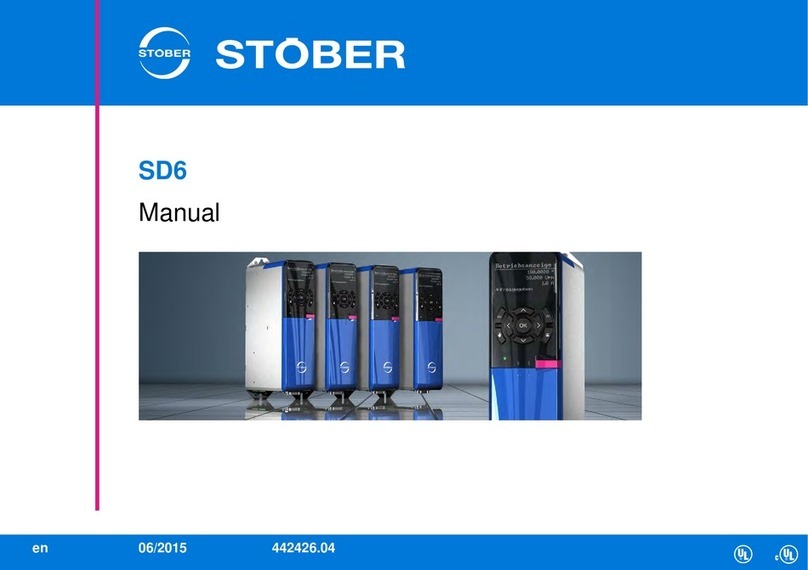

Stober SD6 Series Training manual

SD6

Commissioning Instructions

442537.0101/2015en

ID 442537.01 2WE KEEP THINGS MOVING

Table of contents

Commissioning Instructions SD6

Table of contents

1 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .4

1.1 About this documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Other manuals .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Further support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4 Abbreviations, symbols, indexes . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.5 Symbols, identifiers, marks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Notes on safety .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .7

2.1 Operation in accordance with its intended use . . . . . . . . . . . . . . 7

2.2 Component part of the product . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Risk assessment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4 Qualified personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.5 Working on the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.6 Disposal .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.7 Presentation of notes on safety .. . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .9

3.1 Notes on safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2 Nameplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.3 Type designation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.4 Sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.5 Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.5.1 Control board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.5.2 Power board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.6 Mechanical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.6.1 Device features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.6.2 Dimensions .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

4.1 Notes on safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.2 Drive controller .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.3 Terminal modules .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.4 Communication modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.5 Quick DC-Link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.6 Bottom brake resistor .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.7 EMC shroud .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5 Connecting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

5.1 Notes on safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.2 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.2.1 EMC connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.2.2 Selecting the cables . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.3 Wiring .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.4 Protective measures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

ID 442537.01 3WE KEEP THINGS MOVING

Table of contents

Commissioning Instructions SD6

5.4.1 Line fuse .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.4.2 Residual current safety device .. . . . . . . . . . . . . . . . . 28

5.4.3 Housing ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.5 Drive controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.5.1 Overview of terminals .. . . . . . . . . . . . . . . . . . . . . . . . 30

5.5.2 X1: Enable and relay 1 .. . . . . . . . . . . . . . . . . . . . . . . 35

5.5.3 X2: Motor temperature sensor . . . . . . . . . . . . . . . . . . 36

5.5.4 X3A, X3B: PC, IGB . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.5.5 X4: Encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.5.6 X5, X6: Motor holding brake .. . . . . . . . . . . . . . . . . . . 41

5.5.7 X10: 230 V/400 V power . . . . . . . . . . . . . . . . . . . . . . 42

5.5.8 X11: 24 V power .. . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.5.9 X12: Safety technology . . . . . . . . . . . . . . . . . . . . . . . 44

5.5.10 X20: Motor .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.5.11 X30: Quick DC-Link, braking resistor . . . . . . . . . . . . . 47

5.6 Terminal modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.6.1 X100 .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.6.2 X101 .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.6.3 X102 .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5.6.4 X103A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5.6.5 X103B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.6.6 X103C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5.6.7 X120 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5.6.8 X140 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.7 Communication modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

5.7.1 X200, X201: EtherCAT . . . . . . . . . . . . . . . . . . . . . . . . 60

5.7.2 X200: CANopen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

5.8 Drive controller wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

5.8.1 Examples of connections . . . . . . . . . . . . . . . . . . . . . . 62

6 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

6.1 Drive controller – control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

6.1.1 Menu structure and navigation . . . . . . . . . . . . . . . . . . 64

6.2 Wiring and function test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

6.2.1 Schematic test sequence . . . . . . . . . . . . . . . . . . . . . . 65

6.2.2 Practical test sequence . . . . . . . . . . . . . . . . . . . . . . . 66

6.3 Additional parameter information .. . . . . . . . . . . . . . . . . . . . . . . 67

ID 442537.01 4WE KEEP THINGS MOVING

General Information

1

Commissioning Instructions SD6

1 General Information

The new SD6 drive controller offers maximum precision and productivity

for automation technology and machine manufacturing despite ever

more complex functions. Highly dynamic drives ensure the shortest

recovery times from fast changes in reference value and load jumps.

You also have the option of connecting the drive controllers in a DC

intermediate circuit, which improves the energy footprint of the entire

system.

Properties

• Wide power range thanks to 4 sizes

• Quick DC-Link: Innovative installation concept for the DC link

connection

• Very good control performance

• Easy to service

• Real-time cross-communication (in preparation)

• Modular safety technology (in preparation)

• Free, graphical programming in accordance with IEC 61131-3 CFC

(in preparation)

1.1 About this documentation

This documentation provides support for you in the assembly of the SD6

drive controller together with associated components such as terminal

and communication modules, EMC shrouds, chassis brake resistors

and a quick DC link.

You will also find information for wiring the drive controller correctly and

checking its functionality in the group with an initial test.

For technical data and more detailed information regarding braking

resistors and chokes, projecting a quick DC link as well as assembly

and wiring of the LA6 adapter box, please refer to the SD6 manual.

To ensure proper functionality, we recommend using cables from

STOBER (see SD6 manual). In case of use of unsuitable connection

cables, we reserve the right to reject claims under the warranty.

What is new?

1.2 Other manuals

The documentation listed in the following table provides relevant

information on the SD6 drive controller.

You can find the latest document versions at www.stoeber.de.

Index Date Changes

01 01/2015 • General corrections

Additions

• Technical Data

• Installation

• Connection

• Commissioning

Device/software Documentation Contents ID

SD6 drive controllers Manual Technical data,

installation,

connection, setup,

commissioning and

customer service

442426

ID 442537.01 5WE KEEP THINGS MOVING

General Information

1

Commissioning Instructions SD6

1.3 Further support

If you have technical questions that are not answered by this document,

please contact:

• Phone: +49 7231 582-3060

• E-mail: applications@stoeber.de

1.4 Abbreviations, symbols, indexes

Abbreviations

AES Absolute Encoder Support

BG Size

CAN Controller Area Network

CiA Can in Automation

CNC Computerized Numerical Control

DC Direct Current

EMC Electromagnetic Compatibility

RCD Residual Current protective Device

UL Underwriters Laboratories

ZK DC link

Formula symbol

CCapacity

D Derating

f Frequency

K Ratio of the DC link circuit capacity being charged in the

compound DC link system to the max. charging capacity

of the drive controllers that are supplied with power

I Current

λ(lambda) Power factor; equivalent to cos φbetween the effective

and apparent power

n Speed

p Number of pole pairs

P (Effective) power

R Resistance

T Temperature

τ(tau) Thermal time constant

tTime

UVoltage

Indices

1 Input

2 Output

amb Ambient

BBrake

BAT Battery

BR Braking resistor

CH Brake chopper

Supply Supply current

hHeight

max Maximum

min Minimum

N Nominal

Mains Mains power supply

off Off

on On

PWM Pulse Width Modulation

T Temperature

VLoss

Formula symbol

ID 442537.01 6WE KEEP THINGS MOVING

General Information

1

Commissioning Instructions SD6

1.5 Symbols, identifiers, marks The following names that are used in conjunction with the device, its

optional equipment and its accessories are trademarks or registered

trademarks of other companies:

All other trademarks that are not listed here are the property of their

respective owners.

Symbols

EN 61558-2-20

Choke without overload protection.

Grounding symbol according to IEC 60417-5019

(DB:2002-10).

Identification and test symbols

Lead-free identifier for RoHS

Lead-free identifier according to RoHS directive 2011-65-

EU.

CE mark

Manufacturer's self declaration: The product meets the

requirements of EU directives.

UL test mark

This product is listed by UL for the USA and Canada.

Representative samples of this product have been

evaluated by UL and meet the requirements of applicable

standards.

UL test marks for recognized component

This component or material is recognized by UL.

Representative samples of this product have been

evaluated by UL and meet applicable requirements.

Trademarks

CANopen,

CiA

CANopen and CiA are registered Community trademarks

of CAN in Automation e.V., Nuremberg, Germany.

EtherCAT EtherCAT and the EtherCAT logo are registered

trademarks of Beckhoff Automation GmbH, Verl,

Germany.

ID 442537.01 7WE KEEP THINGS MOVING

Notes on safety

2

Commissioning Instructions SD6

2 Notes on safety

The devices can represent a source of danger. Therefore observe

• the safety guidelines, technical rules and regulations given in the

following sections

• and points.

STOBER shall assume no liability for damage resulting from failure to

comply with the instruction manual or relevant regulations. We reserve

the right to make technical changes for the purpose of improving the

devices.

2.1 Operation in accordance with its intended

use

As defined by DIN EN 50178 (previously VDE 0160), the drive

controllers are electrical equipment operating as power electronics to

control the flow of energy in high voltage systems. They are designed

exclusively for installation in switching cabinets, protection class at least

IP54, and for supplying

• synchronous servo motors and

• asynchronous motors.

Designated use does not include connecting other electrical loads!

2.2 Component part of the product

The technical documentation is a component part of a product.

• Since the technical documentation contains important information,

always keep it handy in the vicinity of the device until the machine is

disposed of.

• If the product is sold, disposed of, or rented out, always include the

technical documentation with the product.

2.3 Risk assessment

Before the manufacturer may bring a machine onto the market, he must

conduct a risk assessment according to Machine Directive 06/42/EC.

As a result, the risks associated with the use of the machine are

determined. The risk assessment is a multi-stage and iterative process.

On no account can sufficient insight into the Machine Directive be given

as part of this documentation. For this reason, seek detailed information

about the norms and legal position. When installing the drive controller

in machines, commissioning is forbidden until it has been determined

that the machine meets the requirements of EC Directive 06/42/EC.

2.4 Qualified personnel

Devices may cause residual risks. For this reason, all work on the

devices as well as operation and disposal must only be performed by

qualified personnel who are aware of the possible dangers.

Qualified personnel are persons who have acquired the authorisation to

perform these activities by

• Training from specialists and/or

• Instruction from specialists

In addition, they must have

• read,

• understood and

• observed the applicable regulations, legal provisions, rules and

standards and existing technical documentation including the safety

information contained in it.

ID 442537.01 8WE KEEP THINGS MOVING

Notes on safety

2

Commissioning Instructions SD6

2.5 Working on the machine

Apply the 5 safety rules in the order stated before performing any work

on the machine:

1. Disconnect.

Also ensure that the auxiliary circuits are disconnected.

2. Protect against being turned on again.

3. Check that voltage is not present.

4. Ground and short circuit.

5. Cover or block off adjacent live parts.

2.6 Disposal

Please comply with the latest national and regional regulations! Dispose

of the individual parts separately depending on their nature and

currently valid regulations such as, for example:

• Electronic scrap (PCBs)

•Plastic

• Sheet metal

• Copper

• Aluminum

2.7 Presentation of notes on safety

NOTICE

Notice

means that property damage may occur

if the stated precautionary measures are not taken.

CAUTION!

Caution

with warning triangle means that minor injury may occur

if the stated precautionary measures are not taken.

WARNING!

Warning

means that there may be a serious danger of death

if the stated precautionary measures are not taken.

DANGER!

Danger

means that serious danger of death exists

if the stated precautionary measures are not taken.

Information

Note that the discharge time of the DC link capacitors is up to 5

minutes. You can only determine the absence of voltage after this

time period.

Information

refers to important information about the product or serves to

emphasize a section in the documentation to which the reader

should pay special attention.

ID 442537.01 9WE KEEP THINGS MOVING

Technical data

3

Commissioning Instructions SD6

3 Technical data

3.1 Notes on safety

Drive controllers are products subject to sales restrictions in accordance

with IEC 61800-3.

The drive controllers are not designed for use in a public low frequency

network that supplies residential areas.

In a residential environment this product may cause high-frequency

interference. If this occurs the user may be asked to take suitable

measures.

The drive controllers are not designed for use in a public low frequency

network that supplies residential areas. High-frequency interference

can be expected if the drive controllers are used in a network of this

type.

Always operate the devices within the limits specified in the technical

data.

The following applications are prohibited:

• Use in areas subject to explosion hazard

• Use in environments with harmful substances as specified by EN

60721, for example oils, acids, gases, vapors, dust and radiation

Implementation of the following applications is only permitted after

approval is obtained from STOBER:

• Use in non-stationary applications

3.2 Nameplate

ID 442537.01 10WE KEEP THINGS MOVING

Technical data

3

Commissioning Instructions SD6

UL test mark

UL and cUL (CSA-UL) certified drive controllers with corresponding test

mark meet the requirements of standards UL 508C and UL 840.

3.3 Type designation

Sample code

Explanation

Designation Value in the example Meaning

Type SD6A06TEX Drive controller type

according to the type

designation

Date 1318 Production week in format

YYWW, in the example

shown here year 2013, week

18

S/N 7000204 Serial number

Nominal connection

voltage

3 x 400 V ~

50 Hz

UL: 3 x 480 V ~ 50–

60 Hz

Nominal connection voltage

Nominal connection

power

2.5 kVA Nominal connection power

Input current 4.0 A Input current

Output data 3 x 3.4 A

0...460 V

0...700 Hz

Output data

Protection class IP20 Protection class

SD 6 A 0 6 T E X

Code Designation Design

SD Type Servo Drive

6Generation 6th generation

A, B Version

0– 3 Size

0 – 9 Power output stage (Within the size)

TSafety module ST6: Safe Torque Off (STO)

N

E

C

Communication module Empty

EC6: EtherCAT

CA6: CANopen

N

X

R

I

Terminal module Empty

XI6: Extended I/O

RI6: Resolver I/O

IO6: Standard I/O

ID 442537.01 11WE KEEP THINGS MOVING

Technical data

3

Commissioning Instructions SD6

3.4 Sizes

The drive controller SD6 includes the following types and sizes:

3.5 Electrical Data

3.5.1 Control board

Type Size

SD6A02 0

SD6A04 0

SD6A06 0

SD6A14 1

SD6A16 1

SD6A24 2

SD6A26 2

SD6A34 3

SD6A36 3

SD6A38 3

Control board

U120.4 – 28.8 V

I1maxa)

a) Depending on the accessories used.

1.5 A

ID 442537.01 12WE KEEP THINGS MOVING

Technical data

3

Commissioning Instructions SD6

3.5.2 Power board

3.5.2.1 Size 0: SD6A0x

Properties of the brake chopper

3.5.2.2 Size 1: SD6A1x

Properties of the brake chopper

Type SD6A02 SD6A04 SD6A06

U1(L1 – N) 1 x 230 V,

+20 % / -40 %,

50/60 Hz;

(L1 – N) 1 x 240 V,

50/60 Hz

(L1 – L3) 3 x 400 V,

+32 % / -50 %,

50/60 Hz;

(L1 – L3) 3 x 480 V,

50/60 Hz

I1N (fPWM = 4 kHz) 8.3 A 2.8 A 5.4 A

I1N (fPWM = 8 kHz) 6 A 2.2 A 4 A

I2N (fPWM = 4 kHz)a)

a) Note the derating for 4 kHz.

4 A 2.3 A 4.5 A

I2N (fPWM = 8 kHz)b)

b) Note the derating for 8 kHz.

3 A 1.7 A 3.4 A

I2max (fPWM = 4 kHz) 180 % for 5 s; 150 % for 30 s

I2max (fPWM = 8 kHz) 250 % for 2 s; 200 % for 5 s

fPWM Adjustable: 4, 8, 16 kHzc)

c) Note the details for the nominal output current and derating for 16 kHz.

f20 – 700 Hz

U20 – U1

PV(I2= IN) 80 W 65 W 90 W

PV(I2= 0 A) Max. 30 Wd)

d) Depending on the option modules and encoders connected.

Type SD6A02 SD6A04 SD6A06

UCHon 400 – 420 V 780 – 800 V

UCHoff 360 – 380 V 740 – 760 V

RBRmin 100 Ω

PBRmax 1.8 kW 6.4 kW

Type SD6A14 SD6A16

U1(L1 – L3) 3 400 V, +32 % / -50 %, 50/60 Hz;

(L1 – L3) 3 480 V, 50/60 Hz

I1N (fPWM = 4 kHz) 12 A 19.2 A

I1N (fPWM = 8 kHz) 9.3 A 15.8 A

I2N (fPWM = 4 kHz)a)

a) Note the derating for 4 kHz.

10 A 16 A

I2N (fPWM = 8 kHz)b)

b) Note the derating for 8 kHz.

6 A 10 A

I2max (fPWM = 4 kHz) 180 % for 2 s; 150 % for 30 s

I2max (fPWM = 8 kHz) 250 % for 2 s; 200 % for 5 s

fPWM Adjustable: 4, 8, 16 kHzc)

c) Note the details for the nominal output current and derating for 16 kHz.

f20 – 700 Hz

U20 – U1

PV(I2= IN) 170 W 200 W

PV(I2= 0 A) Max. 30 Wd)

d) Depending on the option modules and encoders connected.

Type SD6A14 SD6A16

UCHon 780 – 800 V

UCHoff 740 – 760 V

RBRmin 47 Ω

PBRmax 6.4 kW 13.6 kW

ID 442537.01 13WE KEEP THINGS MOVING

Technical data

3

Commissioning Instructions SD6

3.5.2.3 Size 2: SD6A2x

Properties of the brake chopper

3.5.2.4 Size 3: SD6A3x

Properties of the brake chopper

Type SD6A24 SD6A26

U1(L1 – L3) 3 400 V, +32 % / -50 %, 50/60 Hz;

(L1 – L3) 3 480 V, 50/60 Hz

I1N (fPWM = 4 kHz) 26.4 A 38.4 A

I1N (fPWM = 8 kHz) 24.5 A 32.6 A

I2N (fPWM = 4 kHz)a)

a) Note the derating for 4 kHz.

22 A 32 A

I2N (fPWM = 8 kHz)b)

b) Note the derating for 8 kHz.

14 A 20 A

I2max (fPWM = 4 kHz) 180 % for 5 s; 150 % for 30 s

I2max (fPWM = 8 kHz) 250 % for 2 s; 200 % for 5 s

fPWM Adjustable: 4, 8, 16 kHzc)

c) Note the details for the nominal output current and derating for 16 kHz.

f20 – 700 Hz

U20 – U1

PV(I2= IN) 220 W 280 W

PV(I2= 0 A) Max. 30 Wd)

d) Depending on the option modules and encoders connected.

Type SD6A24 SD6A26

UCHon 780 – 800 V

UCHoff 740 – 760 V

RBRmin 22 Ω

PBRmax 29.1 kW 29.1 kW

Type SD6A34 SD6A36 SD6A38

U1

(L1 – L3) 3 x 400 V, +32 % / -50 %, 50/60 Hz;

(L1 – L3) 3 x 480 V, 50/60 Hz

I1N (fPWM = 4 kHz) 45.3 A 76 A 76 A

I1N (fPWM = 8 kHz) 37 A 62 A 76 A

I2N (fPWM = 4 kHz)a)

a) Note the derating for 4 kHz.

44 A 70 A 85 A

I2N (fPWM = 8 kHz)b)

b) Note the derating for 8 kHz.

30 A 50 A 60 A

I2max (fPWM = 4 kHz) 180 % for 5 s; 150 % for 30 s

I2max (fPWM = 8 kHz) 250 % for 2 s; 200 % for 5 s

fPWM Adjustable: 4, 8, 16 kHzc)

c) Note the details for the nominal output current and derating for 16 kHz.

f20 – 700 Hz

U20 – U1

PV(I2= IN) 350 W 600 W 1000 W

PV(I2= 0 A) Max. 55 Wd)

d) Depending on the option modules and encoders connected.

Type SD6A34 SD6A36 SD6A38

UCHon 780 – 800 V

UCHoff 740 – 760 V

RBRmin 15 Ω

PBRmax 42 kW

ID 442537.01 14WE KEEP THINGS MOVING

Technical data

3

Commissioning Instructions SD6

3.5.2.5 Derating

When dimensioning the drive controller, observe the derating of the

output current depending on the clock frequency, surrounding

temperature, and installation altitude. There is no restriction for a

surrounding temperature from 0° C to 45° C and an installation altitude

of 0 m to 1000 m. The details given below apply to values outside these

ranges.

3.5.2.5.1 Effect of the clock frequency

Changing the clock frequency fPWM affects the amount of noise

produced by the drive. However, increasing the clock frequency results

in increased losses. During project configuration, define the highest

clock frequency and use it to determine the nominal output current I2N

for dimensioning the drive controller.

3.5.2.5.2 Effect of surrounding temperature

Derating depending on the ambient temperature is determined as

follows:

• 0° C to 45° C: No restrictions (DT= 100 %)

• 45° C to 55° C: Derating -2.5 % / K

Example

The drive controller will be operated at 50° C.

The resulting derating factor DTfor DT= 100 % - 5 2.5 % = 87.5 %.

3.5.2.5.3 Effect of installation altitude

Derating depending on the installation altitude is determined as follows:

• 0 m to 1000 m above sea level: No restrictions (Dh= 100 %)

• 1000 m to 2000 m above sea level: Derating -1.5 % / 100 m

Example

The drive controller will be installed at an altitude of 1500 m above sea

level.

The resulting derating factor Dhfor Dh= 100 % - 5 1.5 % = 92.5 %.

3.5.2.5.4 Calculating the derating

Follow these steps for the calculation:

1. Determine the highest clock frequency (fPWM) that will be used

during operation and use it to determine the nominal current IN(see

section 3.5.2.5.1).

2. Determine the derating factors for installation altitude and

surrounding temperature (see section 3.5.2.5.3 and 3.5.2.5.2).

3. Calculate the output current I2according to the following formula:

I2= I2N DTDh

Type Nominal output current I2N [A]

4 kHz 8 kHz 16 kHz

SD6A02 4 3 2

SD6A04 2.3 1.7 1.1

SD6A06 4.5 3.4 2.3

SD6A14 10 6 4

SD6A16 16 10 5.7

SD6A24 22 14 8.1

SD6A26 32 20 12

SD6A34 44 30 18

SD6A36 70 50 31

SD6A38 85 60 37.8

Information

Enter the defined clock frequency for setting up the drive controller

in B24.

ID 442537.01 15WE KEEP THINGS MOVING

Technical data

3

Commissioning Instructions SD6

Example

A drive controller of type SD6A06 will be operated at a clock frequency

of 8 kHz at an altitude of 1500 m above sea level and an surrounding

temperature of 50° C.

The nominal current of the SD6A06 at 8 kHz is 3.4 A (see 3.5.2.5.1).

The resulting derating factor DTfor DT= 100 % - 5 2.5% = 87.5 %

(see 3.5.2.5.3).

The resulting derating factor Dhfor Dh= 100 % - 5 1.5 % = 92.5 %

(see 3.5.2.5.2).

The output current to be observed for project configuration is:

I2= 3.4 A 0.875 0.925 = 2.75 A

3.6 Mechanical Data

3.6.1 Device features

If you order a drive controller with accessory parts, the weight is

increased as follows:

• Communication module: 50 g

• Terminal module: 135 g

Protection class of the

device

IP 20

Protection class of the

control cabinet

At least IP 54

Radio interference

suppression

EN 61800-3, interference emission class C3

Overvoltage category III to EN 61800-5-1

Size Weight

Without packaging [kg] With packaging [kg]

0 2,53 3.52

1 3.7 5.47

2 5.05 6.49

3 13.3 14.8

ID 442537.01 16WE KEEP THINGS MOVING

Technical data

3

Commissioning Instructions SD6

3.6.2 Dimensions

d2

d1

h2

h1

h3

e

f

a

b

w

Dimensions [mm] Size 0 Size 1 Size 2

Drive controller Height h1300

Height incl. EMC shroud h2355

Height incl. AES h3367

Width w 70 105

Depth d1194 284

Depth incl. braking resistor

RB 5000

d2212 302

EMC shroud Height e 27

Depth f 40

Fastening holes Vertical distance a 283+2

Vertical distance

to upper edge

b6

ID 442537.01 17WE KEEP THINGS MOVING

Technical data

3

Commissioning Instructions SD6

Dimensions [mm] Size 3

Drive controller Height h1382.5

Height incl. EMC shroud h2540

Width w1190

Depth d1305

EMC shroud Height e 174

Width w2147

Depth f 34

d2113

Fastening

holes

Vertical distance a 365+2

Vertical distance from bottom edge b 6

Horizontal distance from the

fastening holes of the drive

controller

c1150+0.2/-0.2

Horizontal distance from the side

edge of the drive controller g120

Horizontal distance from the

fastening holes of the EMC shroud

c2132

Horizontal distance from the side

edge of the EMC shroud

g27.5

ID 442537.01 18WE KEEP THINGS MOVING

Installation

4

Commissioning Instructions SD6

4Installation

4.1 Notes on safety

Installation work is only admissible when no voltage is present. Observe

the 5 safety rules (see chapter 2.5 Working on the machine).

Remove the additional covers before commissioning so that the device

will not overheat.

Note the minimum open areas specified in the technical data during

installation to prevent the drive controller from overheating.

Protect the device against falling parts (bits or strands of wire, pieces of

metal, etc.) during installation or other work in the control cabinet. Parts

with conductive properties may result in a short circuit or device failure

within the drive controller.

4.2 Drive controller

WARNING!

Electrical voltage!

Danger to life caused by touching live parts!

Activate the control cabinet according to the 5 safety rules.

Requirements:

• Prevent condensation, for example with anti-condensation heating

elements.

• Note that drive controllers in storage must be used annually or no

later than before commissioning.

• For reasons related to EMC, use mounting plates with a conductive

surface (unpainted, etc.).

• Fasten the devices onto the mounting plate with M5 screws.

• Attach the devices vertically.

• Avoid installation above or in the immediate vicinity of heat-

generating devices

such as output deraters or braking resistors.

• To ensure there is sufficient air circulation in the control cabinet,

observe the minimum clearances.

• A contact plan of the system in which the connection of the drive

controller is described must be present.

You need:

• a tool to drill the tapped holes in the mounting plate.

• a tool to tighten the fastening screws.

Drive controller installation

1. If present, install both a terminal module and a communication

module (see section 4.3 Terminal modules and 4.4 Communication

modules).

2. Prepare the mounting plate according to the separately enclosed

drilling diagram.

3. Install the drive controller on the mounting plate. Make certain chips

and oil are cleaned from the mounting plate.

4. Connect the housing ground (see section 5.4.3 Housing ground).

5. Connect the drive controller, terminal module and communication

module according to the contact plan.

ID 442537.01 19WE KEEP THINGS MOVING

Installation

4

Commissioning Instructions SD6

4.3 Terminal modules

WARNING!

Danger of personal injury and material damage due to electric

shock!

Always switch off all power supply voltage before working on the

drive controller! Note that the discharge time of the DC link

capacitors is 5 minutes. You can only determine the absence of

voltage after this time period.

CAUTION!

Danger of property damage due to electrostatic discharge, among

others!

Provide suitable protective measures while handling open PCBs

(e.g., ESD clothing, environment free of dirt and grease).

Do not touch the contact surfaces.

Analog and binary signals can only be connected via one of terminal

modules XI6, RI6 or IO6. Installation is identical for all terminal modules.

You need:

• A Torx screwdriver TX10.

• The accessory enclosed with the terminal module.

Terminal module installation

1. Press the spring lock on the front cover lightly to unlock it.

2. Push the front cover down as far as it will go.

3. Remove the cover towards the front.

4. Insert the terminal module so that the recesses on the module and

the holding down mechanisms on the drive controller can be guided

past one another. The rear of the plug-in card must be resting

against the drive controller.

5. Push the terminal module up so that the pin contacts are pushed

into the female connector strip.

6. Fasten the terminal module onto the drive controller with the

fastening screw.

ID 442537.01 20WE KEEP THINGS MOVING

Installation

4

Commissioning Instructions SD6

4.4 Communication modules

WARNING!

Danger of personal injury and material damage due to electric

shock!

Always switch off all power supply voltage before working on the

drive controller! Note that the discharge time of the DC link

capacitors is 5 minutes. You can only determine the absence of

voltage after this time period.

CAUTION!

Danger of property damage due to electrostatic discharge, among

others!

Provide suitable protective measures while handling open PCBs

(e.g., ESD clothing, environment free of dirt and grease).

Do not touch the contact surfaces.

You will need the EC6 or CA6 communication module to connect

EtherCAT or CANopen. EC6 is installed on the upper slot, the same as

CA6. The installation is identical for both communication modules.

You need:

• A Torx screwdriver TX10.

• The cover and screw included with the communication module.

Installation of the communication module

1. Loosen the fastening screw for the dummy cover on the top of the

drive controller.

2. Push the communication module into the drive controller on the

guide rails.

3. Push the module in so that the pin contacts are pushed into the

female connector strip.

4. Insert the tips of the cover included with the communication module

into the recess in the front at an angle.

5. Set the cover down on the drive controller so that the tips are

resting under the edge.

6. Fasten the cover with the two screws.

Other manuals for SD6 Series

7

This manual suits for next models

10

Table of contents

Other Stober Controllers manuals

Stober

Stober SC6 Series User manual

Stober

Stober MC6 User manual

Stober

Stober SD6 Series User manual

Stober

Stober SD6 Series User manual

Stober

Stober SD6 Series User manual

Stober

Stober SC6 Series Training manual

Stober

Stober SC6 Series Training manual

Stober

Stober SD6 Series Training manual

Stober

Stober SD6 Series Training manual

Stober

Stober SR6 Training manual