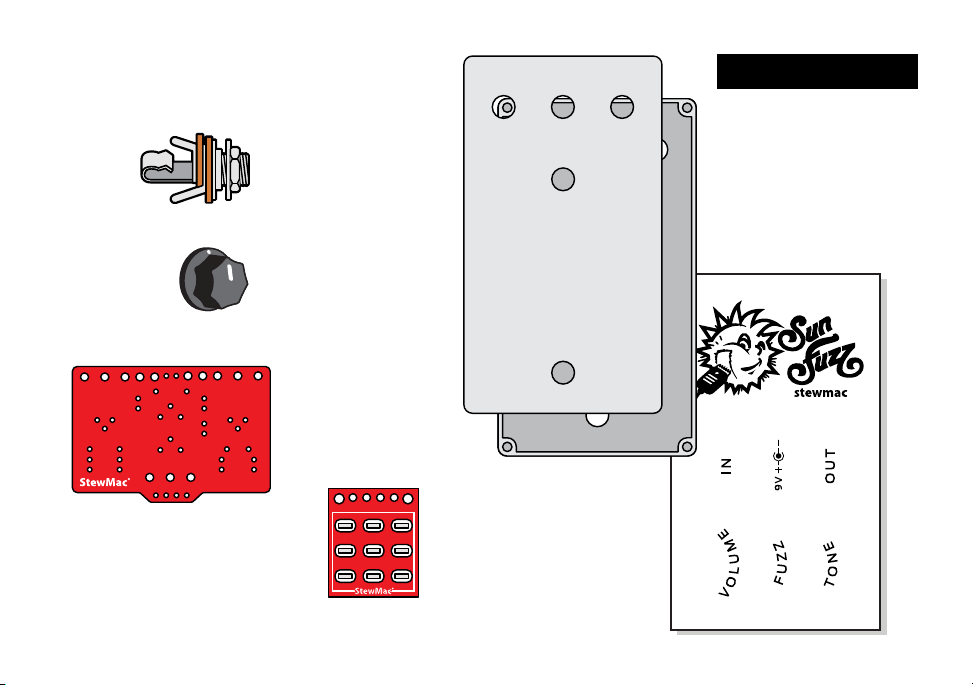

StewMac SUN FUZZ Manual

Table of contents

Other StewMac Music Pedal manuals

StewMac

StewMac SWELL DRIVE Manual

StewMac

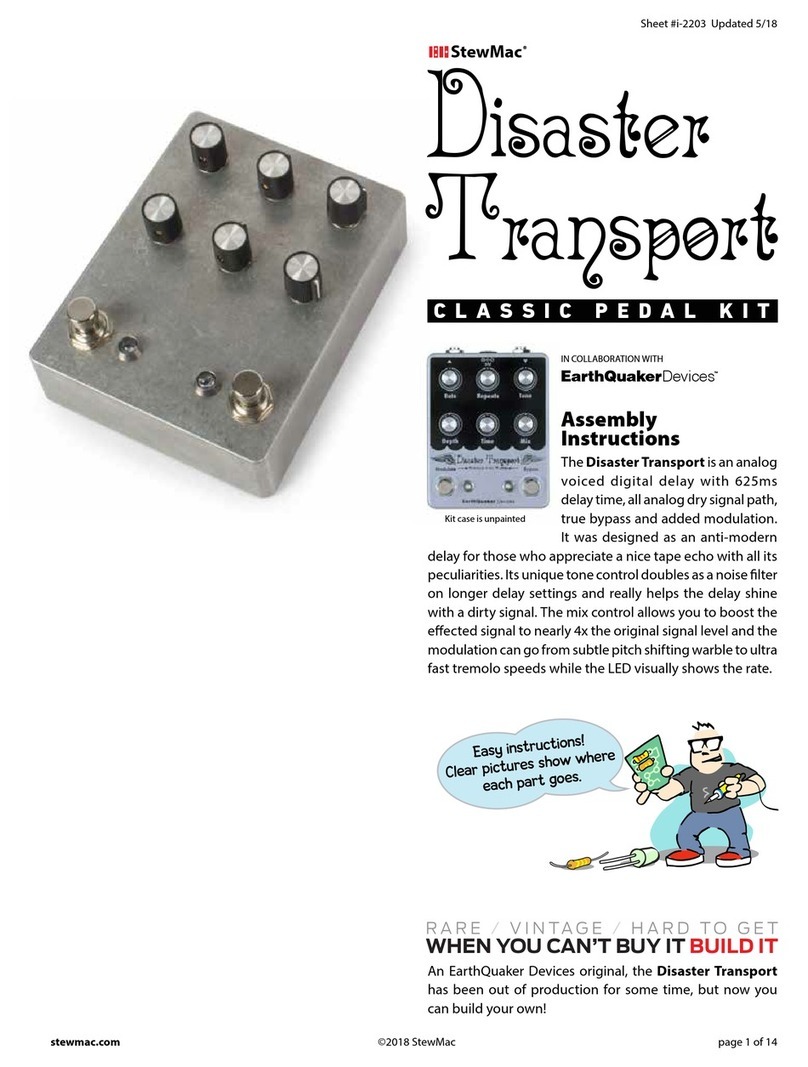

StewMac Disaster Transport User manual

StewMac

StewMac LIGHTCYCLE PHASOR II Manual

StewMac

StewMac EC EXPANDER PEDAL KIT Manual

StewMac

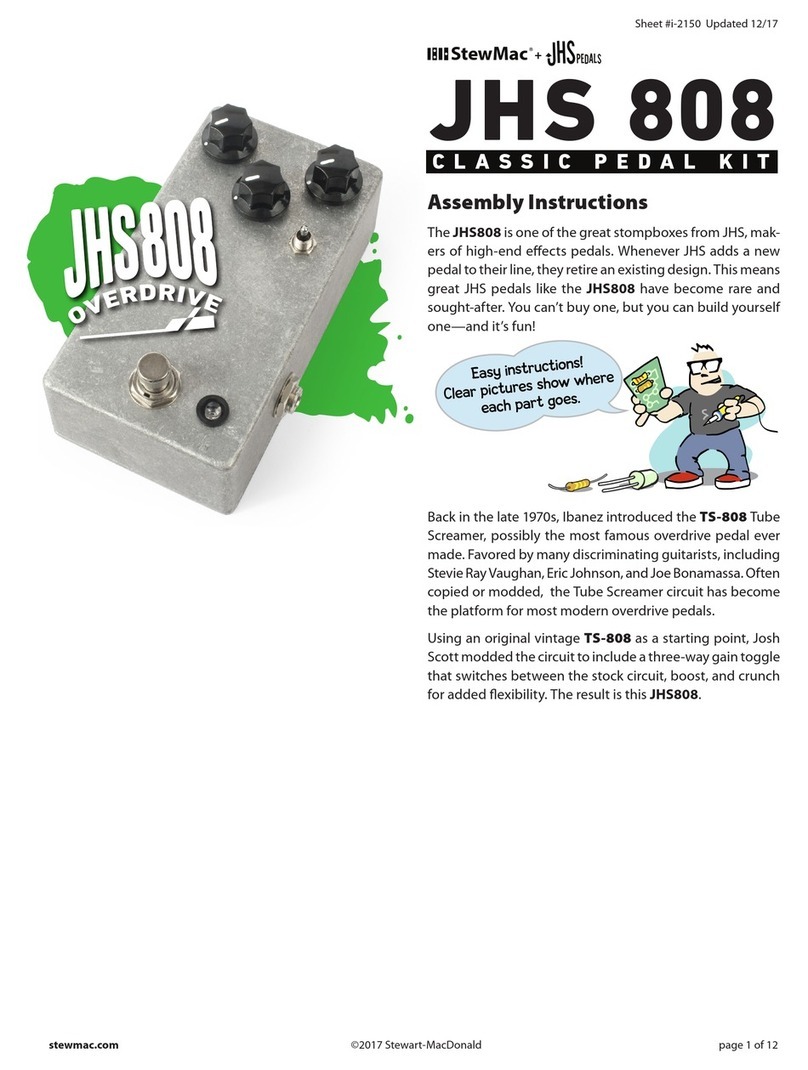

StewMac JHS 808 User manual

StewMac

StewMac TWO KINGS BOOST DOUBLE-POWERED ROYAL TONE Manual

StewMac

StewMac INTERVAL FUZZ Manual

StewMac

StewMac SCREAMER Manual

StewMac

StewMac FAN TREMOLO Manual

StewMac

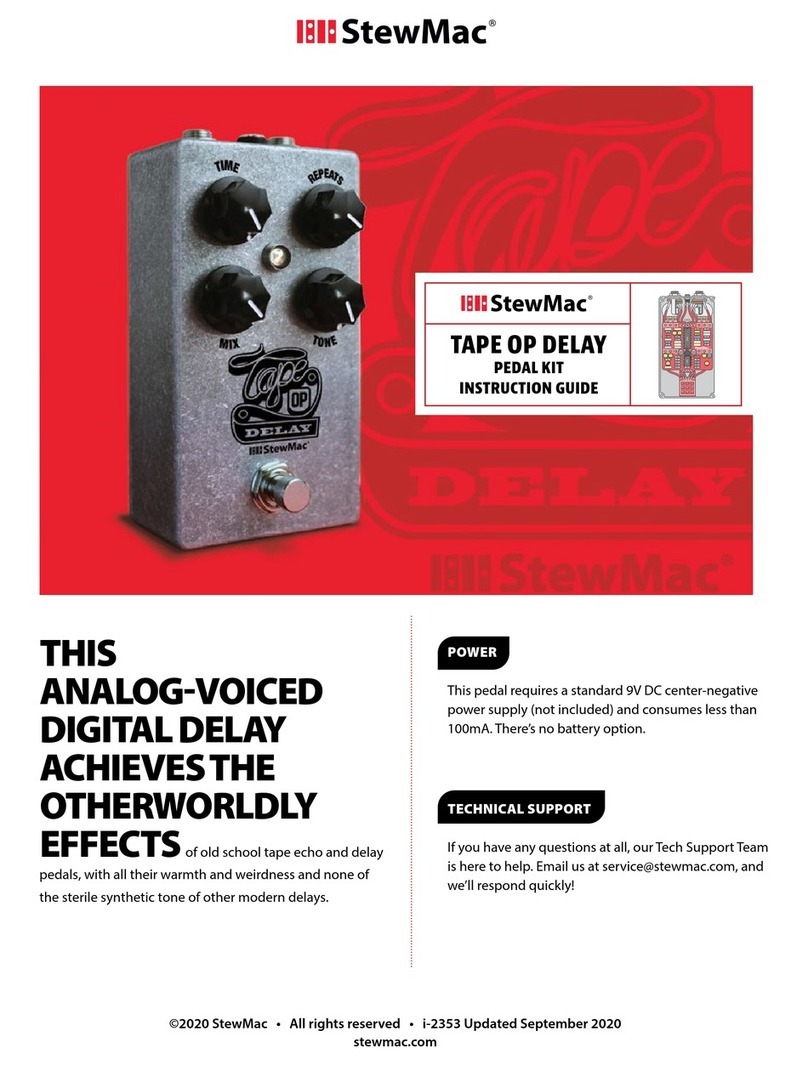

StewMac TAPE OP DELAY Manual

Popular Music Pedal manuals by other brands

PuzzleSounds

PuzzleSounds DOD 250'77 Overdrive manual

Empress Effects

Empress Effects HEAVY MENACE user manual

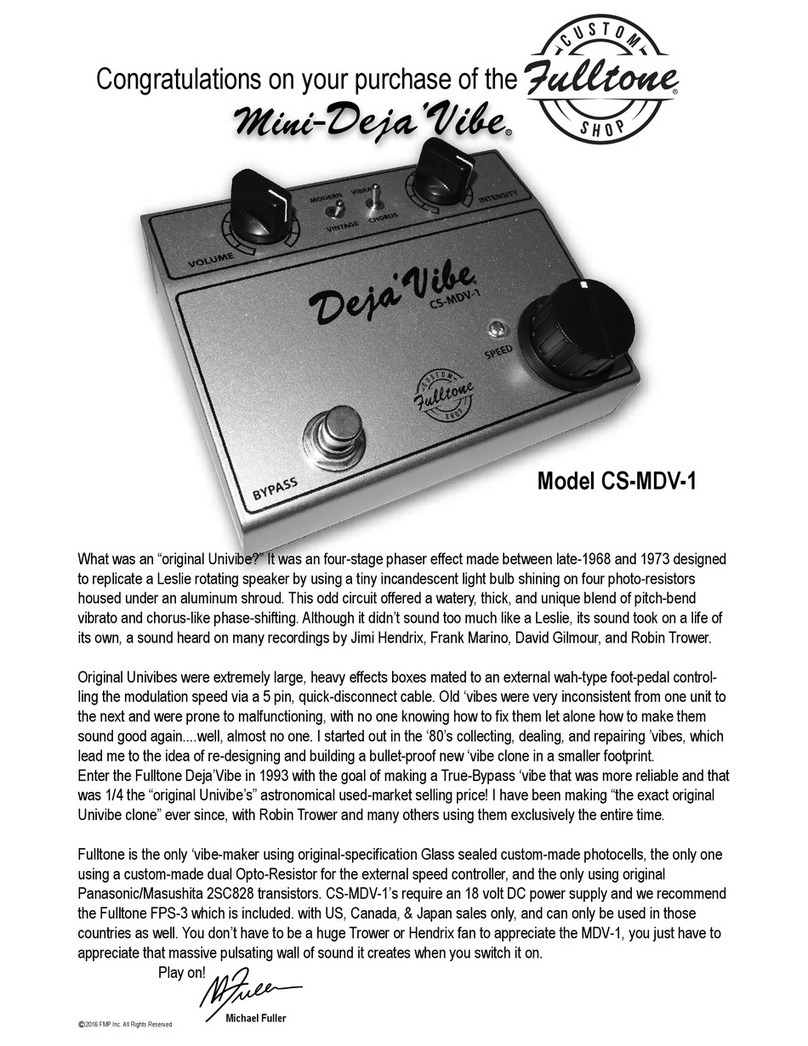

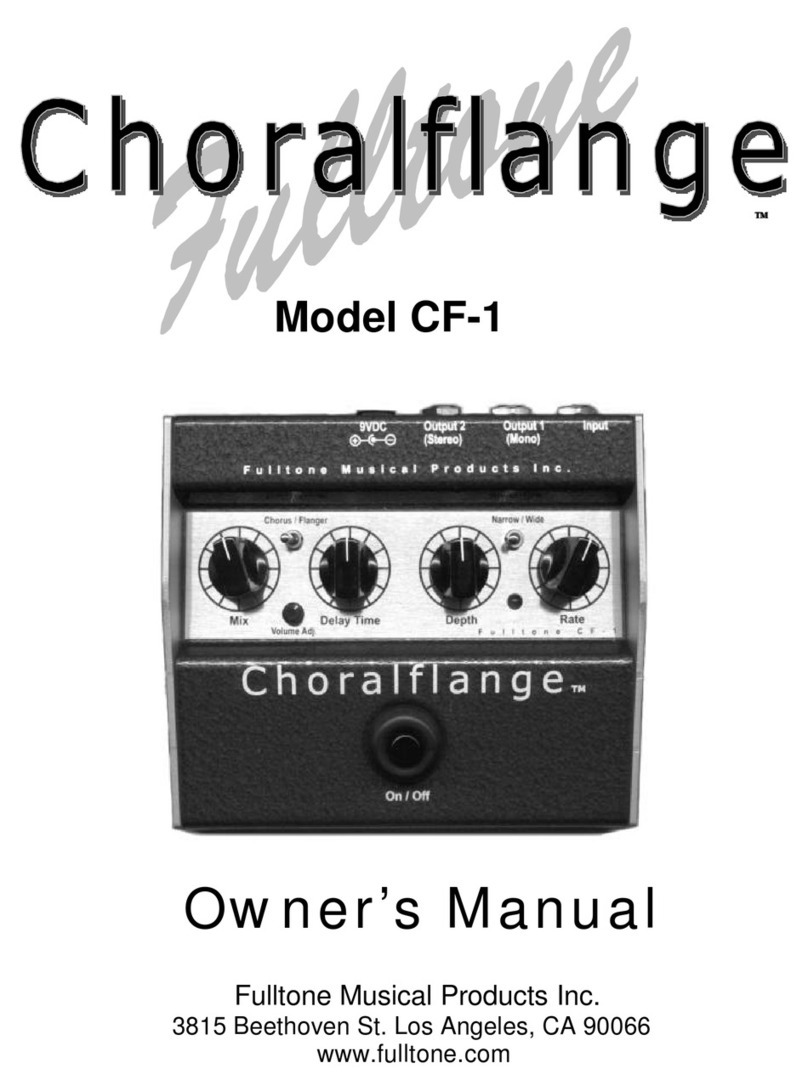

Fulltone Musical Products

Fulltone Musical Products Choralflange CF-1 owner's manual

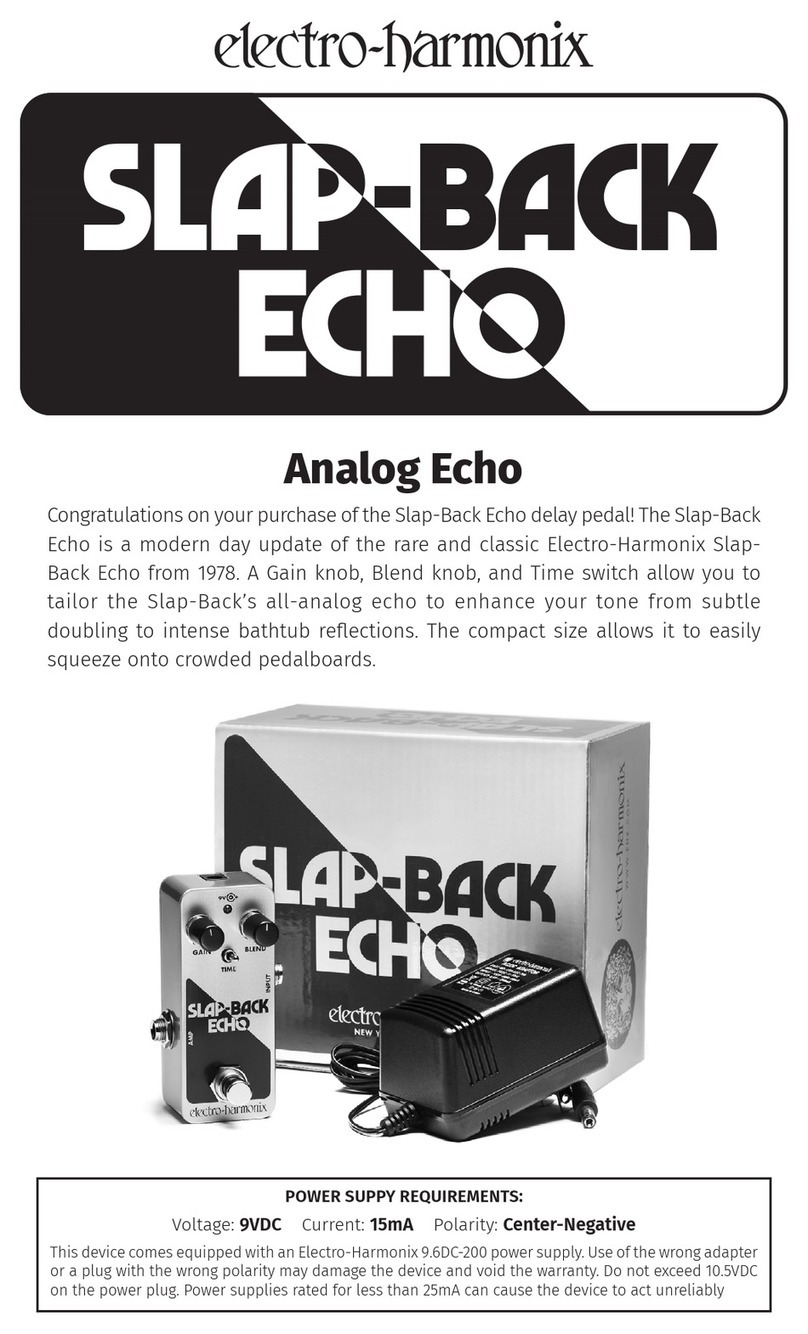

Electro-Harmonix

Electro-Harmonix XO WHITE FINGER manual

mxr

mxr M173 Classic 108 Fuzz Specifications

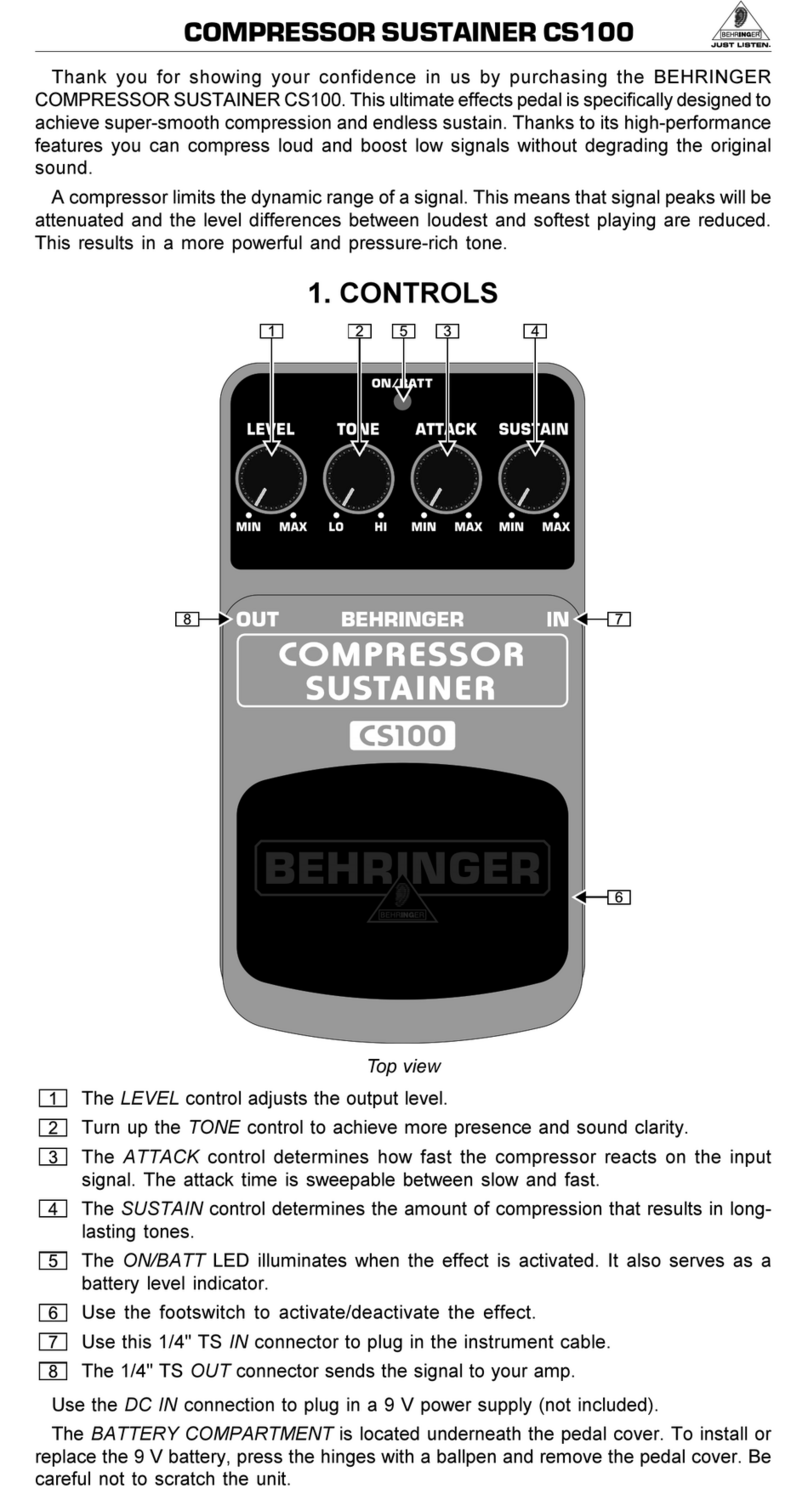

Behringer

Behringer CS100 user guide