Pg. 4

1. WARNINGS

• These wall mounts are intended for use only with the maximum weight capacities listed below.

• Installationbyaqualiedprofessionalishighlyrecommendedforthisproduct.

• Do not begin installation until you thoroughly read and understanding these instructions.

• Ensure the mounting wall will safely support four times the combined weight of the mount and display panel.

• The manufacturer does not accept responsibility for incorrect installation.

CAUTION:

Use with heavier than the maximum weight indicated may result in instability which could possibly cause injury.

1. AVERTISSEMENTS

• Ces supports muraux sont pour être utilisés seulement avec les capacités de poids maximales ci-dessous.

• L’installationparunprofessionnelqualiéestfortementrecommandéepourceproduit.

• Ne commencez pas l’installation avant d’avoir lu et compris ces instructions.

• Assurez-vous que le mur de montage supporte en toute sécurité quatre fois le poids total du support et du panneau

d’achage.

• Le fabricant n’accepte pas la responsabilité por une installation incorrecte.

MISE EN GARDE:

Une utilisation avec un poids plus haut que le poids maximal indiqué peut provoquer une instabilité et ainsi des

blessures.

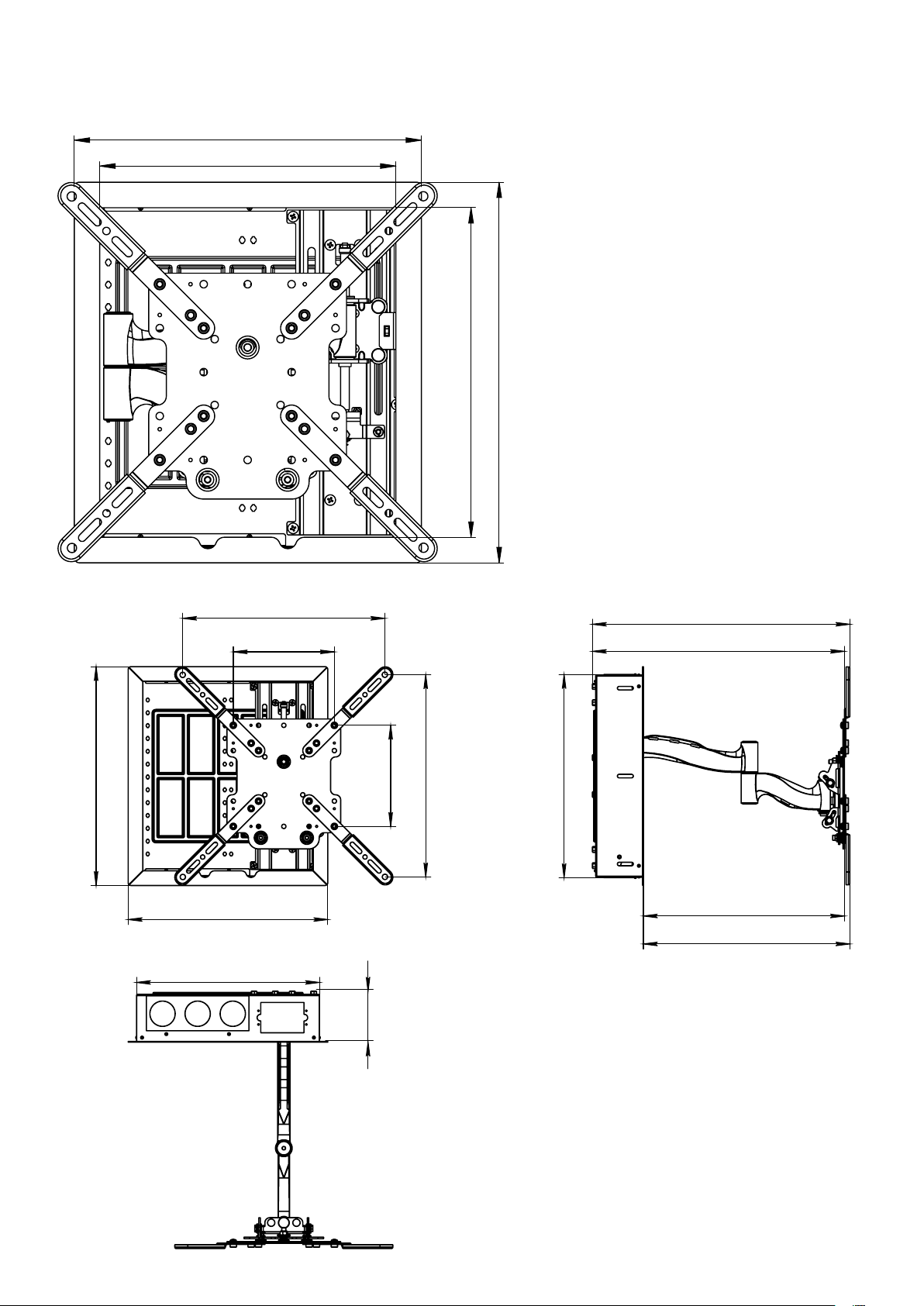

CAUTION: This wall mount is intended for use only with a maximum display weight of 100 lb / 45 kg.

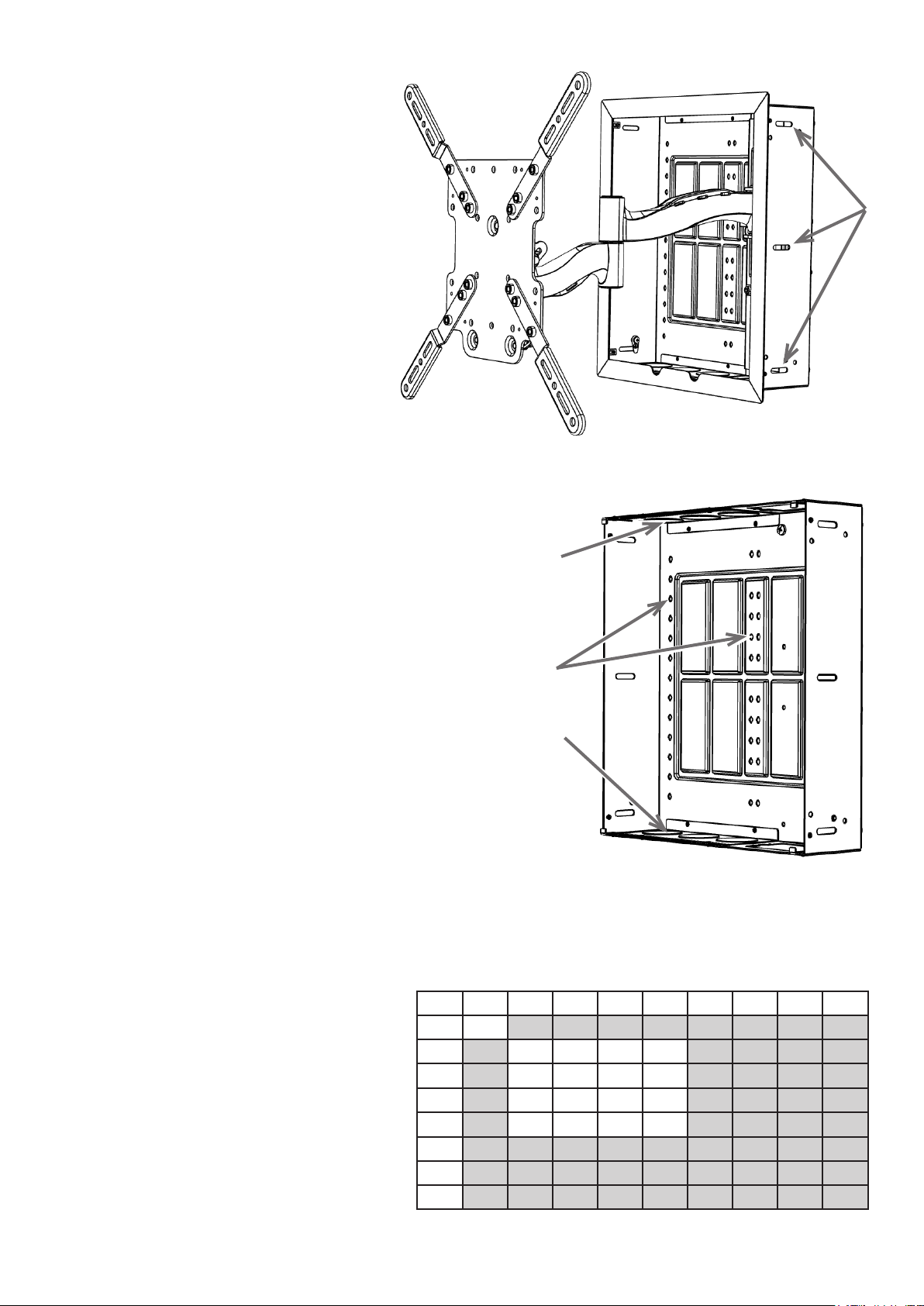

Preparing an Existing Wood Stud Wall (Retrofit with Drywall)

The VersaMount ts a 16" stud bay. Under no circumstances should you mount this product to metal studs.

WARNING: Studs must be a minimum of 2"×4" and covered with no more than 3/8" thick drywall.

Materials required:

- Stud Finder - Cutout Template - Tape or Nails and Hammer - Drill - Drywall Saw

• Locate and mark the edges of the stud bay in the mount location.

• Using tape or nails, secure the provided cutout template in the desired mount location. Use the marks you made to

orient the template properly.

• Using a drill, make holes along the cutout line every 4–6 inches.

• Remove the template and complete the cuts using a drywall saw. Remove the drywall.

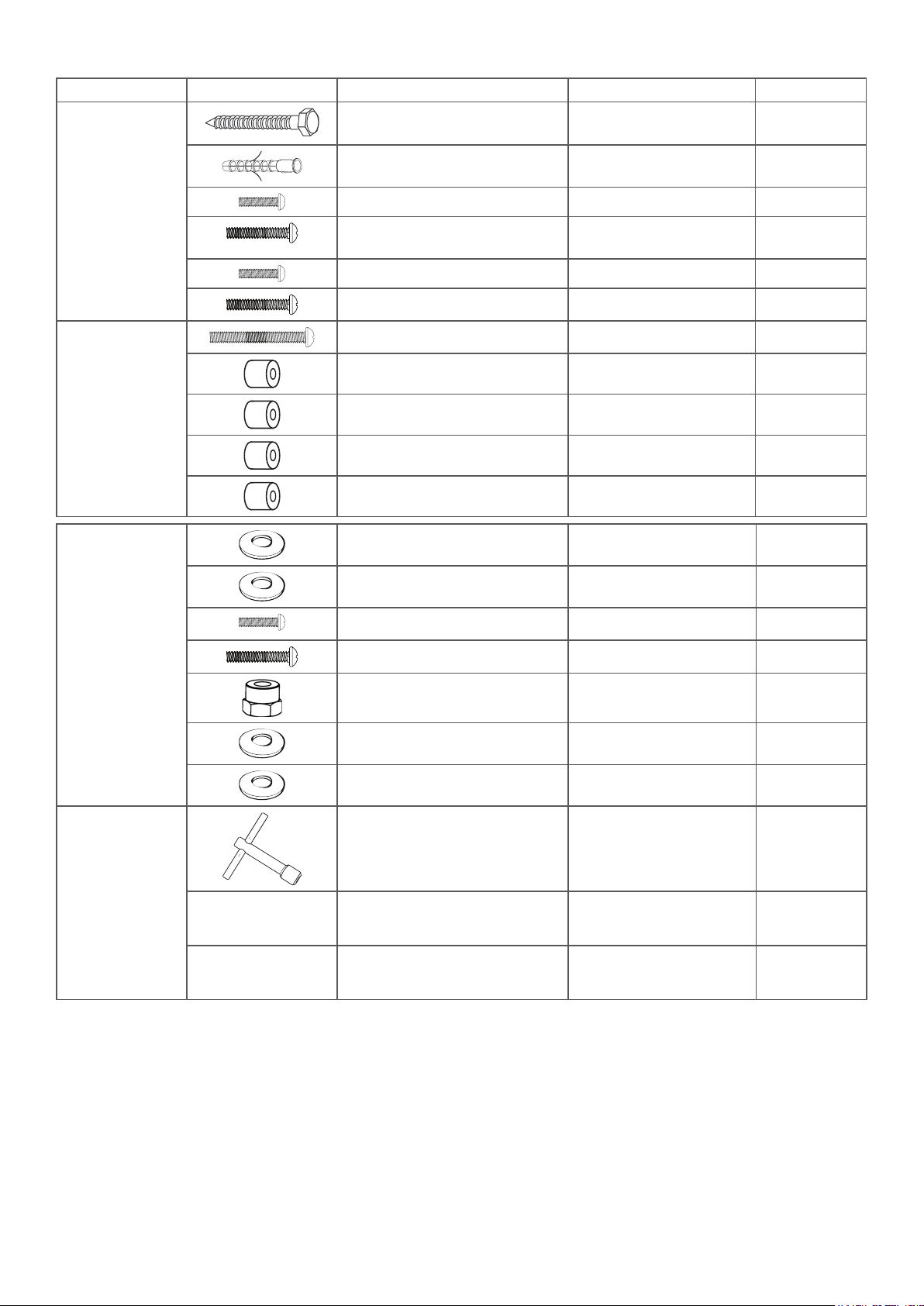

2. Installing the Enclosure into the Wall

Materials required:

- Wood Shims

- 6 × Lag Bolts (A)

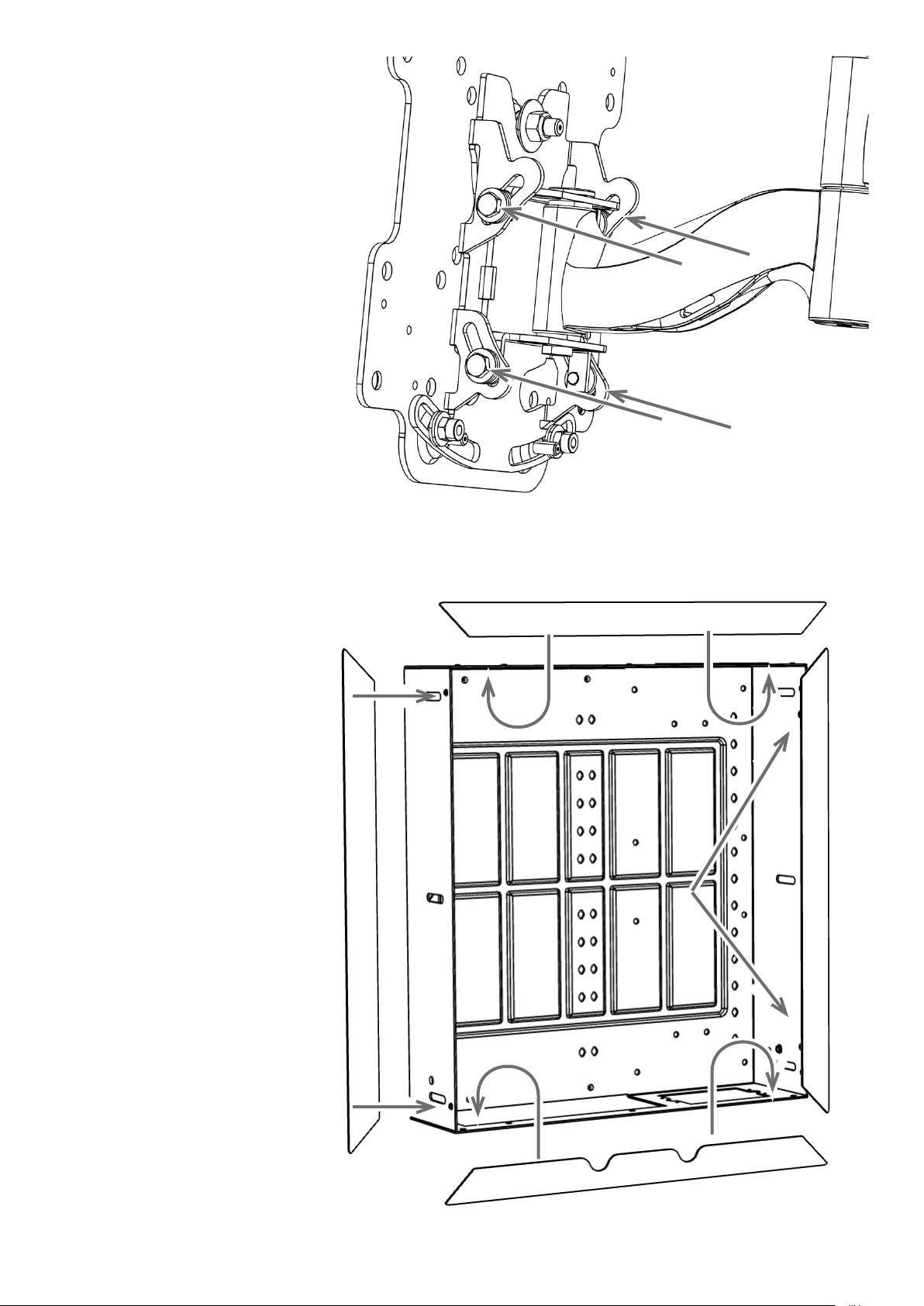

2.1 Reverse the Track Position

(OPTIONAL)

The vertical track and arm come pre-installed at

the right side of the enclosure. If your job requires

that the arm be at the left side of the box, remove

the twelve bolts (the nuts for which are shown to

the right), remove the arm, rotate the enclosure

180°, and use the bolts to re-install the arm.