Strong TROUPERETTE IV User manual

Other Strong Spotlight manuals

Popular Spotlight manuals by other brands

Guangzhou Yinhe Lighting&Sound Equipment Factory

Guangzhou Yinhe Lighting&Sound Equipment Factory NE-204 user manual

LIVARNO home

LIVARNO home 375304 2101 Installation, operating and safety information

Cameo

Cameo CLQS40WW user manual

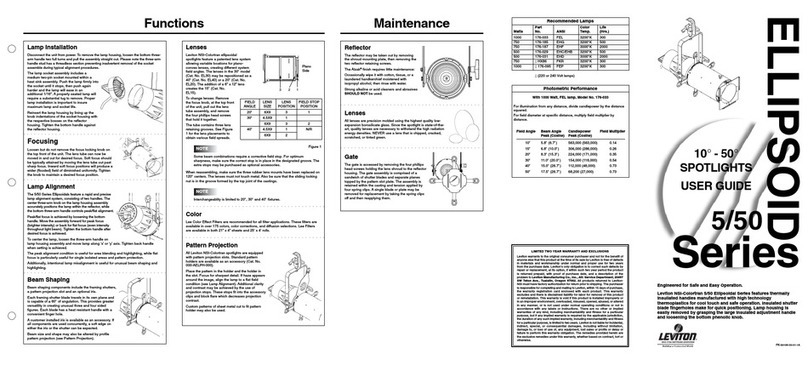

Leviton

Leviton Ellipsoid 5/50 user guide

Monacor

Monacor img Stage Line PARL-56PDX/CR instruction manual

Vector

Vector SL3AKV instruction manual

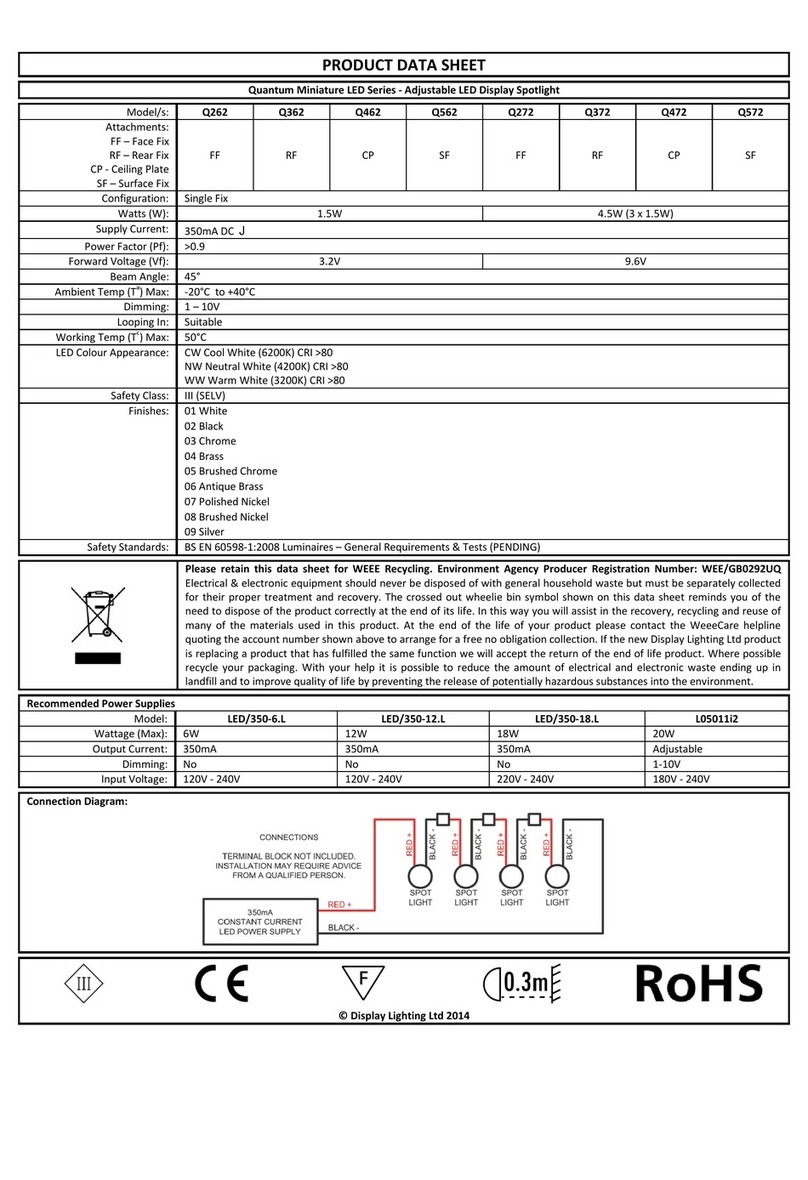

Quantum

Quantum Q262 Product data sheet

Philips

Philips Vari-lite VL3015LT user manual

EUROSPOT

EUROSPOT C51 instruction manual

DTS

DTS MINI BRICK ARC user manual

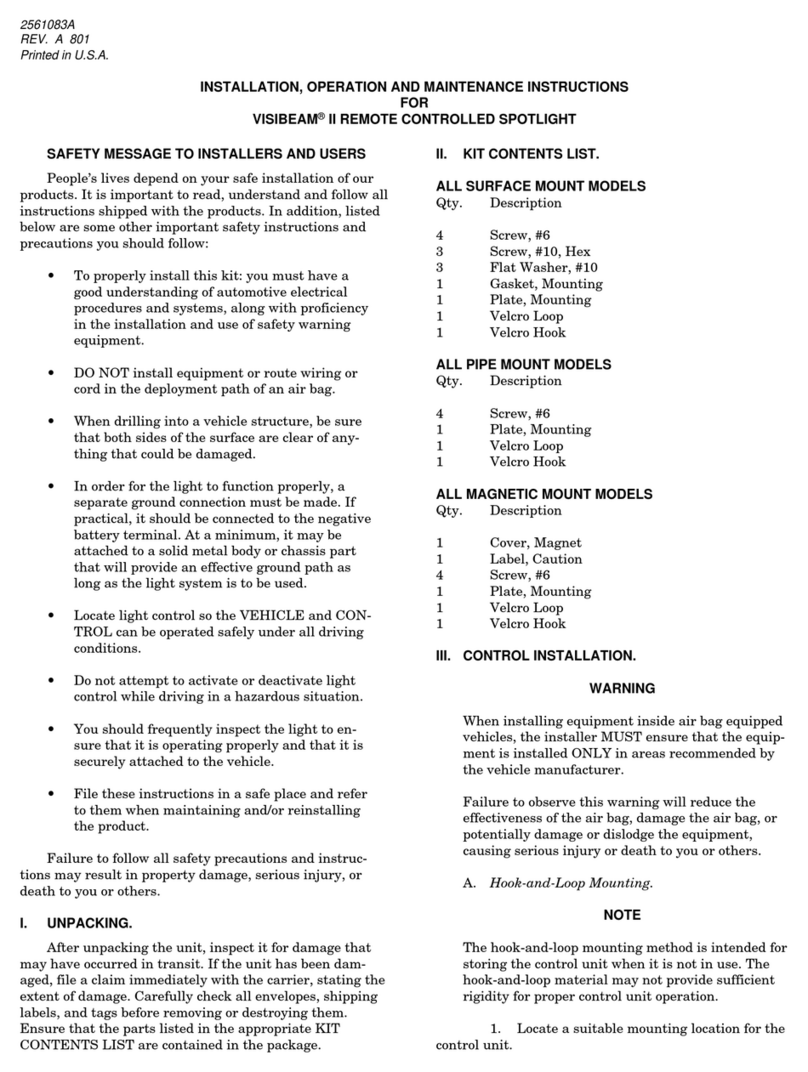

Federal Signal Corporation

Federal Signal Corporation VISIBEAM II Installation, operation and maintenance instructions

ACME

ACME LED-MS350B user manual

EuroLite

EuroLite Akku flat light 1 user manual

Commercial Electric

Commercial Electric SPTM-1401 Use and care guide

Vision & Control

Vision & Control SLB-500-W5K7-P-SL Instructions for use

Teknik

Teknik FLEXI user manual

Craftsman

Craftsman CMXLSB10 instruction manual

EuroLite

EuroLite LED SLS-144 UV Floor Spot user manual