PREFACE

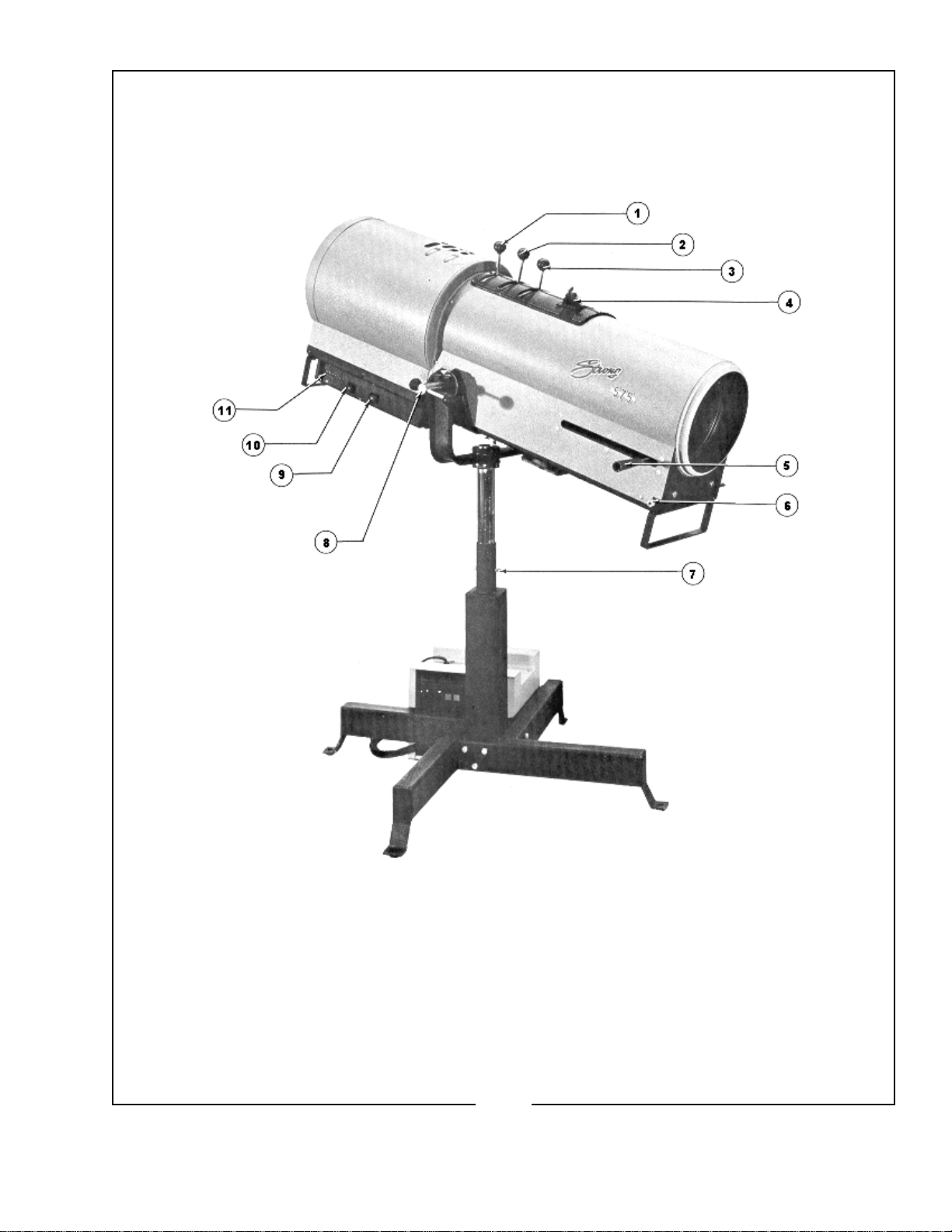

THE STRONG “575” FOLLOW SPOTLIGHT Model 41000 is an AC follow spot

complete with lamphouse, igniter, power supply, optical system, and color boomerang. It is designed

for use with the 575 watt metal halide bulb, Strong part number 41102.

THE “575” LAMPHOUSE has a deep ellipse cold-coated metal reflector designed to

operate in a fixed position, with the bulb mounted horizontally in the lamphouse. The bulb is adjustable

in relation to the reflector to permit positioning on the reflector optical center line. The igniter is

contained in the base of the lamphousing.

THE SEPARATE POWER SUPPLY comes equipped with a three-wire AC line cord

terminating in a 125 volt (±10 volt), 60 Hz. plug that can be connected to an AC outlet, and draws

approximately 7 amperes from the line. The power supply also has two switches and a toggle type

circuit breaker. The circuit breaker must be in the “ON” or “RESET” position to energize the power

supply. The two switches are an “ON” switch and “OFF” switch. The lamp may be turned on or off by

use of the appropriate switch at the power supply or at the lamphouse.

THE IGNITER in the lamphouse requires a 237 V.AC open circuit pulse, provided by a

step-uptransformerinthepowersupply,toignitethebulb. Afterignition,thepowersupplyautomatically

drops the voltage to the value required to maintain the arc.

THE ADJUSTMENT CONTROL for positioning the metal halide bulb is located behind

the cover panel at the rear of the lamphouse. This control mechanism permits focus adjustment of the

bulb in relation to the reflector and also allows the bulb to be centered both vertically and horizontally on

the optical center of the reflector.

THE LAMPHOUSE has a running time meter to indicate the number of hours the bulb

has been used. It also has two switches for the “ON” and “OFF” control at the lamphouse. The lamp

can be controlled from either the power supply or the lamphouse. To break the AC supply at the power

supply and lamphouse, open the circuit breaker on the rear of the power supply.

THE POWER SUPPLY is attached to the lamphouse by a cable assembly approximately

13 feet long, terminating in an MS connector for easy attachment to the lamphouse. This cable assembly

contains all the control wires for the operation of the lamphouse and power supply.

TWO BLOWERS are used in the follow spot system and operate from the 115 volt AC

supply only while the bulb is ignited. One blower is used to cool the lamphouse and bulb; the other, in

the lens mechanism, cools the color gels and lens system.

575/001