Remedying FaultsatPP 1207–KlöcknerMöller

RemedyingfaultsPP1207

page 1–April2005

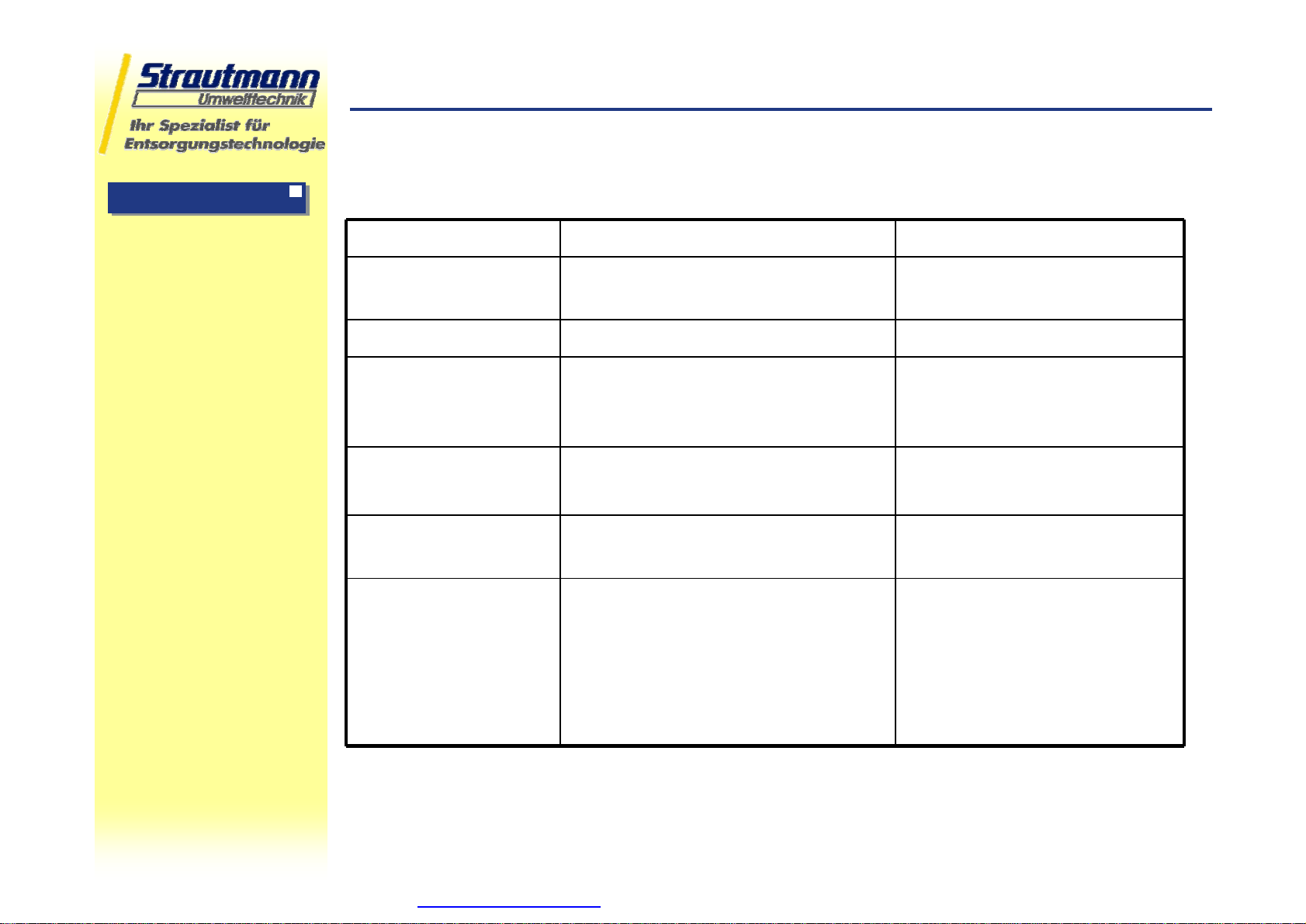

Frequentlyoccurring faultsand remediesforthem

areexplained in thefollowing tables.

The tablesaredividedup according tomainfaultareas.

•Machine hasnofunction

•Machine doesnot run in automaticmode

•Machine doesnot run in manual mode

•Bale cannotbe ejected

•Press platedropping-oilleakage

•Doordoesnot riseautomatically

•Hydraulicproblems

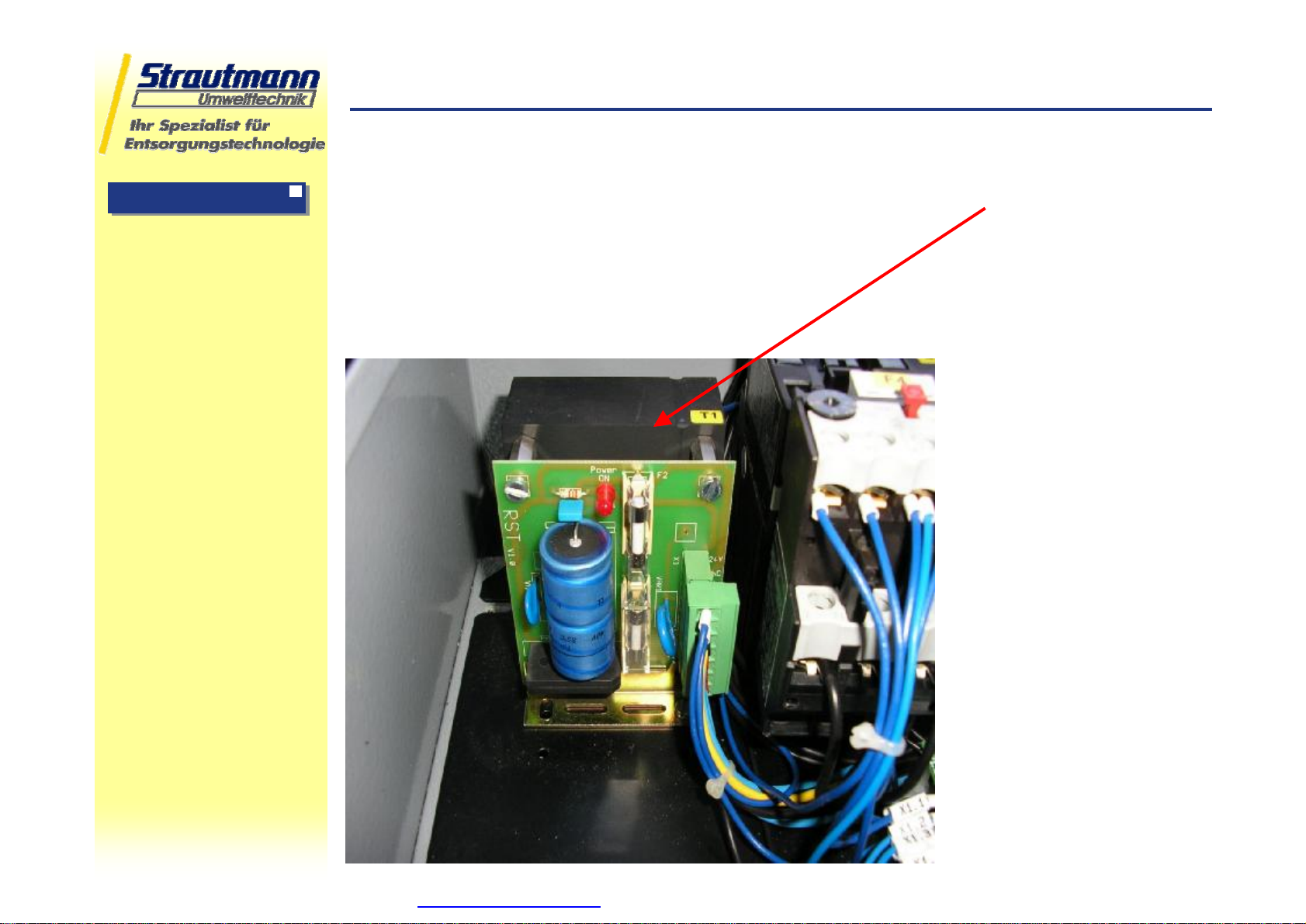

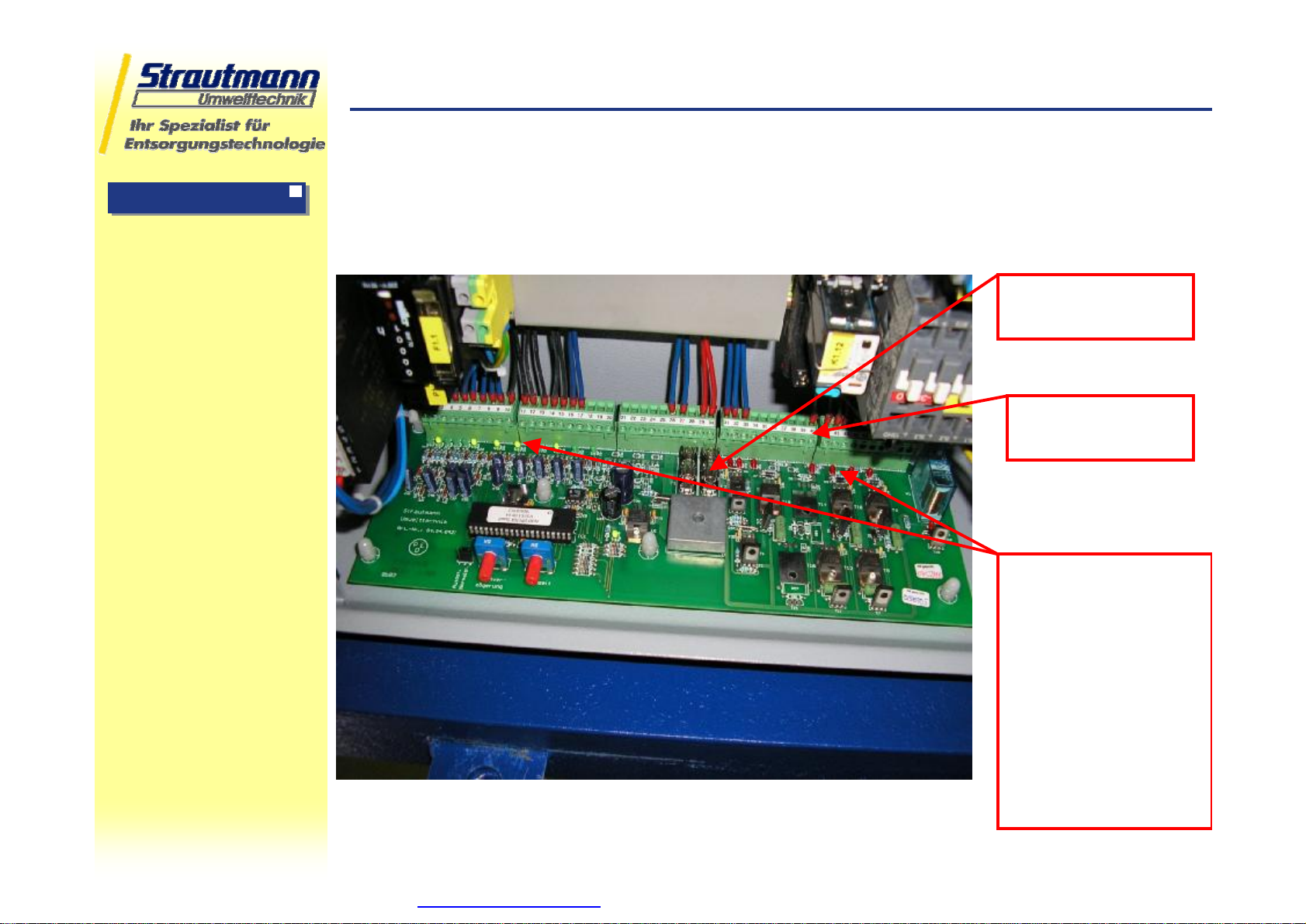

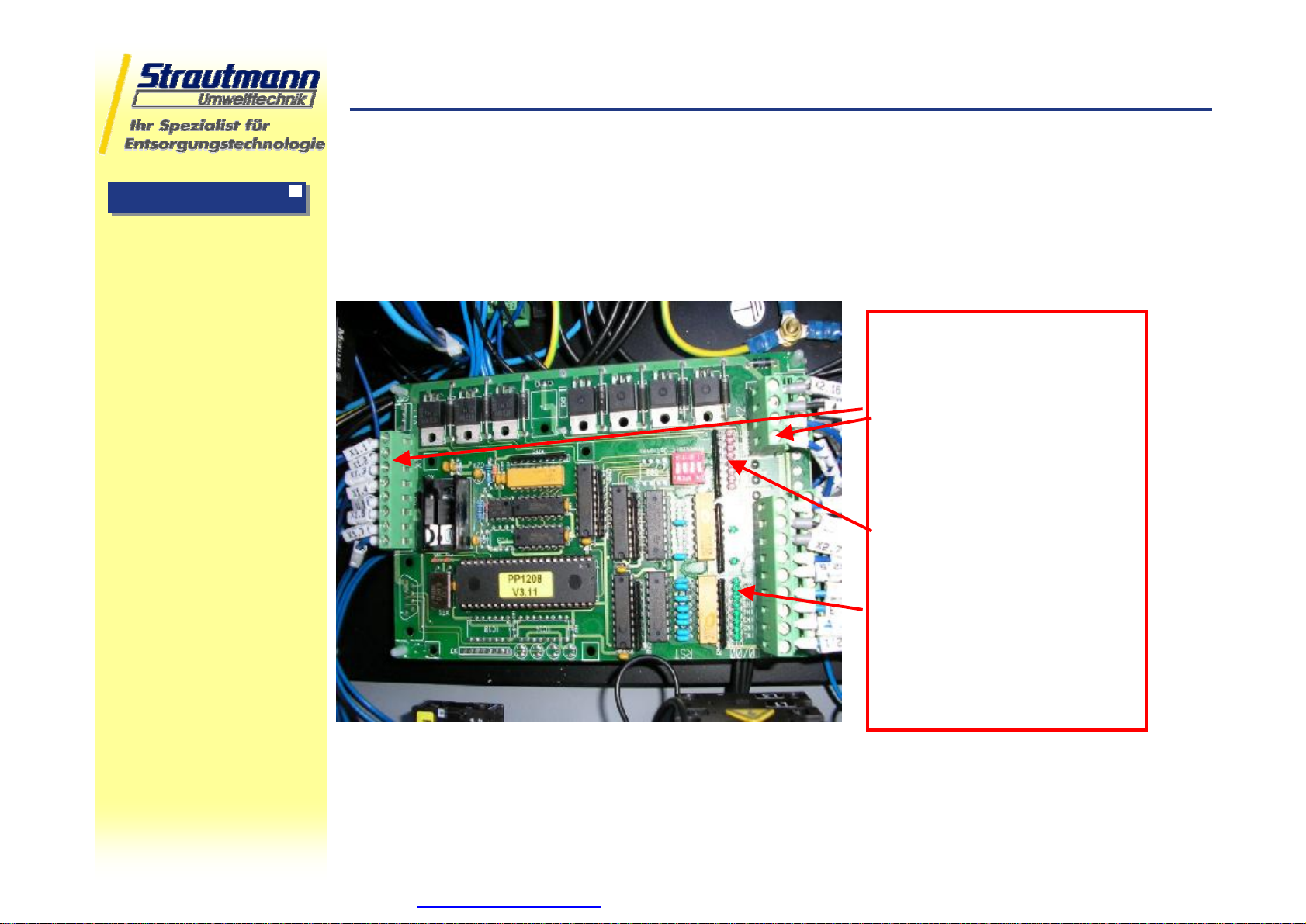

•Electricalproblems

Thisdocumentationisalsointendedforthe EK1107/1109and

PP 1208

PDFwurde mit pdfFactory-Prüfversion erstellt. www.context-gmbh.de