INSTALLATION - OPERATION

INSPECT THE UNIT upon receipt. Any damage must be reported to the freight car-

rier immediately. It is the responsibility of the consignee, not the shipper, to le damage claims.

THE HMI BULB, if ordered with the unit, is included in the accessory kit packed with

the spotlight. DO NOT touch the quartz envelope when handling the bulb; ngermarks will burn into

the vessel, reducing light, and contributing to premature bulb failure. Handle the bulb by the metal

base caps only. The HMI bulb is not polarized, and the iginter lead can attach to either end.

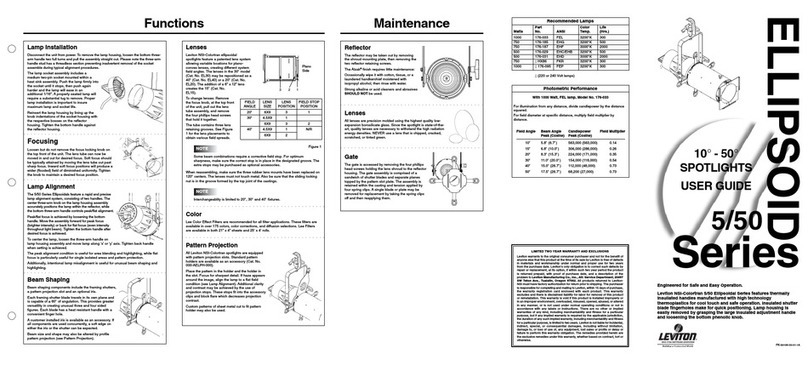

DISMOUNT THE LAMPHOUSE COVER from the rear of the lamphouse by loosening

the (4) captive screws. Loosen the top bulb mounting bracket and remove the threaded nuts from the

ends of the HMI bulb. Pull the upper bulb mount clear of the reector and insert the bulb through the

reector holes. Slide the lower bulb end cap through the lower mounting opening; attach the igniter

lead and secure using the knurled nut. Swing the top bulb mounting bracket over the upper end cap;

attach the upper lead, and secure using the knurled nut. Tighten the top mounting bracket.

IF USING THE OPTIONAL FLOOR STAND ASSEMBLY, drop the legs to the

horizontal position and pin in place. The oor stand may then be moved on its casters to desired

location. IMPORTANT: Once the oor stand has been positioned, lower the leveling feet to transfer

the weight of the unit from the casters to the leveling feet. If the unit is to be permanently installed,

it is advisable to remove both casters and leveling feet, and bolt the stand to the oor.

INSERT THE POST of the yoke assembly into the nylon bushing at the top of the

oor stand tube. Position the yoke for right- or left-hand operation (as desired). Place the spotlight

head on the yoke assembly, making certain that the semicircular friction plate of the spotlight saddle

(see Figure 2, Item 41) is between the yoke and the brake clamping plate. Tighten the (2) handwheel

knobs on each side of the yoke allowing adequate end play for free operation, and tighten the (2) lock

knobs. Vertical movement of the spotlight head can be adjusted by the amount of torque applied to

the lower, spring-loaded braking knob against the friction plate.

SET THE BALANCE of the head assembly. Loosen the (2) hex nuts on each side

securing the saddle brackets to the spotlight base rail (see Figure 2, Item 66). Slide the spotlight head

inside the slots until the proper balance is achieved, and retighten the hex nuts.

THE SPOTLIGHT YOKE, as supplied, is designed for use with standard truss xtures.

Truss mounting the TrussTrouper will depend largely on its application in any given venue.

TT/02