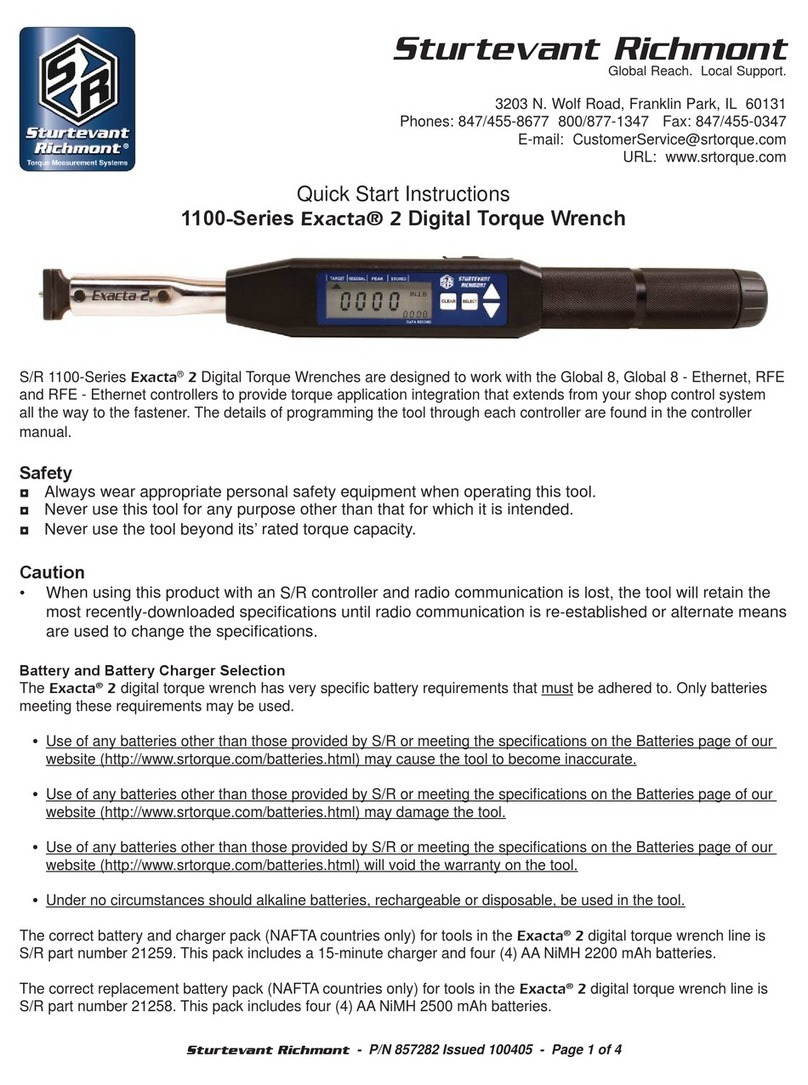

Sturtevant Richmont exacta 2 User manual

Sturtevant Richmont - Exacta®2- Page 1 of 20

Sturtevant Richmont

The Tools You Trust .

555 Kimberly Drive Carol Stream, IL 60188

Phones Worldwide: +1 847/455-8677

Toll Free US Only: 800/877-1347

Fax: 847/455-0347

www.srtorque.com

Operating Instructions

Exacta®2 Digital Torque Wrenches

Safety

•Never use these tools for anything other than their designed purpose.

•Never use these tools beyond their rated capacity.

•Always wear and use appropriate safety equipment when operating these tools.

Modes of Operation - General

The Exacta®2digital torque wrenches have three modes of operation: Track, Peak and Residual.

In the Track mode functions similarly to a dial or beam torque wrench. The current torque is shown on the

display as it rises or falls in response to the force applied. This can be particularly useful when working with

fasteners having a prevailing torque feature (crimping or insert) and for fastener testing.

In the Peak mode, the torque is shown on the display as it rises, and when the force applied to the tool

declines the maximum torque applied before the decline is retained on the screen for a period of time and

stored in memory. This mode is exceptionally useful in assembly operations and some testing operations.

This mode may be used with or without torque specifications having been programmed into the tool.

The Residual mode is designed specifically to capture the torque remaining on a fastener after it has been

installed and tightened. The theory behind this is that when testing the torque remaining on a fastener after

installation, the torque applied to the fastener will rise until the fastener begins to move. When the fastener

begins to move there will be a brief reduction in the torque followed by another rise in the torque. The

bottom of this temporary reduction in applied torque is interpreted as the Residual torque. It must be noted

that this works best on hard joints with stiff fasteners. For joints where this mode works well, the wrench

makes an excellent auditing tool.

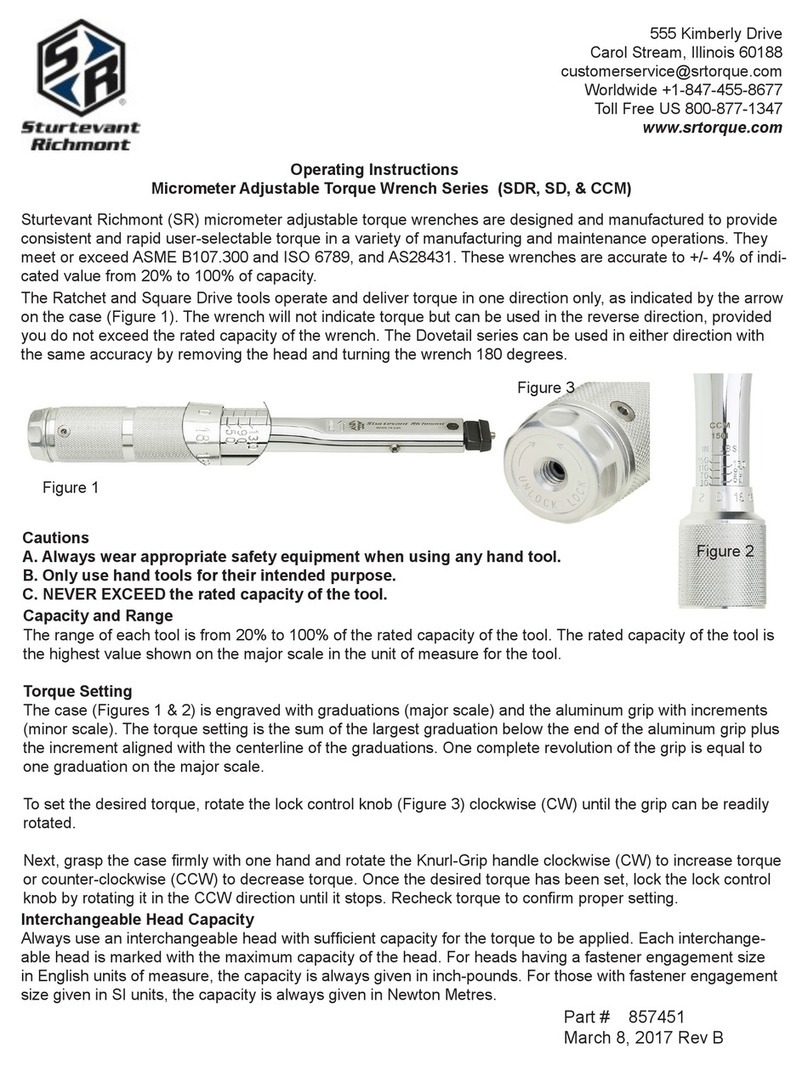

S/R Dovetail and Interchangeable Heads

Those models of the Exacta®2digital torque wrench that are equipped with an S/R dovetail are designed

to be used with S/R interchangeable heads. The dovetail design provides an exceptionally strong and rigid

connection.

Sturtevant Richmont - Exacta®2- Page 2 of 20

The Exacta®2 models with the dovetail are calibrated for use with S/R

interchangeable heads having a 1 7/16” Common Centerline Length

(CCL). Use of interchangeable heads with a different CCL or head

extension(s) will make the tool inaccurate until and unless it is recalibrat-

ed with a head having the same CCL as that which has been selected

for use. Always recalibrate the tool immediately if changing to a head

with a different CCL or if a head extension is to be used.

Ratchets

Some Exacta®2 models have ratcheting square drives instead of the

S/R dovetail. These are slide pin ratchets capable of being set

to ratchet in either the clockwise (CW) or counter-clockwise

(CCW) direction. To change the ratcheting direction, remove all

torque load from the tool and push the slide pin to the opposite

side from that to which it is currently biased.

The ratchet should be disassembled, cleaned and lubricated

periodically. The procedure for performing this function can

be found in the FAQ section of our website. See the Ratchet

Replacement procedure (FAQ 7) and simply clean and replace

the original parts instead of installing new parts. If the ratchet

is damaged, contact your S/R distributor and order the correct

ratchet renewal kit for your tool, then use the instructions on

the website to perform the replacement.

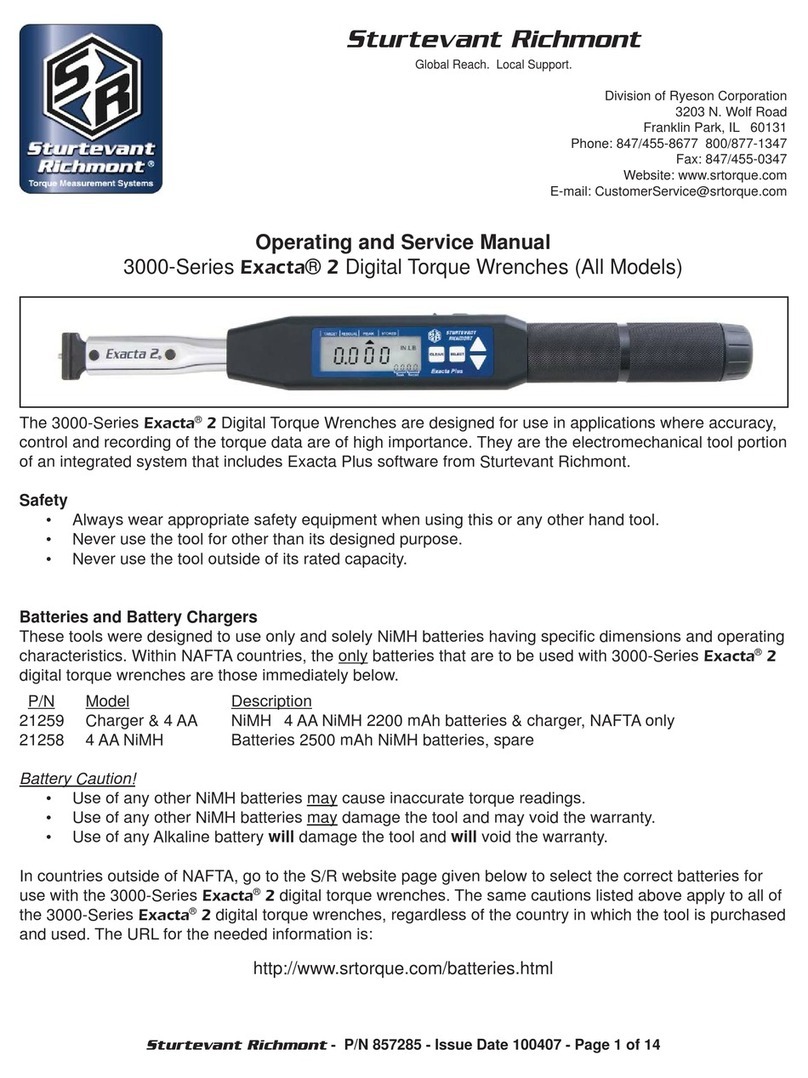

Battery and Battery Charger Selection

The Exacta®2 digital torque wrench has very specific battery requirements that must be adhered to. Only

batteries meeting these requirements may be used.

•Use of any batteries other than those provided by S/R or meeting the specifications on the Batteries

page of our website (http://www.srtorque.com/batteries.html) may cause the tool to become inaccurate.

•Use of any batteries other than those provided by S/R or meeting the specifications on the Batteries

page of our website (http://www.srtorque.com/batteries.html) may damage the tool.

•Use of any batteries other than those provided by S/R or meeting the specifications on the Batteries

page of our website (http://www.srtorque.com/batteries.html) will void the warranty on the tool.

•Under no circumstances should alkaline batteries, rechargeable or disposable, be used in the tool.

The correct battery and charger pack (NAFTA countries only) for tools in the Exacta®2digital torque

wrench line is S/R part number 21259. This pack includes a 15-minute charger and four (4)AANiMH 2200

mAh batteries.

The correct replacement battery pack (NAFTA countries only) for tools in the Exacta®2digital torque

wrench line is S/R part number 21258. This pack includes four (4)AANiMH 2500 mAh batteries.

For countries outside NAFTA, consult the batteries page on our website (http://www.srtorque.com/batteries.

html) to find the correct battery and battery charger for use in your country. Follow the manufacturer links

provided and select the appropriate product for your country and need.

Sturtevant Richmont - Exacta®2- Page 3 of 20

Operating Environment

The Exacta®2digital torque wrenches have been designed to work at any temperature from 32 degrees

Fahrenheit to 115 degrees Fahrenheit. Exacta®2digital torque wrenches will work in any humidity up to

99% non-condensing.

Component Identification

1. Electronics Module

The electronics module houses and protects the circuit boards, display, operating buttons and other

electronic components.

2. Display

The display conveys the visual information needed for use and generated by use.

3. Indicator Labels

These labels, working with indicators on the display, inform the user what mode or function is currently

active.

4. Buttons

These buttons (Clear, Select, Up, Down) are used to access program functions and data on the display.

5. Grip

The grip is where the tool should be grasped when in use. The load point on the grip is marked by the

plain ring in the center of the grip.

6. Battery Compartment Cover

The battery compartment cover protects the batteries and associated parts, and permits access for

battery replacement.

7. Switch Cover

This rubber cover protects the power switch and the

serial port.

8. Serial Port

This is a single-pin serial port for communications.

9. Power Switch

This switch enables and disables electric power from the

batteries to the electronics.

Sturtevant Richmont - Exacta®2- Page 4 of 20

10. Indicators

There are four triangular indicators in a line across the top of the display. These indicators are activated

and deactivated to show what mode or operation is currently active on the tool. To the right of these is a

battery icon (not activated in this photograph) used as a battery level (low battery power) indicator.

11. Unit of Measure Area

This area of the display shows the currently active unit of measure, both during use and during

keyboard programming.

12. Data Record Area

This small four-digit display shows the currently-active data record in memory or, when programming,

part of the function information required.

13. Quality Attribute Area

There are several icons along the bottom of the display to the left of the Data Record area. These

include “OK” and “BAD”, which provide the attribute evaluation of the torque against the programmed

specification when the tool is in use. They also include MAX and MIN

14. CCW Icon

The CCW icon illuminates when the torque is in the counter-clockwise direction.

15. Primary Display Area

The primary display area conveys differing information depending upon the current action of the tool.

This may be numeric information such as torque values or alphabetic information such as is used in

some programming and communication functions.

16. Rear LED Lens

This lens illuminates with the color (Yellow-Orange/Green/

Red) in the same manner as the display when the LED color

system is in use. This permits the user to know the status of the

tightening even when the tool is used in an orientation where the

display is not immediately visible.

17. Buzzer

This buzzer provides an audible indication of the torque status to

augment the visual indicators. When in use, the buzzer emits a

single sound when power to the tool is enabled, a rapid series of

beeps when the torque specification is attained and while within

the specification. It will emit a single longer beep if the torque specification is exceeded.

Sturtevant Richmont - Exacta®2- Page 5 of 20

Battery Installation

To install the batteries in the tool:

1. Move the power switch to the disabled (off) position.

2. Unscrew the battery cover from the rear of the grip.

3. Observe the two labels inside on the battery holder.

4. Install the batteries as shown on the labels and in

the photograph here.

5. Reinstall the battery cover.

Starting Routine

To use the wrench slide the power switch to the Enabled or On position. The tool will begin an internal start-

ing routine and the display will first show the version of the firmware that resides on the tool then display

the model of the tool (tool capacity in foot-pounds).

Once the starting routine is complete, the tool will then show on the display the information for the status in

which it was most recently set. This includes the mode of operation, unit of measure, current data record

number and target torque setting.

Normal Operation - Definition

The phrase “normal operation” will be used in several locations in these instructions. The definition of “nor-

mal operation” is the condition where the tool is being used as a torque wrench and not currently connected

to a computer. Data operations are treated separately.

On-Wrench Programming

The four buttons on the keypad may be in a locked or unlocked state. This section applies when the key-

pad is in an unlocked state. For information on locking and unlocking the keypad, see the section on using

the tool with the Exawin 5 software.

Many, but not all, of the functions of the Exacta®2digital torque wrench may be programmed using the

four buttons on the wrench keypad if the keypad is unlocked. Those that can be programmed from the key-

pad are: Unit of Measure (UOM), Minimum (Lo) Torque Specification, Maximum (Hi) Torque Specification,

and Mode of Operation (Track, Residual or Peak).

Exacta®2 uses a single-level menu to access the primary functions, and scrolling to move through the op-

tions within the functions. To program the tool, follow the steps in this section.

1. Activate power to the tool by sliding the power switch to the enabled (On) position.

2. Allow the unit approximately five seconds to complete

it’s internal starting routine and self-checks.

3. When the starting routine is complete, the normal

operating mode screen will appear about as it does

here during normal operation.

Sturtevant Richmont - Exacta®2- Page 6 of 20

The large number in the center is the Target, or the midpoint value between the minimum and maximum

(Lo and Hi) torque values currently active on the tool. The active Target arrow verifies this.

The current Unit of Measure is displayed beside the large numbers, in this case Foot-Pounds. The ar-

row below the Peak indicator shows that the unit is in Peak mode of operation. The data record displays

the data point or record that will be the next one recorded.

There are four buttons forming a keypad to the right of the display. These buttons are used in the pro-

gramming of tool functions and for reviewing torque data stored on the tool.

4. To begin programming the tool, press the SELECT button twice.

5. The Unit of Measure is the first item to be

programmed. The current UOM is displayed. Press

the Up arrow button to scroll through the available

units of measure. When the desired unit of measure

is displayed, press the Select button once to

make it active and advance to the next item to be

programmed.

6. The next menu item is the Minimum (Lo) Torque

Specification. The appearance of “-Lo-” in the Data

Record area of the display confirms this is the current

programming function. The current specification value

will be displayed, in this case zero foot-pounds. You

can press the “Clear” button to set the minimum and

maximum values to zero.

To increase the minimum torque specification value, press the Up arrow button once. The value will

increase by one. Each time the button is pressed the value will increment by one.

To increment rapidly, press and hold the Up arrow

for two (2) seconds. The value will start rising

rapidly. Release the button when the desired value

is displayed. If the desired value is missed, use

single pushes of the Up or Down buttons to obtain

the desired value. For this example, the minimum

torque value is forty (40). The yellow “Caution”

color will become active at 90% of this value when the tool is in use; the green “Good” color will be

displayed when this value is attained. The green color will remain until either(1) cycle is complete or

(2) the Maximum Torque Specification is exceeded or (3) tool capacity is reached. Press the Select

button to lock in this value and move to the next function. Note: When the minimum torque value is set,

the maximum torque value is set to the same point to permit more rapid programming of the maximum

value.

7. The next function is the Maximum (Hi) Torque

Specification. The Data Record area of the display

will show “-Hi-” to indicate this function is active. The

center numbers will display the current maximum

torque value. This specification value can be changed

to zero if desired by pressing the Clear button.

Sturtevant Richmont - Exacta®2- Page 7 of 20

The Up button is used to increment the value upwards. The increment is one (1) for each press of the button.

If the specification is wide, increasing the value rapidly can be performed as it was on the Minimum

Torque Specification selection; press and hold the Up button for two (2) seconds to begin rapid

incrementing. The Up and Down arrows can be used to set the final value if it is missed while being

rapidly increased. Press the Select button to lock in the desired value and move to the next item.

8. The tool will advance to the Mode of Operation screen. There are three (3) modes of operation

available, each with its’ own screen symbology. The modes and symbols for each are:

“otrA” = Track Mode, torque rises and falls with force

applied. No data is stored.

“oPEA” = Peak Mode, highest torque captured with

each use; the store and print/clear processes are

used if the autoclear time is greater than zero.

“orES” = Residual Mode, used for auditing torque

on installed fasteners. The auto-store/print/clear

process is used if the autoclear time is set to greater than zero.

When the symbol for the desired mode of operation is displayed, press the Select button to make it

active and advance to the next menu item.

The “data” screen is not part of normal operation. It is used to transfer data, and will be covered in a sepa-

rate section of this document.

To leave programming of the tool and begin normal operation with it, press the Select button one time. The

display will show an active indicator under the indicator label for the current mode, an active indicator for

the target torque, the unit of measure selected, the target torque, and the currently active data record. The

tool is now ready for use in torque application.

By default, both the LED color scheme and the beeper will be active. These cannot be programmed or

altered through use of the keyboard programming method.

Programming and Data Collection Using the Exacta®2 with S/R Exawin 5 Software

S/R offers Exawin 5 software that may be used to program the wrench and as a data collection tool. This

software is available for free on the S/R website when you register your Exacta®2. The software is not

required in order to collect data from the tool; the tool is capable of creating a self-generated report when

used with Hyperterminal or other terminal software on a computer. Exawin does, however, provide a rapid

and simple method for obtaining data from the tool.

The serial cable supplied with the wrench may be used to connect the tool to the computer. If the computer

does not have a 9-pin serial port, a powered serial to USB convertor (S/R part no. 10456) is available.

To connect the computer running Exawin 5 to the tool:

1. Ensure the computer is operating and that tool power is disabled (off).

2. Connect the serial cable to the serial port on the computer.

3. Connect the single-pin connector on the cable to the serial port on the tool.

Sturtevant Richmont - Exacta®2- Page 8 of 20

4. Enable power to the tool (turn tool power on).

5. Allow the tool to complete its’ starting routine.

6. Start the Exawin 5 software on the computer. Follow the software instructions for using the software

with the tool.

7. When complete, disconnect the tool from the serial cable.

Uploading Data from Tool to Computer Using Hyperterminal

Hyperterminal (or another terminal emulation program) may be used with the Exacta®2 digital torque

wrench to collect the torque data stored on the wrench. The process for doing this is:

1. Ensure the computer is operating and that tool power is disabled (off).

2. Connect the serial cable to the serial port on the computer.

3. Connect the single-pin connector on the cable to the serial port on the tool.

4. Start the Hyperterminal software.

5. Set the communication protocols within Hyperterminal to the following settings:

Baud Rate = 1200 baud (tool default baud rate at startup)

Data bits = 8

Stop bit = 1

Parity = None

Flow Control = none

6. Ensure that there is no torque load on the tool, and that none will be placed on it during this process.

Enable power to the tool and allow it to complete the starting processes. Communication with the

computer will be established and the tool will send the firmware version and model information to the

computer. In Hyperterminal, the information will appear approximately as it does in the image here.

7. Look at the “Data Record” number on the tool display. The data record number that is on the display

should be one record number higher (larger) than the last record number you wish to upload to the

computer.

Sturtevant Richmont - Exacta®2- Page 9 of 20

Example: There are three torque records on the tool, and the Data Record shows “0003”. You wish to

upload all three torque records. With the display showing “0003”, only two records would be uploaded.

To upload all three, the display must show data record “0004”.

Use the Up or Down button to index to the number of records you wish to upload + 1.

8. Press the Select button to enter and page through the menu until “dAtA” is displayed on the main

section of the display.

9. To begin sending the information to the computer, press the Down button on the tool. This will

cause the information to be sent to the computer. In Hyperterminal, the information will be displayed

approximately as it does in the image immediately below.

The structure of the data record string is:

Torque Direction, + is clockwise, - is counter-clockwise

Numeric value of torque

Unit of measure of the torque

Torque Mode

Compliance to programmed specification (OK or BAD attribute)

Tool record number

Tool Serial Number

16-Character User-Definable String (set using Exawin 5)

Minimum Programmed Torque Specification

Maximum Programmed Torque Specification

Date of Record

Time of Record

10. To clear the uploaded data from the tool memory, press the Up button on the tool and allow the

clearing process to finish before going to the next step. If you wish to retain the data currently on the tool,

just go to the next step.

11. To exit the data transfer process, press the Select button on the tool. This will return the tool to nor-

mal operation.

12. Save, print or transfer the data in the Hyperterminal program using the program’s menu functions.

13. Exit the Hyperterminal program and disconnect the serial cable from the tool.

Sturtevant Richmont - Exacta®2- Page 10 of 20

Using the Exacta®2 - Normal Operation

Once the tool has been programmed to the torque mode, unit of measure and torque specifications

desired, the tool is ready for use. The display will show the target torque (mid-point between minimum and

maximum torque specification values) in the primary section of the display. The triangle below the Target

indicator will be illuminated, as will the triangle below the torque mode (Residual or Peak). The unit of

measure will be displayed, and the current active data record will appear in the lower right-hand corner of

the display.

Grasp the tool by the grip, engage the fastener to be tightened (or item to be torqued) and begin applying

torque using a steadily-increasing force. When you attain approximately 90% of the minimum torque value,

the display and rear LED lens will illuminate with a bright yellow-orange light to warn you that you are

approaching the specified torque.

When you achieve the minimum specified torque the illumination will change from yellow-orange to a bright

green, and rapid beeps will be emitted from the buzzer. Stop applying force immediately.

The torque value (peak or residual) for that use of the tool will remain on the display for two seconds

(default value). The “OK” icon will also illuminate, as will the triangle for Stored. The information will be

stored in memory, the displayed value will then change back to the target torque, and the data record

number will increment by one.

If you inadvertently apply more torque than the maximum specified value, the display and rear LED lens

will illuminate with a bright red color, a single long beep will be emitted by the buzzer, and the BAD icon will

illuminate. This combination will exist for two seconds (or user-defined time) before the value is stored and

the tool indexes and resets for the next tightening.

Stored values from prior uses (tightenings) can be viewed and can be written over. To view a prior value

during normal operation, simply press the Down button to scroll down (decrement) to the data record of

interest. During this you may also press the Up arrow to scroll up (increment) to a record of interest. Re-

member to return to the correct data record number since the tool will record the next torque in the record

active when the tool is used.

If a torque is to be eliminated before being written to memory, press the Clear button before the Autoclear

time expires. This clears the display and the just-completed value is discarded and not written to memory.

This ability to scroll also permits ready correction of an error in torque application. Assume that in tighten-

ing a series of fasteners a slight overtorque occurs on the 7th fastener - data record 0007. After the display

clears, the active data record is 0008. To correct this immediately:

- Press the Down button to return to data record 0007.

- Use the tool to loosen the fastener. This will cause the tool to record that torque and again index to

data record 0008.

- Press the Down button to return again to data record 0007.

- Correctly tighten the fastener. This will produce a correctly tightened fastener and a record of the

torque to which it was tightened.

The tool will store up to 999 data records. Once all the data records are filled, the tool continues writing

subsequent torques in the 999 location.

Sturtevant Richmont - Exacta®2- Page 11 of 20

Calibration

The calibration process for the Exacta®2tools has three sub-processes. The first is testing the tool to find

the “as found” condition. If the tool is out of calibration, then two subsequent processes are performed;

calibration adjustment to bring the tool into calibration, and subsequent repetition of tool testing to assure

that the adjustments were effective and the results are valid. This process addresses only the adjustment,

not pre- and post-adjustment testing.

We strongly recommend that when performing the calibration process a torque tester of not less than

0.25% Indicated Value Accuracy be used, and that it be used in conjunction with a mechanical loader to

obtain proper loading of the tool. We have designed these tools to be as hand-position insensitive as we

can within other constraints, but the use of a mechanical loader is still recommended. The load applied

during testing must be at the loading point on the grip indicated by the plain ring at the middle of the grip.

It is imperative that when calibrating and testing one of the tools having the S/R dovetail that the calibration

be performed with an interchangeable head having the same Common Centerline Length as the head the

tool will be used with. Changing the Common Centerline Length does change the readings and using the

incorrect head will result in torque inaccuracy.

We strongly recommend that the tool be temperature stabilized before testing, and that fresh batteries

be used during the procedure to assure that the tool does not suffer a loss of battery power during the

process.

This section of this document presents the information required to make adjustments when the tool is found

to be out of tolerance.

Needed items (in addition to tester and loader):

• A computer with a serial port and Hyperterminal software

• The serial cable supplied with the torque wrench

Setup for Adjustment

1. Ensure the computer is operating and that tool power is disabled (off).

2. Connect the serial cable to the serial port on the computer.

3. Connect the single-pin connector on the cable to the serial port on the tool.

4. Start the Hyperterminal software.

5. Set the communication protocols within Hyperterminal to the following settings:

Baud Rate = 1200 baud (tool default baud rate at startup)

Data bits = 8

Stop bit = 1

Parity = None

Flow Control = none

6. Ensure that there is no torque load on the tool. Enable power to the tool and allow it to complete the

starting processes. Communication with the computer will be established and the tool will send the

firmware version and model information to the computer. In Hyperterminal, the information will appear

approximately as it does in the next image.

Sturtevant Richmont - Exacta®2- Page 12 of 20

7. Type the diagnostic “D” Command into the terminal and press <enter>. The Terminal display will dis-

play “DiaOn”. You are now in diagnostic mode.

8. Type the M <enter>. The capacity of the tool should be seen on the display.

9. To enter the Calibration process, press the ‘Select‘ button on the tool keypad.

Calibration Procedure Keypad Functions

• Clear button – Restarts calibration process at Cal point CW 0.

• Up Arrow – Selects calibration point to calibrate. Note: If pressed and held, the percent cal point will be

displayed. Upon release the tool will display:

- If under 1% of tool capacity the target torque value the cal point will be displayed.

- If over 1% of the tool capacity, the current torque value will be displayed.

• Down arrow – Saves the new cal point and recalculates the current torque value.

• Select button – Not used during this process

Tool Display Note

• At this point the tool LCD should be displaying “0” in the lower right corner of the LCD display.

• The tool display will use both the main display and the lower right-hand segment to show key informa-

tion needed during these processes.

Procedure - Calibration Adjustment

1. Install drive square on torque tester. Place wrench onto torque tester. Apply three 100% CW FS loads

to ExS 2xxx wrench. See Pages 14 - 16 of this document for correct loads.

2. Remove the torque load from wrench. Remove wrench from tester, and hold in vertical position. Press

DOWN arrow key to save the zero setting. Replace wrench on tester.

3. Press the Up arrow key until 100 appears in the lower right corner of the LCD display. Apply 100% CW

FS load to the unit. When exactly 100% CW FS torque is applied, press the DOWN arrow key. Unload

the tool.

4. Press the Up arrow key until 90 appears in the lower right corner of the LCD display. Apply 90% CW FS

load to the unit. When exactly 90% CW FS torque is applied, press the DOWN arrow key. Unload the

tool.

Sturtevant Richmont - Exacta®2- Page 13 of 20

5. Press the Up arrow key until 80 appears in the lower right corner of the LCD display. Apply 80% CW

FS load to the unit. When exactly 80% CW FS torque is applied, press the DOWN arrow key. Unload

the tool.

6. Press the Up arrow key until 70 appears in the lower right corner of the LCD display. Apply 70% CW FS

load to the unit. When exactly 70% CW FS torque is applied, press the DOWN arrow key. Unload the

tool.

7. Press the Up arrow key until 60 appears in the lower right corner of the LCD display. Apply 60% CW FS

load to the unit. When exactly 60% CW FS torque is applied, press the DOWN arrow key. Unload the

tool.

8. Press the Up arrow key until 50 appears in the lower right corner of the LCD display. Apply 50% CW FS

load to the unit. When exactly 50% CW FS torque is applied, press the DOWN arrow key. Unload the

tool.

9. Press the Up arrow key until 40 appears in the lower right corner of the LCD display. Apply 40% CW FS

load to the unit. When exactly 40% CW FS torque is applied, press the DOWN arrow key. Unload the

tool.

10. Press the Up arrow key until 30 appears in the lower right corner of the LCD display. Apply 30% CW FS

load to the unit. When exactly 30% CW FS torque is applied, press the DOWN arrow key. Unload the

tool.

11. Press the Up arrow key until 20 appears in the lower right corner of the LCD display. Apply 20% CW

FS load to the unit. When exactly 20% CW FS torque is applied, press the DOWN arrow key. Unload

the tool.

12. Press the Up arrow key until 10 appears in the lower right corner of the LCD display. Apply 10% CW

FS load to the unit. When exactly 10% CW FS torque is applied, press the DOWN arrow key. Unload

the tool.

13. Apply 3 full-scale loads to the wrench in the CCW direction.

14. Remove the torque load from wrench. Remove wrench from tester, and hold in vertical position. Press

the Up arrow key until - 0 appears in the lower right corner of the LCD display. With no torque applied,

press the DOWN arrow key. Replace wrench on tester.

15. Press the Up arrow key until -100 appears in the lower right corner of the LCD display. Apply 100%

CCW FS load to the unit. When exactly 100% CCW FS torque is applied, press the DOWN arrow key.

Unload the tool.

16. Press the Up arrow key until - 90 appears in the lower right corner of the LCD display. Apply 90% CCW

FS load to the unit. When exactly 90% CCW FS torque is applied, press the DOWN arrow key. Unload

the tool.

17. Press the Up arrow key until - 80 appears in the lower right corner of the LCD display. Apply 80% CCW

FS load to the unit. When exactly 80% CCW FS torque is applied, press the DOWN arrow key. Unload

the tool.

Sturtevant Richmont - Exacta®2- Page 14 of 20

18. Press the Up arrow key until - 70 appears in the lower right corner of the LCD display. Apply 70% CCW

FS load to the unit. When exactly 70% CCW FS torque is applied, press the DOWN arrow key. Unload

the tool.

19. Press the Up arrow key until - 60 appears in the lower right corner of the LCD display. Apply 60% CCW

FS load to the unit. When exactly 60% CCW FS torque is applied, press the DOWN arrow key. Unload

the tool.

20. Press the Up arrow key until - 50 appears in the lower right corner of the LCD display. Apply 50% CCW

FS load to the unit. When exactly 50% CCW FS torque is applied, press the DOWN arrow key. Unload

the tool.

21. Press the Up arrow key until - 40 appears in the lower right corner of the LCD display. Apply 40% CCW

FS load to the unit. When exactly 40% CCW FS torque is applied, press the DOWN arrow key. Unload

the tool.

22. Press the Up arrow key until - 30 appears in the lower right corner of the LCD display. Apply 30% CCW

FS load to the unit. When exactly 30% CCW FS torque is applied, press the DOWN arrow key. Unload

the tool.

23. Press the Up arrow key until - 20 appears in the lower right corner of the LCD display. Apply 20% CCW

FS load to the unit. When exactly 20% CCW FS torque is applied, press the DOWN arrow key. Unload

the tool.

24. Press the Up arrow key until - 10 appears in the lower right corner of the LCD display. Apply 10% CCW

FS load to the unit. When exactly 10% CCW FS torque is applied, press the DOWN arrow key. Unload

the tool. Remove the torque from the wrench.

25. Press the Up arrow key until a DATE appears on the LCD. Press the DOWN arrow key to save the cali-

bration date.

26. Turn tool ‘Off’, disconnect from computer, wait ten seconds then turn the tool ‘On’. This takes the tool

out of calibration mode and places it in operating mode. It also provides a check to assure that the

information was saved on the tool.

Accuracy Tolerance Tables By Capacity

25 foot-pounds

Capacity in

Ft.Lb

% FS

Torque Value in

In.Lb

+ Tol. -Tol.

25 10 30 30.3 29.7

20 60 60.6 59.4

30 90 90.9 89.1

40 120 121.2 118.8

50 150 151.5 148.5

60 180 181.8 178.2

70 210 212.1 207.9

80 240 242.4 237.6

90 270 272.7 267.3

100 300 303 297

Sturtevant Richmont - Exacta®2- Page 15 of 20

75 foot-pounds

Capacity in

Ft.Lb

% FS

Torque Value in

In.Lb

+ Tol. -Tol.

75 10 90 90.9 89.1

20 180 181.8 178.2

30 270 272.7 267.3

40 360 363.6 356.4

50 450 454.5 445.5

60 540 545.4 534.6

70 630 636.3 623.7

80 720 727.2 712.8

90 810 818.1 801.9

100 900 909 891

150 foot-pounds

Capacity in

Ft.Lb

% FS

Torque Value in

In.Lb

+ Tol. -Tol.

150 10 180 181.8 178.2

20 360 363.6 356.4

30 540 545.4 534.6

40 720 727.2 712.8

50 900 909 891

60 1080 1090.8 1069.2

70 1260 1272.6 1247.4

80 1440 1454.4 1425.6

90 1620 1636.2 1603.8

100 1800 1818 1782

250 foot-pounds

Capacity in

Ft.Lb

% FS

Torque Value in

In.Lb

+ Tol. -Tol.

250 10 300 303 297

20 600 606 594

30 900 909 891

40 1200 1212 1188

50 1500 1515 1485

60 1800 1818 1782

70 2100 2121 2079

80 2400 2424 2376

90 2700 2727 2673

100 3000 3030 2970

Sturtevant Richmont - Exacta®2- Page 16 of 20

400 foot-pounds

Capacity in

Ft.Lb

% FS

Torque Value in

In.Lb

+ Tol. -Tol.

400 10 480 484.8 475.2

20 960 969.6 950.4

30 1440 1454.4 1425.6

40 1920 1939.2 1900.8

50 2400 2424 2376

60 2880 2908.8 2851.2

70 3360 3393.6 3326.4

80 3840 3878.4 3801.6

90 4320 4363.2 4276.8

100 4800 4848 4752

600 foot-pounds

Capacity in

Ft.Lb

% FS

Torque Value in

In.Lb

+ Tol. -Tol.

600 10 720 727.2 712.8

20 1440 1454.4 1425.6

30 2160 2181.6 2138.4

40 2880 2908.8 2851.2

50 3600 3636 3564

60 4320 4363.2 4276.8

70 5040 5090.4 4989.6

80 5760 5817.6 5702.4

90 6480 6544.8 6415.2

100 7200 7272 7128

Sturtevant Richmont - Exacta®2- Page 17 of 20

Other Serial Communications Commands and Communications

The serial communications system used by these tools permits flexibility in terms of tool operation control,

data transfer and tool operation. Some, but not all, of the these options are available readily through the

Exawin software.

Some of the functions covered in this section are only available through the use of Hyperterminal or similar

terminal software, such as changing the baud rate used by the tool to communicate with the computer.

All commands incoming from the tool end in a carriage return and a line feed. All commands going out to

the tool must end with a carriage return. In this section the carriage return keystroke will be represented by

“<cr>’.

Available Tool Baud Rates and Considerations

These tools may communicate at any of the following baud rates: 1200, 2400, 4800, 9600, 19200, 38400,

76800, 115200. The default baud rate is 1200, and when the tool is connected to the computer this rate is

used until and unless the baud rate is changed by sending a command to the tool to change the rate.

The default rate works well in two respects; it does not take a lot of time to transfer data for small or medi-

um quantities of records, and it is highly reliable. Higher baud rates are available to expedite the upload of

large quantities of records, and each increase in speed provides a commensurate decrease in upload time.

Increased baud rates do come at a cost in reliability for these serial communications just as they do with

other serial communications. These tools use a “broadcast” approach; the information is sent and there is

an assumption that it was properly received. There is no checksum or other “error-proofing” methodology

used. Since error rates (both transmission and reception) increase as the baud rate increases, there is an

increased likelihood of communication error when using higher error rates. The error rates are the same for

1200 and 2400 baud, but begin to creep slowly higher as the rate increases.

Note also that when you first enable power (turn on) to the tool, the rate will be 1200. If you send the com-

mand to a higher baud rate, you must then also set the terminal software to communicate at that rate. Note

that after the tool is disconnected and the power disabled, it will revert to the default rate. To re-establish

communication the terminal software will need to be reset to the default rate.

The command to set the baud rate to a different level is “Bb” followed by a <cr> (Enter). In this

command, the lower-case “b” is replaced by the number representing the rate to be used for subsequent

communications.

The table for the number and represented baud rate:

1 2400

2 4800

3 9600

4 19200

5 38000

6 76800

7 115200

Other All other characters set baud rate to 1200

Sturtevant Richmont - Exacta®2- Page 18 of 20

Set Time/Date Stamp

These tools have an internal clock that can be reset with the time/date stamp. The format of the stamp

(U.S. Standard or European Standard) used in the time/date stamp can also be selected. The default is the

U.S. Standard method of reporting this information.

The command to set the time/date stamp is “@”.

To set the time and date when the U.S. format is used, the command will be structured as:

@UMM/DD/YYYY,HH:MM:SS<cr>

Example: @U12/05/2009,13:45:30<cr> would set the date and time as 12/05/2009 13:45:30

To set the time and date when the European format is used, the command will be structured as:

@UDD/MM/YYYY,HH:MM:SS<cr>

Example: @U05/12/2009,13:45:30<cr> would set the date and time as 5/12/2009 13:45:30

Clear Current Tool Data (Partial)

This command uses “CL” followed by <cr> to clear the data records stored on the tool up to the current

record number.

Clear Current Tool Data (All)

This command uses “CLA” followed by <cr> to clear all the data records stored on the tool.

Set Data Report Format

This command allows the user to change the tool-generated report by dropping fields from the data sent by

the tool to the computer. The default setting is to send all data in each record, and this was shown earlier

by a screen capture. Users not wanting the data in one or more fields may instruct the tool to omit these

fields from the transmitted information.

Note that the deletion of fields will be effective for all transmissions to the computer until either another

change command is sent or the tool is turned off. Users with access to programmers or programming skills

may construct scripts that will manage this function using this and related commands.

The command = “TX00000000000000” followed by <cr> sets the data report format to the default of

reporting all fields when the report is generated. Replacing any “0” with a “1” for that field tells the tool to

omit that field in the data sent to the computer.

The field sequence is that shown in the first image on the following page.

There are 14 bits between the “TX”, but only 11 fields, counting the carriage return and line field, in the data

record. The other three bits define the items not particular to an individual data record but pertinent to the

report itself. These items are bits numbered 11, 12, 13 and 14 in the table on the following page.

Bit 12, the “User Defined String” is an accommodation to customer requests pertinent to use of these

tools with Exawin software. The User Defined String in Exawin allows the user to have a 16-character

alphameric identifier (tool number or name) of the user’s own creation and assignment. This line appears in

the top section of the report (above the record data) when this item is printed.

Sturtevant Richmont - Exacta®2- Page 19 of 20

Bit 13 causes the number of records in the report to be printed or not printed. This is true whether the

report includes all of the records on the tool or only a subset of them. This item is printed above the data

record section of the report when the report is printed.

Bit 14 allows the user to choose to keep the comma separation default for field delineation or to switch to

tab delineated separation.

TX Command Byte Usage Table

Field # Default (0) Effect Option (1) Effect

1 Print Sign............................................................Do not print

2 Print Actual Torque..............................................Do not print

3 Print Unit of Measure..........................................Do not print

4 Print Torque Mode of Operation..........................Do not print

5 Print Torque Attribute..........................................Do not print

6 Print Data Record Number .................................Do not print

7 Print Minimum Specification ...............................Do not print

8 Print Maximum Specification ..............................Do not print

9 Print Time & Date Stamp....................................Do not print

10 Print U.S. format.................................................Print European format

11 Print Serial Number at start and end of report*...Serial Number not printed

12 Print User Defined String....................................Do not print

13 Print Records in report........................................Do not print

14 Print comma for field separator...........................Print tab for field separator

*See Page 9 Number 9.

Sturtevant Richmont - Exacta®2- Page 20 of 20

Frequently Asked Questions

Can I modify the light scheme?

Yes. There are several ways to use the Warn/Good/Overtorque light scheme.

If you program the tool from the keypad with a maximum torque specification only, the yellow-orange

Warning and green “Good” colors will not be used. The LED will illuminate red for Overtorque (and

overload) if the maximum torque specification (or tool capacity) is exceeded.

If you program a minimum torque only, the LED will illuminate with green for torque above the minimum,

there will be no warning illumination, and the red illumination will occur only if the tool is overloaded.

If you program neither a minimum nor a maximum torque specification, there will be no LED illumination

unless tool is loaded above capacity.

The display turned red and showed “OL”. What happened?

The tool is designed to be used within its rated capacity, and one of the calibration points for the tool is the

100% of capacity point. The tool is not designed to be used above this point.

At approximately 106% of capacity we use the LED and show “OL” on the display to tell the user that the

rated capacity has been exceeded and that the tool is in danger of being damaged. Even a single use

above this level can cause the tool to become less accurate, and repeated use at this level increases the

probability of accuracy degradation and expensive damage to the tool.

At approximately 120% of rated tool capacity there is a very high probability of damage to the sensor,

including damage of a level that necessitates replacement.

We strongly recommend that the tool never be used beyond its rated capacity, and that if the tool is

inadvertently overloaded it be immediately removed from service and the calibration checked.

During the starting routine I saw “CAL” and 0 (or -0) appear on the display. What does this mean?

During the starting routine the tool checks the calibration table against the output from the sensor. This

message appears if the two are not in agreement. Most frequently this is a response to an overload of the

sensor (and tool) to the point where the sensor has suffered a deformation.

If this occurs the tool should not be used. Have the tool calibrated, and repaired if necessary, before use.

Additional Information

You can find additional information (parts prints and other materials) on our website. You can also contact

your S/R distributor or S/R Representative, or you can contact us using the information on the front of this

document.

Instruction P/N 857284

Rev. Date 091110

Other manuals for exacta 2

2

Other Sturtevant Richmont Power Tools manuals

Sturtevant Richmont

Sturtevant Richmont SLTCR-FM 2.4GHz 3000I User manual

Sturtevant Richmont

Sturtevant Richmont LTCR Series User manual

Sturtevant Richmont

Sturtevant Richmont SLTC-FM 2.4GHz Series User manual

Sturtevant Richmont

Sturtevant Richmont SDR Series User manual

Sturtevant Richmont

Sturtevant Richmont SLTC Series Operating instructions

Sturtevant Richmont

Sturtevant Richmont exacta 2 3000 series Service manual

Sturtevant Richmont

Sturtevant Richmont exacta 2 Service manual

Sturtevant Richmont

Sturtevant Richmont exacta 2 Programming manual

Sturtevant Richmont

Sturtevant Richmont SD Series User manual

Sturtevant Richmont

Sturtevant Richmont DTC User manual