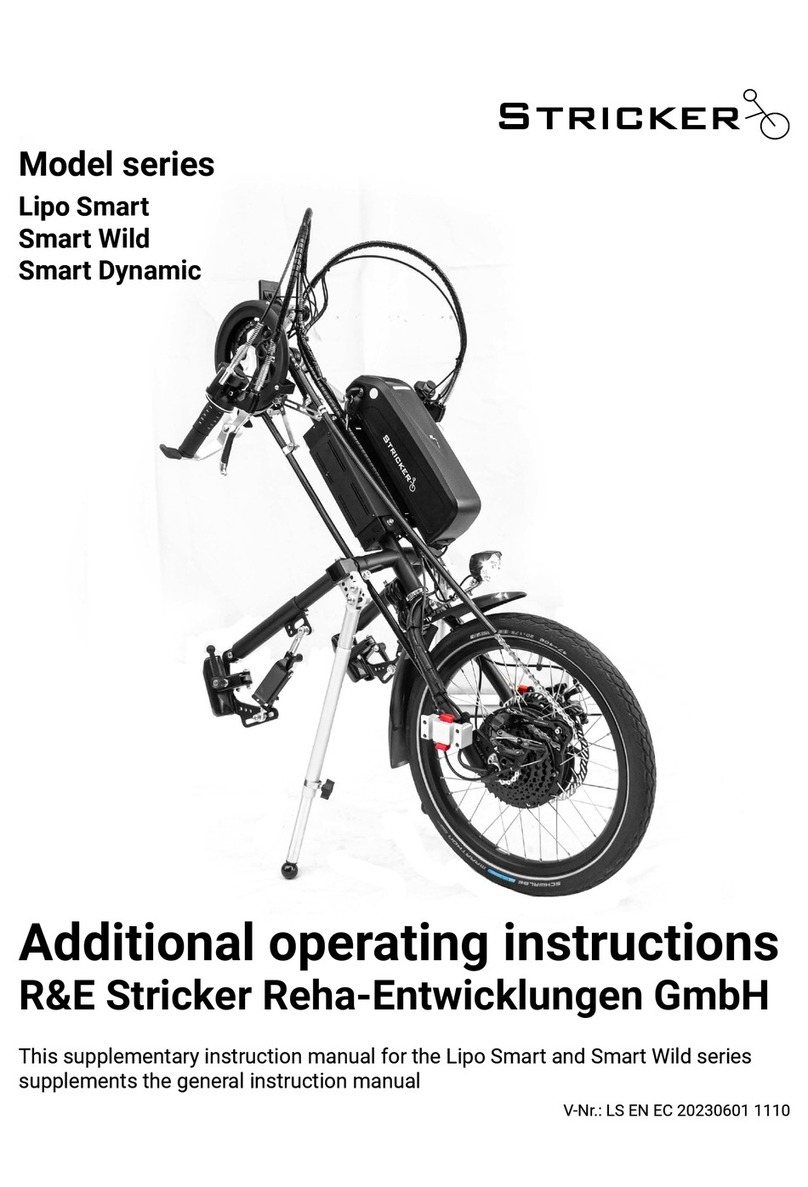

Stricker Neodrives Operating instructions

Additional operating instructions

R&E Stricker Reha-Entwicklungen GmbH

Model series

Neodrives

This supplementary operating manual for the Neodrives model series supplements

the general operating manual for the City, Ultra, Sport, Neodrives and Lipo Smart mo-

del series..

Manufacturer

R&E Stricker Reha-Entwicklungen GmbH

Klotzberg 64

D-77815 Bühl

Phone: +49 7223 / 72510

Fax: +49 7223 / 74947

E-Mail: [email protected]

Web: www.stricker-handbikes.de

Misprints, errors and price or product changes reserved. Product changes include, but are not limited to, changes

resulting from further development of mechanics, software or legal requirements.

Date: 2.11.2021

© R&E Stricker Reha-Entwicklungen GmbH, Bühl

Reprint, even in part, only with the written permission of R&E Stricker Reha-Entwicklungen GmbH , Bühl.

Notice to reader

For reasons of readability, the masculine form has been chosen in these operating instructions;

nevertheless, the information refers to members of all genders.

R&E Stricker Reha-Entwicklungen GmbH

1

Additional operating instructions Neodrives

Table of contents

1 Declaration of Conformity ..................................................................................................................2

2 Introductory notes..............................................................................................................................2

3 Note on the general instructions for use.............................................................................................2

4 Product Description & Intended Use ...................................................................................................2

5 Safety and driving instructions for accident prevention ......................................................................2

5.1 Safety instructions for battery and charger...............................................................................................3

6 Operation ...........................................................................................................................................4

6.1 Key................................................................................................................................................................4

6.2 Start driving .................................................................................................................................................5

6.3 Display of the charge level..........................................................................................................................6

6.4 End of ride....................................................................................................................................................6

7 Battery and charger............................................................................................................................6

7.1 Charging the battery....................................................................................................................................6

7.2 Attaching the battery...................................................................................................................................7

7.3 Charging the battery....................................................................................................................................8

7.4 Storage.........................................................................................................................................................9

8 Repair, cleaning and maintenance ......................................................................................................9

8.1 Motor............................................................................................................................................................9

8.2 sMMI Connect .............................................................................................................................................9

8.3 Akku .......................................................................................................................................................... 10

8.4 Motor......................................................................................................................................................... 10

8.5 Removing the drive wheel........................................................................................................................ 10

8.6 Attaching the drive wheel ........................................................................................................................ 11

9 Transport .........................................................................................................................................12

9.1 Transportation in vehicle ......................................................................................................................... 12

10 Disposal and recycling .....................................................................................................................12

11 Warranty and guarantee ...................................................................................................................13

12 Liability ............................................................................................................................................13

Attachment ............................................................................................................................................14

A Technical data.......................................................................................................................................... 14

2

R&E Stricker Reha-Entwicklungen GmbHAdditional operating instructions Neodrives

Declaration of Conformity

1 Declaration of Conformity

The device complies with the current EU standards and directives. We certify this in

the EC Declaration of Conformity. If required, we will be pleased to send you the

corresponding declaration of conformity. Our power assist devices have been tested by

means of an electromagnetic compatibility test (EMC).

In the event of a change not agreed with R&E Stricker GmbH, this declaration loses its validity.

2 Introductory notes

WARNING

Before operating the handcycle, please read these instructions for use and all other instructions for use

supplied with the handcycle carefully and observe them.

WARNING

Visually impaired persons or persons with cognitive impairments must have the information material

and the operating instructions read aloud by assistants. Corresponding documents are available on our

website www.stricker-handbikes.de on the Internet. Videos and photos are also available there.

DEALER NOTICE

Be sure to hand out these instructions for use to each customer when handing over the handcycle and

expressly draw the customer‘s attention to the safety and hazard information.

Never deliver a handbike without operating instructions!

3 Note on the general instructions for use

WARNING

This is the supplementary instruction manual for handbikes of the Neodrives model series. It supplements

the general instructions for use for the City, Ultra, Sport, Neodrives and Lipo Smart model series. Be sure

to read both instruction manuals before operating the handcycle.

4 Product Description & Intended Use

The handbike is coupled to a manual wheelchair as an electrically assisted manual traction aid. This

allows the rider to be supported in his mobility. The aim is to extend the range of action by enabling longer

distances to be covered more easily and independently. Coupling the handbike creates a three-wheeled

vehicle with three relatively large wheels. The handbike therefore improves driving characteristics on

uneven surfaces. Obstacles can also be overcome more easily. Driving downhill and on slopes becomes

safer due to the additional braking systems. The handbike can be independently coupled to and released

from the wheelchair by the rider. The wheelchair as such is not changed and its characteristics remain

completely unchanged.

5 Safety and driving instructions for accident prevention

WARNING

These instructions are for your own safety. Please read them carefully before using the handbike and

follow the instructions! Failure to observe the instructions for use could result in damage to the product

as well as serious personal injury. We accept no liability for damage resulting from failure to observe the

operating instructions.

R&E Stricker Reha-Entwicklungen GmbH

3

Additional operating instructions Neodrives

Safety and driving instructions for accident prevention

NOTE

Observe all safety and hazard information and

instructions, both in this and in all other operating

instructions supplied.

5.1 Safety instructions for battery

and charger

WARNING

Before performing any repair, cleaning or

maintenance tasks on the handbike, switch off the

electrical components and remove the batteries

from the handbike.

The batteries supplied are used exclusively to

operate the drive systems of the handbike. Do not

connect any other systems to the battery. Any use

beyond this requires the written approval of the

manufacturer. All information is state of the art at

the time of printing. Cases of misuse include:

• Use of the battery contrary to the description

and instructions in the user manual.

• Use of the battery in excess of the technical

performance limits

• Technical modication of the battery

• Modication of the battery software

• Use of the battery to supply other systems

We accept no liability for damage in the event of

misuse.

HEALTH INFORMATION

In case of contact with leaking gases, supply

fresh air. In case of body contact with battery

uids, rinse the affected body part with plenty

of water. In case of contact with mucous

membranes or discomfort, consult a physician.

5.1.1 Operation

Make sure that the batteries are rmly seated in

the holders provided and lock the batteries. This

applies especially if you have previously removed

the batteries from the power assist device for

charging.

Observe the battery temperature on the display

during extreme uphill travel. The temperature must

not exceed 45 °C. To prevent overheating, take an

operating break to relieve the batteries.

Only operate the battery in ambient temperatures

between -20 °C and 50 °C. Operation outside the

temperature range shortens the service life of the

battery and poses a risk of ignition.

Do not subject the battery to shocks. If the battery

has been dropped or has taken a knock, the battery

must be checked by the manufacturer. Contact

your dealer or the manufacturer for return and

repair/disposal procedures. This also applies to

otherwise damaged or defective batteries. Never

continue to use a damaged or defective battery. Do

not open the battery yourself.

Keep the battery dry and clean. Protect the battery

against the ingress of moisture or foreign particles.

Do not connect the battery‘s contacts to metallic

or other conductive objects. Keep the battery away

from small metallic objects such as screws, coins,

paper clips, keys or similar to avoid a short circuit.

Clean dirty contacts with a dry, clean cloth only. Do

not immerse the battery in water.

If you notice that the battery is overheating, leaking,

smoking, emitting an unusual odour or deforming,

stop using the battery immediately and switch it

off.

Protect the battery from heat and open re

(radiators, microwaves, ovens, strong sunlight).

Exposure to heat can cause ignition and explosion.

Do not open the battery casing. Do not

disassemble the battery. Damage to the battery

cells or contact with oxygen can cause re and

explosion. Opening the battery will void the

warranty.

FIRE FIGHTING

Do not attempt to extinguish lithium-ion

batteries with water or other liquids in the event

of a re. Sand is recommended by battery cell

manufacturers as the only extinguishing agent.

There is a risk of explosion in the event of a re.

Extinguish lead-gel batteries with water, foam or

CO2. Dangerous gases may be formed in a re

involving lead-gel batteries. Do not breathe in the

gases under any circumstances.

5.1.2 Charging process

WARNING

Do not leave the battery unattended during the

charging process.

4

R&E Stricker Reha-Entwicklungen GmbHAdditional operating instructions Neodrives

Operation

Only charge the battery at temperatures between

0 and 40 °C. A charging process outside the

temperature range is automatically aborted by the

battery. To optimize the service life, charge the

battery at temperatures of 10-30 °C.

Charge the battery in a sufciently ventilated, dry

and dust-free environment. Ensure sufcient air

circulation during the charging process.

Do not charge the battery near ammable

substances (solids, liquids, gases).

Protect the battery from moisture during the

charging process. Do not charge the battery in

rooms where water could condense on the battery

or the charger. Only use the charger when it is

completely dry. If condensation has formed, allow

the charger to dry completely before charging.

Only use the charger supplied to charge the

battery. Using any other charger may cause

malfunction, damage, defect, ignition or explosion.

Do not charge the battery with a defective charger.

Replace a defective charger immediately.

Do not use a charger that has been knocked

or dropped. Do not open or repair the charger

yourself.

Do not charge damaged batteries.

Avoid unnecessary charging and do not charge the

battery for a long time when not in use.

The battery charging process is automatically

terminated as soon as the battery is fully charged.

When charging is complete, rst disconnect the

charger from the mains socket and then from the

battery.

Do not carry the charger by the mains cable or the

charging cable. Do not pull on the mains cable to

disconnect the charger from the mains socket. Do

not subject the cables and plugs to pressure or

pinch the parts. There is a risk of electric shock or

ignition.

Position the charger so that no one can step on

or trip over the cable or charger. Also protect the

charger and all related components from other

harmful inuences or stresses.

5.1.3 Storage

Do not store the batteries in places that are

exposed to heat for long periods of time (sunlit

car boot, garden shed, etc.). The service life of

the battery depends, among other things, on the

storage conditions.

Only use your car for transport, not for storing or

keeping the battery.

For optimum service life, store the battery at

18-23 °C and a maximum humidity of 80 %. Do not

expose the battery to moisture (rain, snow, etc.)

during storage.

Charge the battery before storage according to

the specications of the respective battery. Check

the charge level at least every three months and

recharge the battery if necessary. („7.4 Storage“).

Ensure that the battery is stored away from

damage and unauthorised access.

Store the battery out of the reach of children.

6 Operation

NOTE

Unpacking and installation video can be found on

www.stricker-handbikes.de/installationsupport

NOTE

The contents listed in this user manual for

Neodrive‘s components were provided to us with

the kind support of Alber GmbH (93.0001.4.01.03

as of: 02.10.2014). The original instructions can

also be found on the website www.neodrives.

com in the Service > Downloads tab. More

comprehensive information on assembly and

repair is also available there.

6.1 Key

Two keys for locking the battery in the battery

rail are included in the scope of delivery. The

identication engraved on the key is noted by the

specialist dealer in the delivery bill of the handbike

so that they can be reordered if necessary. Please

therefore check whether the key marking is entered

in the papers. If this is not the case, please add

it. Keys can only be reordered from AXA via the

specialist trade (as of November 2013). (Fig. 1).

R&E Stricker Reha-Entwicklungen GmbH

5

Additional operating instructions Neodrives

Operation

Fig. 1: Key with marking

6.2 Start driving

INFORMATION

Basically, there are two different operating

modes for the rechargeable battery. The battery

is either in „Active Mode“ or in „Deep Sleep

Mode“. In „Active Mode“, the battery consumes

at least 5 mA per hour (self-consumption of the

electronics). To keep the self-consumption as low

as possible, the battery automatically switches to

the so-called „Deep Sleep Mode“ after 48 hours.

If you have used the battery in the last 48 hours,

you can start up the handbike via the neodrives

sMMI Connect.

If you have not used the battery in the last 48

hours, switch it on using the On/Off button [4]).

To do this, briey press the button. Successful

switching on is signaled by the LEDs [5] ashing

three times. The battery is now ready for operation

and you can now start up the handbike via the

neodrives sMMI Connect. (Fig. 2).

Fig. 2: Switching on the battery

NOTE

To operate the neodrives sMMI Connect terminal,

please read the supplied neodrives sMMI Connect

Quick Start Guide. This is only available in German

and English.

Fig. 3: neodrives sMMi Connect Kurzanleitung

If you have not yet connected the motor cable to

the battery, the battery will still be set to „Active

Mode“ when switched on. If the battery cannot be

switched on, the cell voltage may be too low. In this

case, connect the charger and then press the On/

Off button [4]. The battery is then charged for one

minute.

6

R&E Stricker Reha-Entwicklungen GmbHAdditional operating instructions Neodrives

Battery and charger

NOTE

If the system comes to a standstill due to

increased temperatures (caused, for example,

by uninterrupted driving or at a standstill due to

continuous direct sunlight), allow the motor to

cool down for about 10 minutes before continuing

your journey.

6.3 Display of the charge level

You can check the charge status of the battery

at any time using the LED display. If the battery

has not been used for more than 48 hours, briey

press the button [4]. The battery is switched on, all

LEDs (a to e) ash three times. Press the button [4]

again briey. Now the capacity of the accumulator

is indicated by the LEDs as shown in the following

table.

If the battery has been used within the last 48

hours, press the button [4] briey. Now the capacity

of the battery, as shown in the table below, is

indicated by the LEDs.

LED is on LED ashes Capacity

- a < 19 %

a - 20 – 39 %

a, b - 40 – 59 %

a, b, c - 60 – 79 %

a, b, c, d - 80 – 99 %

a, b, c, d, e - 100 %

Fig. 4: Neodrives battery LED display

6.4 End of ride

The battery is switched off using the sMMI

controller (see neodrives sMMI Connect Quick

Start Guide). The battery is initially set to „Active

Mode“ for 48 hours. This means that the sMMI

can be reactivated at any time during this period

without having to switch on the battery rst. The

power required for this is minimal.

7 Battery and charger

SAFETY NOTICE

Be sure to read and observe all safety and hazard

information „5.1 Safety instructions for battery

and charger“.

WARRANTY NOTICE

Batteries are wearing parts. The warranty period

is 24 months.

DISPOSAL INSTRUCTIONS

Dispose of batteries only at designated disposal

points. If you have any questions, please contact

a specialist dealer or the manufacturer.

7.1 Charging the battery

WARNING

Before using the charger, check that the mains

voltage matches the connection voltage of the

charger. The connection voltage of the charger is

indicated on its type plate.

We recommend charging the battery after each

use of the pulling device, if possible. If you have

completely discharged the battery, charge it again

immediately.

Charge the battery before each use. Check the

charge level of the battery before each trip. If the

battery is completely discharged during travel,

further travel is only possible manually via the

cranks.

Only switch on the battery for use. Switch off the

battery immediately when you stop the traction

unit.

R&E Stricker Reha-Entwicklungen GmbH

7

Additional operating instructions Neodrives

Battery and charger

7.2 Attaching the battery

Place the battery [1] on the battery rail [6] mounted

on the handbike. Push the battery [1] to the front

edge of the battery rail [6] as shown in the diagram.

Lock the battery [1] by gently turning the key [2]

clockwise until it stops. The battery can now no

longer be removed from the battery rail. Remove

the key [2] from the battery [1]. (Fig. 5).

Fig. 5: Insert battery into battery rail

Insert the plug [7] of the cable coming from the

motor into the socket [3] on the battery [1]. The

correct alignment and locking of the two parts is

done automatically by a magnetic lock. Before

inserting the plug [7] into the socket [3], make sure

that both parts are clean and that there are no

metallic particles in them. If these are present, they

must be removed with a clean, dry cloth (Fig. 6).

Fig. 6: Establish cable connection

Switch off the handbike at the sMMI. Then pull the

plug of the motor cable [7] out of the socket [3] .

Make sure that the plug of the motor cable [7] does

not come into contact with any metallic particles

when it is removed (risk of contamination). (Fig. 7).

Fig. 7: Disconnect cable connection

Insert the key [2] into the lock on the battery [1].

Turn the key [2] counterclockwise until it stops.

The lock is now released and the key can no longer

be removed from the battery. Pull the battery [1]

approx. 2 cm upwards along the rail [6] and then

8

R&E Stricker Reha-Entwicklungen GmbHAdditional operating instructions Neodrives

Battery and charger

remove it completely. Place the battery in a clean

place. Make sure that the socket [3] does not

come into contact with any metallic particles when

placing the battery (risk of contamination).(Fig. 8).

Fig. 8: Remove battery from battery rail

7.3 Charging the battery

Fully charge the battery before using it for the rst

time. The charge level of the rechargeable battery

is generally 30 % at delivery. The rechargeable

battery can be charged in any state of charge

without this affecting its service life. The battery

reaches its maximum service life when it is

charged at an ambient temperature between 10 °C

and 30 °C.

Fig. 9: Connecting the charger

The battery [1] does not have to be removed

from the handpiece for charging, but can remain

attached. Pull the plug of the motor cable [7] out

of the socket. Insert the plug [9] of the charger into

the socket [3] on the battery. The correct alignment

and locking of the two parts is done automatically

by a magnetic lock. (Fig. 7) (Fig. 9).

Carry out the charging process according to the

instructions in the charger operating manual. Also

observe the notes on the charging process. Before

inserting the plug [9] into the socket [3], make sure

that both parts are clean and that there are no

metallic particles in them. If these are present, they

must be removed with a clean dry cloth. („5.1.2

Charging process“)

When charging the battery, follow the instructions

in the charger operating manual. Also observe

the safety and warning notes in „5.1 Safety

instructions for battery and charger“ & „7 Battery

and charger“.

R&E Stricker Reha-Entwicklungen GmbH

9

Additional operating instructions Neodrives

Repair, cleaning and maintenance

Fig. 10: LEDs during charging

The following table shows the LED display [5]

of the battery during the charging process. If an

error occurs during the charging process, all LEDs

light up. Check whether all criteria (e.g. ambient

temperature, correctly attached charging plug, etc.)

for the charging process are fullled in accordance

with this and the instructions for use enclosed

with the charger are fullled. Do not leave the

charger connected to the power supply for longer

than is necessary for the charging process. After

the charging process, rst disconnect the charger

from the mains socket and then from the battery.

Always check the charge status of the battery

before starting to drive. The battery should be

fully charged before the start of the journey in

order to have the motor support available at all

times. The battery may only be charged in a dry

room at temperatures between 0° and a maximum

of 40 °Celsius. Observe the instructions in the

operating manual enclosed with the charger.

Observe the safety and warning instructions for the

battery in chapters 2.1 to 2.5 of these operating

instructions (Fig. 10).

LED is on LED ashes Charge status

- a ca. 0-19 %

a - ca. 20 – 39 %

a, b - ca. 40 – 59 %

a, b, c - ca. 60 – 79 %

a, b, c, d - ca. 80 – 99 %

a, b, c, d, e - Battery 100 %

charged.

7.4 Storage

Charge the battery to 70 % before storing it for

a longer period. Check the charge level every

three months and recharge the battery to 70 %

if necessary. Also observe the notes in „5.1.3

Storage“.

8 Repair, cleaning and

maintenance

Never use benzene, thinner, acetone or similar

agents for any cleaning processes. Likewise, do

not use abrasive or aggressive cleaning agents.

Instead, use only commercially available household

cleaning agents and disinfectants (isopropanol).

8.1 Motor

The motor of your handbike should be regularly

cleaned of dirt, preferably with a dry brush or a

damp (not wet) cloth. Cleaning should not be done

with running water such as a water hose or even a

high-pressure cleaner. However, driving in the rain

and on wet roads is possible without any problems.

Penetrating water can destroy the engine. When

cleaning, therefore, always ensure that neither

liquids nor moisture penetrate the engine.

Do not clean the engine when it is warm, e.g.

directly after a journey. Wait until it has cooled

down. Otherwise, damage may occur.

If the motor is removed, e.g. for cleaning purposes,

it must not be held or transported by the cables

under any circumstances, otherwise there is a risk

of cable breakage.

If the motor has been removed from the frame of

the handbike, the plug of the motor and the socket

of the cable to the battery pack must be checked

or cleaned with regard to possible contamination

before assembly.

8.2 sMMI Connect

The contacts of the sMMI dock are spring-loaded

and should be cleaned from time to time with

a contact spray to ensure their proper and

long-lasting function.

The sMMI housing may only be cleaned with a

damp (not wet) cloth.

10

R&E Stricker Reha-Entwicklungen GmbHAdditional operating instructions Neodrives

Repair, cleaning and maintenance

8.3 Akku

Never use benzene, thinner, acetone or similar

agents for any cleaning processes. Instead, use

only commercially available household cleaning

agents and disinfectants (isopropanol).

The plug of the charging cable on the charger [9],

the plug of the motor cable [7] and the charging

socket [3] on the battery may only be cleaned with

a dry cloth.

The battery must never be sprayed with a steam jet

or similar.

8.4 Motor

The drive wheel of your hand bike can be removed

from the bike frame at any time, for example for

cleaning purposes or in case of a at tire. Proceed

with extreme care during this process and during

subsequent assembly and, in particular, also

observe the instructions and information provided

by the manufacturers of the various components

attached to the wheel, especially the brake disc.

NOTE

For reasons of clarity, only the drive motor

integrated in the wheel is shown in the following

graphics, but not the complete drive wheel.

8.5 Removing the drive wheel

Before removing the drive wheel, note or memorize

the cable routing as well as the fastening points

of the cable ties. First loosen and remove all cable

ties with which the cable [16] coming from the

motor as well as cables and supply lines of other

components are fastened to the bicycle frame.

Then disconnect the plug [15] on the motor cable

[16] from the socket [17] on the battery cable.

Loosen the two nuts [18] or the quick release with

which the wheel is attached to the frame so that

the complete wheel can be removed from the

frame of your handbike. (Fig. 14)(Fig. 11).

Fig. 11: Cable connection to wheel hub motor

NOTE

Note or mark the position of the torque arm

[20] . When attaching the wheel later, it must be

attached in exactly the same position as before

removal. (Fig. 14).

WARNING

Never hold or transport the removed wheel by the

cable coming from the motor [16]! There is a risk

of cable breakage.

R&E Stricker Reha-Entwicklungen GmbH

11

Additional operating instructions Neodrives

Repair, cleaning and maintenance

Fig. 12: Do not carry motor by cable

8.6 Attaching the drive wheel

Make sure that all components attached to the

wheel have been mounted according to the

instructions and specications of the respective

manufacturer. This applies in particular to the

brake and the gear shift. Do not forget to remount

the torque arm [20] in the same position in which it

was previously removed. Then push the wheel into

the receptacle of the frame and tighten it with the

axle nut [18] in the following order:

• rst tighten on the side of the gear shift ( Fig.

13)

• then tighten on the brake side (Fig. 14)

The tightening torque of both nuts is between 30

and 40 Nm. Also make sure that the ratchet washer

[19] is under the axle nut, otherwise there is a risk

that the axle nut [18] will come loose.

Fig. 13: Fastening to the fork [1]

Fig. 14: Attachment to the fork [2] and torque arm

If your wheels are equipped with quick-releases,

please observe the manufacturer‘s specications

for mounting and tightening torque.

12

R&E Stricker Reha-Entwicklungen GmbHAdditional operating instructions Neodrives

Transport

Once the wheel is correctly attached to the frame,

the motor can be connected to the cable end that

leads to the battery. Make sure that the plug [15] is

correctly aligned with the socket [17]. The rounded

surfaces ([A] and [B]) must be aligned with each

other! Now fasten all cables and supply lines to the

bicycle frame again with cable ties and carry out a

nal function test (Fig. 15).

Fig. 15: Correct connection of cables

WARNING

Make sure that the cable is laid correctly, as

incorrect laying could result in the cable getting

caught in the brake disc, the drive or in the

spokes, which could cause the bike to lock up and

fall.

NOTE

In all your assembly work, be sure to follow

the instructions and specications of the

manufacturers of the various components

attached to the wheel. This applies in particular to

the brakes, gears and quick-releases.

WARNING

Never mount the motor without the torque arm

[20] . This would result in a total loss (twisting

off of the cable). In this case, all guarantee and

warranty claims are void. (Fig. 14).

NOTE

In addition to your repair tools, also carry 5 cable

ties with you in order to be able to securely fasten

any cables that may come loose during a trip.

9 Transport

NOTE

Special legal regulations apply to the transport

and shipping of lithium-ion batteries and must be

strictly observed.

The shipping of lithium-ion batteries is strictly

regulated. Therefore, take a defective battery

personally to your specialist dealer. Contact your

specialist dealer beforehand.

The legal transport regulations for taking

lithium-ion batteries with you may change annually.

Before starting a journey, enquire in good time

about the applicable regulations with the airline or

shipping company or your tour operator.

9.1 Transportation in vehicle

Always transport the handbike only when it is

disconnected. If necessary, detach the attachment

stand from the handbike. Secure all individual parts

against slipping. The batteries can be transported

in any position, as they are leak-proof batteries.

Only use your car for transport, not for storing or

keeping the battery.

NOTE

Remove the battery and the sMMI Connect from

the handbike to avoid damage during loading and

during the journey. Make sure that cable ends

cannot cause any damage to the handbike or your

car while driving.

10 Disposal and recycling

Electrical appliances, batteries, accessories

and packaging should be recycled in an

environmentally friendly manner.

Avoid taping parcel tape to the handcycle, as

adhesive residue is difcult to remove.

Dispose of all other components of your handbike

in accordance with the regulations of your region at

appropriate collection points or in household waste

(paper, cardboard, plastic packaging).

R&E Stricker Reha-Entwicklungen GmbH

13

Additional operating instructions Neodrives

Warranty and guarantee

11 Warranty and guarantee

NOTE

Do not throw the batteries, chargers and electrical

components of your handbike in the household

waste. According to the current EU directives,

electrical devices and batteries must be collected

separately and recycled in an environmentally

friendly manner.

Complaints due to incomplete or incorrect delivery

or recognizable defects must be made in writing

immediately, at the latest 8 days after receipt of

the goods. Our obligation in the case of justied

complaints is limited to replacement delivery or

repair by us. In the case of warranty repairs, which

have been agreed with us in advance, the rejected

parts are to be sent back to us. Modication or

repair work carried out by the customer or a third

party without our prior consent shall invalidate the

warranty obligation.

The warranty period for the handbike is 2 years.

The batteries for our Lipo and Neodrives models

also have a 2 year warranty. Not covered by the

warranty are defects due to wear and tear or

improper handling. Wear parts are for example:

tires, brake pads, Bowden cables, light bulbs. Also

wear parts are lead-acid batteries, on which we

grant a half-year warranty.

12 Liability

NOTE

The information on liability is taken from our

general terms and conditions (as at the time

of printing). These can be viewed in full at the

web address https://stricker-handbikes.de/en/

general-business-terms.

We shall only be liable for consequential damages

or other claims for damages if we, our legal

representatives or vicarious agents are guilty of

intent or gross negligence insofar as this is in

accordance with the statutory provisions.

14

R&E Stricker Reha-Entwicklungen GmbHAdditional operating instructions Neodrives

Liability

Attachment

A Technical data

Power Assist Device

from 22

kg

Total weight from

18,5 kg

Range**

Drive 120 km

Wheel hub motor electric 25

km/h

Rated power (Peak) 250 W

(650 W)

Operating voltage 36 V

Nominal torque 12 Nm

Peak torque 40 Nm

Efciency 80 %

(incl. electronics)

Control power electronics integrated in the wheel

hub

Cassette mount standard plug-in cassette, up to

10-speed

Brake disc from 160 mm diameter

Torque absorption variable torque support

adaptable to dropout

Weight 4.36 kg (drive only incl. plug and cable,

without brake disc, freewheel, cassette)

Smart MMI

Display control monochrome

Display Diagonal, resolution 2,4 Zoll,

240 X 320 Pixel

Dimensions sMMI without dock (B X L

X H) 53 mm x 85 mm x 14 mm

Connectivity

Micro-B 1.1 USB, 5 volt power supply, 500 mA,

Connection to PC with diagnostic and

parameterization software

Mechanical/electrical contacting Twist

bayonet lock (twist-to-lock), corrosion-protected

contacts, spring-mounted

Lighting LED

backlight, 70 - 350 cd/m²

Display lens

scratch-resistant, coated acrylic glass pane

Weight sMMI (removed) 55 g

Smart MMI Dock

Controller 23 mm

inner diameter, 3 buttons (up, down, menu), xed

wired

Mounting plate Stem

and handlebar mount, angle adjustable in 10°

increments,

Height adjustable with spacers

Weight (incl. cable and remote control) 60 g

Total system

Operating temperature - 20 °C

to + 50 °C (below 0 °C automatic deactivation of

recuperation or

deactivation of the recuperation or the brake

assistant)

Protection class IP65

Battery

Designation

10INR19/66-5

Battery type Lithium

Ion

Nominal capacity in Ah 17.25

Rated voltage in V 36.2

End of charge voltage in V 42

Total energy in Wh 515

Maximum discharge current in A 30

Charging ambient temperature 0 °C to

40 °C

Operating ambient temperature -20 °C

to 60 °C

Number of cells 50

Protection class IP54

R&E Stricker Reha-Entwicklungen GmbH

15

Additional operating instructions Neodrives

Attachment

Weight approx. 3.5 kg

(*) The transport weight is the total weight minus the battery and the mounting frame. It is recommended to

remove these parts for easier transport.

(**) The range varies depending on the battery used, as well as the terrain traveled and the prevailing driving

conditions. Under optimal riding conditions (for example, a level terrain, freshly charged batteries, ambient

temperature of 20 °C, steady ride, etc.), a drive power of 100 watts and a pedaling power of 100 watts, the

indicated range can be achieved.

Subject to changes in technology and design due to continuous further developments.

These operating instructions are available for download from our website www.neodrives.de. If you need a

version with a larger font, please contact the Alber Service Center.

16

R&E Stricker Reha-Entwicklungen GmbHAdditional operating instructions Neodrives

Attachment

R&E Stricker Reha-Entwicklungen GmbH

17

Additional operating instructions Neodrives

Misprints, errors and price or product changes reserved. Product changes include, but are not limited to, changes

resulting from further development of mechanics, software or legal requirements.

Date: 2.11.2021

© R&E Stricker Reha-Entwicklungen GmbH, Bühl

Reprint, even in part, only with the written permission of R&E Stricker Reha-Entwicklungen GmbH , Bühl.

V-Nr.: NEO EN EC 20211102 1119

Table of contents

Other Stricker Bicycle manuals

Stricker

Stricker Lipo Smart Series User manual

Stricker

Stricker Lipo Lomo V16/4 User manual

Stricker

Stricker City User manual

Stricker

Stricker CITY 7 User manual

Stricker

Stricker Lipo Smart Series Operating instructions

Stricker

Stricker Lipo Smart Series Operating instructions

Stricker

Stricker Lipo Smart Para User manual

Popular Bicycle manuals by other brands

Yamaha

Yamaha Waverunner FX 160 Service manual

Liberty 123

Liberty 123 24v FoldNGo user manual

Urban Arrow

Urban Arrow Family quick start guide

Juiced Bikes

Juiced Bikes RipCurrent S owner's manual

Flyer

Flyer Upstreet2 Folding Instructions

J&B Importers

J&B Importers Sun Bicycles HT-3 Hand-Trike owner's manual