Stoneridge SE5000 Use and maintenance manual

Stoneridge - Setting the standard

www.SE5000.com

SE5000 Digital Tachograph

Ready to

drive

Control Manual

Important

Important

The Stoneridge tachograph SE5000 Rev 7.4 has full

type approval for use in the European union accord-

ing with Commission Regulation (EC) No.

1360/2002 of 13 June 2002 and other related leg-

islatives.

The Approval Certificate number is e5-0002. This

number will be indicated on all Stoneridge tacho-

graph.

The tachograph fulfils the requirements of UNECE

regulation number 10, revision 03, approval No

03XXX, in respect of electromagnetic compatibility.

Contact Stoneridge

You are welcome to forward any queries or sug-

gestions you may have about the Tachograph and

the operating instructions to any of our sales offices,

as listed below.

United Kingdom

Stoneridge Electronics Ltd

Charles Bowman Avenue

Claverhouse Industrial Park

Dundee, Scotland

UK

Phone: +44 (0)1382 866 400

Fax: +44 (0)1382 866 401

E-mail: amsales@stoneridge.com

France

Stoneridge Electronics France

Z.I St. Etienne

F-64100 Bayonne

France

Phone: +33 (0)5 59 50 80 40

Fax: +33 (0)5 59 50 80 41

E-mail: france.amsales@stoneridge.com

Germany

IVEKA Automotive Technologies

Schauz GmbH

Talweg 8

D-75417 Mühlacker-Lomersheim

Germany

Phone: +49 (0)7041 9695-0

Fax: +49 (0)7041 9695-55

E-mail: info@iveka.de

Italy

Stoneridge Electronics s.r.l.

Viale Caduti nella Guerra di Liberazione, 568

00128 Rome

Italy

Phone: +39 06 50 86 10 01

Fax: +39 06 50 86 10 06

E-mail: italy.amsales@stoneridge.com

Netherlands

C.A.S.U. - Utrecht b.v.

Ravenswade 118

NL-3439 LD Nieuwegein

Netherlands

Phone: +31 (0)30 288 44 70

Fax: +31 (0)30 289 87 92

E-mail: info@casuutrecht.nl

Spain

Stoneridge Electronics España

Avda. Severo Ochoa 38

Pol. Ind. Casa Blanca

28108 Alcobendas

Madrid

Spain

Phone: +34 91 662 32 22

Fax: +34 91 662 32 26

E-mail: spain.amsales@stoneridge.com

Sweden

Stoneridge Nordic AB

Gårdsfogdevägen 18 A

SE-168 66 Stockholm

Sweden

Phone: +46 (0)8 154400

Fax: +46 (0)8 154403

E-mail: info@stoneridgenordic.se

Tachograph Version

Digital Tachograph SE5000 Rev 7.4.

Internet Information

Further information about Stoneridge Digital Tacho-

graph SE5000 and about Stoneridge Electronics Ltd

can be found at:

www.se5000.com

www.stoneridgeelectronics.info

Copyright

This manual must not be reprinted, translated, or

otherwise reproduced in whole or in part, without

written permission from Stoneridge Electronics AB.

- 1 -

Important

Blank Page

- 2 -

Table of Contents

Table of Contents

Important 1

Contact Stoneridge 1

United Kingdom 1

France 1

Germany 1

Italy 1

Netherlands 1

Spain 1

Sweden 1

Tachograph Version 1

Internet Information 1

Copyright 1

Blank Page 2

Table of Contents 3

Blank Page 4

Introduction 5

The Control Card 5

Don't open the Case 5

Blank Page 6

Overview 7

Encrypted Motion Sensor (1) 7

Digital Tachograph (2) 7

Display in Instrument Cluster (3) 7

Control and Driver Card (4) 7

Blank Page 8

User Interface 9

Blank Page 10

Downloading Data 11

General 11

Download Equipment 11

Control Card 11

Inserting a Control Card 11

Eject a Control Card 11

Storing Data 11

Storing Data on the Control Card 11

Storing Control Activities in the Tachograph 12

Downloading Data 12

System Inspection 13

General 13

Visual Check 13

Inspection Procedure 13

Installation Plaque 13

Checking Second Source Motion Sensor 14

Pictograms 15

Symbols 15

Symbol Combinations 15

Blank Page 16

Printouts 17

Printout Examples 17

18

Technical Data 18

Events and Faults (VU) 19

Details of Events and Faults (VU) 20

Events and Faults (card) 20

Daily Printout (card) 21

Daily Printout (card) continued 21

Daily Printout (VU) 22

Daily Printout (VU) continued 22

Overspeeding 23

Blank Page 24

Display Messages 25

- 3 -

Table of Contents

Blank Page

- 4 -

Introduction

Introduction

This manual concerns the control mode of oper-

ation. However, knowledge of the operational mode

of the unit is also required in case of driving a tacho-

graph fitted vehicle.

A Stoneridge tachograph can be operated in one of

four modes of operation:

lOperational (driver card or no card inserted)

lControl (control card inserted)

lCalibration (workshop card inserted)

lCompany (company card inserted)

Company Lock-in/Lock-out details can be used to

identify the true owners of blocks of stored tacho-

graph data. Enforcement officers should encourage

companies to Lock-in tachograph data as it not only

identifies their company as the owner of the data,

but also prevents third party company card owners

from viewing or downloading their data.

Also, when transferring ownership of a tachograph

to another company, the current tachograph owner

must Lock-out the data before transfer of the tacho-

graph. Thus any future data stored after the Lock-

out would be clearly identified as not applying to

them.

Due to data protection laws, care must be taken to

ensure that the tachograph data is not downloaded

and passed on to third parties without the per-

mission of the tachograph owner.

The control card can be inserted in either of the

trays. If control cards are inserted in both trays the

card in tray 1 will be used for the control operation

and the card in tray 2 will be ignored.

The Control Card

lMust be obtained via an application to the relevant

authorities.

lIs valid for 2 years only.

lWill only be issued to enforcement officers or

enforcement authorities.

lAre personal to the enforcement officer and

authority and is not transferable.

lAllows read-only access to data stored in the driver

card or in the tachographs internal memory respec-

tively.

lCan store a minimum of 230 records of displaying

and/or printing and/or VU downloading and/or

card downloading. The maximum number of rec-

ords is dependent on the card type. When the

upper limit is reached the oldest data will be over-

written.

Note!

Extra care must be taken to ensure that only the

authorised owner of a control card has access to

it at all times.

Don't open the Case

The tachograph has been installed by authorised per-

sonnel.

A tachograph case must never be opened. No tam-

pering with or modifications to the tachograph sys-

tem are permitted. A tamper label is placed inside the

printer housing. The tamper label must not be torn

apart.

Here you can see where the tampering label is placed

and how it looks when it is untouched.

A tampered label might look like this.

Note!

Unauthorized persons that modify this equipment

are committing a punishable offence, depending

on the legislation in the country concerned.

- 5 -

Introduction

Blank Page

- 6 -

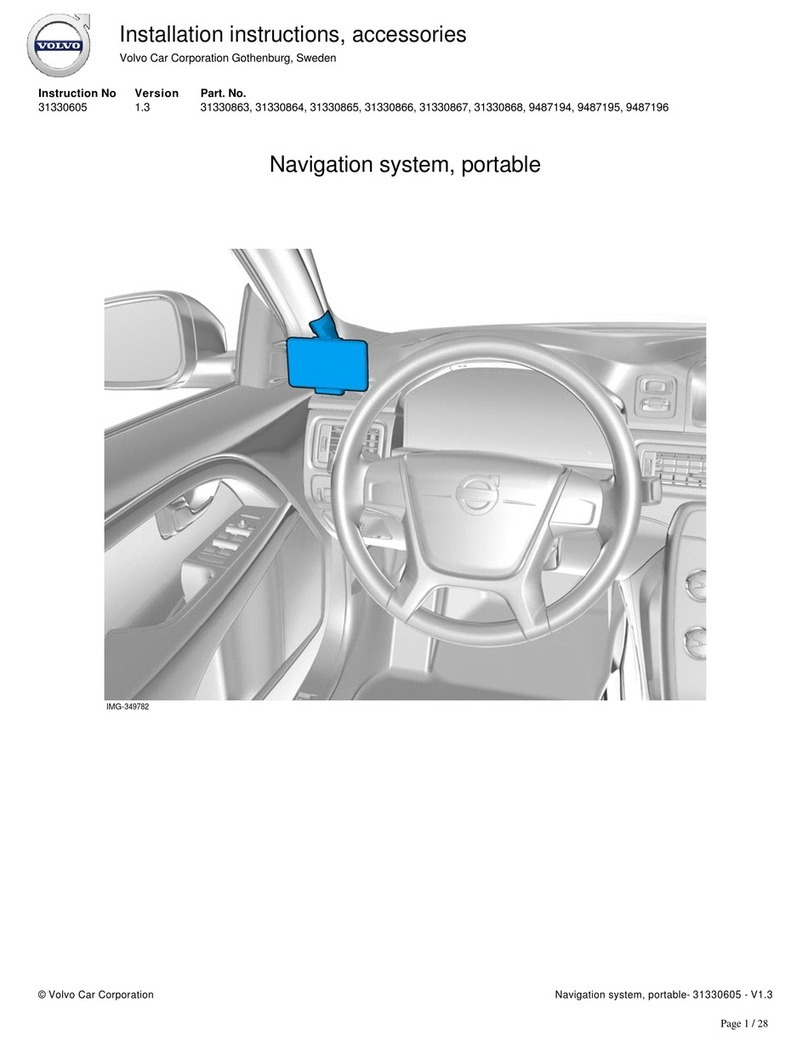

Overview

Overview

The Tachograph installation.

1

2

4

3

1. Encrypted motion sensor

2. Digital tachograph, with integrated display and

printer

3. Display in vehicle’s instrument cluster

4. Card

Encrypted Motion Sensor (1)

Used to provide the tachograph with speed signal

pulses from the vehicle gearbox. To ensure the integ-

rity of the speed sensor signal, the speed signal is

transferred between the sensor and the tachograph

in an encrypted form. Encrypting the speed signal

ensures that any tampering with the signal will be

detected and recorded.

Digital Tachograph (2)

The tachograph records and stores various data:

lWorkshop or driver card data.

lWarnings and malfunctions relating to tachograph,

driver, company and workshop.

lVehicle information, odometer data and detailed

speed.

lTampering the tachograph. For more information

on the tachograph, see the Driver & Company

Manual.

Display in Instrument Cluster (3)

The display in the instrument cluster can be used to

display information passed from the tachograph,

such as speed (speedometer) and distance travelled

(trip and odometer).

Control and Driver Card (4)

The following cards dedicated for specific usage can

be used in the tachograph:

lDriver card - records the drivers activities.

lControl card - authority control and inspection.

lWorkshop card - calibration mode.

lCompany card - hauliers and vehicle owners, down

loading and storage of data.

Note!

All cards are personal and may not be used by

anyone else but the rightful card holder.

- 7 -

Overview

Blank Page

- 8 -

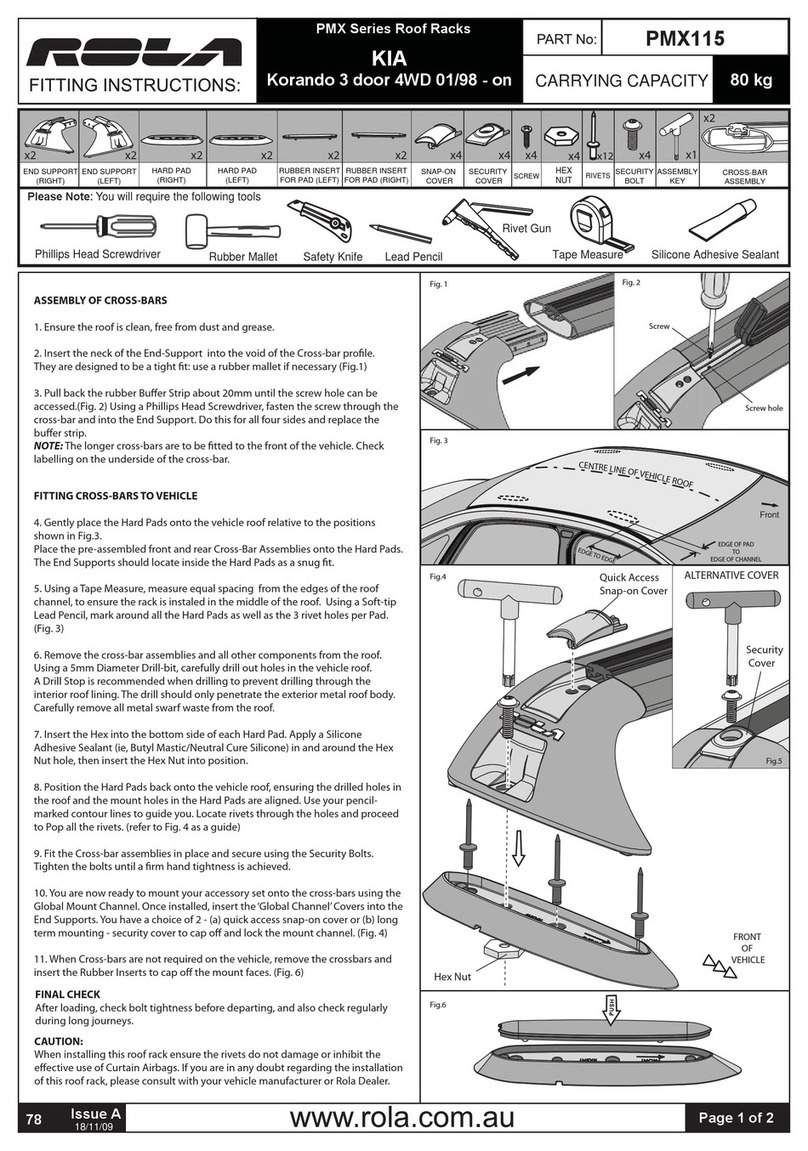

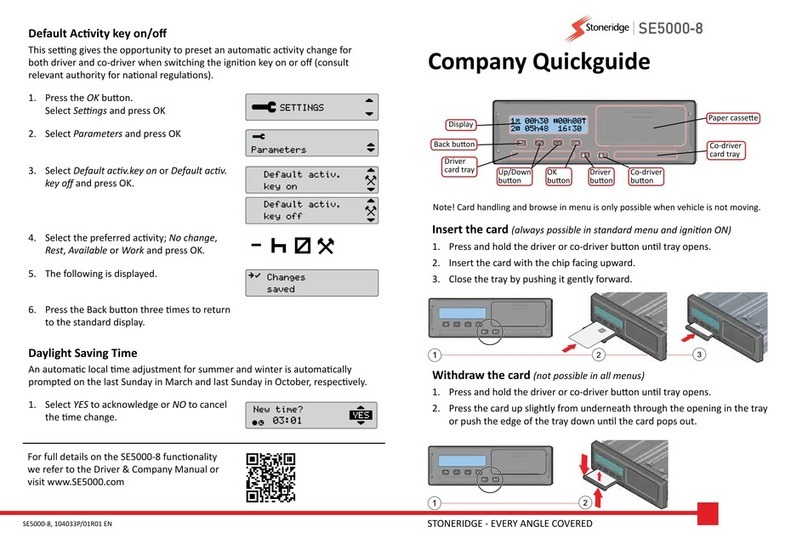

User Interface

User Interface

The tachograph detailed within this manual com-

prises two card tray mechanisms, a printer, an LCD

display, a calibration/download interface (6-pin con-

nector located behind paper cassette) and user con-

trols, located in an ISO standard radio enclosure.

This type of enclosure enables mounting in a variety

of locations, ensuring that insertion and removal of

the driver cards and operation of the controls can be

easily achieved by an operator.

The tachograph complies with EU Regulations and

displays and records speed and distance in metric

units (kilometres per hour and kilometres respec-

tively).

The tachograph also incorporates an internal clock,

which is used to indicate the current time on the

tachograph display. The tachograph is available for

use in both 12 and 24 V vehicle systems.

1

78

345 6

00h30

05h48

00h00

16:30

1. Display

2. Printer, 6-pin calibration/download connector,

behind the paper cassette

3. Driver card tray

4. Cancel button

5. Up button

6. Down button

7. Enter button

8. Driver button

9. Co-driver button

10. Co-driver card tray

- 9 -

User Interface

Blank Page

- 10 -

Downloading Data

Downloading Data

General

An enforcement officer can download data from a

digital tachograph system. Downloading means the

copying, together with a security digital signature, of

a partial or a complete set of data that is stored in the

memory of a tachograph or on a driver card.

The download must be done to aid investigations

into “Drivers Hours” legislation checks and to aid

determination of the validity of the digital tacho-

graph systems. When carrying out “Drivers Hours”

investigations, care must be taken to identify the true

owners of blocks of stored tachograph data.

Dedicated download equipment or a valid control

card is essential for the downloading of the data

stored in the tachograph or on the driver card.

Download Equipment

Behind the paper cassette is a 6-pin connector

located. This is where the required downloading

equipment is connected.

Control Card

A valid control card is required to download or to

view driving data stored on either an inserted driver

card or in the tachographs data memory. The control

card provides read-access to the entire tachograph

data memory contents whether or not the data has

been company locked using a valid company card.

Inserting a Control Card

Insert the control card in either of the trays (No. 1 in

our example).

1. Press and hold button 1on the tachograph until

the tray is opened.

2. Insert the card with the chip facing forward and

upwards.

3. Close the tray by pushing it carefully forward.

The control card must be inserted to identify the

controller/user.

4. Close the tray by pushing it in carefully. The

tachograph now processes the control card data.

If the control card authentication fails, see heading

Display Messages on page 25.

The card tray is locked when the vehicle is in

motion, while the tachograph is busy processing the

control card and if the power supply to the tacho-

graph is interrupted.

Eject a Control Card

1. Press button 1or 2on the tachograph and hold it

until the tray opens.

2. Press the card up slightly from underneath

through the opening on the tray, or push the

edge of the tray down until the card pops out.

3. Close the tray by pushing it carefully forward.

Note!

Withdrawal of the Control Card is not possible in

all menus.

Storing Data

When a control card is inserted into a tachograph in

order to perform a control activity, a record of the

control activity is stored on the control card and in

the tachograph as described below. The type of con-

trols that can be performed are displaying, down-

loading or printing data from the tachograph and/or

the card.

Storing Data on the Control Card

On the control card a single record will be stored.

This record contains the following:

lThe card number.

lThe issuing Member state, issuing authority name

and the issue date.

lThe card validity date.

lThe control body name and address.

lThe surname and forename of the card holder.

lThe preferred language.

Each time a control card is used to carry out a con-

trol activity the following data is stored on the con-

trol card:

lThe date and time of the control activity.

lThe type of control activity performed.

lThe period downloaded, if applicable.

lThe VRN (Vehicle Registration Number) and

Member State registering authority of the con-

trolled vehicle.

lThe card number and card issuing Member State,

in case of controlling a card.

- 11 -

Downloading Data

Storing Control Activities in the

Tachograph

Each time a control card is used to carry out a con-

trol activity a record of the activity is stored in the

tachograph. The data in each record is:

lDate and time of the control.

lThe control card number and card issuing Member

State.

lThe type of control.

Note!

In case of downloading, the date of the oldest

and most recent days downloaded must also be

recorded.

Downloading Data

To download data do the following:

1. Remove the paper cassette.

2. Attach the download equipment to the tacho-

graph through the 6-way front download con-

nector.

3. Start downloading data according to the instruc-

tion on the download equipment.

When the download is completed, the following

message will be displayed.

Download complete

If the download process has failed and is incomplete

the following message will be displayed:

Download failed

If the download fails:

4. Remove the control card.

5. Check the connections.

6. Check the download equipment.

7. Re-insert the control card and redo the process

until downloading is made.

If the data download cannot be completed and the

following message is displayed:

Download fault

The tachograph is found to be the cause or if it is

unsure whether the card or the tachograph is faulty,

the vehicle must be taken to a Tachograph Work-

shop for investigation.

- 12 -

System Inspection

System Inspection

General

The control function involves a number of different

functions associated with the digital tachograph sys-

tem. A tachograph inspection is done to ensure that

it still meets the EU legislation requirements.

For example, downloading and checking the data

stored on either the driver card or in the tachograph

internal memory, and an inspection of the tacho-

graph system.

Note!

If any unit fails the inspection the vehicle must be

taken to a Workshop for further investigation.

Visual Check

1. Ensure that there is no damage to or drill-holes in

the entire exterior casing including underneath

rubber acorn, which would imply a tampering

attempt.

2. Check for evidence of tampering with the seals

and labels.

3. Check for additional seals and labels that do not

belong to the tachograph, as they might cover

drill-holes. There should be only one label on the

tachograph.

4. Check that the heat seals is present.

5. Check the tachograph type approval mark.

6. Check that the predetermined breakpoints are

unbroken.

1

1. Predetermined breakpoint.

7. Check that all tachograph system seals are intact.

8. Confirm the presence of the installation plaque.

9. Check that the label and Stoneridge logotype hol-

ogram is present and in one piece. The position

of the label is shown in the illustration below.

Two different seals are used.

Inspection Procedure

Follow this procedure to confirm that the function

of the recording equipment is correct:

1. Check that the operation of the recording equip-

ment including data storage on cards is sat-

isfactory.

2. Determine that the tachograph operates within

maximum tolerances for both speed and dis-

tance.

3. Compare that the actual circumference and tyre

size corresponds with the information on the

installation plaque.

4. Check the internally stored calibration factors

according to the installation plaque with a tech-

nical printout.

5. Check the internally stored vehicle parameters,

VIN (Vehicle Identification Number) and VRN

(Vehicle Registration Number) and compare to

the actual vehicle data with a technical printout

6. Check the correctness of the UTC time.

Note!

If the UTC time is inaccurate by more than 20 min-

utes, the vehicle must be taken to a workshop for

recalibration.

Installation Plaque

The final part of the digital tachograph system instal-

lation procedure is the completion and fitment of an

installation plaque.

The installation plaque must be clearly visible and

easily accessible. The installation plaque is normally

placed on the recording equipment, the vehicle's "B"

pillar or the doorframe on the driver's side of the

vehicle.

The installation plaque state the following:

lConstant of the tachograph, K factor (imp/km).

lEffective circumference of the wheel tyres, L fac-

tor (mm).

- 13 -

System Inspection

lCharacteristic coefficient of the vehicle, W factor

(imp/km).

lTyre size.

lVehicle Identification Number (VIN).

lName, address or trade name of the approved fitter

or workshop.

lDate of calibration.

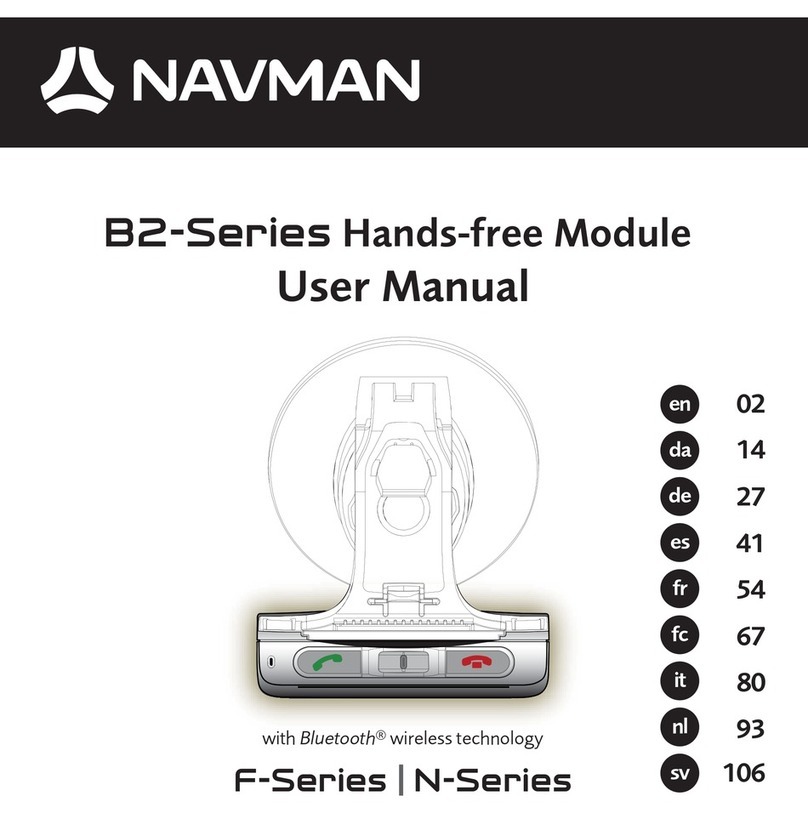

Checking Second Source Motion

Sensor

If the tachograph system is required to have a sec-

ond motion sensor this section describes how this

shall be checked. Checking can be carried out by

viewing the Motion Sensor View.

With the control card inserted, press the arrow down

button several times until you reach the last view,

which is the Motion Sensor View. See position (3)

below to check if a second source motion sensor is

present.

Note!

If second source of motion function is disabled

this view will not be shown.

34

2

1

1 045Km/h

2 050Km/h 27

1. Primary Motion Sensor speed.

2. Indicates motion. If this pictogram is shown ( - ),

no motion is detected.

3. Second source of motion speed. The digits

shows the speed indication of the second

source.

If these characters (- - -) are shown instead of

the digits, the tachograph does not receive sig-

nals from a second source motion sensor.

4. Fault number.

- 14 -

Pictograms

Pictograms

Symbols

This is a list of the most frequently shown symbols

on the display and on the printouts.

Symbol Description

Function not available

Driver or slot

Co-driver or slot

Card

Eject

Work

Driving/driver (mode of Operation)

Rest/break

Available

Ferry / train crossing

OUT Out of scope, -i.e. no recording is

required

Local time/location

Start of daily work period

End of daily work period

Break

From or to

Printer, printout

Paper

Display

Processing, please wait

Time, clock

UTC UTC time

24h Daily

|Weekly

|| Two weeks

Total/summary

Speed

Over speeding

Faults

!Events

?Pre-warning/question/unknown activity

Workshop

Company

Controller

Manufacturer

Security

External storage/download

Buttons

Finished

Tachograph (VU), vehicle

Tyre size

Sensor

Power supply

Print

Print, submenu

Company lock

Places

Places, sub menu

Settings

Symbol Combinations

The following combination of symbols are the most

common.

Symbols Description

Location start of daily work period

Location end of daily work period

From time (UTC)

To time (UTC)

Local time

Crew driving

Driving time for two weeks

OUT

Out of scope - begin

OUT

Out of scope - end

Cumulative driving time of current day

Printer low temperature

Printer high temperature

No card

Driver card

Workshop card

Company card

Control card

Control place

From vehicle

- 15 -

Pictograms

Blank Page

- 16 -

Printouts

Printouts

The information stored on the tachograph and on the driver cards can be printed. There are a number of dif-

ferent printouts available, see below.

1. Press OK to show the menu and select:

PRINT

1. Press OK and select the type of printout to make. Then press OK.

Some types of printouts require specification of the driver card and a date. If so the following is displayed:

Select card 1 or 2

2. Select 1to make a printout for the current driver's card or 2to make a printout for a co-driver's card. The fol-

lowing is displayed:

Select date

3. Select the desired date by using the arrow buttons and press OK.

4. Now you select whether to view the data on the display only or to make a printout on paper.

lTo view the data on the display only, select:

display

lPress OK and scroll through the data using the arrow buttons and then press OK to return.

lTo make a printout on paper, select

printer

lPress OK. The display will show:

Printer busy

lIf you would like to cancel the process, press and hold the Back button. Wait until the message is cleared

and then pull the printout upwards to tear it off.

Note!

To avoid paper jam make sure the slot on the paper cassette is not blocked.

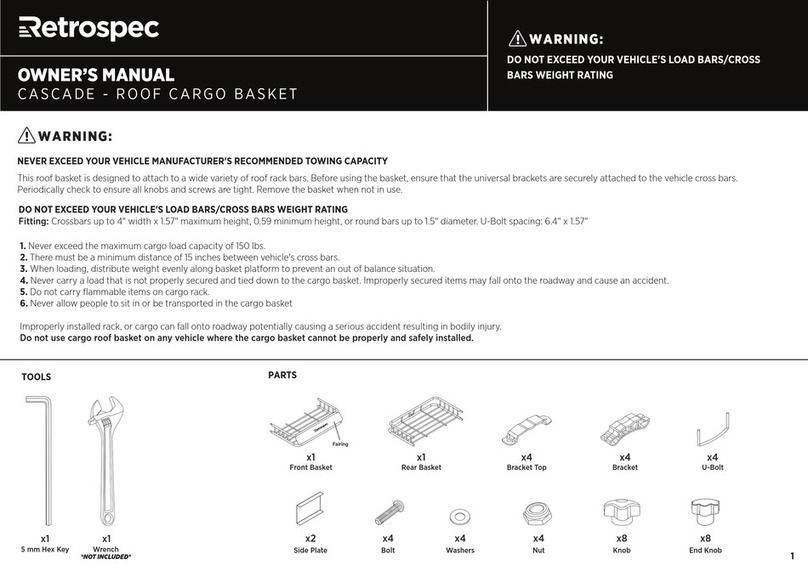

Printout Examples

On the following pages there are a number of printout examples that can be selected from the PRINTmenu:

lDaily printout (card) 24h card (including local time).

lEvent and faults (card) event card.

lEvent and faults (VU) event vu.

lDrive Time Info drive time info

lTechnical data technical data.

lOverspeeding overspeeding.

lVehicle speed vehicle speed.

lEngine speed (rpm) engine speed.

lStatus D1/D2 status D1/D2.

lManual Entry Sheet man entry sheet.

- 17 -

Printouts

Technical Data

This printout list data as speed settings, tyre

size, calibration data and time of adjust-

ments.

The display shows the following (on the sec-

ond line):

technical data

12

4

3

6

1

5

2

8

10

7

9

11

Stoneridge Electronics

Adolfsbergsvägen 3

S70227 örebro

900208E7.3/01R01

ABCD1E2345678910

19/10/2010 08:41 (UTC)

NL /AA-BB-12

SVN31309

1234567890/7878/06/A2

1234567890/1006/07/A1

2010

vP477 31/07/2010

Stoneridge

Andersson

Richard

S /00007001106910 0 0

23/05/2015

14

13 e1-175

05/08/2010

22

20

24

26

23

21

19

18

17

16

15

25

27

w

k

l

29

30

28

ABCD1E2345678910

NL /AA-BB-12

S /12345678901012 1 0

Johansson and Sons

123 45 BROMMA

31/08/2016

06/08/2010 (2)

9 150 Imp/km

9 150 Imp/km

3 331 mm

w

k

l315/80R22.5

89 km/h

0 km; 26 km

15 km; 15 km

S /12345678901012 1 0

31/08/2016

05/08/2010 (1)

?????????????

9 150 Imp/km

9 150 Imp/km

3 331 mm

315/80 R22.5

89 km/h

STONERIDGE ELECTRONICS

168 66 BROMMA

NL /AA-BB-12

33

34

32

31

S /12345678901012 1 0

19/10/2010 08:40

19/10/2010 08:40

!!x

x

06/08/2010 10:40

06/08/2010 10:41

!

Johansson and Sons

123 45 BROMMA

1. Date and time.

2. Type of printout (technical data).

3. Cardholder ID.

4. Vehicle Identification Number (VIN).

5. Vehicle Registration Number (VRN) and country of

registration.

6. Tachograph manufacturer.

7. Tachograph part number.

8. Tachograph approval number.

9. Tachograph serial number, date of manufacture,

type of equipment and code of manufacturer.

10. Year of manufacture.

11. Software version and installation date.

12. Motion sensor serial number.

13. Motion sensor approval number.

14. Date of first installation of motion sensor.

15. Workshop having performed the calibration.

16. Workshop address.

17. Workshop card identification.

18. Workshop card expiry date.

19. Calibration date and purpose.

20. VIN

21. VRN and country of registration.

22. Characteristic coefficient of vehicle.

23. Constant of the recording equipment.

24. Effective circumference of wheel tyres.

25. Vehicle tyre size.

26. Authorized speed setting.

27. Old and new odometer values.

28. Calibration date and purpose.

29. VIN.

30. VRN and country of registration.

31. Old date and time (Before time adjustment).

32. New date and time (After time). adjustment

33. Most recent event time.

34. Most recent fault date time.

- 18 -

Other manuals for SE5000

8

Table of contents

Other Stoneridge Automobile Accessories manuals

Stoneridge

Stoneridge ORLACO Sets MirrorEye MP User guide

Stoneridge

Stoneridge SE5000-8 RG User manual

Stoneridge

Stoneridge Optac 3 User manual

Stoneridge

Stoneridge MirrorEye 0416100 User guide

Stoneridge

Stoneridge SE5000 User manual

Stoneridge

Stoneridge SE5000-8.1 User manual

Stoneridge

Stoneridge SE5000-8 User manual

Stoneridge

Stoneridge ELD1.0 User manual