Stober SC6 Series Training manual

SC6 drive controller

Commissioning instructions

en-US

11/2017

ID 442793.00

stober.com

Table of contents STÖBER

ii

11/2017 | ID 442793.00

Table of contents

1 Foreword .............................................................................................................................. 5

2 User information.................................................................................................................. 6

2.1 Storage and transfer .....................................................................................................6

2.2 Described product type.................................................................................................6

2.3 Timeliness.....................................................................................................................6

2.4 Original language..........................................................................................................6

2.5 Limitation of liability.......................................................................................................6

2.6 Formatting conventions ................................................................................................7

2.6.1 Use of symbols............................................................................................... 7

2.6.2 Markup of text elements ................................................................................. 8

2.7 Symbols, markings and test marks...............................................................................9

2.8 Trademarks.................................................................................................................10

3 General safety instructions .............................................................................................. 11

3.1 Directives and standards ............................................................................................11

3.2 Qualified personnel.....................................................................................................11

3.3 Intended use ...............................................................................................................12

3.4 Transport and storage ................................................................................................12

3.5 Operational environment and operation .....................................................................12

3.6 Working on the machine .............................................................................................13

3.7 Disposal ......................................................................................................................13

4 Drive controller technical data ......................................................................................... 14

4.1 General technical data................................................................................................14

4.2 Electrical data .............................................................................................................15

4.2.1 Control unit ................................................................................................... 15

4.2.2 Power unit: Size 0......................................................................................... 15

4.2.3 Power unit: Size 1......................................................................................... 17

4.2.4 Power unit: Size 2......................................................................................... 18

5 Storage ............................................................................................................................... 20

5.1 Drive controller............................................................................................................20

5.1.1 Annual reforming .......................................................................................... 20

5.1.2 Reforming before commissioning................................................................. 21

6 Installation.......................................................................................................................... 23

6.1 Safety instructions for installation ...............................................................................23

6.2 Basic assembly instructions........................................................................................23

6.3 Minimum clearances...................................................................................................25

STÖBER Table of contents

11/2017 | ID 442793.00

iii

6.4 Drilling diagram and dimensions.................................................................................26

6.5 Length of copper rails .................................................................................................27

6.6 Installing the drive controller without a rear section module .......................................28

6.7 Installing the DC link connection.................................................................................29

6.8 Mounting the drive controller on the rear section module...........................................30

7 Connection......................................................................................................................... 31

7.1 Safety instructions for connection...............................................................................31

7.2 Line routing .................................................................................................................32

7.3 Protective measures ...................................................................................................32

7.3.1 Line fuse....................................................................................................... 32

7.3.2 Residual current protective device ............................................................... 34

7.3.3 Housing grounding ....................................................................................... 36

7.3.4 EMC recommendations................................................................................ 37

7.4 Drive controller............................................................................................................38

7.4.1 Overview....................................................................................................... 38

7.4.2 X2A: Motor holding brake A.......................................................................... 39

7.4.3 X2A: Motor temperature sensor A................................................................ 40

7.4.4 X2B: Motor holding brake B.......................................................................... 40

7.4.5 X2B: Motor temperature sensor B................................................................ 40

7.4.6 X4A: Encoder A............................................................................................ 41

7.4.7 X4B: Encoder B............................................................................................ 46

7.4.8 X9: Ethernet service interface ...................................................................... 46

7.4.9 X10: 400V supply ........................................................................................ 47

7.4.10 X11: 24V supply .......................................................................................... 48

7.4.11 X12: Safety technology................................................................................. 49

7.4.12 X20A: Motor A .............................................................................................. 50

7.4.13 X20B: Motor B .............................................................................................. 51

7.4.14 X21: Braking resistor .................................................................................... 51

7.4.15 X22: DC link connection ............................................................................... 52

7.4.16 X101: BE1 – BE4.......................................................................................... 52

7.4.17 X103: BE6 – BE9.......................................................................................... 54

7.4.18 X200, X201: EtherCAT................................................................................. 55

7.4.19 X200, X201: PROFINET............................................................................... 56

7.4.20 X300: Brake 24V supply.............................................................................. 57

7.4.21 X700: SD slot................................................................................................ 58

7.4.22 Connecting a drive controller........................................................................ 58

8 Commissioning.................................................................................................................. 60

8.1 Initiating the project.....................................................................................................60

8.1.1 Projecting the drive controller and axis......................................................... 60

8.1.2 Creating other modules and drive controllers............................................... 62

8.1.3 Specifying a module ..................................................................................... 62

8.1.4 Specifying the project ................................................................................... 63

Table of contents STÖBER

iv

11/2017 | ID 442793.00

8.2 Mapping the mechanical drive model .........................................................................63

8.2.1 Parameterizing a STOBER motor ................................................................ 64

8.2.2 Parameterizing the axis model ..................................................................... 64

8.3 Testing the project configuration.................................................................................67

9 Appendix ............................................................................................................................ 69

9.1 Wiring examples .........................................................................................................69

9.1.1 Stand-alone operation with direct brake control ........................................... 69

9.2 Detailed information....................................................................................................70

9.3 Symbols in formulas ...................................................................................................71

9.4 Abbreviations .............................................................................................................. 72

Glossary ............................................................................................................................. 73

STÖBER 1 | Foreword

11/2017 | ID 442793.00

5

1 Foreword

The compact stand-alone SC6 drive controller allows for sensorless control of STOBER LM

series Lean motors. These motors provide energy efficiency at the performance level of a

synchronous servo motor. With higher efficiency than that required for comparable IE4

asynchronous motors, they also guarantee investment protection. However, the SC6 can also

be used in combination with asynchronous motors and synchronous servo motors, such as the

STOBER EZ series, as well as with encoders. The SC6 drive controller is available in three

sizes with a nominal output current of up to 19A: sizes 0 and 1 as a double-axis controller, size

2 as a single-axis controller.

Features

§Sensorless position control by STOBER Lean motors

§Control of rotary synchronous servo motors, asynchronous motors and torque motors

§HIPERFACE DSL One Cable Solution

§Electronic motor nameplate via HIPERFACE DSL or EnDat 2.2 digital encoder interface

§Integrated EtherCAT or PROFINET communication

§STO safety technology using terminals or STO and SS1 using FSoE (Safety over

EtherCAT): PLe/SIL3

§Integrated holding brake activation

§Single-ended load on double-axis controllers for operation of motors with different power

§Energy supply over DC link connection

2 | User information STÖBER

6

11/2017 | ID 442793.00

2 User information

This documentation covers the SC6 drive controller. You will receive support for the assembly of

the individual modules along with the associated components that you will need to operate the

drive controllers in the control cabinet.

You will also find information on wiring the modules correctly and checking their functionality in

the group with an initial test.

More information on project configuration and diagnostics can be found in the manual for the

SC6 drive controller; see the chapter Detailed information [}70].

Information

To ensure proper functionality, we recommend using cables from STOBER that are matched to

the complete system. In case of use of unsuitable connection cables, we reserve the right to

reject claims under the warranty.

2.1 Storage and transfer

As this documentation contains important information for handling the product safely and

efficiently, it must be stored in the immediate vicinity of the product until product disposal and be

accessible to qualified personnel at all times.

Also pass on this documentation if the product is transferred or sold to a third party.

2.2 Described product type

This documentation is binding for:

SC6 drive controller in conjunction with the

DriveControlSuite software V 6.3-A or higher and associated firmware V 6.3-A or higher.

2.3 Timeliness

Check whether this document is the most up-to-date version of the documentation. We provide

the latest document versions for our products for download on our website:

http://www.stoeber.de/en/download.

2.4 Original language

The original language of this documentation is German; all other language versions are derived

from the original language.

2.5 Limitation of liability

This documentation was created taking into account the applicable standards and regulations

as well as the current state of technology.

STOBER shall assume no responsibility for damage resulting from failure to comply with the

documentation or from use that deviates from the intended use of the product. This is especially

true for damage caused by individual technical modifications to the product or projecting and

operation of the product by unqualified personnel.

STÖBER 2 | User information

11/2017 | ID 442793.00

7

2.6 Formatting conventions

Orientation guides in the form of signal words, symbols and special text markups are used to

emphasize specific information so that you are able identify it in this documentation quickly.

2.6.1 Use of symbols

Safety instructions are identified with the following symbols. They indicate special risks when

handling the product and are accompanied by relevant signal words that identify the extent of

the risk. In addition useful tips and recommendations for efficient and faultless operation are

specially highlighted.

ATTENTION!

Notice

This indicates that damage to property may occur

▪ if the stated precautionary measures are not taken.

CAUTION!

Caution

This word with a warning triangle indicates that minor personal injury may occur

▪ if the stated precautionary measures are not taken.

WARNING!

Warning

This word with a warning triangle means there may be a considerable risk of fatal injury

▪ if the stated precautionary measures are not taken.

DANGER!

Danger

This word with a warning triangle indicates that there is a considerable risk of fatal injury

▪ if the stated precautionary measures are not taken.

Information

Information indicates important information about the product or serves to emphasize a section

in the documentation that deserves special attention from the reader.

2 | User information STÖBER

8

11/2017 | ID 442793.00

2.6.2 Markup of text elements

Certain elements of the continuous text are distinguished as follows.

Quick DC-Link module Words or expressions with a special meaning

Detailed information Internal cross-reference

http://www.stoeber.de External cross-reference

Software and display indicators

The following formatting is used to identify the various information content of elements

referenced by the software interface or the drive controller display, as well as any user entries.

Main menu

Settings

Window names, dialog names, page names or buttons,

combined proper nouns, functions referenced by the

interface

Select

Referencing method A

Predefined entry

Save your

<own IP address>

User-defined entry

EVENT 52:

COMMUNICATION

Display indicators (status, messages, warnings, faults)

for status information referenced by the interface

Keyboard shortcuts and command sequences or paths are represented as follows.

[CTRL], [CTRL] +

[S]

Key, shortcut

Table > Insert table Navigation to menus/submenus (path specification)

Interpretation of parameter identification

Parameter identification consists of the following elements, where short forms are also possible,

i.e. only specifying a coordinate or the combination of coordinate and name.

E50 Drive controller G6 0

Coordinate

Name

Version

Drive controller

generation/series

STÖBER 2 | User information

11/2017 | ID 442793.00

9

2.7 Symbols, markings and test marks

The following symbols, markings and test marks are used in this document.

Grounding symbol

Grounding symbol in accordance with IEC 60417-5019

(DB:2002-10).

RoHS lead-free marking

Marking in accordance with RoHS directive 2011-65-EU.

CE mark

Manufacturer's self declaration: The product meets the

requirements of EU directives.

UL mark

This product is listed by UL for the United States and Canada.

Representative samples of this product have been evaluated by

UL and meet the requirements of applicable standards.

UL test marks for recognized components

This component or material is recognized by UL. Representative

samples of this product have been evaluated by UL and meet

applicable requirements.

2 | User information STÖBER

10

11/2017 | ID 442793.00

2.8 Trademarks

The following names used in connection with the device, its optional equipment and its

accessories are trademarks or registered trademarks of other companies:

EnDat®EnDat® and the EnDat® logo are registered trademarks of Dr.

Johannes Heidenhain GmbH, Traunreut, Germany.

EtherCAT®,

Safety over EtherCAT®,

TwinCAT®

EtherCAT®, Safety over EtherCAT® and TwinCAT® are registered

trademarks of patented technologies licensed by Beckhoff

Automation GmbH, Verl, Germany.

HIPERFACE®HIPERFACE® and the HIPERFACE DSL® logo are registered

trademarks of SICK STEGMANN GmbH, Donaueschingen,

Germany.

PLCopen®PLCopen® is a registered trademark of the PLCopen

Organisation, Gorinchem, Netherlands.

PROFIBUS®,

PROFINET®

The PROFIBUS and the PROFINET logo are registered

trademarks of PROFIBUS Nutzerorganisation e.V., Karlsruhe,

Germany.

speedtec®, springtec®speedtec® and springtec® are registered trademarks of

Intercontec Pfeiffer Industrie-Steckverbindungen GmbH, 94559

Niederwinkling, Germany.

All other trademarks not listed here are the property of their respective owners.

Products that are registered as trademarks are not specially indicated in this documentation.

Existing property rights (patents, trademarks, protection of utility models) are to be observed.

STÖBER 3 | General safety instructions

11/2017 | ID 442793.00

11

3 General safety instructions

There are risks associated with the product described in this documentation that can be

prevented by complying with the described warning and safety instructions as well as the

included technical rules and regulations.

3.1 Directives and standards

The following European directives and standards are relevant to the product specified in this

documentation:

§Machinery Directive 2006/42/EC

§Low Voltage Directive 2014/35/EU

§EMC Directive 2014/30/EU

§EN 61326-3-1:2008

§EN 61800-3:2004 and A1:2012

§EN 61800-5-1:2007

§EN 61800-5-2:2007

§EN 50178:1997

§IEC 61784-3:2010

Subsequent references to the standards do not specify the respective year in order to improve

readability.

3.2 Qualified personnel

In order to be able to perform the tasks described in this documentation, the persons instructed

to perform them must have the appropriate professional qualification and be able to assess the

risks and residual hazards when handling the products. For this reason, all work on the products

as well as their operation and disposal may be performed only by professionally qualified

personnel.

Qualified personal are persons who have acquired authorization to perform these tasks either

through training to become a specialist and/or instruction by specialists.

Furthermore, valid regulations, legal requirements, applicable basic rules, this documentation

and the safety instructions included in it must be carefully read, understood and observed.

3 | General safety instructions STÖBER

12

11/2017 | ID 442793.00

3.3 Intended use

As defined by DIN EN 50178, SC6 drive controllers are electrical devices operating as power

electronics to control the flow of energy in high-voltage systems.

They are intended solely for the operation of STOBER LM series Lean motors, synchronous

servo motors (e.g. from the STOBER EZ series), asynchronous motors or torque motors.

The connection of other electronic loads constitutes improper use.

3.4 Transport and storage

Inspect the delivery for any transport damage immediately after you receive it. Notify the

transport company of any damage immediately. Do not put a damaged product into operation.

To ensure the faultless and safe operation of the products, they must be professionally set up,

installed, operated and maintained. If you have to transport or store the products, you must

protect them from mechanical impacts and vibrations as well as observe the recommended

transport and storage conditions in the technical data.

Store the products in a dry and dust-free room if you do not install them immediately.

3.5 Operational environment and operation

The products are subject to sales restrictions in accordance with IEC 61800-3.

The products are not designed for use in a public low-voltage network that supplies residential

areas. Radio-frequency interference can be expected if the products are used in this type of

network.

The products are designed exclusively for operation in TN networks.

The products are intended exclusively for installation in control cabinets with at least protection

class IP54.

Always operate the products within the limits specified by the technical data.

The following applications are prohibited:

§Use in potentially explosive atmospheres

§Use in environments with harmful substances as specified by EN 60721, such as oils, acids,

gases, vapors, dust and radiation

Implementation of the following applications is permitted only after approval from STOBER:

§Use in non-stationary applications

§The use of active components (drive controllers, supply modules, energy recovery units or

discharge units) from third-party manufacturers

STÖBER 3 | General safety instructions

11/2017 | ID 442793.00

13

The drive controller is exclusively intended for operation in TN networks and only suitable for

use in supply grids. At 480VAC, the drive controllers are permitted to supply a maximum

symmetrical nominal short-circuit current in accordance with the following table:

Size Max. symm. nominal short-circuit current

Size 0 – Size 2 5000A

Tab. 1: Maximum symmetrical nominal short-circuit current of the drive controller

3.6 Working on the machine

Apply the 5 safety rules in the order stated before performing any work on the machine:

§Disconnect (also ensure that the auxiliary circuits are disconnected).

§Protect against being turned on again.

§Check that voltage is not present.

§Ground and short circuit.

§Cover adjacent live parts.

Information

Note that the you can only determine that voltage is no longer present once the discharge time

has elapsed. The discharge time depends on the self-discharge of the drive controller. You can

find the discharge time in the general technical data.

3.7 Disposal

Observe the current national and regional regulations when disposing of the product! Dispose of

the individual product parts depending on their properties, e.g. as:

§Electronic waste (circuit boards)

§Plastic

§Sheet metal

§Copper

§Aluminum

§Battery

4 | Drive controller technical data STÖBER

14

11/2017 | ID 442793.00

4 Drive controller technical data

This chapter contains the general technical data and the electrical data for the SC6 drive

controller. Additional technical data on the drive controller and accessories can be found in the

manual; see the chapter Detailed information [}70].

4.1 General technical data

The following specifications apply to all drive controller types.

Device features

Protection class of the device IP20

Protection class of the

installation space

At least IP54

Radio interference suppression Integrated line filter in accordance with EN 61800-3:2012,

interference emission class C3

Overvoltage category III in accordance with EN 61800-5-1:2008

Test symbols

Tab. 2: Device features

Transport and storage conditions

Storage/

transport temperature

−20°C to +70°C

Maximum change: 20K/h

Relative humidity Maximum relative humidity 85%, non-condensing

Vibration (transport) in

accordance with DIN

EN60068-2-6

5Hz ≤ f ≤ 9Hz: 3.5mm

9Hz ≤ f ≤ 200Hz: 10m/s²

200Hz ≤ f ≤ 500Hz: 15m/s²

Tab. 3: Transport and storage conditions

Operating conditions

Surrounding temperature

during operation

0°C to 45°C with nominal data

45°C to 55°C with derating −2.5%/K

Relative humidity Maximum relative humidity 85%, non-condensing

Installation altitude 0m to 1000m above sea level without restrictions

1000m to 2000m above sea level with −1.5%/100m

derating

Pollution degree Pollution degree 2 in accordance with EN 50178

Ventilation Installed fan

Vibration (operation) in

accordance with DIN EN

60068-2-6

5Hz ≤ f ≤ 9Hz: 0.35mm

9Hz ≤ f ≤ 200Hz: 1m/s²

Tab. 4: Operating conditions

STÖBER 4 | Drive controller technical data

11/2017 | ID 442793.00

15

Discharge times

Self-discharge of DC

intermediate circuit

5min

Tab. 5: Discharge times of the DC link circuit

4.2 Electrical data

The electrical data of the available SC6 sizes as well as the properties of the brake chopper can

be found in the following sections.

Information

Direct, repeat activation of the supply voltage is possible for cyclical line on/line off operation in

the event that charging capacity is not increased.

An explanation of the symbols used for formulas can be found in Chapter Symbols in formulas.

4.2.1 Control unit

Electrical data All types

U1CU 24VDC, +20%/−15%

I1maxCU 0.5A

Tab. 6: Control unit electrical data

4.2.2 Power unit: Size 0

Electrical data SC6A062

U1PU 3 × 400 VAC, +32% / −50%, 50/60 Hz;

3 × 480 VAC, +10% / −58%, 50/60 Hz

f2PU 0 – 700 Hz

U2PU 0 – max. U1PU

CPU 270µF

CmaxPU 1400µF

Tab. 7: SC6 electrical data, size 0

The maximum charging capacity depends on the time between energizing two devices:

Information

If a time span of ≥ 15min is maintained between energizing two devices, the maximum charging

capacity CmaxPU increases to 1880μF.

4 | Drive controller technical data STÖBER

16

11/2017 | ID 442793.00

Nominal currents up to +45°C (in the control cabinet)

Electrical data SC6A062

fPWM,PU 4kHz

I1N,PU 10A

I2N,PU 2×4,5A

I2maxPU 210% for 2s

Tab. 8: SC6 electrical data, size 0, for 4kHz clock frequency

Electrical data SC6A062

fPWM,PU 8 kHz

I1N,PU 8,9A

I2N,PU 2×4A

I2maxPU 250% for 2s

Tab. 9: SC6 electrical data, size 0, for 8kHz clock frequency

Electrical data SC6A062

UonCH 780–800 VDC

UoffCH 740–760VDC

R2minRB 100Ω

PmaxRB 6.4kW

PeffRB 2.9kW

Tab. 10: Brake chopper electrical data, size 0

STÖBER 4 | Drive controller technical data

11/2017 | ID 442793.00

17

4.2.3 Power unit: Size 1

Electrical data SC6A162

U1PU 3 × 400 VAC, +32% / −50%, 50/60 Hz;

3 × 480 VAC, +10% / −58%, 50/60 Hz

f2PU 0 – 700 Hz

U2PU 0 – max. U1PU

CPU 940µF

CmaxPU 1400µF

Tab. 11: SC6 electrical data, size 1

Information

If a time span of ≥ 15min is maintained between energizing two devices, the maximum charging

capacity CmaxPU increases to 1880μF.

Nominal currents up to +45°C (in the control cabinet)

Electrical data SC6A162

fPWM,PU 4kHz

I1N,PU 23,2A

I2N,PU 2×10A

I2maxPU 210% for 2s

Tab. 12: SC6 electrical data, size 1, for 4kHz clock frequency

Electrical data SC6A162

fPWM,PU 8 kHz

I1N,PU 20,9A

I2N,PU 2×9A

I2maxPU 250% for 2s

Tab. 13: SC6 electrical data, size 1, for 8kHz clock frequency

4 | Drive controller technical data STÖBER

18

11/2017 | ID 442793.00

Electrical data SC6A162

UonCH 780–800 VDC

UoffCH 740–760VDC

R2minRB 47Ω

PmaxRB 13.6kW

PeffRB 6.2kW

Tab. 14: Brake chopper electrical data, size 1

4.2.4 Power unit: Size 2

Electrical data SC6A261

U1PU 3 × 400 VAC, +32% / −50%, 50/60 Hz;

3 × 480 VAC, +10% / −58%, 50/60 Hz

f2PU 0 – 700 Hz

U2PU 0 – max. U1PU

CPU 940µF

CmaxPU 1400µF

Tab. 15: SC6 electrical data, size 2

Information

If a time span of ≥ 15min is maintained between energizing two devices, the maximum charging

capacity CmaxPU increases to 1880μF.

Nominal currents up to +45°C (in the control cabinet)

Electrical data SC6A261

fPWM,PU 4kHz

I1N,PU 22,6A

I2N,PU 19A

I2maxPU 210% for 2s

Tab. 16: SC6 electrical data, size 2, for 4kHz clock frequency

STÖBER 4 | Drive controller technical data

11/2017 | ID 442793.00

19

Electrical data SC6A261

fPWM,PU 8 kHz

I1N,PU 17,9A

I2N,PU 15A

I2maxPU 250% for 2s

Tab. 17: SC6 electrical data, size 2, for 8kHz clock frequency

Electrical data SC6A261

UonCH 780–800 VDC

UoffCH 740–760VDC

R2minRB 47Ω

PmaxRB 13.6kW

PeffRB 6.2kW

Tab. 18: Brake chopper electrical data, size 2

5 | Storage STÖBER

20

11/2017 | ID 442793.00

5 Storage

Store the products in a dry and dust-free room if you do not install them immediately.

Observe the Transport and storage conditions [}14] specified in the technical data.

5.1 Drive controller

The DC link capacitors can lose their electrical strength due to long storage times.

ATTENTION!

Material damage due to reduced electrical strength!

Reduced electrical strength can cause considerable material damage when switching on the

drive controller.

▪ Reform drive controllers in storage annually or before commissioning.

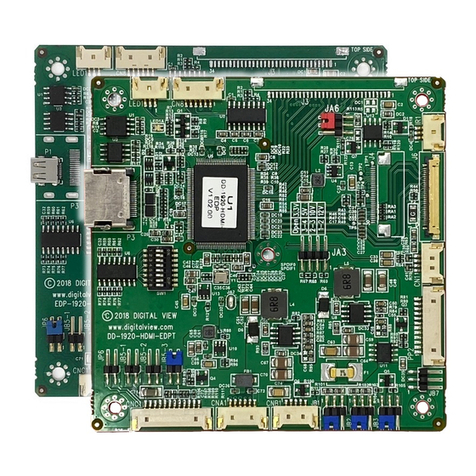

5.1.1 Annual reforming

To prevent damage to stored drive controllers, STOBER recommends connecting stored

devices to the supply voltage once per year for one hour.

The following graphics show the basic line connection for 3-phase devices.

X10

L1

F1

PE

L1 L2

T1 PE

L3

L2

L3

L1–L3 Lines 1 to 3

N Neutral conductor

PE Grounding conductor

F1 Fuse

T1 Drive controller

Other manuals for SC6 Series

3

This manual suits for next models

3

Table of contents

Other Stober Controllers manuals

Stober

Stober SC6 Series User manual

Stober

Stober SD6 Series User manual

Stober

Stober SD6 Series User manual

Stober

Stober MC6 User manual

Stober

Stober SC6 Series Training manual

Stober

Stober MC6 User manual

Stober

Stober SR6 Training manual

Stober

Stober SD6 Series User manual

Stober

Stober SD6 Series Training manual

Stober

Stober SD6 Series Training manual