Strack PowerMax SN5650-PMO-0065 User manual

CAM UNIT

SN5650-PMO-0065

—

SN5650-PMO-0260

OPERATING INSTRUCTIONS

PowerMax

2STRACK NORMA GmbH & Co. KG · Königsberger Str. 11 · D-58511 Lüdenscheid · Tel +49 2351 8701-0 · www.strack.de

08.2018

IOperating instructions -- PowerMax cam unit PMO

PowerMax

Content: Seite:

Preamble 3

1. Safety instructions. Please absolutely consider! 4

2. After receipt of delivery 5

3. Characteristics 6

3.1 Description of the construction types 7

4. Scope of delivery 7

5. Design of the PowerMax side cam 8

6. Preparation of tool and press 9

7. Shouldering 9

8. Production 10

8.1 Handling 11

8.1.1 Handling with safety ring bolt adapter (SN5650-PMO-SRA) 11

8.1.2 Handling with safety ring bolt (SN1594) 14

8.2 Marking of the cams 15

9. Dismounting of the mounting plate at cam widths 0065-0260 (only Premium) 16

9.1 Mounting of the mounting plate at cam units 0065-0260 (only Premium) 17

10. The Lock-Out-Systems 18

10.1 Lock-Out-System 5651-LOS 19

10.1.1 Mounting of the Lock-Out-System 5651-LOS 20

10.2 Lock-Out-System 5654-LOS 22

10.2.1 Information of the Lock-Out-System 5654-LOS 25

11. Dismounting / Mounting of the gas springs 26

12. Modification of the system pressure of the gas springs 27

12.1 Discharging of the pressure at a gas spring 27

12.2 Increase of the pressure / charging of a gas spring 28

13. Standstill and storing 30

14. Maintenance 30

14.1 Adjustment of the active return 31

14.2 Comparison bronze with solid lubricant and SNS sinter guiding elements 32

15. Appendix 35

15.1 Internet and CAD 35

15.2 General description of gas springs 36

15.3 Maximal operating conditions for gas springs 37

15.4 Calculations gas springs 38

15.5 Mounting instructions gas springs 39

15.6 Filling pressure list gas springs 40

16. Exploded view and item list 44

3

STRACK NORMA GmbH & Co. KG · Königsberger Str. 11 · D-58511 Lüdenscheid · Tel +49 2351 8701-0 · www.strack.de

08.2018

IOperating instructions -- PowerMax cam unit PMO

PowerMax

PowerMax cam unit SN5650-PMO-0065 — SN5650-PMO-0260

Preamble

Thank you for the confidence in the product of STRACK NORMA GmbH & Co. KG

We are pleased about your decision to buy a product of STRACK. To facilitate the handling with the product,

we established these operating instructions.

The operating instructions are an important element to the side cam unit SN5650-PMO and provide the

secure and efficient operating. It is intended for all persons which are working with these cam units and

which are responsible for the secure operating.

For reasons of the operating safety a copy of these operating instructions has to be left at the side cam unit

to guarantee the direct access for the operating personnel.

The security advices in the operating instructions have particularly been respected to recognize and to avoid

possible dangers. Please read the operating instructions carefully and completely before mounting and initial

operation of the side cam unit SN5650.

A regular maintenance is necessary to guarantee a secure and economic application.

If the instructions and advices of these operating instructions are not observed, any liability on our part for

resulting damages and performance losses will be excluded.

4STRACK NORMA GmbH & Co. KG · Königsberger Str. 11 · D-58511 Lüdenscheid · Tel +49 2351 8701-0 · www.strack.de

08.2018

IOperating instructions -- PowerMax cam unit PMO

PowerMax

PowerMax cam unit SN5650-PMO-0065 — SN5650-PMO-0260

1. Security advices. Please absolutely consider!

Before mounting and initial operation and all further works at the STRACK PowerMax cam please

absolutely read the following safety instructions.

The cam has to be used according to these operating instructions. If new operating instructions will be

established, this version loses its validity.

Service and maintenance works at the mounted STRACK nitrogen-gas springs may only be effected by

persons trained and instructed by STRACK NORMA with good professional knowledge.

If the mounted STRACK nitrogen-gas spring is used incorrectly or not for the intended application, menace:

Dangers for the health

Dangers for the STRACK nitrogen-gas springs

and other property holdings of the operator,

Dangers for the efficiency of the STRACK nitrogen-gas springs.

For all operations at the STRACK side cam, the valid Ordinance on Industrial Safety and Health paragraph 3

has to be considered.

Press, tool and peripheral devices have to be suited, prepared and adjusted for the application of the

STRACK side cams.

Attention:

Before and during the service- and maintenance operations at the tool respectively

at the STRACK cam there is an increased risk of accident. Therefore these operations

may only be effected at cam units which are driven back.

Seized cam units at faultless gas springs can cause an abrupt decompression.

Thus they can be an injury risk.

Damaged gas spring may not be used again. The exchange of individual parts has to be agreed with STRACK

NORMA.

5

STRACK NORMA GmbH & Co. KG · Königsberger Str. 11 · D-58511 Lüdenscheid · Tel +49 2351 8701-0 · www.strack.de

08.2018

IOperating instructions -- PowerMax cam unit PMO

PowerMax

PowerMax cam unit SN5650-PMO-0065 — SN5650-PMO-0260

2. After receipt of delivery

Before opening, please check the delivery concerning damages. Please reclaim damages directly at the

transport company, which has delivered the consignment.

Please compare the content of the consignment with the delivery note respectively the enclosed list of items

(see appendix). Please also ascertain that all parts are present and unpacked.

Not till then dispose of the transport- and packing material.

If the content is damaged without visible damage of the packing material, please do not return it for repair

or exchange.

Please contact STRACK NORMA GmbH & Co. KG, Lüdenscheid, to get further information.

Phone: 02351 / 8701 – 0 reception

– 252 Mr. Müller

6STRACK NORMA GmbH & Co. KG · Königsberger Str. 11 · D-58511 Lüdenscheid · Tel +49 2351 8701-0 · www.strack.de

08.2018

IOperating instructions -- PowerMax cam unit PMO

PowerMax

PowerMax cam unit SN5650-PMO-0065 — SN5650-PMO-0260

3. Characteristics

The execution of this STRACK cam unit is a “side cam unit type SN5650”.

These cams can be mounted: - without mounting plate as “Basis” and “Medium” version

- with mounting plate as “Premium version”

These PowerMax cam units consists of:

- cam retainer

- cam body

- driver

with the corresponding accessories

All PowerMax cam units are equipped with gas springs.

In this system, nitrogen with a purity grade of ≥99.8 vol.-% is used as active fluid medium for the

gas springs.

The cylinder dimension, cylinder number and filling pressure (different at the diverse cam types)

determine the reset force which is available.

Please consider that all PowerMax cam units are the successful result of a long development work.

The resulting advantages optimally develop at the full exploitation of the respective cam stroke

during the work process; that means, the stamping- and benching operation of the cam unit should

be carried out in the front end position.

The complete exploitation of the cam stroke allows the maximal intervention of the active return and

the therewith connected highest possible supply of retracting- and stripper forces (about 10 % of the

pressing force).

In the front endpoint of the cam stroke there is the maximal retraction of the gas spring. Generally

applies: The construction and the resulting values, like assembly height and restoring forces, require

that the cam unit is mounted in the front end position.

7

STRACK NORMA GmbH & Co. KG · Königsberger Str. 11 · D-58511 Lüdenscheid · Tel +49 2351 8701-0 · www.strack.de

08.2018

IOperating instructions -- PowerMax cam unit PMO

PowerMax

PowerMax cam unit SN5650-PMO-0065 — SN5650-PMO-0260

Attention:

The mounted gas springs serve for the additional reset of the cam slide.

The working powers which are necessary for the operation are absorbed by the

active return (only Medium- and Premium version).

4. Scope of delivery

The PowerMax cam units are delivered preassembled and with a precise guide clearance.

The mounted gas springs, unless otherwise desired, are delivered with maximal filling pressure.

The working surface can already contain client-specific insertions. Also Premium special mounting

plates belong to these.

All cams can also be produced for the machining of high strength sheets, contrary to the angles in five

steps described in the catalogue, in all intermediate angles according to customers’ requirements.

Please contact us.

3.1 Description of the construction types

Unique in the world is the differentiation of a cam program in 3 types:

BASIS, MEDIUM, PREMIUM.

These types which are totally similar in the dimensions differ exclusively in their performance values and

the equipment details.

The BASIS cam is equipped with guide elements out of bronze-graphite. The working surface is out of

cast iron.

The MEDIUM cam is equipped with guide elements out of sintermetal, the working surface is out of cast

iron and the active return can be adjusted.

The PREMIUM cam is equipped with guide elements out of sintermetal, the working surface is a remov-

able mounting plate and the active return can be adjusted.

8STRACK NORMA GmbH & Co. KG · Königsberger Str. 11 · D-58511 Lüdenscheid · Tel +49 2351 8701-0 · www.strack.de

08.2018

IOperating instructions -- PowerMax cam unit PMO

PowerMax

PowerMax cam unit SN5650-PMO-0065 — SN5650-PMO-0260

5. Design of the PowerMax cams

STRACK NORMA PowerMax cams are produced in a high-precision manner.

The guidances which are grinded to a tight guide clearance allow highest loads. The cam units can be

equipped with the tool on the working surface. In doing so you have to consider that the force affects

in the centre of the working surface.

If you have an off-center load irregular forces

arise on the guidances and produce an increased

wear.

(See 3.1. description of the construction types)

Herefrom you can clearly read the maximal force outside the centre of activity for the x respectively the y

axis. Modifications of position which will be possible in future should be considered previously to choose a

cam size which corresponds to the force.

To be able to guarantee an equal running life, the load forces reduce, according to the position, on the

working face.

You will find detailed information in the catalogue indications concerning to your cam in the internet

under:

www.strack.de

Basis <750,000 strokes

Medium >1,000,000 strokes

Premium >1,000,000 strokes

Attention:

If the cam should be superstructed with accessories

a new calculation is necessary.

Please contact us.

SN5650-PMO-0230-20°-M/P-N/Z

53

57

60

63

63

60

57

68

75

80

85

85

80

74

249

313

391

517

488

374

300

112

130

148

166

163

145

127

6 x 20

137

17

3 x 15

230

3 x 25 3 x 25

17,5

17,5

159

189

218

253

247

213

184

53

55

55

55

55

55

55

146

146

146

146

146

146

146

67

67

67

67

67

67

67

86

85

85

85

85

85

85

103

102

102

102

102

102

102

122

121

121

121

121

121

121

90

101

111

121

120

110

100

53

55

55

55

55

55

55

67

67

67

67

67

67

67

86

85

85

85

85

85

85

103

102

102

102

102

102

102

122

121

121

121

121

121

121

53

57

60

63

63

60

57

68

75

80

85

85

80

74

112

130

148

166

163

145

127

159

189

218

253

247

213

184

90

101

111

121

120

110

100

F max. = 595 kN

9

STRACK NORMA GmbH & Co. KG · Königsberger Str. 11 · D-58511 Lüdenscheid · Tel +49 2351 8701-0 · www.strack.de

08.2018

IOperating instructions -- PowerMax cam unit PMO

PowerMax

PowerMax cam unit SN5650-PMO-0065 — SN5650-PMO-0260

6. Preparation of tool and press

Tool, press and peripheral devices have to be suited, prepared and adapted according to the indications

of STRACK NORMA for the utilisation of the PowerMax cam unit.

Drain off fluid (for example water or drawing compounds) well-directed by drainage. You have to take

care that punching wastes don’t fall in or on the cam guidance.

Cam slide and guidances can seize. Parts falling down can damage the guidances, hereby possibly the

running life of the cam reduces. If there is a failure, the cam slide can’t be placed back in the initial

position.

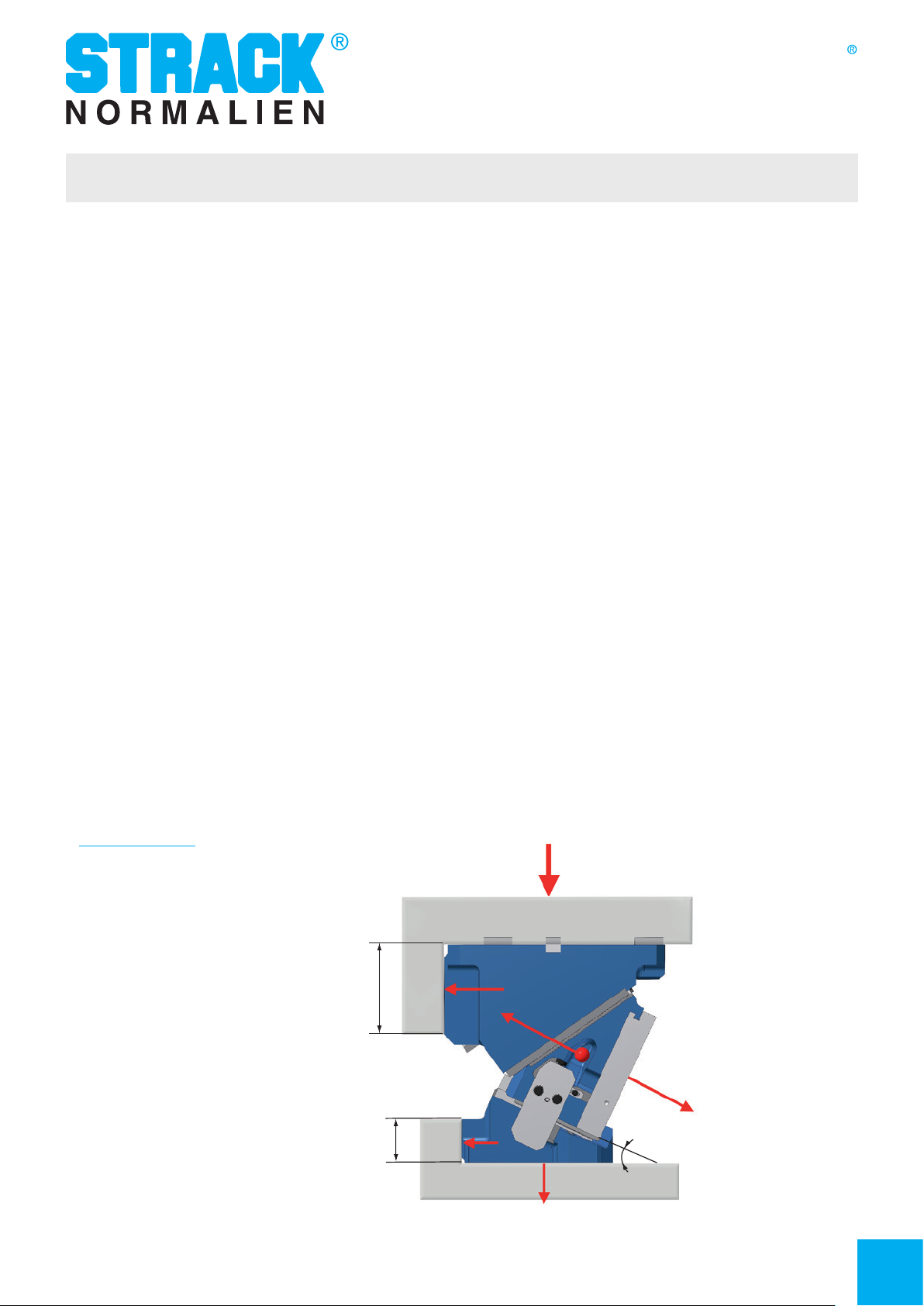

7. Shouldering

The force distribution of the individual forces in the cams depends on the right shouldering in the tool

and the cam angle.

If the heights h1 and h2 (see the picture below) reduce in the tool, the forces of the shouldering can’t

be completely absorbed.

You will find detailed information in the catalogue indications concerning your cam in the internet under

www.strack.de FP

FS

FW

FA

h1

h2

Fh1

Fh2 α

10 STRACK NORMA GmbH & Co. KG · Königsberger Str. 11 · D-58511 Lüdenscheid · Tel +49 2351 8701-0 · www.strack.de

08.2018

IOperating instructions -- PowerMax cam unit PMO

PowerMax

8. Production

During the production no particular precautionary measures have to be taken, which exceed the valid

operating safety regulations paragraph 3.

Advice:

Please secure that the STRACK cams especially the gas springs are not dipped

in fluid.

If you are using for example aggressive drawing oils during the production, make

a controlled drain for them (drainage borings, cutouts and so on), so that the

fluids are directed away from the gas springs.

Thereby seal damages are avoided.

Tip:

Control the nitrogen pressure of the gas springs in regular intervals, to detect

changes in the pressure level in time. During maintenance works you have to

consider a correct return of the cam slide.

Advice:

The cam units are equipped with low-maintenance slide elements out of bronze

with solid lubricant. In normal case lubrication is not necessary.

A lubrication may only be effected in case of need with the following lubricants:

PowerMax cam unit SN5650-PMO-0065 — SN5650-PMO-0260

Company Oils Greases

AGIP Potra ATF Agip GR MU 2

BP Autran DX II Energrease

ESSO ATF Suffix A Nebula EP 2

ESSO ATF - D Beacon EP 2

OMV ATF Serie OMV signum CX 2

SHELL Donax TM Retinax LX

SHELL Donax TF

11

STRACK NORMA GmbH & Co. KG · Königsberger Str. 11 · D-58511 Lüdenscheid · Tel +49 2351 8701-0 · www.strack.de

08.2018

IOperating instructions -- PowerMax cam unit PMO

PowerMax

PowerMax cam unit SN5650-PMO-0065 — SN5650-PMO-0260

8.1 Handling

8.1.1 Handling with safety ring bolt adapter (SN5655-PMO-SRA)

The safety ring bolt adapter SRA facilitates the handling in

many installation situations at the standard cams of the

width 90, 125, 165, 230 and completes the existing hand-

ling screw thread.

The safety ring bolt adapter will be place on the prism surface and slips between the forced retreat to the

noses hit and disengage the spring-loaded bolt and lock.

12 STRACK NORMA GmbH & Co. KG · Königsberger Str. 11 · D-58511 Lüdenscheid · Tel +49 2351 8701-0 · www.strack.de

08.2018

IOperating instructions -- PowerMax cam unit PMO

PowerMax

PowerMax cam unit SN5650-PMO-0065 — SN5650-PMO-0260

Together with SN5653-Set-Montage-

hilfe (assembling aid) which is

available for each cam unit size the

threading of the sliding carriage is

facilitated in the slide mount.

The safety ring bolt adapter SN5655-PMO-SRA and the set of the assembling aid additionally supports

you concerning the mounting of the cam slide together with the cam retainer in the tool.

Because of the flexible positioning possibilities the cam can thus be positioned nearly parallel to the tool

bottom.

13

STRACK NORMA GmbH & Co. KG · Königsberger Str. 11 · D-58511 Lüdenscheid · Tel +49 2351 8701-0 · www.strack.de

08.2018

IOperating instructions -- PowerMax cam unit PMO

PowerMax

PowerMax cam unit SN5650-PMO-0065 — SN5650-PMO-0260

SN5653-Set-

Montagehilfe

SN5653-Set-

Montagehilfe

SN5653-M16-Montagehebel

(Assembly lever)

SN5653-M56

SN5653-M48

SN5653-M36

SN5653-M30

SN5653-Set-Montagehilfe (Assembling aid)

consisting of: for cam units

SN5653-M16-Montagehebel + SN5653-M30 SN5650-PMO-0125

(Assembly lever) SN5650-PMU-0125

SN5653-M16-Montagehebel + SN5653-M36 SN5650-PMO-0165

(Assembly lever) SN5650-PMU-0165

SN5650-PMO-0230

SN5650-PMU-0230

SN5650-PMO-0260

SN5650-PMU-0260

SN5653-M16-Montagehebel + SN5653-M48 SN5650-PMU-0330

(Assembly lever) SN5650-PMU-0400

SN5653-M16-Montagehebel + SN5653-M56 SN5650-PMO-0330

(Assembly lever) SN5650-PMO-0400

SN5650-PMO-0460

SN5650-PMU-0460

SN5650-PMO-0580

SN5650-PMU-0580

SN5650-PMO-0700

SN5650-PMU-0700

SN5650-PMO-0850

SN5650-PMU-0850

SN5650-PMO-1000

SN5650-PMU-1000

SN5650-PMO-1200

SN5650-PMU-1200

14 STRACK NORMA GmbH & Co. KG · Königsberger Str. 11 · D-58511 Lüdenscheid · Tel +49 2351 8701-0 · www.strack.de

08.2018

IOperating instructions -- PowerMax cam unit PMO

PowerMax

8.1.2 Handling with safety ring bolt (SN1594)

Beginning from the cam units 260, cam retainers and slides

can simplified be mounted together by means of the safety

ring bolt SN1594, because of the fact that the different

positions of the handling screwing thread facilitates the

mounting of the cam slide in the slide retainer.

By changing the position of the safety ring bolt,

the cam retainer and the cam slide can be simpler

mounted together into the tool.

Mounting of the cam retainer with the cam slide

in the tool with lateral thread for the flexible

mounting and turning of the cam.

PowerMax cam unit SN5650-PMO-0065 — SN5650-PMO-0260

15

STRACK NORMA GmbH & Co. KG · Königsberger Str. 11 · D-58511 Lüdenscheid · Tel +49 2351 8701-0 · www.strack.de

08.2018

IOperating instructions -- PowerMax cam unit PMO

PowerMax

8.2 Marking of the cams

All PowerMax cams are equipped with a type plate.

On this type plate the name and the serial number of the cam are lasered.

Name of the cam

6-digit serial number

For additional information

for customers

The serial number refers to all cams of an order and is different concerning order to order. The PowerMax

cams were adjusted in the company STRACK. For this the hardened steel gide strips were ground to the

corresponding dimension. The appropriate screws were additionally secured by the screw locking adhesive

Z9093.

Attention: Don’t remove the rails. If this should be inevitable in a case of a crash, the replacement strips

have to be adjusted again.

To avoid confusions within a series the assembly groups of the individual cams are marked within the series

with numbers of 1 to ... (see picture below). During the mounting please absolutely consider the right

coordination of the components to avoid problems.

PowerMax cam unit SN5650-PMO-0065 — SN5650-PMO-0260

(GGG60)

SN5650-PMO-0065-25-B-N-V01

Sn.-Nr.: 1 2 3 4 5 6

1

1

1

Additional markings on slide retainer and slide body

make it possible to control the position of the cam in

the tool.

If the cam is moved together, the upper markings

correspond; if the cam is extended the lower markings

correspond.

If the marking on the slide body is between the markings

of the slide retainer, the whole cam is not driven back in

the correct initial position.

16 STRACK NORMA GmbH & Co. KG · Königsberger Str. 11 · D-58511 Lüdenscheid · Tel +49 2351 8701-0 · www.strack.de

08.2018

IOperating instructions -- PowerMax cam unit PMO

PowerMax

9. Dismounting of the mounting plate at cam widths 0065-0260

(only Premium)

The PREMIUM version of thr PowerMax® is equipped with a demountable mounting plate, which makes a

simpler handling possible.

The high-precision plate can be dismounted easily to be able to carry out further machining.

Step 1

Loose the fixing screws of the guide strips. Remove the guide strips and put them aside (picture 1).

Please take care that the sinter sliding surface is not damaged.

Step 2

Push the mounting plate out of the precision groove guidance (picture 2).

Reference borings on the sides of the mounting plate facilitate the adjustment and the positioning on the

machining center.

PowerMax cam unit SN5650-PMO-0065 — SN5650-PMO-0260

picture 1 picture 2

AN

17

STRACK NORMA GmbH & Co. KG · Königsberger Str. 11 · D-58511 Lüdenscheid · Tel +49 2351 8701-0 · www.strack.de

08.2018

IOperating instructions -- PowerMax cam unit PMO

PowerMax

9.1 Mounting of the mounting plate at cam widths 0065-02030

(only Premium)

Step 1

Before pushing the mounting plate back in the groove guidance it is absolutely necessary to clean the stop

lug (AN) and the t-nut guidance of both components, in order that the bearing surface for the guide strips

builds a level during the assembly. The mounting plate is constructed in such a manner that the surface

stands about 0.01 till 0.02 back behind the guide strip bearings.

Step 2

Only mount the guide strips at the provided assembly site.

Please that care the screws are secured with the screw locking adhesive Z9093.

PowerMax cam unit SN5650-PMO-0065 — SN5650-PMO-0260

AN

picture 1 picture 2

18 STRACK NORMA GmbH & Co. KG · Königsberger Str. 11 · D-58511 Lüdenscheid · Tel +49 2351 8701-0 · www.strack.de

08.2018

IOperating instructions -- PowerMax cam unit PMO

PowerMax

PowerMax cam unit SN5650-PMO-0065 — SN5650-PMO-0260

10. The Lock-Out-Systems

10.1 Lock-Out-System SN5651-LOS

This lock-out system can be used at

mounted and dismounted standard cams.

10.2 Lock-Out-System SN5654-LOS

This lock-out system can only be used at

dismounted standard cams.

19

STRACK NORMA GmbH & Co. KG · Königsberger Str. 11 · D-58511 Lüdenscheid · Tel +49 2351 8701-0 · www.strack.de

08.2018

IOperating instructions -- PowerMax cam unit PMO

PowerMax

PowerMax cam unit SN5650-PMO-0065 — SN5650-PMO-0260

Type for cam SN5651-PMO-LOS-

SPB SN5651-LOS-SPS SN5651-LOS-DS

SN5651-PMO-LOS-0065 SN5650-PMO-0065 SN5651-PMO-LOS-

SPB-0065 1SN5651-LOS-SPS-

M6 x 120 1SN5651-LOS-DS-

19 x 15 1

SN5651-PMO-LOS-0090 SN5650-PMO-0090 SN5651-PMO-LOS-

SPB-0090 1SN5651-LOS-SPS-

M8 x 120 1SN5651-LOS-DS-

19 x 15 1

SN5651-PMO-LOS-0125 SN5650-PMO-0125 SN5651-PMO-LOS-

SPB-0125 1SN5651-LOS-SPS-

M8x120 1SN5651-LOS-DS-

25 x 15 1

SN5651-PMO-LOS-0165 SN5650-PMO-0165 SN5651-PMO-LOS-

SPB-0125 1SN5651-LOS-SPS-

M8 x 140 1SN5651-LOS-DS-

32 x 15 1

SN5651-PMO-LOS-0230 SN5650-PMO-0230 SN5651-PMO-LOS-

SPB-0230 1SN5651-LOS-SPS-

M12 x 140 1SN5651-LOS-DS-

32 x 15 1

SN5651-PMO-LOS-0230 SN5650-PMO-0260 SN5651-PMO-LOS-

SPB-0230 1SN5651-LOS-SPS-

M12 x 140 1SN5651-LOS-DS-

32 x 15 1

10.1 Lock-Out-System SN5651-LOS

SN5651-LOS

SN5651-LOS-Type

Mat.: ST

SN5651-LOS-DS

SN5651-LOS-SPS

SN5651-LOS-SPB

further details under: www.strack.de

20 STRACK NORMA GmbH & Co. KG · Königsberger Str. 11 · D-58511 Lüdenscheid · Tel +49 2351 8701-0 · www.strack.de

IOperating instructions -- PowerMax cam unit PMO

PowerMax

09.2020

10.1.1 Mounting of the Lock-Out-System SN5651-LOS

To fasten the cam for the insertion of borings, the fixation of the cam slide by means of a lock-out-system

is necessary. For this purpose please act as following.

PowerMax cam unit SN5650-PMO-0065 — SN5650-PMO-0260

1. Dismounting of the gas spring

2. Dismounting of the slide stop

with the damper

picture 1

picture 2

1

2

This manual suits for next models

1

Table of contents

Other Strack Industrial Equipment manuals

Strack

Strack PMOK-V04 User manual

Strack

Strack PowerMax SN5650-PMU-0330 User manual

Strack

Strack PowerMax light SN5650-PMOL-0065 User manual

Strack

Strack PowerMax SN5650-PMO-0330 User manual

Strack

Strack SN 5620-2000 Series User manual

Strack

Strack PowerMax PMOKL-V04 User manual

Strack

Strack PowerMax SN5650-PMO-0260-V04 User manual

Strack

Strack PowerMax light SN5650-PMOL-0330 User manual