Stober CiA 402 User manual

CiA 402 Controller Based

Operation manual

ID 442454.0212/2015en

ID 442454.02 2WE KEEP THINGS MOVING

Table of contents

Operation manual CiA 402 Controller Based

Table of contents

1 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .3

2 Basic information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .8

3 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . .49

4 Object directory - References . . . . . . . . . . . . . . . . . . . . . .. . . .52

ID 442454.02 3WE KEEP THINGS MOVING

General Information

1

Operation manual CiA 402 Controller Based

1 General Information

Overview of sections

1.1 About this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .4

1.2 Further documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .5

1.3 Technical support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .5

1.4 Important information and conventions . . . . . . . . . . . . . .. . . . .6

1.4.1 Safety instructions and pictograms . . . . . . . . . . . . . . . . . . . . . . . 6

1.4.2 Abbreviations, symbols, indexes . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.5 Instructions for use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .7

1.5.1 Using the software .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.5.2 Product maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

ID 442454.02 4WE KEEP THINGS MOVING

General Information

1

Operation manual CiA 402 Controller Based

Using the CiA 402 Controller Based (CiA CB) application in the SD6 drive

controller, you can implement applications with synchronized, cyclic

assignment of reference values by a motion control unit (type MC6, for

example).

1.1 About this manual

This manual describes the control of the drive controller, operation modes and

functions of the CiA 402 Controller Based (CiA CB) application. It also

describes projecting and setup of the application and drive controller in the

DriveControlSuite commissioning software and how to place the drive and

control unit in operation.

The manufacturer-specific jog operation mode is available for commissioning,

emergency mode and for maintenance and repair work. You can also use

different operation modes as specified by CANopen device profile CiA 402.

This makes the Homing mode operation mode available for referencing. In

Production mode choose between Interpolated position mode, Cyclic

synchronous position mode, Cyclic synchronous velocity mode or Cyclic

synchronous torque mode. Associated with each operation mode is the

corresponding control mode of the drive (position, speed, or torque/force

control).

In accordance with CiA 402 you can use the Touch probe function with CiA CB

for the position measurement with a binary signal.

This documentation applies to the following devices:

• Drive controller SD6 from DriveControlSuite V 6.1-A

What is new?

Index Date Changes

00 09/2013 First edition

01 03/2014 General corrections

02 10/2015 General corrections

Supplemented:

• Object directory annex- References

ID 442454.02 5WE KEEP THINGS MOVING

General Information

1

Operation manual CiA 402 Controller Based

1.2 Further documentation

The documentation listed in the following table provides relevant information on

the SD6 drive controller. You can find the latest document versions at

www.stoeber.de (Services).

1.3 Technical support

If you have technical questions that are not answered by this document, please

contact:

• Phone: +49 7231 582-3060

• E-mail: applications@stoeber.de

Device/Software Documentation Contents ID

SD6 drive controllers Manual System

environment,

technical data,

commissioning,

communication,

diagnosis

442426

SD6 drive controllers Commissioning

instructions

Technical data,

installation,

commissioning,

function test

442537

EtherCAT EC6

communication module

Manual Technical data,

installation,

commissioning,

data transfer

442516

CANopen CA6

communication module

Manual Technical data,

installation,

commissioning,

data transfer

442637

MC6 Motion Controller Manual Technical data,

installation,

commissioning

diagnosis

442461

ID 442454.02 6WE KEEP THINGS MOVING

General Information

1

Operation manual CiA 402 Controller Based

1.4 Important information and conventions

1.4.1 Safety instructions and pictograms

The devices can represent a source of danger. Therefore observe

• the safety guidelines, technical rules and regulations given in the following

sections

• and points.

STOBER shall assume no liability for damage resulting from failure to comply

with the instruction manual or relevant regulations. We reserve the right to

make technical changes for the purpose of improving the devices.

The following conventions apply to the safety instructions used in this

documentation:

WARNING!

Warning

means that there may be a serious danger of death

if the stated precautionary measures are not taken.

1.4.2 Abbreviations, symbols, indexes

The following abbreviations, formula symbols and indices are used in this

documentation.

Information

refers to important information about the product or serves to

emphasize a section in the documentation to which the reader

should pay special attention.

Abbreviations

CAN Controller Area Network

CiA CB CiA 402 Controller Based

CiA CAN in Automation

csp Cyclic synchronous position mode

cst Cyclic synchronous torque mode

csv Cyclic synchronous velocity mode

Enc Encoder

Drive follows Drive follows the command value

IGB Integrated Bus

ip Interpolated position mode

LS Limit Switch

neg Negative

pos Positive

RS Reference Switch

ZP Zero Pulse

Formula symbol

FForce

M Torque

Indices

hex Hexadecimal

ID 442454.02 7WE KEEP THINGS MOVING

General Information

1

Operation manual CiA 402 Controller Based

1.5 Instructions for use

1.5.1 Using the software

The DriveControlSuite software package can be used to select the application

and adjust the parameters and signal monitoring of the 6th generation of

STÖBER drive controllers. The functionality is specified by selecting an

application and transmitting these data to an drive controller.

The software is the property of STÖBER ANTRIEBSTECHNIK GmbH & Co.

KG and is copyrighted. The software is licensed for the user.

The software is only provided in machine-readable form. STÖBER

ANTRIEBSTECHNIK GmbH & Co. KG gives the customer a non-exclusive

right to use the software (license) provided it has been legitimately obtained.

The customer is authorized to use the software for the above activities and

functions and to make copies of the software, including a backup copy for

support of this use, and to install same.

The conditions of this license apply to each copy. The customer promises to

affix the copyright notation to each copy of the software and all other property

notations.

The customer is not authorized to use, copy, change or pass on/transmit the

software for purposes other than those in these regulations. The customer is

also not authorized to convert the software (i. e., reverse assembly, reverse

compilation) or to compile it in any other way. The customer is also not

authorized to issue sublicenses for the software, or to rent or lease it out.

1.5.2 Product maintenance

The obligation to maintain refers to the two latest software versions created by

STÖBER ANTRIEBSTECHNIK GmbH & Co. KG and approved for use.

STÖBER ANTRIEBSTECHNIK GmbH & Co. KG will either correct software

errors or will provide the customer with a new software version. This choice will

be made by STÖBER ANTRIEBSTECHNIK GmbH & Co. KG. If, in individual

cases, the error cannot be immediately corrected, STÖBER

ANTRIEBSTECHNIK GmbH & Co. KG will provide an intermediate solution

which may require the customer to comply with special operation regulations.

A claim to error correction only exists when the reported errors are reproducible

or can be indicated with machine-generated outputs. Errors must be reported

in a reconstructable form and provide information which is useful to error

correction.

The obligation to correct errors ceases to exist for software which the customer

changes or edits in any way unless the customer can prove that such action is

not the cause of the reported error.

STÖBER ANTRIEBSTECHNIK GmbH & Co. KG will keep the respective valid

software versions in an especially safe place (fireproof data safe, bank deposit

box).

ID 442454.02 8WE KEEP THINGS MOVING

Basic information

2

Operation manual CiA 402 Controller Based

2 Basic information

Overview of sections

2.1 Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . .10

2.1.1 Device state machine according to CiA 402 . . . . . . . . . . . . . . . 10

2.2 Operating modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . .14

2.2.1 Selection of the active operation mode . . . . . . . . . . . . . . . . . . . 14

2.2.2 Jog .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.2.2.1 Input and output signals .. . . . . . . . . . . . . . . . . . . . . . 15

2.2.2.2 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.2.2.3 Control commands and status information .. . . . . . . . 17

2.2.3 Homing mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.2.3.1 Input and output signals .. . . . . . . . . . . . . . . . . . . . . . 18

2.2.3.2 Reference position . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.2.3.3 Referencing methods .. . . . . . . . . . . . . . . . . . . . . . . . 20

2.2.3.3.1 Referencing method 1 . . . . . . . . . . . . . . . 22

2.2.3.3.2 Referencing method 2 . . . . . . . . . . . . . . . 22

2.2.3.3.3 Referencing method 3 . . . . . . . . . . . . . . . 23

2.2.3.3.4 Referencing method 5 . . . . . . . . . . . . . . . 23

2.2.3.3.5 Referencing method 7 . . . . . . . . . . . . . . . 24

2.2.3.3.6 Referencing method 11 . . . . . . . . . . . . . . 25

2.2.3.3.7 Referencing method 17 . . . . . . . . . . . . . . 26

2.2.3.3.8 Referencing method 18 . . . . . . . . . . . . . . 26

2.2.3.3.9 Referencing method 19 . . . . . . . . . . . . . . 27

2.2.3.3.10 Referencing method 21 . . . . . . . . . . . . . . 27

2.2.3.3.11 Referencing method 23 . . . . . . . . . . . . . . 28

2.2.3.3.12 Referencing method 27 . . . . . . . . . . . . . . 29

2.2.3.3.13 Referencing methods 33 and 34 . . . . . . . 30

2.2.3.3.14 Referencing method 35 . . . . . . . . . . . . . . 30

2.2.3.3.15 Referencing method 37 . . . . . . . . . . . . . . 30

2.2.3.3.16 Referencing method -1 . . . . . . . . . . . . . . . 31

2.2.3.3.17 Referencing method -2 . . . . . . . . . . . . . . . 31

2.2.3.3.18 Referencing method -3 . . . . . . . . . . . . . . . 32

2.2.3.3.19 Referencing method -4 . . . . . . . . . . . . . . . 32

2.2.3.4 Control commands and status information .. . . . . . . . 33

2.2.4 Interpolated position mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.2.4.1 Input and output signals . . . . . . . . . . . . . . . . . . . . . . . 34

2.2.4.2 Control commands and status information .. . . . . . . . 35

2.2.5 Cyclic synchronous position mode . . . . . . . . . . . . . . . . . . . . . . 35

2.2.5.1 Input and output signals . . . . . . . . . . . . . . . . . . . . . . . 36

2.2.5.2 Control commands and status information .. . . . . . . . 37

2.2.6 Cyclic synchronous velocity mode .. . . . . . . . . . . . . . . . . . . . . . 37

ID 442454.02 9WE KEEP THINGS MOVING

Basic information

2

Operation manual CiA 402 Controller Based

2.2.6.1 Input and output signals .. . . . . . . . . . . . . . . . . . . . . . 38

2.2.6.2 Control commands and status information .. . . . . . . . 39

2.2.7 Cyclic synchronous torque mode . . . . . . . . . . . . . . . . . . . . . . . 39

2.2.7.1 Input and output signals .. . . . . . . . . . . . . . . . . . . . . . 40

2.2.7.2 Control commands and status information .. . . . . . . . 41

2.3 Feed forward . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . .42

2.3.1 Control-unit-generated external feed forward . . . . . . . . . . . . . . 42

2.3.2 Drive-generated internal feed forward .. . . . . . . . . . . . . . . . . . . 43

2.3.3 Without feed forward . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

2.4 Interpolation .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . .44

2.5 Additional functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . .45

2.5.1 Touch probe .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

2.5.1.1 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

ID 442454.02 10WE KEEP THINGS MOVING

Basic information

2

Operation manual CiA 402 Controller Based

This section contains essential information about the basic settings that must

be considered in each project for the drive controller and adjusted for your

application. The section describes control of the drive controller and the

available operating modes and also covers feed forward and interpolation. A

description of the CiA-402-compliant Touch probe function is also included.

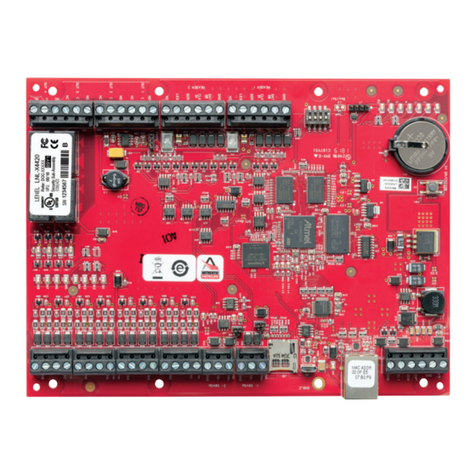

2.1 Controller

The application is based on the internationally standardized CANopen device

profile CiA 402 for electrical drives. The SD6 drive controller is controlled

accordingly with CiA-402-compliant control and status words.

2.1.1 Device state machine according to CiA 402

The illustration below shows the device states and possible changes in state in

accordance with CiA 402.

Fig. 2-1Device state machine according to CiA 402

ID 442454.02 11WE KEEP THINGS MOVING

Basic information

2

Operation manual CiA 402 Controller Based

The table below shows the conditions for changes in the state machine.

Change of state Conditions

0 Device start-up > self test Control board power supply turned on.

1 Self test > switch on disable Self test completed without errors

AND initialization complete.

2 Switch on disable > ready to switch on Enable active

AND DC link charged

AND command Shutdown

AND safety technology deactivated

AND IGB motion bus inactive OR (IGB motion bus active AND (IGB state = 3:IGB motion bus OR IGB exception

mode active OR Local mode active)).

3 Ready to switch on > switched on Enable active

AND command Switch On

4 Switched on > operation enabled Enable active

AND command Enable operation

5 Operation enabled > switched on Enable active

AND command Disable operation

6 Switched on > ready to switch on Enable active

AND command Shutdown

7 Ready to switch on > switch on disable Enable inactive

OR DC link not charged

OR command Quick stop

OR command Disable voltage

OR safety technology active

OR (IGB motion bus active AND IGB state not equal to 3:IGB motion bus AND IGB exception mode inactive AND

local mode inactive)

8 Operation enabled > ready to switch on Shutdown command

ID 442454.02 12WE KEEP THINGS MOVING

Basic information

2

Operation manual CiA 402 Controller Based

9 Operation enabled > switch on disable Enable inactive

OR command Disable voltage

OR safety technology active

10 Switched on > switch on disable Enable inactive

OR DC link not charged

OR command Quick stop

OR command Disable voltage

OR safety technology active

OR (IGB motion bus active AND IGB state not equal to 3:IGB motion bus AND IGB exception mode inactive AND

local mode inactive)

11 Operation enabled > quick stop Command Quick stop

OR (Enable inactive AND Quick stop signal with enable off signal active)

12 Quick stop > switch on disable Quick stop complete

OR DC link below 130 V

OR safety technology active

OR command Disable voltage

13 All states > fault response active Fault detected

14 Fault response active > fault Fault response complete

15 Fault > switch on disable Command Fault reset (positive edge)

Change of state Conditions

ID 442454.02 13WE KEEP THINGS MOVING

Basic information

2

Operation manual CiA 402 Controller Based

The device state machine must receive specific commands for changes of

state. The commands are given as a bit combination in the control word in

accordance with CiA402 (parameter A515 Control word). The table below

shows the states of the bits in A515 and how they are combined for commands

(bits marked with X are irrelevant).

The standard device state machine has the same states as in the device state

machine according to CANopen device profile CiA 402.

The table below lists manufacturer-specific designations and the designations

according to CiA.

Command

Bit of the control word (A515 control word)

Bit 7 Bit 3 Bit 2 Bit 1 Bit 0

Fault

reset

Enable

operation

Quick

stop

Enable

voltage

Switch

on

Shutdown 0 X 1 1 0

Switch on 0 0 1 1 1

Disable voltage 0 X X 0 X

Quick stop 0 X 0 1 X

Disable operation 0 0 1 1 1

Enable operation 0 1 1 1 1

Fault reset Pos. of

edge X XXX

Manufacturer-specific

designation

Designation according to CiA 402

Self test Not ready to switch on

Switch on disable Switch on disabled

Ready to switch on Ready to switch on

Switched on Switched on

Operation enabled Operation enabled

Fault Fault

Fault reaction active Fault reaction active

Quick stop active Quick stop active

ID 442454.02 14WE KEEP THINGS MOVING

Basic information

2

Operation manual CiA 402 Controller Based

2.2 Operating modes

Different operation modes are available with the CiA CB application.

For commissioning, emergency mode and for maintenance and repair

work:

•Jog

Control-independent movement of the drive.

You can also use the following operation modes with CiA CB in accordance

with CANopen device profile CiA 402.

For referencing:

• Homing mode

Control-independent referencing of the drive. The drive calculates the

necessary motion profiles independently.

In production mode:

• Interpolated position mode

Cyclic position assignment by the control unit. Position-controlled drive.

• Cyclic synchronous position mode

Cyclic position assignment by the control unit. Position-controlled drive.

• Cyclic synchronous velocity mode

Cyclic velocity assignment by the control unit. Velocity-controlled drive.

• Cyclic synchronous torque mode

Cyclic torque/force assignment by the controller. Torque-/force-controlled

drive.

2.2.1 Selection of the active operation mode

You can choose the desired operation mode in parameter A541 Modes of

operation. The currently active operation mode is displayed via the parameter

A542 Modes of operation display.

2.2.2 Jog

You can use Jogging mode to move the drive independently of the control unit,

for example during commissioning, in emergency mode, or for setup and repair

work.

ID 442454.02 15WE KEEP THINGS MOVING

Basic information

2

Operation manual CiA 402 Controller Based

2.2.2.1 Input and output signals

!

!"# $%&'"

!()*'&!+

",&-!.

"

,& /

01 /

2 / !!

ID 442454.02 16WE KEEP THINGS MOVING

Basic information

2

Operation manual CiA 402 Controller Based

2.2.2.2 Function

1I13 Tip acceleration

2I45 Tip deceleration

3I18 Tip jerk

If signal TipPos is set to 1, the drive accelerates with ramp I13 and jerk limit I18

to velocity I12. If signal TipPos is set to 0, the drive brakes with ramp I45 to a

complete stop.

If signal TipNeg is active, the drive will accelerate to -I12. The same applies to

acceleration and jerk.

If signals TipPos and TipNeg are set to 1 at the same time, the drive brakes to

a complete stop:

Taste

Taste

12

3

+I12

n

-I12

0

1

0

1

+I12

n

-I12

0

1

0

1

Taste

Taste

ID 442454.02 17WE KEEP THINGS MOVING

Basic information

2

Operation manual CiA 402 Controller Based

2.2.2.3 Control commands and status information

To select the Jog operation mode, set the parameter A541 to the value -1.

The active operation mode is output in parameter A542. If Jog operation mode

is active, the display contains as information -1: Jog.

The following mode-specific bit is used in the control word A515.

No mode-specific bit is used in the status word A516.

2.2.3 Homing mode

During the referencing in Homing mode, the reference system of the machine

and controller are absolutely matched to each other. The drive is only able to

perform absolute movements in the referenced state (movements to defined

positions).

Bit Designation Comment

4 TipPos 1 = Jog in positive

direction

5 TipNeg 1 = Jog in negative

direction

Information

For all graphical displays of axes in this section, the smallest

position value is on the left, the largest on the right. Accordingly

positive motion moves to the right, negative to the left.

ID 442454.02 18WE KEEP THINGS MOVING

Basic information

2

Operation manual CiA 402 Controller Based

2.2.3.1 Input and output signals

!"#$

%&

%&#$#

%''#

()

*#+

,-.+

/+

*'+.)

()

%#

%&

ID 442454.02 19WE KEEP THINGS MOVING

Basic information

2

Operation manual CiA 402 Controller Based

2.2.3.2 Reference position

The reference position is the value that is set in the reference point. The

reference point is determined by the referencing method, which is described in

greater detail on the following pages.

Position A569 Home offset = 2.50 m is assigned to the reference point by

means referencing.

When the reference has been set, the drive comes to a complete stop just after

the reference position.

ID 442454.02 20WE KEEP THINGS MOVING

Basic information

2

Operation manual CiA 402 Controller Based

2.2.3.3 Referencing methods

You can implement the following referencing method, which are described in greater detail on the following pages.

Switch position (S) and initial direction of

travel when the switch is not activated

Referencing

method

Reference to Description

Zero pulse Limit

switch

Torque/force (M/F)

1yesyes —

Negative limit switch, encoder zero pulse,

negative initial movement.

5yes— — Negative reference switch, encoder zero

pulse, negative initial movement.

17 — yes — Negative limit switch, negative initial

movement.

21 — — — Negative reference switch, negative initial

movement.

2yesyes —

Positive limit switch, encoder zero pulse,

positive initial movement.

3yes— —

Positive reference switch, encoder zero pulse,

positive initial movement.

18 — yes — Positive limit switch, positive initial movement.

19 — — — Positive reference switch, positive initial

movement.

7yes— —

Centrally arranged reference switch,

encoder zero pulse, positive initial movement.

23 — — — Centrally arranged reference switch,

positive initial movement.

S

S

S

Table of contents

Other Stober Controllers manuals

Stober

Stober MC6 User manual

Stober

Stober SD6 Series Training manual

Stober

Stober SR6 Training manual

Stober

Stober SD6 Series User manual

Stober

Stober SC6 Series Training manual

Stober

Stober PROFINET SD6 User manual

Stober

Stober SC6 Series User manual

Stober

Stober MC6 User manual

Stober

Stober SD6 Series User manual

Stober

Stober SD6 Series User manual