before,

during, or after this project, please do

not hesitate to reach out to our Tech

Support Team. They are available by

21 N. Shafer St., Athens, OH 45701

stewmac.com

©2020 StewMac. All rights reserved. • #2351 Updated February 2020

Table of contents

Other StewMac Music Pedal manuals

StewMac

StewMac EC EXPANDER PEDAL KIT Manual

StewMac

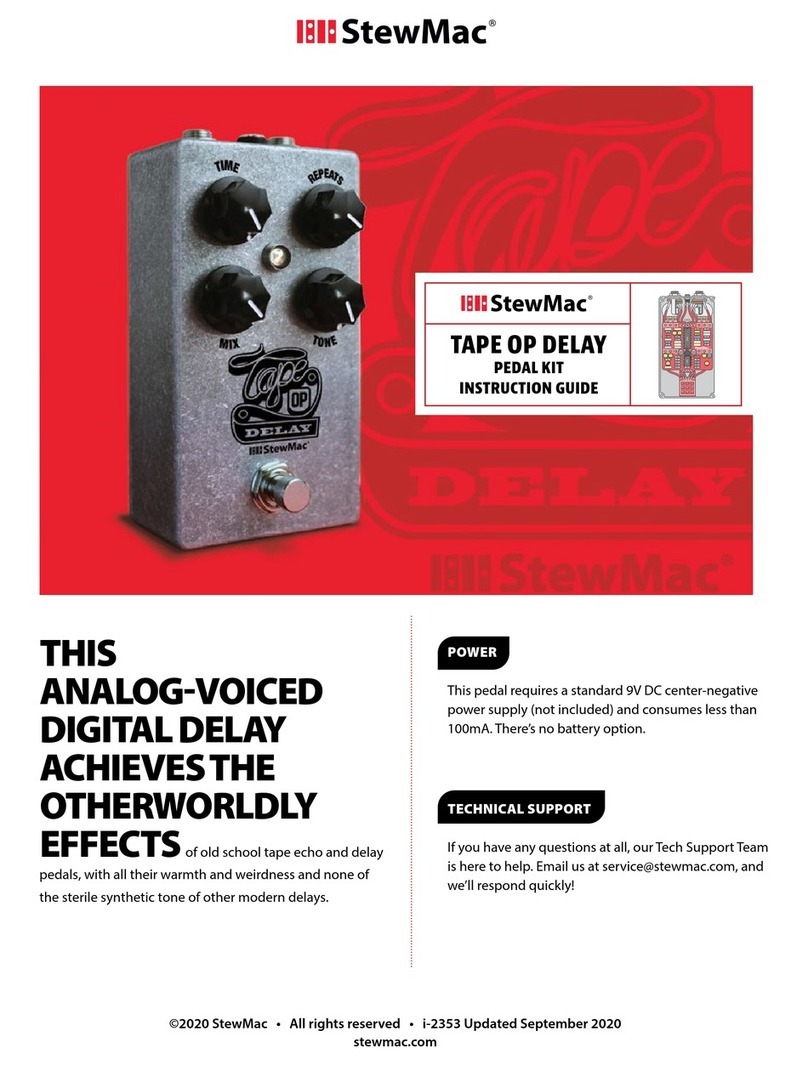

StewMac TAPE OP DELAY Manual

StewMac

StewMac NYC BIG MUFF PI User manual

StewMac

StewMac LIGHTCYCLE PHASOR II Manual

StewMac

StewMac TWO KINGS BOOST DOUBLE-POWERED ROYAL TONE Manual

StewMac

StewMac Monarch User manual

StewMac

StewMac Disaster Transport User manual

StewMac

StewMac MXR PHASE 90 User manual

StewMac

StewMac SUN FUZZ Manual

StewMac

StewMac SWELL DRIVE Manual