Stratus SAE-UT12000 Guide

Model No. SAE-UT12000

Full Rise Ultra Thin

Scissor Lift

Lifting Capacity 12000 lbs

Installation & Operation &

Maintenance Instructions

Important Note

1. This equipment can not be installed, operated or repaired without reading instructions.

2. Electricity must be hooked up by certified electrician.

3. Do not use this equipment beyond its rated capacity.

3

12000LBS Ultra-thin Scissor Lift

Contents

Chapter 1 Safety Precautions.................................................4

Chapter 2 Product and Parameters............................................5

Chapter 3 Preparation for Installation..........................................9

Chapter 4 Commissioning....................................................18

Chapter 5 Maintenance......................................................20

Chapter 6 Exploded views....................................................24

4

SAE-UT12000

Chapter 1 Safety Precautions

1. Make sure that you have read the User’s Manual completely including relevant

instructions on installation, operation and safety before operating the lift.

2. Do not use the lift if any abnormality is found in the lift.

3. Do not overload the lift beyond its rated load 3000KG.

4. The lift can be operated by trained personnel only. The vehicle customer or the

inexperienced person is prohibited from operating the lift at will.

5. The rubber pad of the small scissor lift must have contact with the support point

of the vehicle, otherwise the vehicle chassis may be damaged. (It is recommended

to consult the vehicle manufacturer by telephone if the location of the support

point is not clear.)

6. Be sure to perform mechanical locking after the vehicle is lifted. It is forbidden to

work under the vehicle before mechanical locking is performed.

7. Keep the area around the lift clean and tidy as any oil stain or obstacle may pose

a safety risk.

8. Never lift the vehicle with people in it.

9. Make sure there is no obstacle under the vehicle before lowering it.

10. It is prohibited to remove any hydraulic component when the hydraulic system

is under pressure.

11. Do not put hands at any dangerous place, such as the space between tool arms.

12. It is prohibited to use the product outdoors as it is only suitable for indoor use.

13. Press and hold the Down button while lowering, so the platforms ascend a little

automatically to open the safety lock, and then descend automatically.

14. Always wear safety shoes during operation.

15. It is forbidden to lift the vehicle when someone is in the vehicle.

16. Cut off the power supply after the use of lift.

17. When a vehicle is being loaded onto or unloaded from the lift, no person is

allowed to stand in the vehicle passage.

18. Ensure that the platforms of main and sub lifts are lowered to the lowest

positions before the vehicle departs from/leaves the lift.

19. Use wedge blocks to lock the vehicle so that the vehicle cannot move.

20. Read the operation warning label carefully and thoroughly

5

12000LBS Ultra-thin Scissor Lift

Chapter 2 Product Features and Parameters

2.1 Product features

Movable ramp which can be used as extension board

Monolithic base-plate without splice

Stable and reliable control system

Aluminum alloy motor with low noise and fast heat dissipation

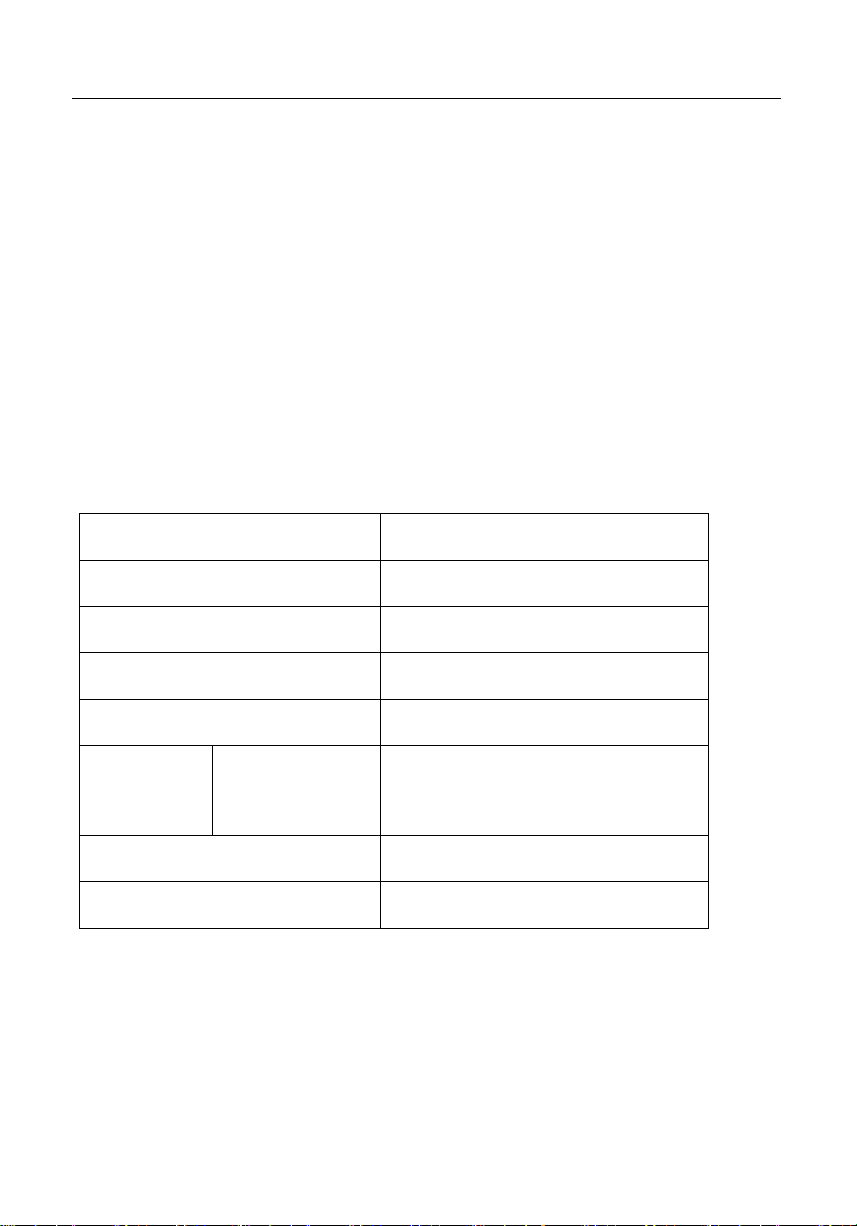

2.2 Technical parameters

Rated lifting capacity

12000LBS (5500KG)

Initial height

5 4/8”(140mm)

Lifting height

74 13/16”(1900mm)

Platform length

61 7/16”--85 1/16”(1560-2160mm)

Platform width

29 4/8”(750mm)

Motor

parameters

50CBL

1PH,220VAC,3KW

Type of hydraulic oil

IS0 46#

Air pressure

0.6-0.8MPa

6

SAE-UT12000

Diagram of product:

7

12000LBS Ultra-thin Scissor Lift

Electrical diagram

8

SAE-UT12000

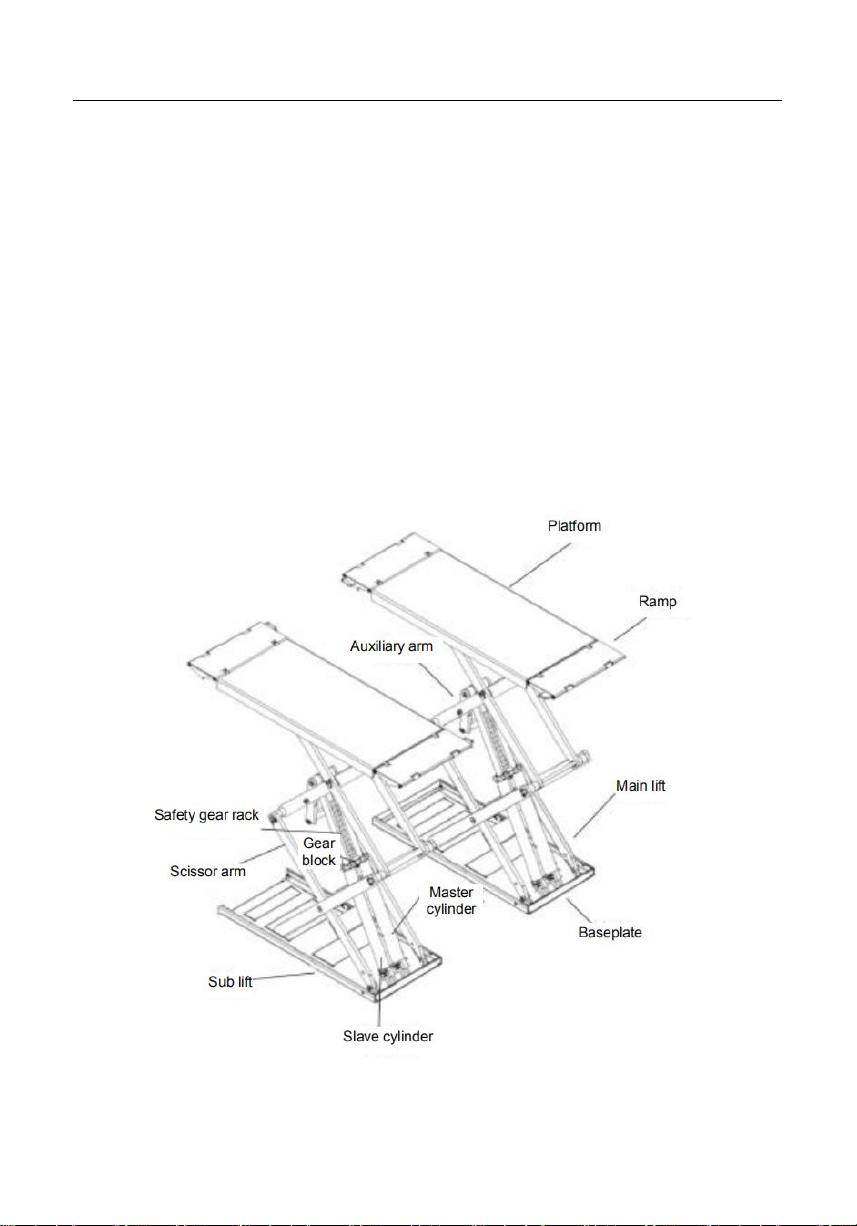

2.3 Schematic diagram for main components

Working platform: For lifting the vehicle by contacting the chassis.

Safety gear rack: Safety mechanism for mechanical locking.

Gear block: Blocking safety gear rack.

Ramp: Can be pulled up and used as extension board to bear load.

Auxiliary arm: Providing help at the start of lowering and raising.

Control cabinet: Control unit, providing the power takeoff.

Master cylinder: Actuator, pushing the platform to rise, with two oil pipes.

Slave cylinder: Actuator, pushing the platform to rise, with one oil pipe.

Scissor arm: Main lifting structure.

9

12000LBS Ultra-thin Scissor Lift

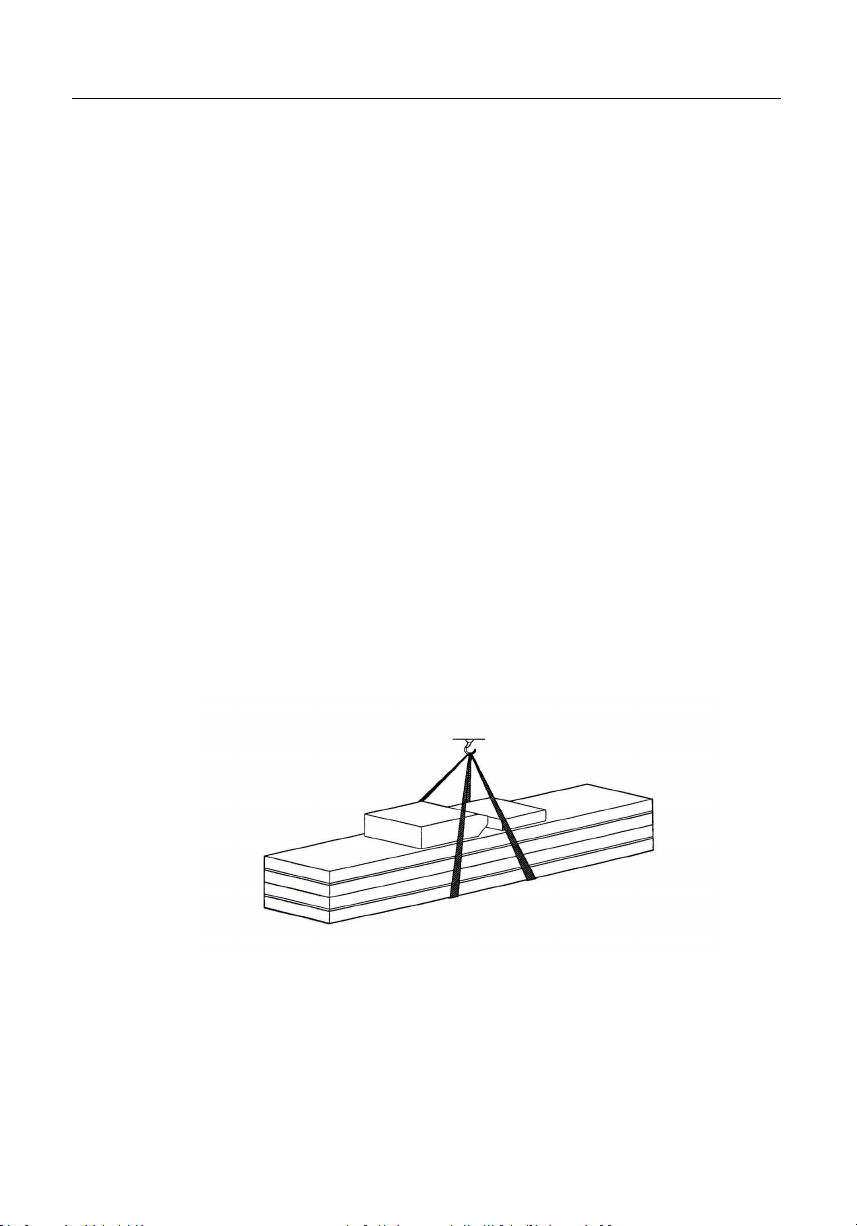

Chapter 3 Preparation for Installation

3.1 Unpacking

All packing, loading/unloading, transportation and unpacking operations must be

performed by

professional personnel.

Transportation:

The scissor lift shall be loaded/unloaded and moved by a lifting machine and

forklift with capacity over 3

tons. To prevent the scissor lift falling off, one person shall pay attention to the

scissor lift during the

lifting operation for fear of accidents. The scissor lift shall be transported by an

automobile or ship.

The scissor lift shall be inspected for completeness when it arrives, for fear of

damage or loss during

transportation.

If the packing box is broken during transportation, inspect the broken box

according to the Packing List,

confirm the damaged articles and lost components, and at the same time, inform

the carrier

immediately.

The lift is heavy! Therefore, manpower loading/unloading and handling are

forbidden. Safety is of much

importance. In addition, the hoisting of scissor lift during loading/unloading shall

be operated as

illustrated.

Storage:

Machinery equipment shall be stored in an indoor warehouse, and waterproof

treatment shall be

adopted in case of outdoor storage. A van truck shall be used for highway

transportation, and a

container for waterway transport. The control cabinet must be placed upright

during transportation, and

be protected from squeezing by other goods.

10

SAE-UT12000

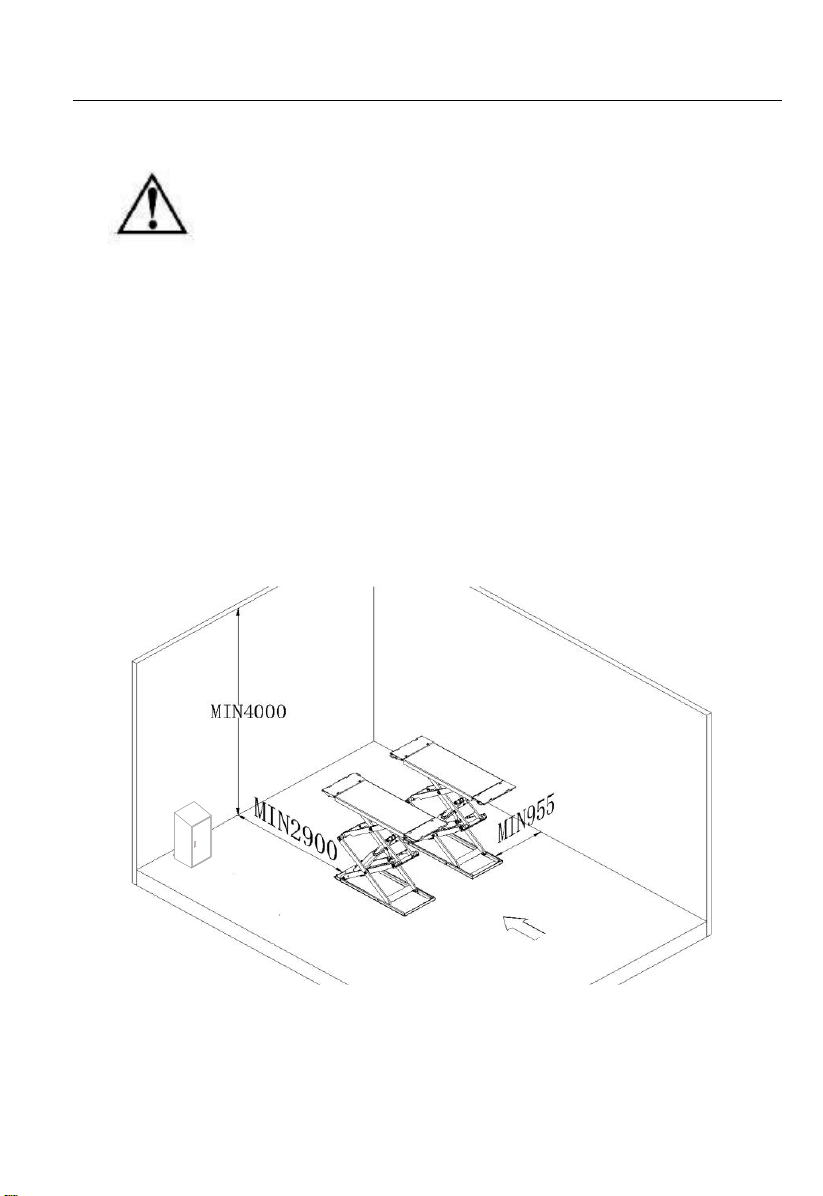

3.1 Preparation for installation

Installation scheme

11

12000LBS Ultra-thin Scissor Lift

Volta

ge

Power

Start

current

Operating

current

Wire size

Air switch

Applicable to

220V

3KW

60A

21A-25A

≥4mm²

C63

Scissor lift

220V

2.2KW

60A

20A-22A

≥4mm²

C63

Two posts,four

posts

12

SAE-UT12000

3.3 Installation:

•Only professionals are allowed to conduct the installation

work. Moreover, they shall read and follow the operation

instructions below carefully to prevent machine damage or

injuries.

•Only authorized technicians are allowed to install the lift.

3.3.1 Installation requirements:

The lift must be installed in accordance with the specified safe distances from

walls, columns and other

equipment (as shown in Fig. 8), including the minimum distance

2000mm-2900mm from walls.

The ceiling height cannot be less than 4000mm. It is recommend to install the

lift in a pit, and construct the foundation as required in Fig. 8.

Nevertheless, the lift can be installed on any indoor floor, provided that the

floor meets the leveling requirements and has enough bearing capacity

(≧25MPa).

Fig. 8

The arrived goods shall be inspected for completeness before installation of

scissor lift.

The movement and installation of the lift shall be carried out by the

professionals.

13

For the transportation and storage of the machine, refer to the“Transportation

and Storage” on page 11.

14

12000LBS Ultra-thin Scissor Lift

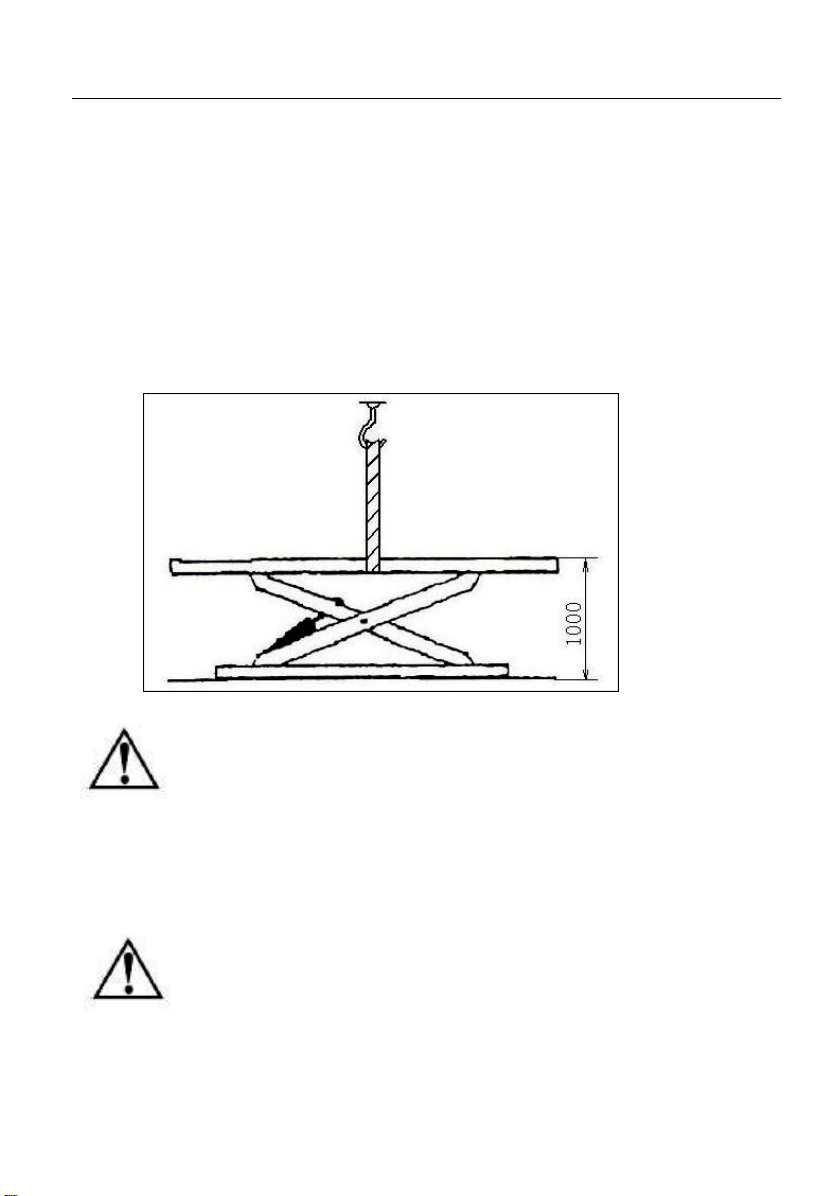

3.3.2 Installation of lifting platforms

Determine the installation direction of the lift according to the arrows

on the lift package. When the lift is

installed in the pit or on the ground, insert adjusting sizing blocks

under the platform, lift the lifting

platform with a forklift or other lifting equipment (Fig. 9) to about

1000MM, so as to ensure that the

mechanical safety device is activated and locked.

Fig.9

• To avoid the failure of the mechanical safety device, a wood block can

be inserted at the middle of the connecting rod. When the hydraulic

system is not fully filled with hydraulic oil and has the lifting and

lowering actions, do not work under the lift. Move the lifting platforms,

adjust the distance between two platforms to make them parallel, and

connect the electric circuit, oil circuit and pneumatic circuit as

specified in the Electrical Diagram and Oil Circuit Connection Diagram.

• Only after the hydraulic system connection is completed, the

pneumatic circuit connection can be conducted.

• Oil pipes, electric wires and air pipes shall not be damaged.

• Connection of electrical circuit: Connect the electrical circuit according

to the wire diameter and wire size specified in the Electrical Diagram.

14

SAE-UT12000

Only the professionals qualified for electrical operation are allowed to conduct the

electrical installation

•Open the upper cover of the control cabinet first

•Connection of power line: Connect the 380V three-phase four-wire power line

(cable of 3×2.5MM2+1×1.5 MM2) to the control cabinet interfaces U, V, W and

input terminal, and connect the PE grounding wire to the labeled grounding bolt

firstly and then to the labeled grounding bolts at the bottom of the two platforms

(Fig. 10, 11)

Fig. 10 Fig. 11

15

12000LBS Ultra-thin Scissor Lift

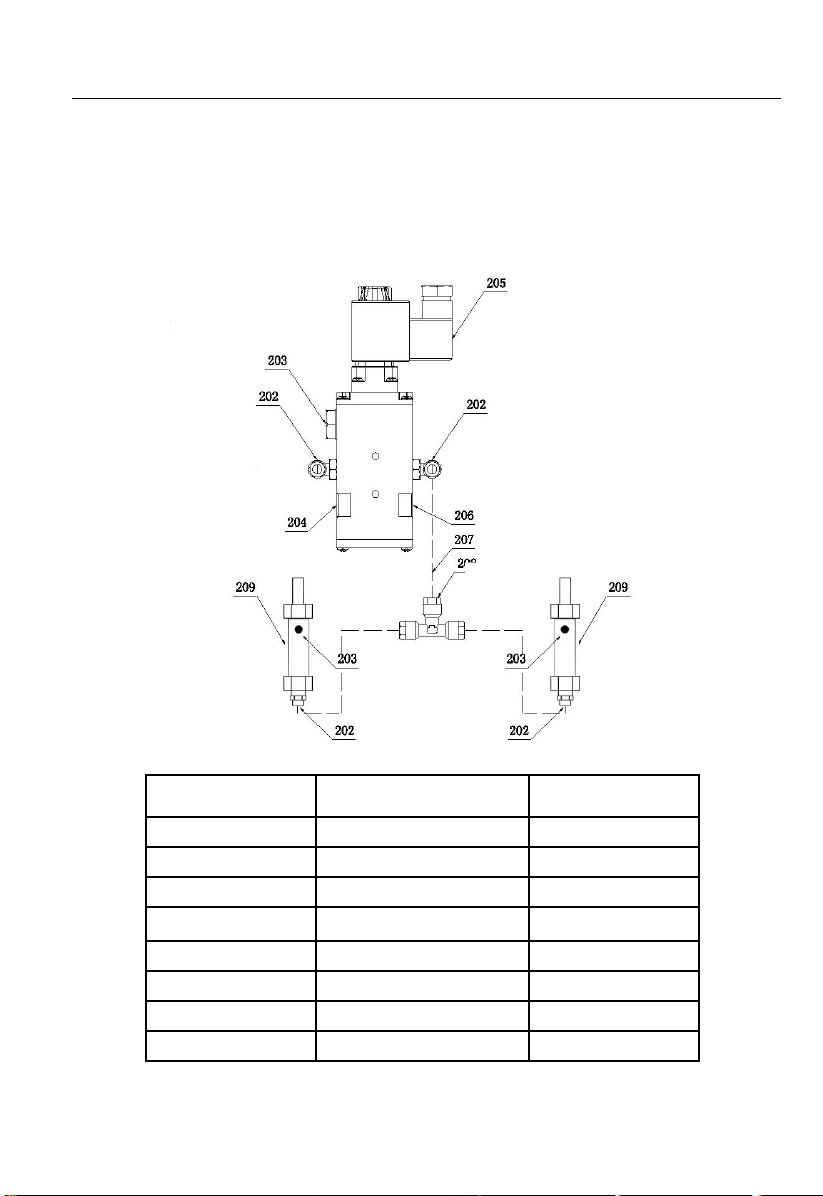

Connection schematic diagram of air pipe joint:

S/N

Part No.

Quantity

203

Muffle

3

204

Plug 1/8

1

205

Solenoid valve

1

206

Plug 1/4

1

207

Air pipe

PU0604

1

208

T-joint APE

1

209

Small cylinder

2

211

Air pipe

PU0806

16

SAE-UT12000

Schematic diagram of oil pipe joint:

Note: Adjustment is only necessary in case of imbalance of both platforms

17

18

12000LBS Ultra-thin Scissor Lift

Hydraulic schematic diagram:

Table of contents

Other Stratus Scissor Lift manuals

Popular Scissor Lift manuals by other brands

Airo

Airo X Series Use and maintenance manual

JLG

JLG 530LRT Service and maintenance manual

Custom Equipment

Custom Equipment Hy-Brid Lifts PUSH-AROUND Maintenance and troubleshooting manual

Oshkosh Corporation

Oshkosh Corporation JLG 400RTS Operation & safety manual

DINGLI

DINGLI JCPT2212DC operators manual with maintenance information

Atlas Equipment

Atlas Equipment 12ASL Installation & operation manual