Children, animals and bystanders must not be

allowed near the machine.

When not using the machine, it must be laid

down in such a way that it does not endanger

anyone. Ensure that the machine cannot be

used without authorization.

The user is responsible for accidents or risks

involving third parties or their property.

Do not lend or rent your power tool without the

User Manual. Be sure that anyone using it under‐

stands the information contained in this manual.

The use of machines that emit noise may be limi‐

ted to certain hours of the day as specified by

national and/or regional or local regulations.

Anyone operating the machine must be well res‐

ted, in good physical health and in good mental

condition.

If you have any condition that might be aggrava‐

ted by strenuous work, check with your doctor

before operating a machine.

If you have a pacemaker: The ignition system of

your machine produces an electromagnetic field

of very low intensity. This field may interfere with

some pacemakers. STIHL recommends that per‐

sons with pacemakers consult their physician

and the pacemaker manufacturer to reduce any

health risk.

Anyone who has consumed alcohol or drugs or

medicines affecting their ability to react must not

operate a power tool.

Postpone the work if the weather is bad (snow,

ice, wind) – higher risk of accidents!

The machine may only be used for cutting. It is

not suitable for cutting wood or wooden objects.

Asbestos dust is extremely toxic - the machine

must therefore never be used to cut asbestos!

Other uses are not permitted and may lead to

accidents or damage to the machine.

Never attempt to modify your power tool in any

way since this may increase the risk of personal

injury. STIHL excludes all liability for personal

injury and damage to property caused while

using unauthorized attachments.

Only use abrasive wheels or accessories which

have been approved by STIHL for this machine

or which are technically equivalent. If you have

any questions in this respect, consult your

dealer. Only use high-quality abrasive wheels

and attachments. in order to avoid the risk of

accidents and damage to the machine.

STIHL recommends the use of genuine STIHL

abrasive wheels and accessories. They are spe‐

cifically designed to match the product and meet

your performance requirements.

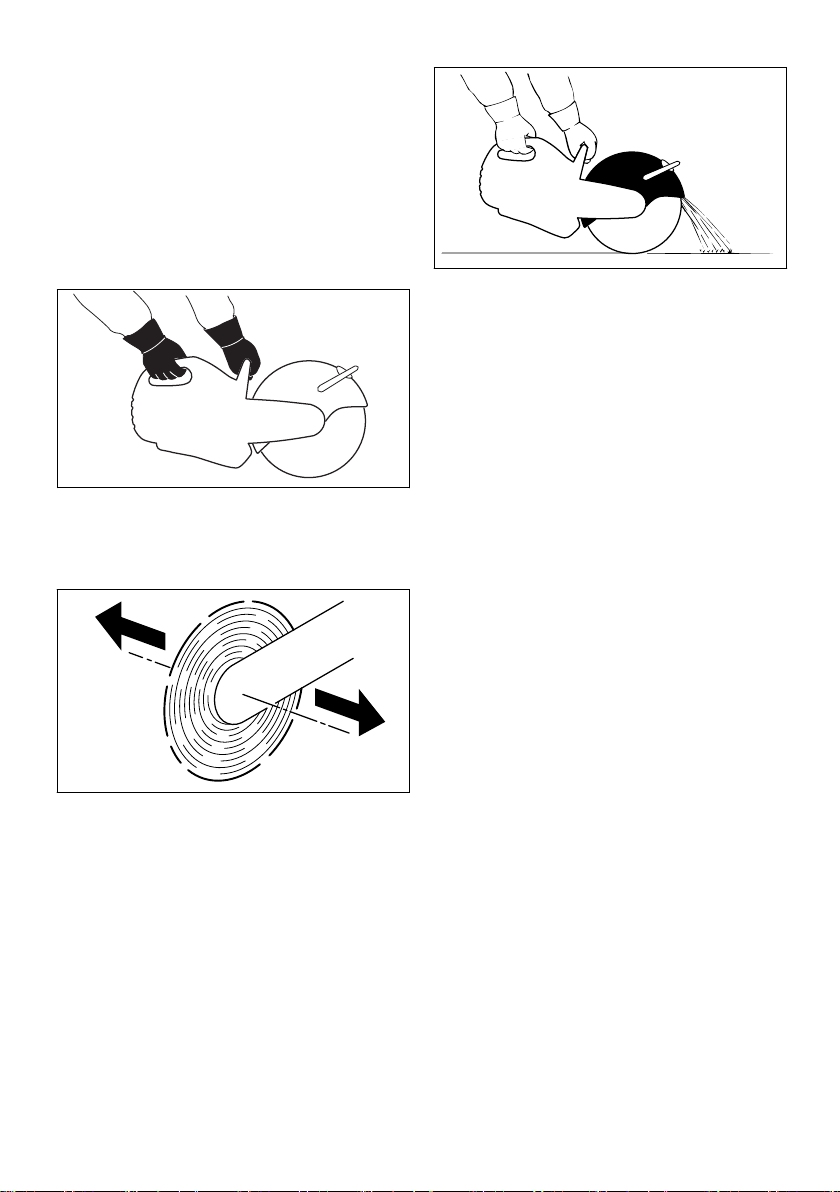

Do not use a high-pressure washer to clean the

power tool. The solid jet of water may damage

parts of the unit.

Do not spray the power tool with water.

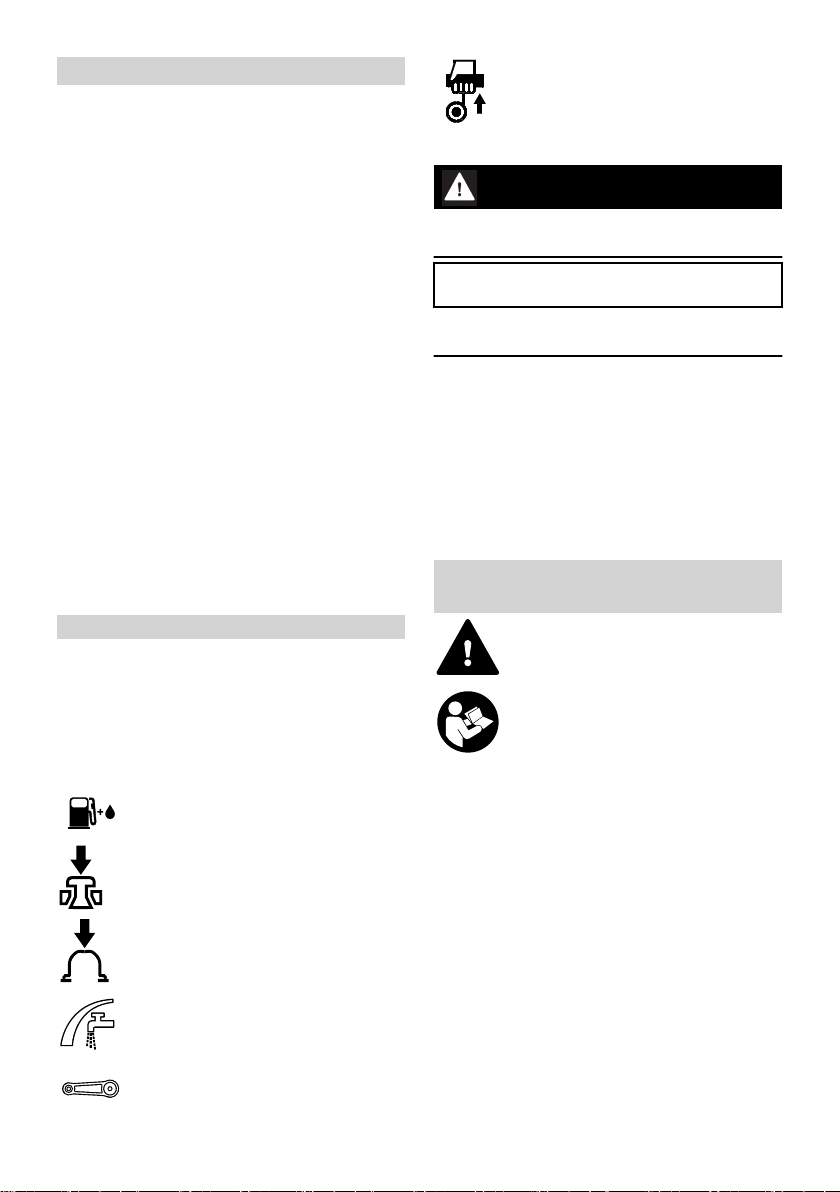

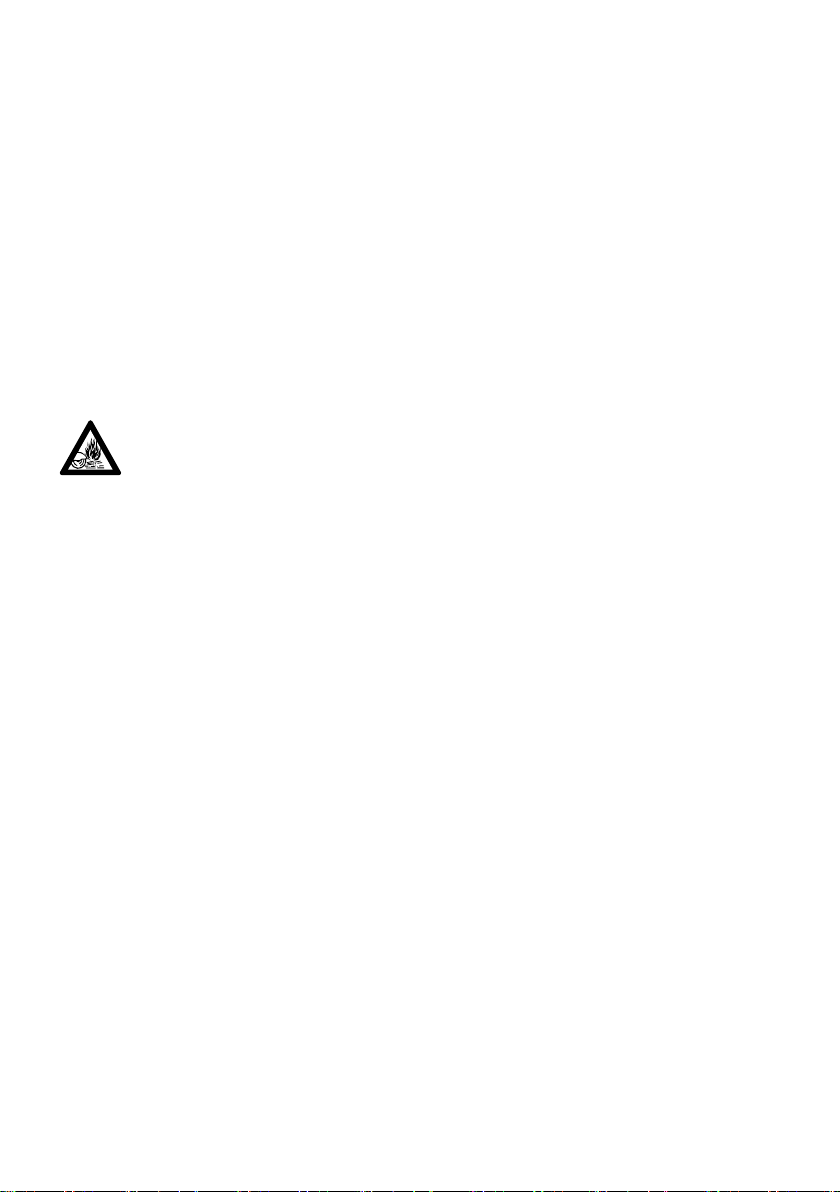

Never use circular saw blades, car‐

bide, rescue or wood cutting attach‐

ments or saws of any kind – these

may cause fatal injuries!Instead of

uniformly removing particles as when

cutting with an abrasive wheel, the

teeth of a circular saw blade may

snag in the material. This causes the

machine to react in a highly aggres‐

sive manner with uncontrolled and

extremely dangerous kickback.

2.1 Clothing and equipment

Wear proper protective clothing and equipment.

Clothing must be sturdy but allow

complete freedom of movement.

Wear close-fitting clothes such as a

boiler suit, not a work coat.

When cutting steel, always wear clothing made

of barely flammable material (e.g., leather or cot‐

ton with flame-retardant finish) – no man made

fibers – risk of fire due to flying sparks!

Clothing must be free from flammable deposits

(chips, fuel, oil, etc.).

Do not wear clothes that may be caught by mov‐

ing parts – no scarf, no tie, no jewelry. Tie up and

confine long hair above your shoulders.

Wear steel-toed safety boots with

non-slip soles.

WARNING

To reduce the risk of eye injuries,

wear close-fitting safety glasses in

accordance with European Standard

EN 166. Make sure the safety

glasses are a snug fit.

Wear a safety hard hat where there is a danger

of head injuries from falling objects.

Dust (e. g., crystalline material from the object

being cut), fumes and smoke may be produced

while cutting - health hazard!

2 Safety Precautions and Working Techniques English

0458-370-8321-C 3