StewMac MXR PHASE 90 User manual

Table of contents

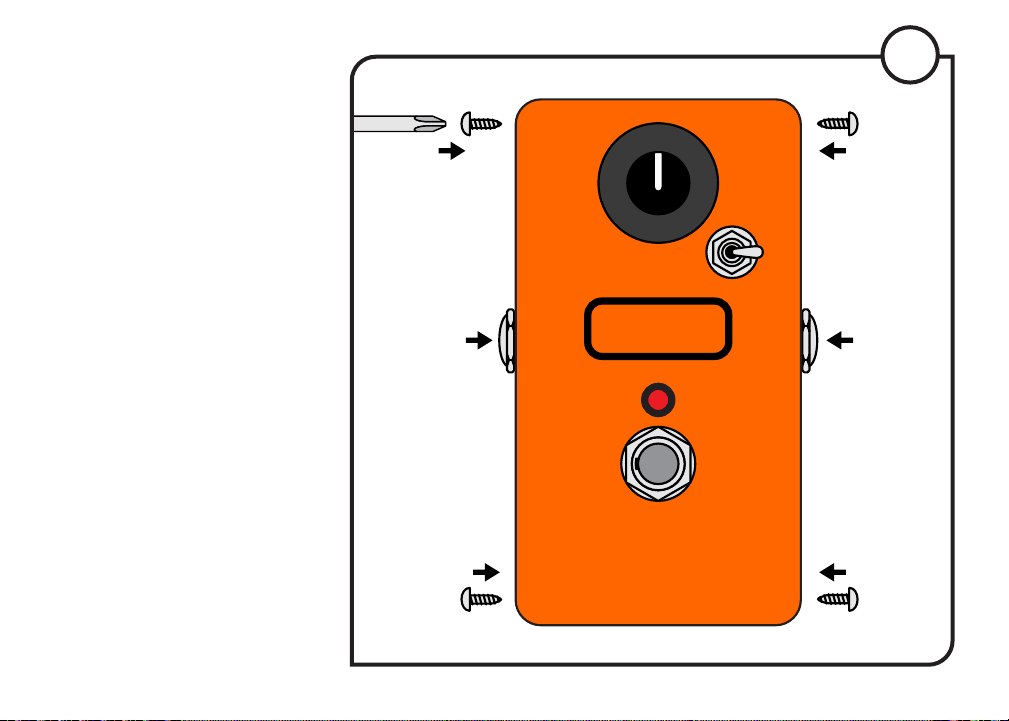

Other StewMac Music Pedal manuals

StewMac

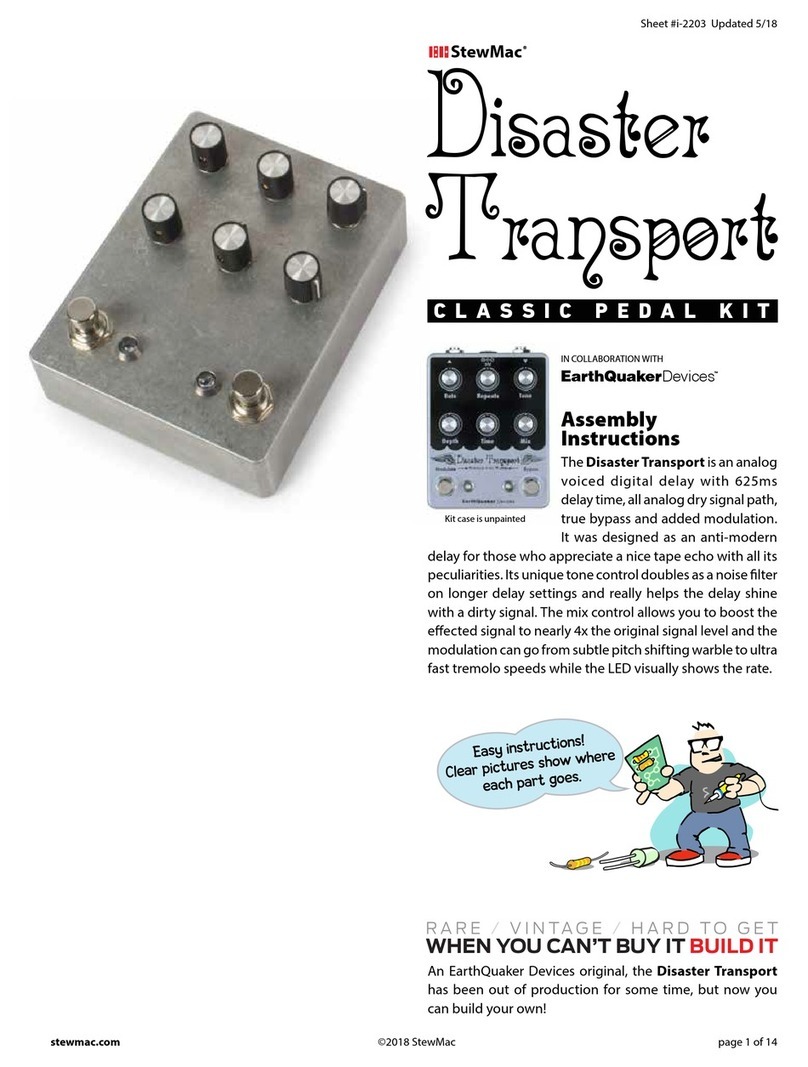

StewMac Disaster Transport User manual

StewMac

StewMac Monarch User manual

StewMac

StewMac SWELL DRIVE Manual

StewMac

StewMac LIGHTCYCLE PHASOR II Manual

StewMac

StewMac INTERVAL FUZZ Manual

StewMac

StewMac TWO KINGS BOOST DOUBLE-POWERED ROYAL TONE Manual

StewMac

StewMac NYC BIG MUFF PI User manual

StewMac

StewMac SCREAMER Manual

StewMac

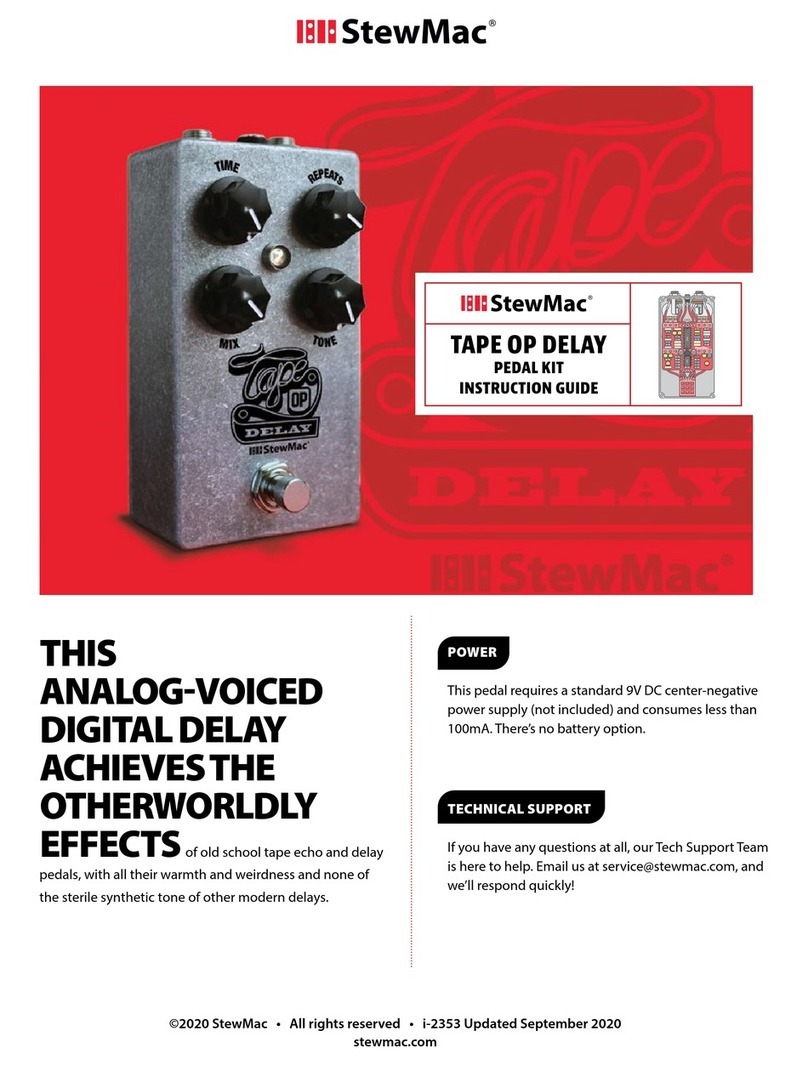

StewMac TAPE OP DELAY Manual

StewMac

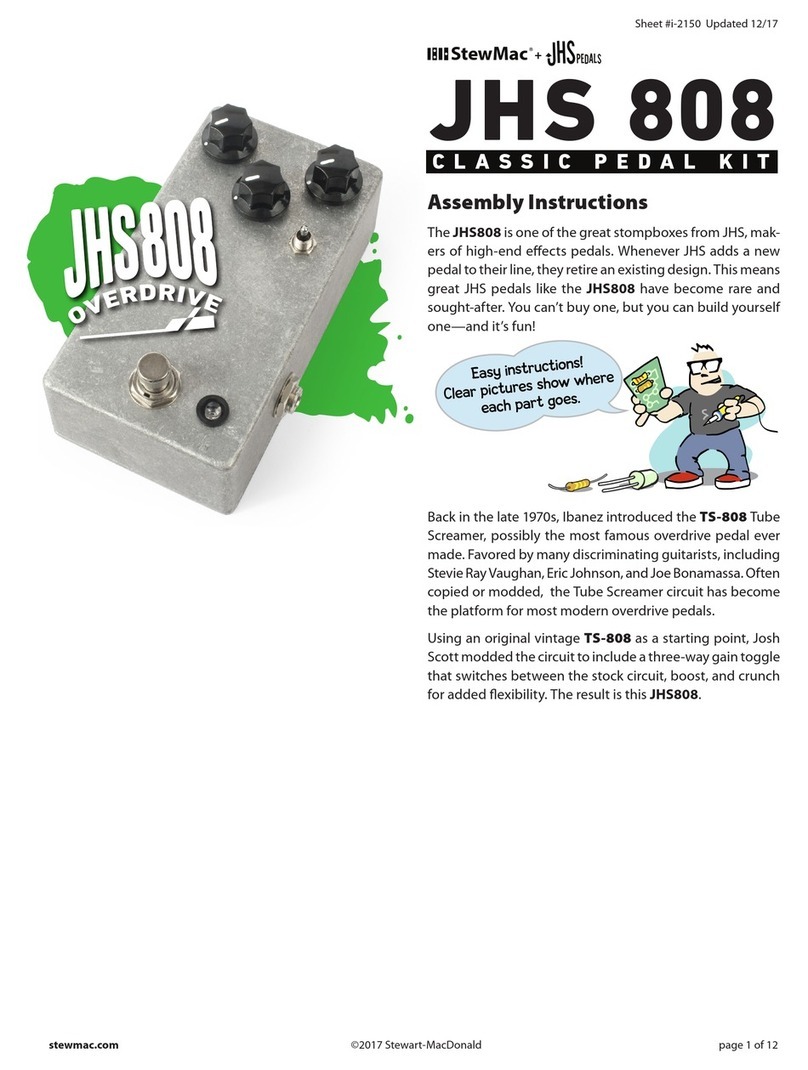

StewMac JHS 808 User manual

Popular Music Pedal manuals by other brands

Electro-Harmonix

Electro-Harmonix 720 instruction manual

Electro-Harmonix

Electro-Harmonix Iron Lung instructions

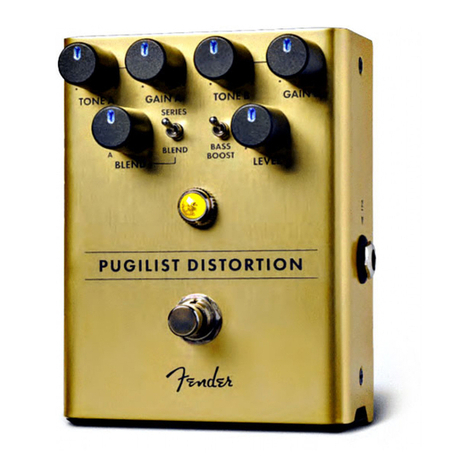

Fender

Fender Pugilist Distortion manual

TC Electronic

TC Electronic 3RD DIMENSION CHORUS quick start guide

Ibanez

Ibanez Analog Delay Mini owner's manual

Darkglass Electronics

Darkglass Electronics Super Symmetry user manual