Stober PHK User manual

Operating manual

Explosion-protected right angle servo gear units KL/KS/PHK/PHKX/PHQK/PK/PKX

101/2019

WE KEEP THINGS MOVING

ID 443005_en.01

en

www.stober.com

These operating instructions contain information about the

transport, assembly, commissioning and service of gear units

from STOBER. Observe the applicable documents of

attached motors and additional drive components.

1 Operation in accordance with its

intended use

Explosion-protected gear units from STOBER meet the

requirements of the ATEX Directive 2014/34/EU and comply

with the following standards:

• EN 1127-1:2011-07

• EN ISO 80079-36:2016-04

• EN ISO 80079-37:2016-04

The gear units are intended for installation in commercial

machines and systems. Intended use includes:

• Use of the gear unit exclusively for the application that it

was designed for.

• No modifications to the gear unit by the customer.

• Use of the gear unit only in the zone subject to explosion

hazard that corresponds to the identification on the ATEX

nameplate.

• Use of the gear unit in the surrounding temperature range

Ta that is specified on the ATEX nameplate.

• The maximum thickness of the dust deposit on the gear

unit may not be more than 5 mm according to EN 50281-

2-1.

• No overload of the gear unit with regard to the maximum

permitted speeds and torques that are specified in the

order confirmation.

• Compliance with the inspection and maintenance

intervals.

• Observe these operation instructions.

WARNING!

Unintended use of the gear unit can lead to explosions

that can cause serious injuries or even death.

Only use the gear unit as intended!

2 Safety information

WARNING!

Failure to comply with these operating instructions can

cause ignition sources when using the gear unit in areas

subject to explosion hazard and lead to explosions that

can cause serious injuries or even death.

Comply with the instructions in these operating

instructions!

Also follow the applicable national, local and system-specific

requirements.

CAUTION!

Burns!

The surface temperature of the gear unit can significantly

exceed 65° C in operation!

Allow the gear unit to cool down sufficiently before

touching it or wear protective gloves.

2.1 Ignition hazard and protective

measures

The following is an overview of ignition hazards that can arise

when operating the gear unit and protective measures that

are described in these operating instructions.

Ignition hazard: hot surfaces

Possible causes: increased friction due to improper

assembly, wear, overload or leaks.

Protective measures:

• Compliance with the maximum permitted torques and

speeds

• Limitation of the motor current

• Control before commissioning

• Measurement of the maximum surface temperature

during commissioning

• Regular inspection and maintenance

Ignition hazard: mechanically generated sparks

Possible causes: improper assembly of leaks

• Control before commissioning

• Regular inspection and maintenance

Ignition hazard: electrostatic discharge

Possible causes: friction processes, potential differences

between components

• Exclusive use of components with ATEX approval

• Earth the gear unit housing

2.2 Personnel requirements

All work on the electrical equipment of the drive units must be

performed by qualified electricians. Installation, maintenance

and repairs of mechanical parts must be performed by fitters,

industrial mechanics or persons with comparable

qualifications.

Operating manual

Explosion-protected right angle servo gear units KL/KS/PHK/PHKX/PHQK/PK/PKX

2

ID 443005_en.01

WE KEEP THINGS MOVING

01/2019

en

www.stober.com

3 Description of the gear unit

The technical data of the gear unit/geared motor can be found

in the order confirmation. This refers to the lubricant used that

is specified on the nameplate of the gear unit. Other technical

data as well as dimensional drawings can be found in the

appropriate catalog from STOBER.

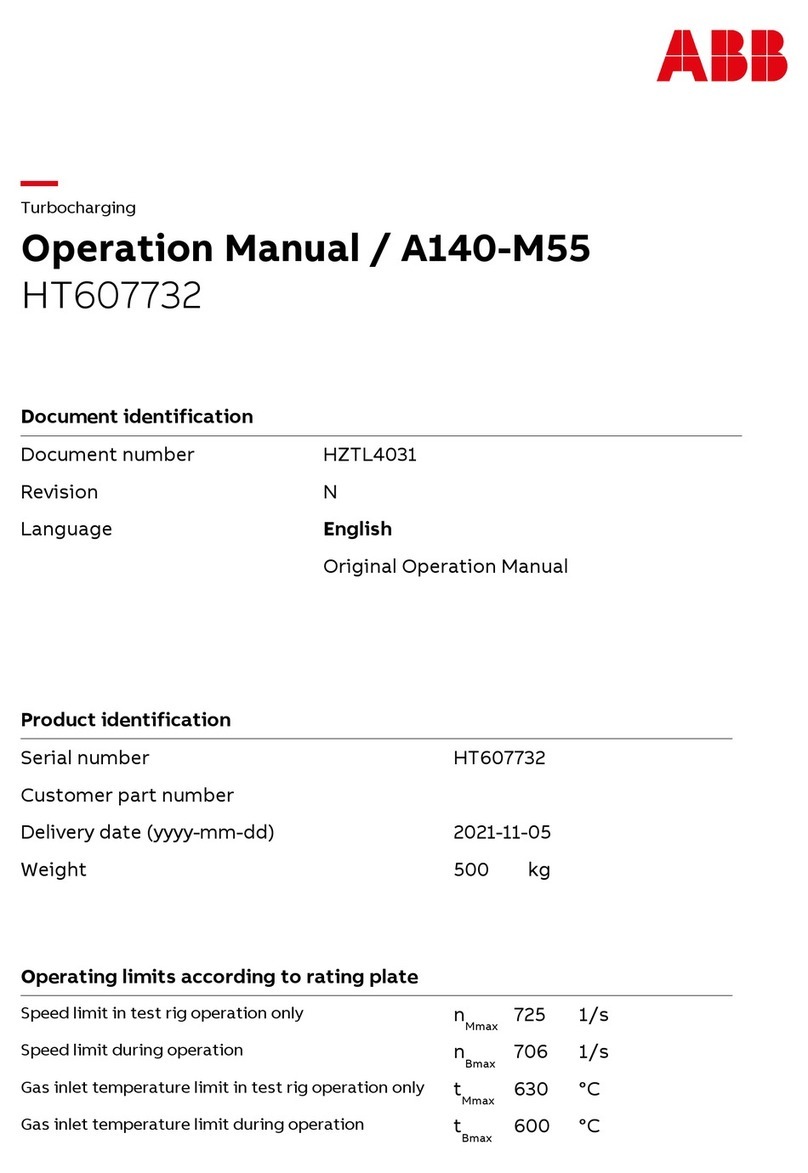

3.1 ATEX identification

The gear unit is identified on the ATEX nameplate as follows.

1) According to IEC 60079-10-X

4 Transportation and storage

When transporting the gear units/geared motors make certain

not to damage the shafts and bearings with impacts.

Use the ring screws on the gear unit housing for vertical

transport of the gear units. Sling the gear units without ring

screw with a suitable support cable directly on the gear unit

housing.

Note that ring screws are only intended for vertical transport

of the gear units without additional attachments. In addition

sling the motor mounted on the gear unit and make sure that

there is no diagonal pull.

If the ring screws are removed after assembly, permanently

seal the threaded holes according to the protection class of

the gear unit.

The gear units/geared motors may only be stored in

enclosed, dry rooms. Storage in open air areas with a roof is

only permitted for brief periods. Protect the gear units/geared

motors from all damaging environmental effects and

mechanical damage.

Avoid extreme temperature fluctuations with high relative

humidity when the gear units/geared motors are being stored

temporarily to prevent formation of water from condensation.

Long-term storage

If long-term storage is planned, protect the bare parts of the

gear unit against corrosion. Completely fill the gear unit with

lubricant that is specified on the nameplate. Reduce the

lubricant to the correct filling quantity according to the

nameplate before commissioning the drive.

5 Mounting

Inspect the delivery for any transport damage immediately

after you receive it. Notify the transport company of any

damage immediately. Do not operate damaged gear units/

geared motors.

Remove the packaging of the gear unit/geared motor and

dispose of it according to the applicable legal requirements on

site.

Check the following before installing the gear unit:

• Do the specifications on the ATEX nameplate of the gear

unit (gear group, category, EPL, temperature class and

maximum surface temperature) correspond with the

zone subject to explosion hazard where the gear unit is

to be used?

• Is the gear unit installed in a zone that is not subject to

explosion hazard?

• Do all drive and output elements to be mounted have

appropriate explosion protection?

NOTICE

The lip seals of the shaft seal rings can be damaged by

the use of solvents.

When removing the corrosion protection, make sure that

the lip seals of the shaft seal rings do not come into

contact with solvents.

Completely remove all corrosion protection on the shaft ends

prior to installation.

5.1 Installation positions

The version of the gear unit and the lubricant amount filled at

the factory is matched to the installation position of the gear

unit. The gear unit may therefore only be installed at the

installation position specified in the order confirmation. A sign

on the gear units shows which gear unit side must point

downwards.

II 2 G Ex h IIC T3 Gb

Identification according to

ATEX Directive

Identification according to

EN ISO 80079-36

Code Designation Explanation

Ex-symbol According to ATEX

Directive

II Device group

2

3

Device category

G

D

Type of explosive

atmosphere

Gas

Dust

Ex Ex-symbol According to EN ISO

80079-36

hCode letter for non-

electrical devices

IIC

IIIC

Explosion group Gases (such as hydrogen)

Combustible suspended

particles non-conductive

and conductive dusts

T3

T4

T200°

T120°

Temperature class For gases (max. 200°C)

For gases (max. 135°C)

For dusts (max. 200°C)

For dusts (max. 120°C)

Gb

Gc

Db

Dc

Equipment Protection

Level (EPL)

For zone 11

For zone 21

For zone 211

For zone 221

Operating manual

Explosion-protected right angle servo gear units KL/KS/PHK/PHKX/PHQK/PK/PKX

301/2019

WE KEEP THINGS MOVING

ID 443005_en.01

en

www.stober.com

5.2 Installation of gear unit

Mount the gear unit on an even, vibration-reducing and

torsion resistant substructure. Use screws of strength class

10.9 to fasten the gear unit KL, KS, PK, PKX . Use screws of

strength class 12.9 for all other gear units.

Fit the gear unit on the pilot (H7 fit).

Observe the following for assembly:

• Only for KL gear units with foot fastening: the housing

feet and attachment area may not be braced against

each other.

• The permitted shear and axial forces may not be

exceeded.

• Existing vent valves must be freely accessible.

• Earthing the gear unit housing via metal components of

the system must be ensured.

Gear units/geared motor with solid shaft; installation of

power transmission elements:

The output shaft is equipped with a centering thread

according to DIN 332, Sheet 2, which is provided both for

fitting and for axial mounting of transmission elements (gear,

chain wheel, pulley, coupling hub) by means of a central

screw. Shaft ends with a diameter up to 55 have tolerance

ISO k6, those larger than 55 have tolerance ISO m6. The

fitting keys correspond to DIN 6885, Sheet 1.

NOTICE

Damage to the bearing race.

Avoid all impacts to the output shafts.

Gear units/geared motor with hollow shaft and fitting key

connection:

a) Shaft-mounted gear units are mounted on the drive shaft of

the machine to be driven. The reactive torque must be

supported either by flange-mounting of the gear unit or a

torque bracket. If flange-mounted, the flange connection point

on the machine must not exceed a right-angle deviation to the

shaft axis of 0,03/100 mm (danger of distortion of bearings,

excessive bending strain on the machine shaft).For gear units

with a hollow shaft, always make sure that the machine shaft

is aligned with the hollow shaft of the gear unit (max. deviation

≤ 0.03 mm).b) The hollow shaft bore is designed according to

tolerance ISO H7 and the keyway according to DIN 6885

Sheet 1. The machine shaft must be ISO k6! The machine

shaft must have a centering thread according to DIN 332,

Sheet 2. The integrated fitting/push-off disk is provided for

axial mounting of the gear unit by means of a central screw.

Fitting the gear unit onto the machine shaft:

- Coat machine shaft with mounting grease

- Coat hollow shaft spiral groove and keyway with mounting

grease

- Fit gear unit by means of central screw. Do not use

hammer!

NOTICE

Rust on of the gear unit.

Never mount the gear unit without lubrication, since it will

rust on and cannot be removed for repairs.

Disassembly: Press the gear unit off by means of the push-

off disk and matching push-off screw. Support machine shaft

to keep it centered! If the shaft is stuck, we recommend

applying rust penetrating oil to the shaft ends in the key seat

for an extended period.

Gear units/geared motor with hollow shaft and shrink

disk:

The information under a) applies here as well and must be

observed! The description of the shrink disk connection and

the installation and safety instructions can be found in the

TECHNICAL INFORMATION SHEET “Installation

instructions for hollow shaft with shrink disk”.

5.3 Ventilation

The gear units are closed on all sides and are not vented.

6 Commissioning

6.1 Prior to commissioning

Check the following before commissioning:

• Is it ensured that the gear unit is adequately vented and

no external heat input (e.g. Via a coupling) is present?

The cooling air may not exceed a temperature of 40° C.

• For gear units with hollow shaft and shrink disk: were the

clamping bolts tightened to the specified torque? Is the

cover of the shrink disk properly mounted?

• Does the attached motor cover the full flange surface of

the motor adapter for gear units with motor adapters so

that IP65 protection class is provided?

• For gear units with motor adapter ME: is the clamp

coupling tightened to the specified torque? Is the plug

properly mounted?

• If ring screws were dismantled, are the holes sealed with

appropriate plugs?

• Is it ensured that no gear unit overload relating to the

permitted torque can occur due to the mounted motor?

(The permitted torque can be found in the order

confirmation.)

• When operating the attached motor at a drive controller:

is the drive controller parameterized so that a gear unit

overload is prevented?

WARNING!

Risk of injury due to moving parts!

Before switching on the drive, check the following:

Are no persons in danger due to start-up?

Is all protection and safety equipment properly installed,

in test operation too?

Is the drive not blocked?

Are the brakes released?

Is the direction of rotation of the drive correct?

Are components attached to the output such as feather

keys or coupling elements adequately secured against

centrifugal forces?

Operating manual

Explosion-protected right angle servo gear units KL/KS/PHK/PHKX/PHQK/PK/PKX

4

ID 443005_en.01

WE KEEP THINGS MOVING

01/2019

en

www.stober.com

6.2 During commissioning

As the operating conditions for gear units are very different, it

must be ensured for safe operation under maximum

operating conditions that the surface temperature of the gear

unit does not exceed the maximum permitted value. For this

purpose, take the following measurement with a standard

commercial temperature measurement device.

Determine the surface temperature at the gear unit/motor

transition where the terminal box position prevents ventilation

by the motor fan.

For gear units with a motor adapter or free drive shaft,

determine the surface temperature at the joining seam

between the gear unit flange on the input side and the

attachments.

The maximum surface temperature is reached after approx. 3

hours under full load and may not exceed the maximum value

of 90° C for the highest surrounding temperature. Stop the

drive immediately if the maximum value is exceeded and

contact STOBER Service.

7 Service

7.1 Inspection and maintenance

To ensure safe operation with regard to explosion protection,

carry out the following inspections and maintenance work at

the specified intervals:

Daily or according to dust accumulation

• Remove dust deposits from the gear unit surface

(STOBER recommends removing dust deposits with a

thickness of 1 mm or more)

Every 500 operating hours, every 3 months at the latest

• Visually check the shaft seal rings for leaks

• Check operating noise for possible bearing damage

Every 5000 operating hours, every 5 years at the latest

• Replace lubricant

• Replace shaft seal rings

Every 10000 operating hours

• Replace rolling bearing

Comply with the lubricant specification and amount that is

stated on the nameplate of the gear unit when changing the

lubricant. Do not mix lubricants with different specifications.

7.2 In the event of disruptions

Changes compared to normal operation indicate that the

function of the drive has been impaired. This includes:

• Higher power consumption, temperatures or vibrations

• Unusual noises or odors

• Leaks on the gear unit

• Monitoring devices responding

In this case, stop the drive as quickly as possible and contact

STOBER Service.

7.3 Contact

STOBER Service will be happy to help you:

• If you have queries about the product

• In the event of a fault

• Carrying out maintenance work

• If you need spare parts.

Have the serial number and the type designation of the gear

unit ready when you contact us. This can be found on the

nameplate of the gear unit.

For spare part orders, you will also need the item number of

the spare part in the relevant spare parts list.

Contact data Parent company Germany:

STÖBER ANTRIEBSTECHNIK GmbH & Co. KG

Kieselbronner Str. 12

75177 Pforzheim

Service Hotline +49 7231 582-3000

mail@stoeber.de

Contact data Subsidiary USA:

STOBER Drives Inc.

1781 Downing Drive

Maysville KY 41056

Service Hotline +1 606 563-6035

service@stober.com

7.4 Disposal

This product contains recyclable materials. Observe local

applicable regulations for disposal.

This manual suits for next models

6

Other Stober Industrial Equipment manuals