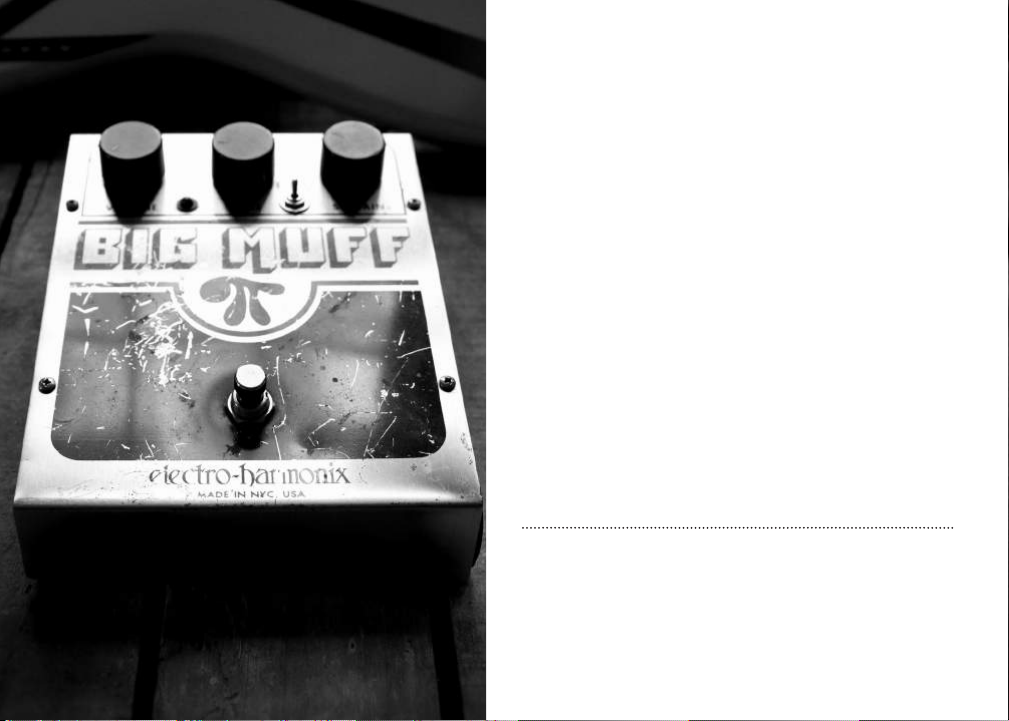

StewMac NYC BIG MUFF PI User manual

NYC BIG MUFF PI

TONE BYPASS MOD

INSTRUCTIONS

WITH THIS MOD

YOU'LL KEEP

YOUR MIDS AND

GET ALL THE FUZZ

YOU WANT. It's a necessary

mod for anyone who loves the BMP, but dislikes the

way it scoops the middle frequencies of your tone.

This switch was a feature on the 1970's Big Mus,

but was not included in the 2000's "reissues" of the

pedal. This mod is only intended for the big box NYC

Big Mu Pi pedals released in the 2000's.

If you run into issues with this modication,

a StewMac tech advisor is a click or call away:

stewmac.com/contactus or 1.800.848.2273

Big Mu is a registered trademark of New Sensor Corp.

Guitar Tech Screwdriver

and Wrench Set

#3693

1/4" Drill Bit

#4850

Kester Pocket-Pak Solder

#0505

Solder Sucker

#0503

Solder

Wick

#0504

PARTS LIST

[1] Black and white

pushback wire

[2] 1/8" heat shrink - 2" length

[1] Mini toggle switch

[1] NYC Big Mu Pi Tone Bypass

Mod instructions

Fine-gauge

Wire Stripper

#1606

Wire Cutter

#1607

Solomon SR-965

Soldering Station

#0502

TOOLS YOU’LL NEED

CONNECTING THE NEW SWITCH

For your new switch to be connected properly, an understanding of tinning and soldering is necessary.

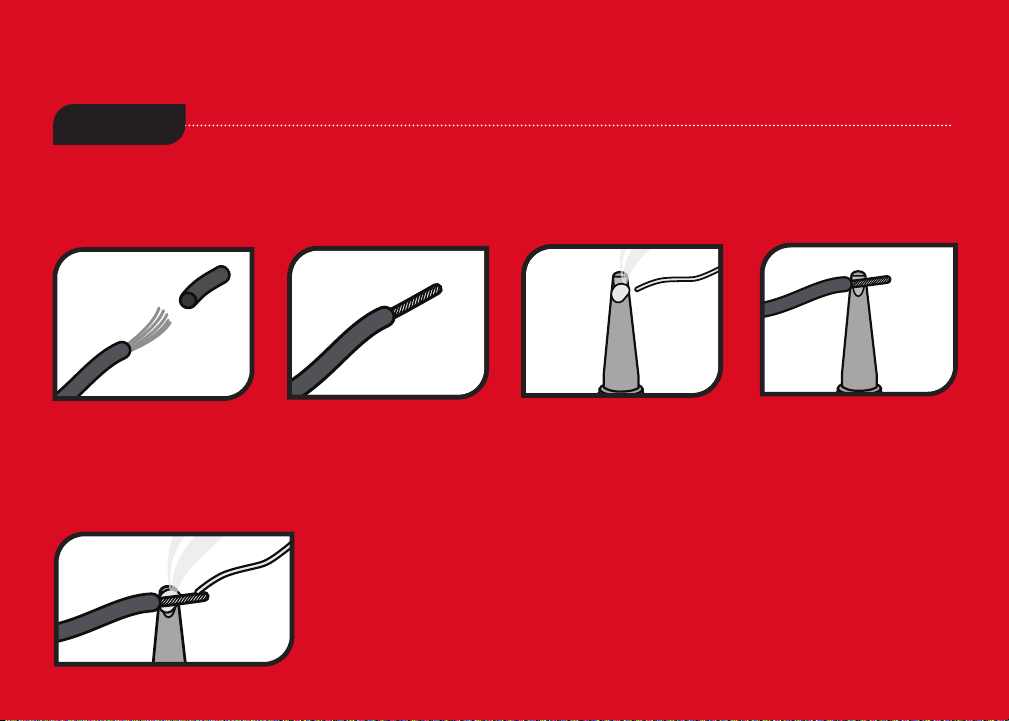

TINNING

Tinning is an important part of the soldering process as it helps to make stronger solder joints. Tinning a

wire is done by heating the wire with a soldering iron and then melting a layer of solder on it. If the wire

you plan to tin is made up of many strands of wire, follow all of the steps below.

1. Strip roughly 1/4"of

the wire sheathing from

the end of the wire you

intend to solder.

2. Twist the wire

strands of the exposed

wire rmly. Don’t twist

solid core wires.

3. Dab a tiny amount

of solder onto the end

of your soldering iron.

4. Touch the soldering

iron with its dab of

solder to the exposed

wire closest to the

sheathing. This will help

to hold the iron in place

as it heats the exposed

wire. Wire will heat

within a few seconds.

5. With the iron still touching the wire, take a

length of solder and touch it on the exposed end

of the wire and slide it along the wire slightly

towards the sheathing and iron. The solder will

nd its way into the braids of the exposed wire.

MORE HELPFUL

SOLDERING TIPS

AND TRICKS

•Keep your

soldering tip clean

by wiping it often

on a damp sponge.

• Also keep it tinned by

occasionally melting

a little solder onto it.

•Don’t blow on the

hot solder or touch

anything until the joint

has cooled completely.

A good solder joint

is shiny – a sign that

it was left to cool

undisturbed.

• Plan so each joint

is only soldered once.

Resoldered joints

are messy and more

likely to fail.

SOLDERING

1. Insert tinned wire through lug hole

before soldering and bend to secure.

2. Melt a small amount of solder onto

the tip of the iron (“tinning” the iron).

3. Hold the tip against the connection

until the connection reaches soldering

temperature. This should take just a

few seconds.

4. Feed solder to the connection, not

to the iron. Stop feeding solder once

the lug hole is lled. Keep the iron on

the connection for a second longer;

this pause gives time for all of the ux

to cook out of the joint. After the joint

has cooled, trim away the excess wires.

DESOLDERING

Much like soldering, you run the risk of damaging the circuit board while desoldering. If too much heat is

applied to a circuit board the solder pad can pull away from the board, breaking its electrical connection. A

solder sucker and solder wick are your best friends when desoldering. Here are a few tips on how to use them:

1. USE A SOLDER SUCKER

Depress the plunger on the solder

sucker to prepare it. Tin your

soldering iron, apply it to the

solder joint, and hold the solder

sucker a fraction of an inch away.

Within a few seconds, the joint

will liquefy. As soon as it does,

push the button on the side of

the solder sucker and remove

the soldering iron from the joint.

Inspect the solder joint and

repeat the process until all of the

solder is removed.

2. USING SOLDER WICK

Solder wick is a at, braided

wire that can be used to remove

solder from a joint. Simply place

the wick on the solder joint and

press your soldering iron against

the wick, heating the joint

through the wick. The solder will

liquefy and absorb into the wick.

Keep inching the wick down as

it absorbs solder so it does not

become saturated.

3. LIFT THE LEAD

Once the solder is removed from

the joint, use a pair of pliers to lift

the lead from the circuit board

contact. If the lead doesn’t want

to come up, heat the solder joint

up to liquefy the residual solder

which will free the lead. Once

the lead is lifted, use the solder

sucker or solder wick to remove

any leftover solder.

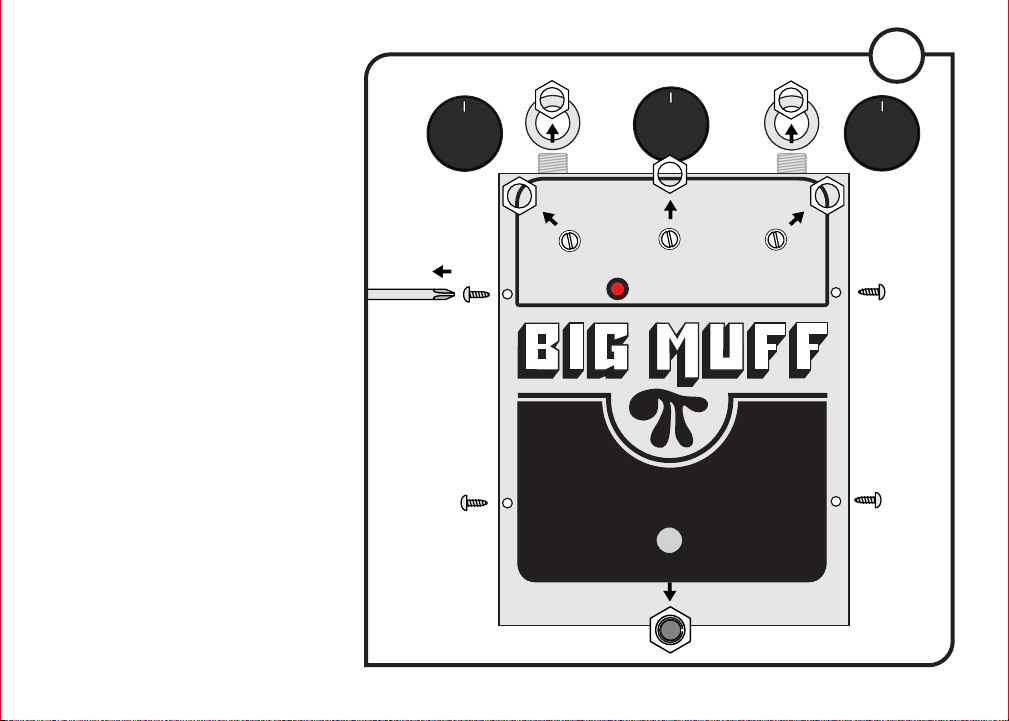

DISASSEMBLE THE PEDAL

Remove the four screws that

secure the back of the pedal

housing. As you are removing

the back panel, be careful not

to catch the circuit board on

any of the wires. If your pedal

has a glued LED light, do not

remove it. Pull the knobs o of

the front of the pedal, unscrew

the mounting nuts for the

potentiometers and the switch,

and unscrew the mounting nuts

for the instrument and power

jacks on the top panel. Set all of

the components to the side for

now.

AMPLIFIER

VOLUME TONE SUSTAIN

11

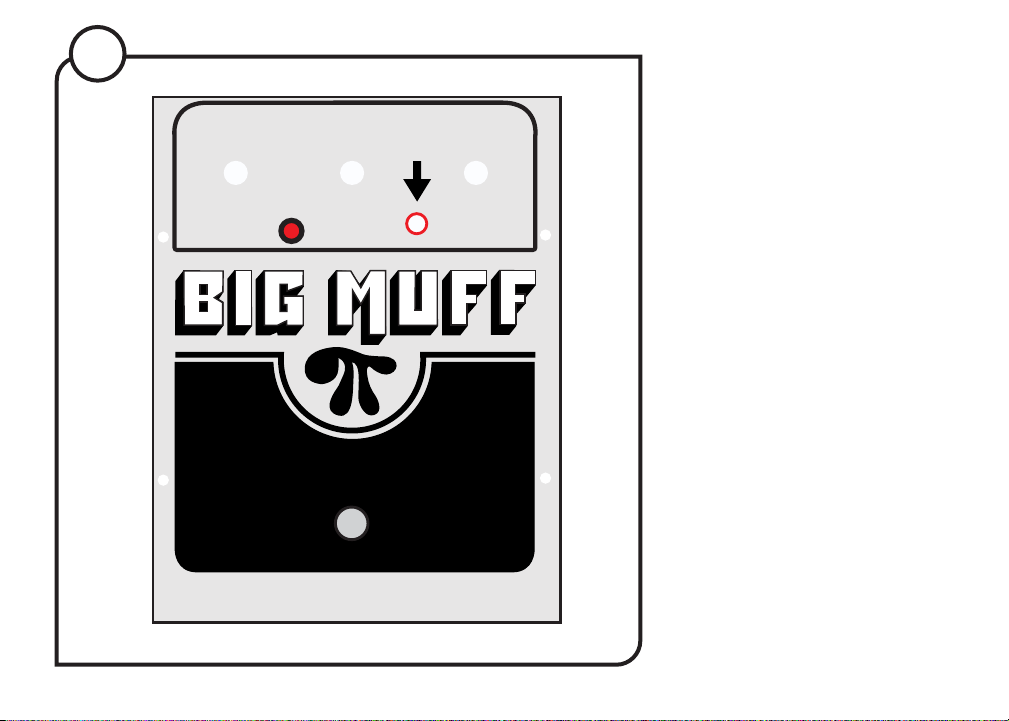

DRILL A HOLE FOR

THE NEW SWITCH

Use a 1/4" drill bit to drill a hole

in the pedal housing directly

between the tone and sustain

holes and just above the black

line (pictured). Measure the

location of the hole you will drill

and mark that location on the

underside of the housing. Drill

the hole from the underside of

the housing to avoid bending

the housing while drilling.

AMPLIFIER

VOLUME TONE SUSTAIN

22

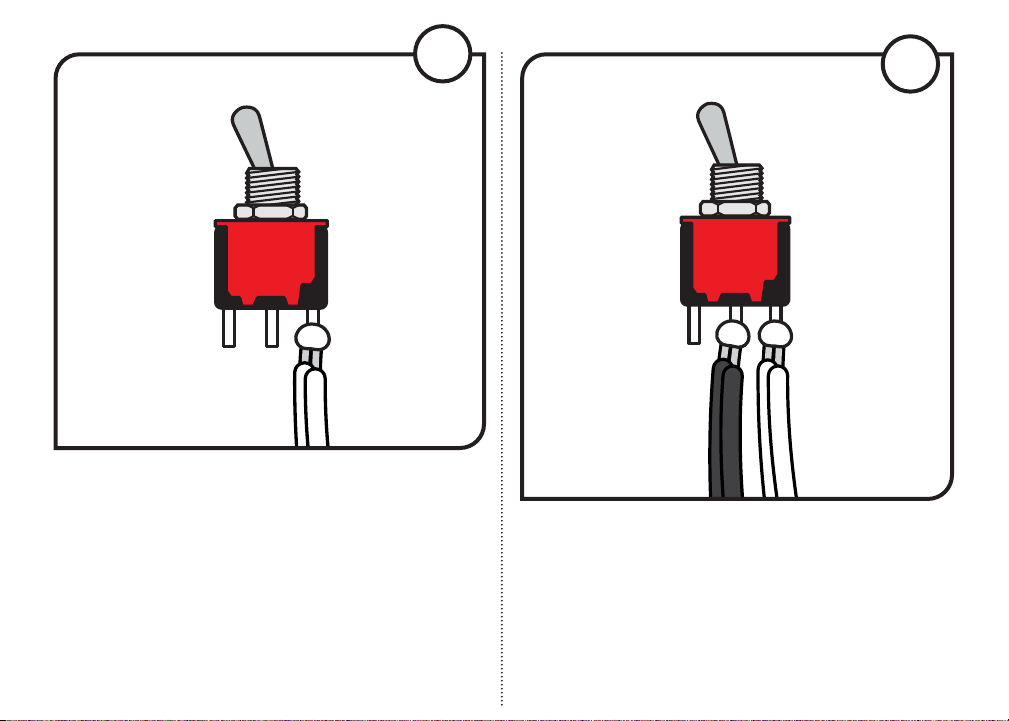

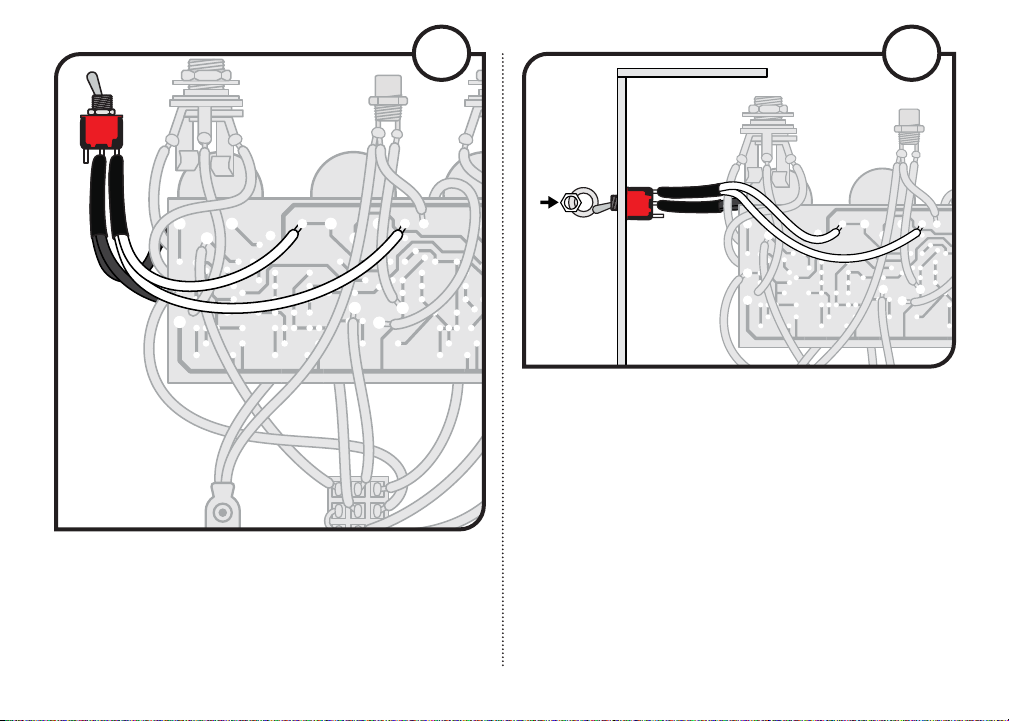

ATTACH BLACK WIRES TO SWITCH

Cut two 4" black jumpers, strip roughly 1/4" of

insulation from the end of the wires, and tin the

freshly exposed wire. Wrap the wires through the

eyelet of the middle solder lug on the switch and

solder them.

44

INSTALL JUMPERS ON THE SWITCH

Cut two 4" white jumpers, strip roughly 1/4" of

insulation from the end of the wires, and tin the

freshly exposed wire. Wrap the wires through the

eyelet of one of the outside solder lugs on the

switch and solder them. Even though it's called

”pushback wire” you must strip the insulation to

make a solid solder connection.

33

HEAT SHRINK SOLDER JOINTS

Add a 1" length of heat shrink to each solder joint

and use a heat source to shrink the insulation over

the solder joints and wires.

55TIPS ON HEAT SHRINKING

1. Heat shrink is used

to insulate an

electrical connection,

like a solder joint, to

prevent the connection

from shorting.

2. Slide the heat shrink

all the way up to the

switch, completely

covering the solder joint

and solder lug.

3. Wave the ame from

a lighter or the tip of a

soldering iron near the

positioned heat shrink

until the wrap constricts

to a rm hold. Allow

heat shrink to cool.

ADD HEAT SHRINK TO ONE LEG

Slide another 1" length of heat shrink over one of

the black wires that you just soldered to the new

switch.

77

66

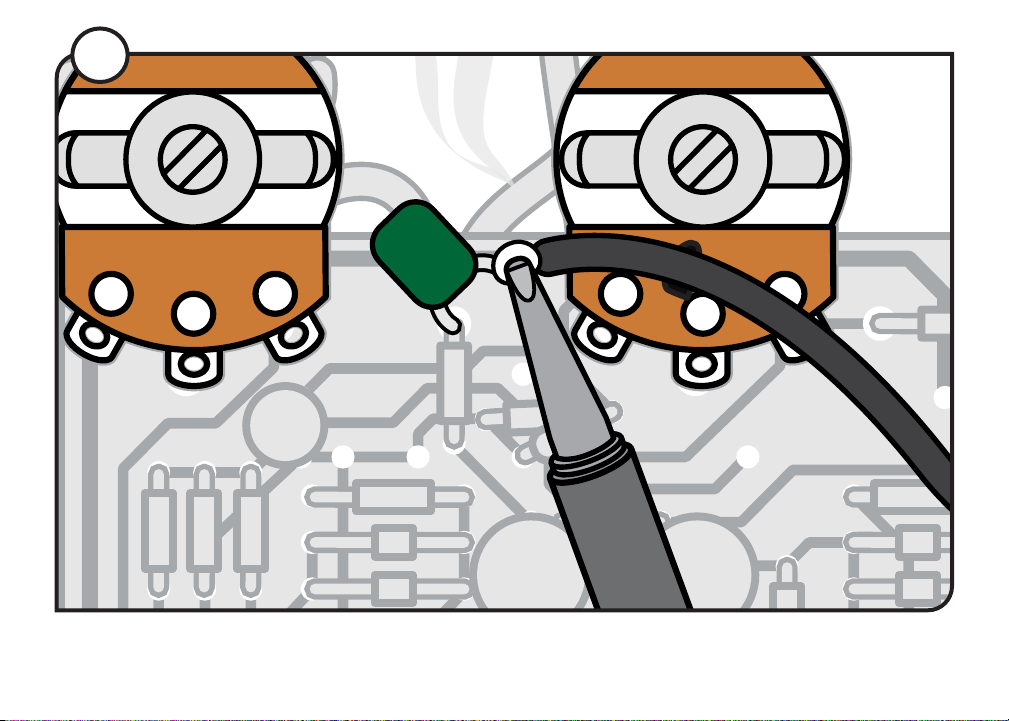

FIND CAPACITOR C8

The location of this capacitor varies by model. To

nd out which model you have, locate the version

code. The code (similar to “EC3003 REV B”) is printed

in large white letters along the bottom of the board.

The last letter in that code (A, B, C, D, or E) is the

version you have. Now locate capacitor C8. It will be

either yellow or green. On version A or B, C8 will be

located between the volume and tone pots. On this

version, desolder and lift the leg of C8 that is closest

to the edge of the board. On version C, D, or E, C8

is located between the tone and sustain pots. On

this version, desolder and lift the leg of C8 that is

closest to the sustain pot.

Circuit board ipped

C8

88

ATTACH BLACK WIRE TO C8

Solder the free end of the same black wire to the lifted leg of C8.

HEAT SHRINK SOLDER JOINT

Slide the heat shrink over the new solder joint

and use a heat source to shrink the insulation to

the joint.

Circuit board ipped

C8

99

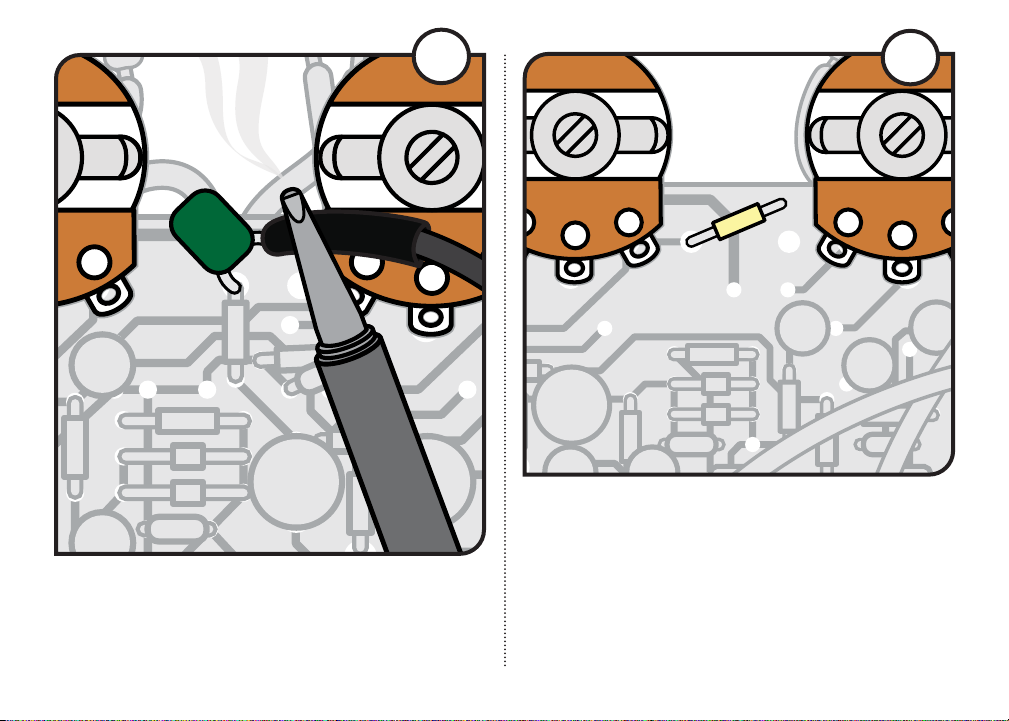

FIND RESISTOR R5

If your Big Mu is version A or B, it will be located

between the tone and sustain pots. On version C, D,

or E, it will be located just below capacitor C8. For

all versions, locate the leg closest to the sustain pot

and desolder and lift it.

Circuit board ipped

C8

R5

1010

ATTACH BLACK WIRE TO R5

Slide another 1" length of 1/8" diameter heat shrink

over the second black wire that you just soldered

to the new switch. Solder the free end of the same

black wire to the lifted leg of R5.

Circuit board ipped

C8

R5

1111

HEAT SHRINK SOLDER JOINT

Slide the heat shrink over the new solder joint and use

a heat source to shrink the insulation to the joint.

Circuit board ipped

C8

R5

1212

INSTALL THE WHITE WIRES

Solder the free end of one of the white wires to the

hole vacated by the lifted leg of C8, and solder the

free end of the other white wire to the hole vacated

by the lifted leg of R5.

REASSEMBLING AND TESTING

Install the new switch into its hole rst, and then

reinstall the rest of the components back in to the

pedal housing. Re-attach the back panel with the

four mounting screws. Plug in your guitar and an

amp, and take your Big Mu for a test drive. When

the tone bypass switch is engaged, the pedal

should be noticeably louder. If you experience

intermittent signal or other irregularities, pull the

back panel o the pedal again and inspect your

solder joints.

1313

Chassis side view

1414

21 N. Shafer St., Athens, OH 45701

800-848-2273 stewmac.com

©2019 StewMac. All rights reserved. • #2215 Updated December 2019

TECHNICAL SUPPORT:

If you have any questions before, during, or after

attempting these modications, please don't hesitate

to reach out to our Tech Support Team. They are

phone M-F 9:00AM-5:00PM ET at 1-800-848-2273.

DISCLAIMER: Performing the modications

outlined in these instructions will void any warranty

on your pedal. StewMac is not responsible for any

damage caused by attempting these modications.

Table of contents

Other StewMac Music Pedal manuals

StewMac

StewMac Disaster Transport User manual

StewMac

StewMac SCREAMER Manual

StewMac

StewMac TWO KINGS BOOST DOUBLE-POWERED ROYAL TONE Manual

StewMac

StewMac SUN FUZZ Manual

StewMac

StewMac SWELL DRIVE Manual

StewMac

StewMac FAN TREMOLO Manual

StewMac

StewMac INTERVAL FUZZ Manual

StewMac

StewMac TAPE OP DELAY Manual

StewMac

StewMac JHS 808 User manual

StewMac

StewMac LIGHTCYCLE PHASOR II Manual

Popular Music Pedal manuals by other brands

DIY

DIY REPLICA Series Assembly manual

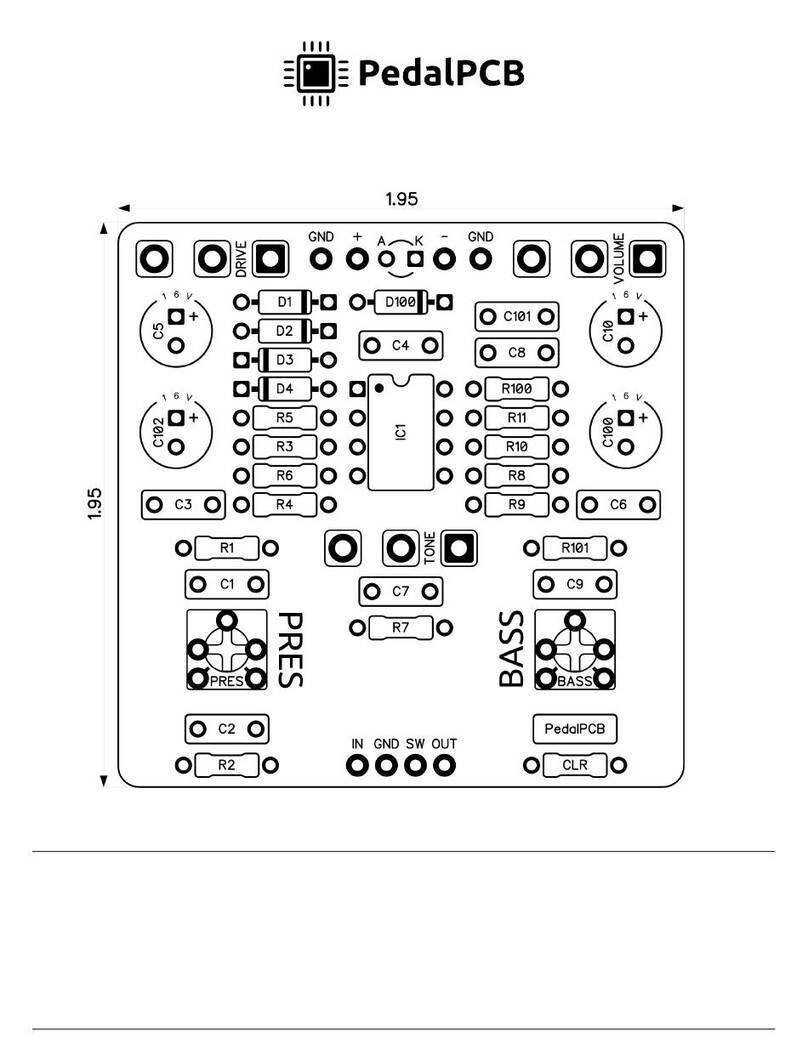

PedalPCB

PedalPCB Canis Distortion quick start guide

Nady Systems

Nady Systems TS-30 owner's manual

Electronic Audio Experiments

Electronic Audio Experiments Dude Incredible Technical manual

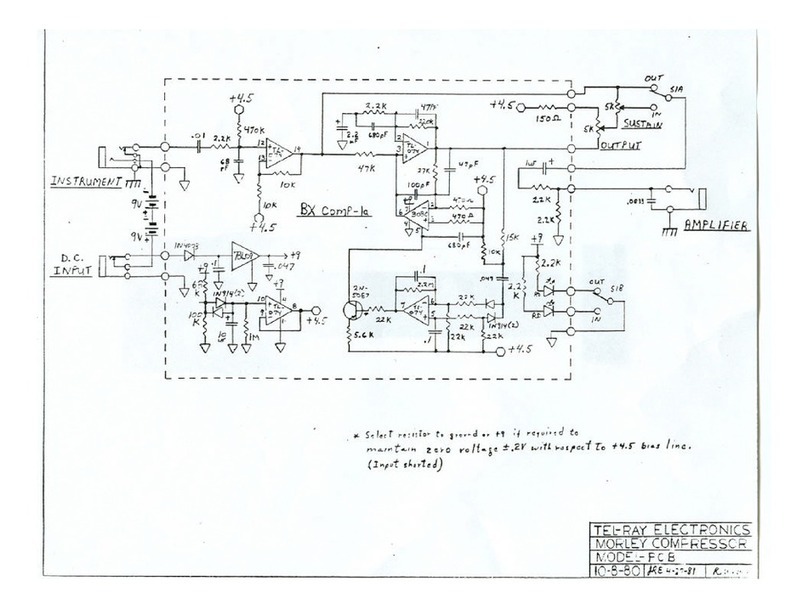

MORLEY

MORLEY PCBES manual

Rainger FX

Rainger FX Dr FREAKENSTEIN CHOP FUZZ user manual