Sturtevant Richmont DTC User manual

Sturtevant Richmont P/N 857421 Rev A - 08/9/19 Page 1

Torque Testers

•Calibrationweightscancausetester

anditsbasetotip

Wear safety goggles (users and

bystanders).

Counterbalance or anchor mounting

base.

Tipping base can cause injury.

Torque Wrenches

•Overtorquingcancausebreakage

•Wrenchcanbreakwhilebreaking

fastenersloose

•Anout-of-calibrationtorquewrenchcan

causepartortoolbreakage

Wear safety goggles (user and

bystanders).

Do not exceed rated torque.

Do not use a torque wrench to break

fasteners loose.

Periodic recalibration is necessary to

maintain accuracy.

Broken tools can cause injury.

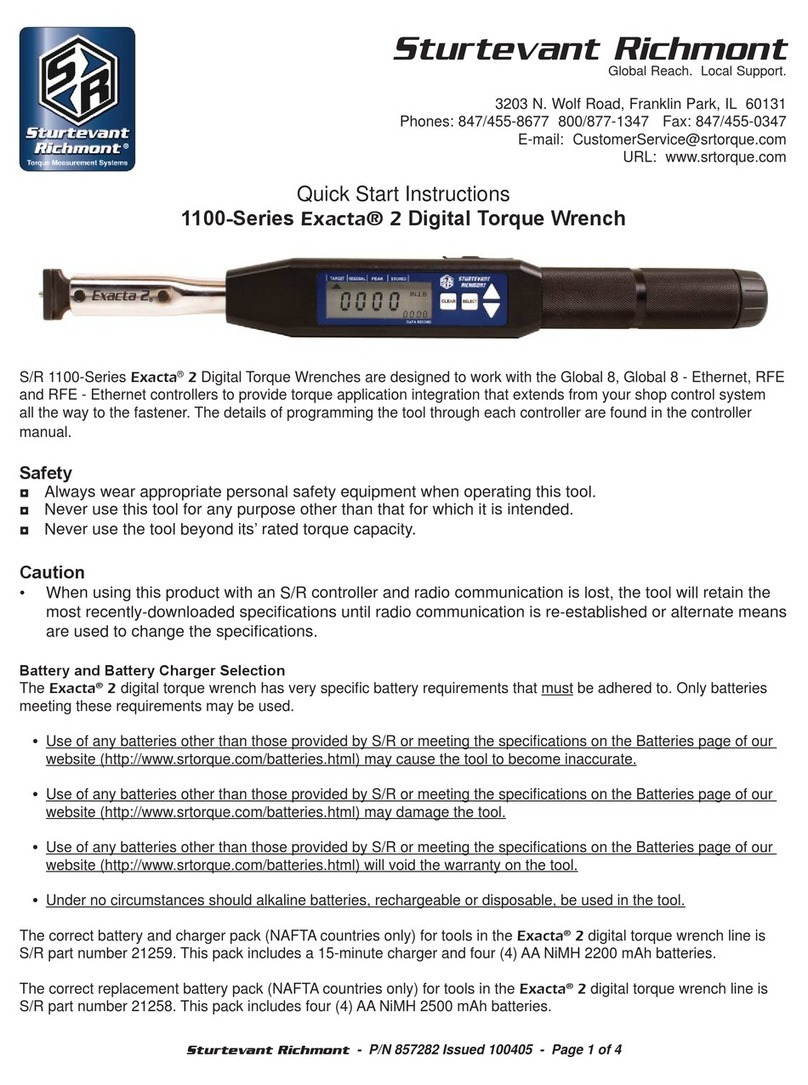

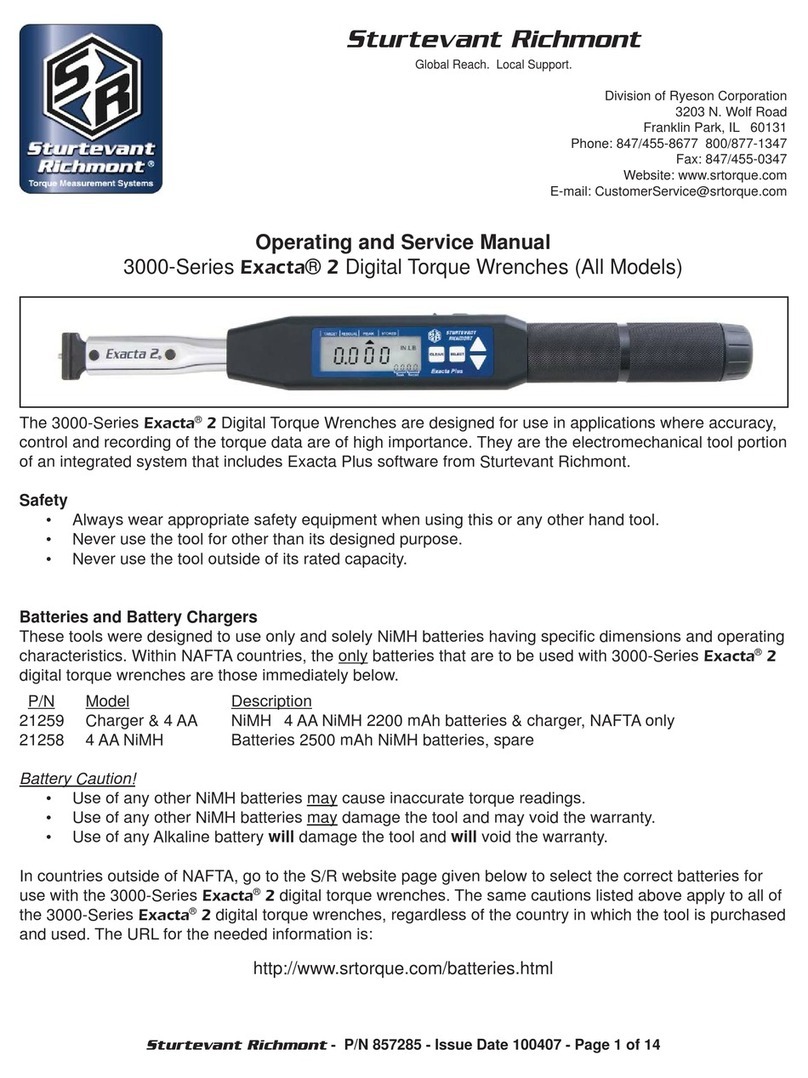

Battery Information

NiMHBatteriesrated1400mAhto2400

mAhareacceptable.HighermAhratings

meanmorecyclesbetweenrechargeand

longerrechargetimes.

Unlikeourotherdigitaltorquewrenches,

theDTCcanusealkaline,Ni-MH,or

LithiumIonbatteries.Nevermixtypesof

batteries(e.g.nevercombinealkalineand

Ni-MHbatteries,orNi-MHandLithium

Ionbatteries)andnevermixnewandold

batteriesintheDTC.

AlthoughtheDTCusesbothalkalineand

rechargeablebatteries,werecommend

rechargeablebatteriesbecausetheyare

environmentallyfriendly.

TheDTCusesthreeAAAbatteriesina

reusablecartridge.

Safety

DTC Wrench

Operating Instructions

555KimberlyDriveCarolStream,IL60188

Phones:847/455-8677800/877-1347Fax:847/455-0347

E-mail:[email protected]

URL:srtorque.com

Sturtevant Richmont P/N 857421 Rev A - 08/9/19 Page 2

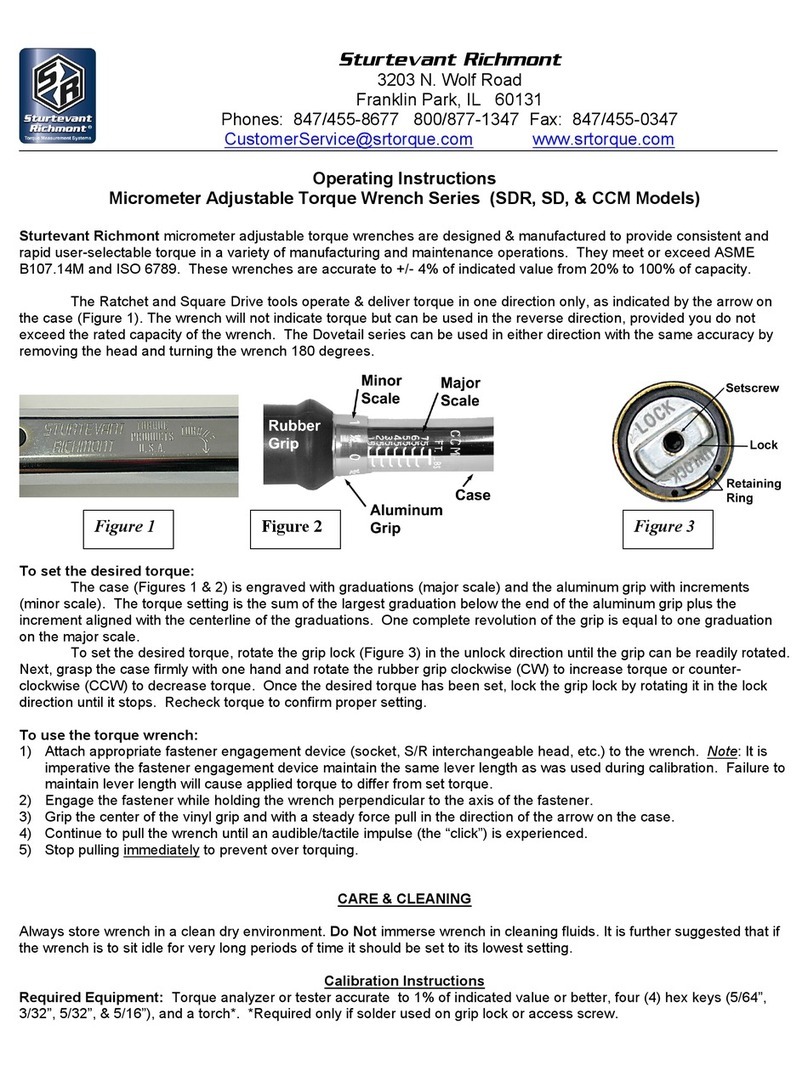

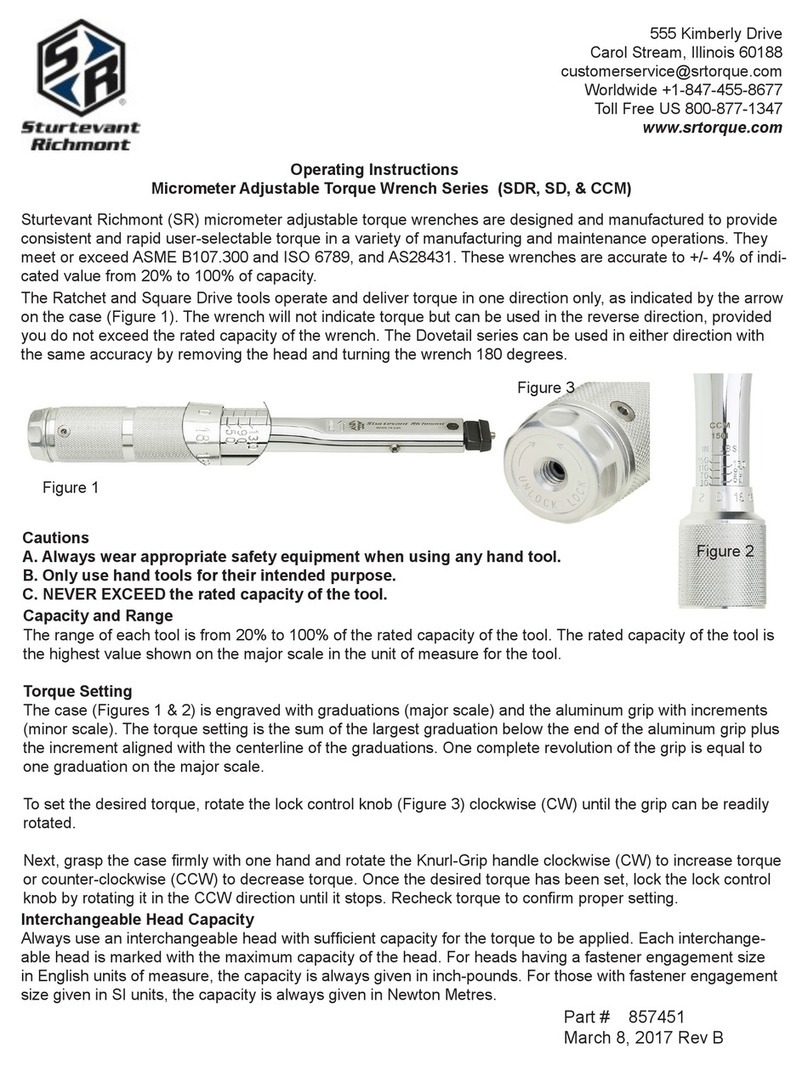

WRENCHFEATURES

•Keypad: Meaning:

P

!

"

P-Set

Up

Escape

U

#

$

Units

Down

Enter

•BacklitLCDgraphicdisplay

•DisplayedIcons:

!Press!toincreasethedisplayedvalueorscrollup

#Press#todecreasethedisplayedvalueorscrolldown

$Press$togotonextscreeninsequenceorselectthehighlightedline

Showingtargettorqueandangle,asopposedtoactual

Clockwisetargetorcurrenttorquedirection

Counterclockwisetargetorcurrenttorquedirection

Eithertargetdirection

Keypadand/orP-Setsarelocked

Batterychargelevel

•Statusindicators–LEDs,buzzer,handlevibration

•USBconnectorandcord–ConnectstoaPCCOMportforwrenchsetupandeventloggingvia

theDTCConnectapplication.

•Store99parametersettings(P-Sets).

•Storeover1000results.

OPERATINGINSTRUCTIONS

PowerOn/PowerOff

•Insert3AAAbatteriesinthebatteryholder,theninserttheholderinthewrench.Thewrench

willpowerupanddisplay:

oZEROINGANGLE

DONOTMOVETOOL

(Forbestresults,setthewrenchonahardsurfacetozerotheanglesensor.)

oSturtevantRichmontlogo.

oAnidentificationscreendisplayingthemodelandfirmwareversion.

oThenextscreenshownisconfiguration-dependent.

•Wheneverpowerison,pressandhold"toputthewrenchintoanultra-low-power/sleep

state.

•Wheneverthewrenchisidle(notorqueapplied,noangularmotiondetected,nokeyspressed)

for4hours(bydefault),thewrenchwillenterthesleepstatetoconservebatterylife.

•Wheneverthewrenchisinthesleepstate,pressanykeytoturnpoweron.

DTC-75

V2.00

Sturtevant Richmont P/N 857421 Rev A - 08/9/19 Page 3

oAfterabout3secondsthewrenchwillshowtheIdleScreen(seebelow).

oTo“cold-start”attheSRlogo,thebatterycapmustbebackedofffarenoughtoblank

thedisplay,thenturnedfullyclockwise.

•Press"momentarilyatanytimetogototheIdleScreen.

•PressUatanytimetochangeUnitofMeasure.

•PressPatanytimeforP-Setselection.

ConfiguringtheDisplay

CompleteconfigurationoftheDTCisavailableviaDTCConnect.

ThesimplestconfigurationshowsanIdleScreenaftertheidentificationscreen,inPeakmode.

•Apply4%offullscaletorqueormoretoswitchfromtheIdleScreentotheMeasurement

Screen.

•Thelargedigitsshowthetargetormeasuredpeaktorque.

•Directionofintendedormeasuredtorqueisshown.

•TheIdleScreenwillreappearwhentorqueisreleasedaftertheauto-cleartimeexpiresor"is

pressed.

•Thissequencecanberepeatedindefinitely.

Incontrast,themaximumconfigurationconsistsofthissequenceofscreens:

•CalibrationScreen(onlyafteracoldstart)

•IdleScreen

•ModeScreen

•TargetTorqueScreen

•MinimumTorqueScreen

•MaximumTorqueScreen

•SnugTorqueScreen

•TargetAngleScreen

•MaximumAngleScreen

•HeadLengthScreen

•Auto-ClearScreen

•LockScreen

•P-SetScreen

•LogScreen

Tostepfromonescreentothenextinthelist,press$.AftertheLogScreen,thelistrepeatsfromthe

IdleScreenondown.Notallscreensareavailableinthedefaultsetup.

PEAK

IN

LB

123.4

IN

LB

56.7

Sturtevant Richmont P/N 857421 Rev A - 08/9/19 Page 4

Additionalscreenscanbereachedbypressingotherkeys.Forexample,pressing#ontheCalibration

Screenstartsasub-sequenceofmorescreenstoworkthroughcalibration.

AnyscreeninthesequencecanbeaddedtoorremovedfromawrenchconfigurationusingDTC

Connect.

UnitsofTorque

PressUtochangetheunitsoftorquemeasurementatanytime.

•Ifnotcurrentlyshowingunitsoftorque,pressUtoshowtheIdleScreenwiththecurrentunits

oftorque.

•Onceunitsoftorquearedisplayed(ontheIdleScreenortheTarget,Minimum,orMaximum

TorqueScreen),pressUrepeatedlyasneededtostepthroughallchoicesofunits,withthe

displayedtorqueconvertedtothoseunits.

•Choicesare:INLB,FTLB,CNM,NM,CMKG,andMKG.

GeneralOperation

Threephasesofoperationarerepeatedforeachjoint:

1. Idle:showingthemeasurementmodeandtarget,andwaitingfortorque;

2. TorqueApplied:showingtheMeasurementScreen;

3. TorqueReleased:showingtheMeasurementScreenandwaitingtoclear.

IdleScreen

Asshownbelow,theIdleScreenissomewhatdifferentforeachmode.TrackandResidualmodesdon’t

showtargetvalues.Thetargetangle,nottorque,isshownforT2Amode.

•Press$togotothenextscreeninsequence.

0°

IN

LB

0.0

PEAK

IN

LB

123.4

T2A

123°

RESIDUAL

IN

LB

0.0

PEAK

IN

LB

123.4

PEAK

FT

LB

10.28

TAM

IN

LB

123.4

Sturtevant Richmont P/N 857421 Rev A - 08/9/19 Page 5

MODE RESIDUAL

PEAK

TRACK

•Press!or#toskiptoasettingsscreen.

MeasurementScreen

•Whentorqueisapplied,theMeasurementScreenreplacestheIdleScreen.

•Thelargedigitsshowthecurrentpeaktorqueorangledependingonthemode.

•Thecurrentangleofrotationisshownwhite-on-black.

•Statusisshownfortorqueandforangle–OK,HI,orLO.(Thetargeticondisappears.)

•Directionofmeasuredtorqueisshown.

•Whentorqueisreleased,thedigitsshowthefinaltorqueandanglemeasured.Attheauto-clear

timeout,theIdleScreenisshownagain.

ModeScreen

Ifmorethanonemeasurementmodeisconfigured,theModeScreenshouldbeincludedinthe

configuration.

•Thescreenlistsupto3modesatatime.Thecurrentmodeishighlighted.

•Press!or#toscrollthroughthelistofmodes,wrappingaroundateitherendofthelist.

•Press$toselectthehighlightedmodeandgotothenextscreeninthesequence.

SettingsPerMode

•Somesettingshavedifferentmeaningsfordifferentmodes.

•Somesettingsareirrelevantinsomemodes.

•WhentheIdleScreenisshowing,press!or#todisplaythefirstsettingsscreenforthat

mode.

TargetTorqueScreen

•Press!or#toincrement/decrementby1intherightmostdigit.

•Pressandhold!or#toaccelerateincrementing/decrementing.

•Atzero,pressing#causesalternationbetween(clockwise),(counterclockwise)and

(both).Then!startsincrementingfromzero.

12° OK LO

IN

LB

56.7

TAM

IN

LB

123.4

TARGET TORQUE

IN

LB

100.0

Sturtevant Richmont P/N 857421 Rev A - 08/9/19 Page 6

oIfisshown,torquewillaccumulateinbothdirections,e.g.,whenawrenchis

flippedoverbetweensmallangularswingsinatightlocation.

oIforisshown,torqueinthewrongdirectionwilllighttheredLED,butotherwise

itwillhavenoeffect.Thisallowslooseningajointbeforeretightening,withnothing

loggedorreported,onlyawarninglight.

•Press$toproceedtothenextscreeninsequenceor"togohometotheIdleScreen.

TorqueTolerances

Torqueforajointmaybespecifiedwitha“plusorminus”tolerance.Inpractice,thisdoesn’talwaysgive

thedesiredcontrolovertheuseofatorquetool.Instead,iftorquefallsbetweenaminimumanda

maximumvalue,thejointisdeemedOK.

TheDTCcanuseeitherstrategysincevaluesarestoredseparately.TargetTorqueisstoredinternallyas

atorquevalueinaunitofmeasure,MinimumTorqueisstoredasa“minus”tolerancepercentage,and

MaximumTorqueisstoredasa“plus”tolerancepercentage.Onceset,iftolerancepercentagesdonot

change,onlytheTargetTorquevalueneedbechangedfromonejointtoanother.

Duringoperation,thetoollightsthegreenLEDifafinalresultisintheminimumtomaximumrangeand

redifthemaximumisexceeded.TheTargetTorquescreenwasaddedtoholdoffthegreenLEDuntilthe

operatorpulledtoachosenvaluehigherthantheminimumtorque,typicallythemidpointoftherange.

Thiscorrespondsto“targetplusorminustolerance”.

MinimumTorqueScreen

•WhenTargetTorqueischanged,TargetTorqueminusthelowtoleranceisthenewMinimum

Torque.Intheexampleabove,foratargetof100.0in.lb.anda3%tolerance,MinimumTorque

wouldinitializeto97.0in.lb.

•Use!or#toincrement/decrementMinimumTorqueinthesamewayasTargetTorque.The

finalvalueofMinimumTorquedeterminesanewlowtolerance,namely(Targetminus

Minimum)dividedbyTarget.

•ApossiblestrategyistosetMinimumequaltoTarget.Thenewlowtolerancewillbe0%.Every

subsequentchangetoTargetwillchangeMinimumtomatchthenewTarget.Thenunder-

torquingwillnevergetagreenlightoranOKstatus.

•Press$toproceedtothenextscreeninsequenceor"togohometotheIdleScreen.

MaximumTorqueScreen

ThisisanalogoustotheMinimumTorqueScreen.

MAX TORQUE 3.0%

IN

LB

MIN TORQUE 3.0%

IN

LB

97.0

Sturtevant Richmont P/N 857421 Rev A - 08/9/19 Page 7

•WhenTargetTorqueischanged,TargetTorqueplusthehightoleranceisthenewMaximum

Torque.Intheexample,foratargetof100.0in.lb.anda3%tolerance,MaximumTorquewould

initializeto103.0in.lb.

•Use!or#toincrement/decrementMaximumTorqueinthesamewayasTargetTorque.The

finalvalueofMaximumTorquedeterminesanewhightolerance,namely(TargetplusMaximum)

dividedbyTarget.

•Press$toproceedtothenextscreeninsequenceor"togohometotheIdleScreen.

SnugTorque

Fortheoperationofthiswrench,SnugTorqueisdefinedasthepeaktorqueatwhichanglestarts

countingupfrom0°.

•SnugTorqueissetlikeMaximumTorque.Directionisnotspecified.

•Press$toproceedtothenextscreeninsequenceor"togohometotheIdleScreen.

TargetAngle

•Press!or#toincrement/decrementby1intherightmostdigit.

•Pressandhold!or#toaccelerateincrementing/decrementing.

•TheTargetAngleScreendoesnotspecifyadirectionbecauseitisalwaysinthesamedirection

astorque.

•Press$toproceedtothenextsettingor"togohometotheIdleScreen.

MaximumAngle

MaximumAngleissetlikeTargetAngle.Directionisnotspecified.WhenTargetAngleischanged,

MaximumAngleisalsochangedtokeeptherangethesamenumberofdegrees.

•DecrementingstopsatTargetAngleandincrementingstopsat9999°.

•Press$toproceedtothenextsettingor"togohometotheIdleScreen.

103.0

TARGET ANGLE

40°

SNUG TORQUE

FT

LB

2.00

MAXIMUM ANGLE

9999°

Sturtevant Richmont P/N 857421 Rev A - 08/9/19 Page 8

HeadLengthScreen

•Press!or#toincrement/decrementHeadLength.Unitsarealwaysmillimeters.

Decrementingstopsat0andincrementingstopsat99.99.

•Press$toproceedtothenextscreeninsequenceor"togohometotheIdleScreen.

AutoClearScreen

•Press!or#toincrement/decrementtheAutoCleartime.Unitsarealwaysseconds.

Decrementingstopsat0.0andincrementingstopsat9.9.

•Press$toproceedtothenextscreeninsequenceor"togohometotheIdleScreen.

LockScreen

•Press!tolockoutkeypadchangestoanysettings.

•Press#tomakeP-Setsread-only(disablestheSAVEPSETScreen).

•TheUkeyisnotdisabledbylockingthekeypadorP-Sets.

•WhenP-Setsarelocked,thebottompromptbecomesUNLOCKPSETS.

•Press$toproceedtothenextscreeninsequenceor"togohometotheIdleScreen.

Whenkeypadislocked,alockicon––appearsinthetopline.TheTargetTorquevaluecannotbe

changed.Howeverthe3phases–Idle,TorqueApplied,andTorqueReleased–operatenormally.

TounlockeitherthekeypadorP-Sets,a4-digitpasswordmustbeenteredcorrectly.

•Whenthekeypadislocked,pressanykeytoshowtheUNLOCKPASSWORDScreen.

•WhenP-Setsarelocked,press#ontheLockScreentochooseUNLOCKPSETSorpressandhold

thePkeytosaveaP-Set.TheUNLOCKPASSWORDScreenwillbedisplayed.

LogScreen

LOCK KEYPAD

NO CHANGE

LOCK PSETS

HEAD LENGTH

MM

36.51

AUTO CLEAR TIME

SEC

1.0

DISABLE LOG

SKIP

CLEAR LOG

Sturtevant Richmont P/N 857421 Rev A - 08/9/19 Page 9

•Press!tostoploggingtooleventsinnon-volatilememory.Thefirstlineofthescreenwill

changetoENABLELOG.The!keytogglesbetweenstartingandstoppinglogging.

•Press#toclearthetooleventlog.Whencleared,loggingwillrestartwithsequencenumber1.

(Loggingsequencenumberscontinueto999,thenwraparoundto000.)

•Press$toleavethisscreenandreturntoattheIdleScreen.

UnlockPasswordScreen

•Press!or#toincrement/decrementthehighlighteddigitby1,wrappingaroundupward

from9to0anddownwardfrom0to9.

•Press$tomovethehighlightonedigittotherightor,whenall4digitshavebeenentered,to

verifythepassword.Thefactorydefaultpasswordis2114.ItcanbechangedusingDTCConnect.

•Whenunlockingthekeypad:

oIfthepasswordisincorrect,theIdleScreenisshownagainwiththeicon.

oIfthepasswordiscorrect,theIdleScreenisshownwithouttheicon.

SaveP-SetScreens

AllsettingsforonetypeofjointcanbesavedasaP-Set.TheP-Setcanberecalledfromthelistas

needed,insteadofreenteringallindividualsettingseachtime.

•PressandholdPatanytimetosavethecurrentmode,torqueandanglesettings,andhead

lengthasaP-Set.

oIfP-Setsarelocked,theUNLOCKPASSWORDscreenisdisplayed.

!Enterthepasswordasdescribedpreviously.

!PressandholdPagaintosavethesettings.

oInitiallynoP-Setsaredefined.AvailableP-Setindicesaredesignated“FREE”.

•Press!or#toscrollthroughthelistofP-Sets,wrappingaroundateitherendofthelist.After

theinitialscreen,3linesofthelistarealwaysdisplayed.Alphanumericnamescanbeassigned

toP-SetsusingDTCConnect.ThenameswilldisplayontheSAVEPSETandSELECTPSETscreens.

•Press$tosavesettingstothehighlightedP-Setnumber.Itmaybe“FREE”,oranexistingP-Set

maybeoverwritten.WhenafreeP-Setischosen,itsnameisshortenedtoPandits2-digitindex

(P01intheexampleabove).

•Press"atanytimetoexitwithoutsavingaP-Set.

- SAVE PSET -

P01 - FREE

UNLOCK PASSWORD

0000

UNLOCK PASSWORD

2114

Sturtevant Richmont P/N 857421 Rev A - 08/9/19 Page 10

SelectP-SetScreens

•PressPmomentarilyatanytimetoentertheSELECTPSETscreen.ThemostrecentlyretrievedP-

Setisshownhighlighted.

oIfnoP-Setshavebeensaved,“NOPSETSFOUND”isdisplayed.

!Press"togobacktotheIdleScreen.

•Press!or#toscrollthroughthelistofP-Sets,wrappingaroundateitherendofthelist.After

theinitialscreen,3linesofthelistarealwaysdisplayedinsortedorder.(“FREE”P-Setsarenot

displayedinthislist.)

•Press$toretrieveallsettingsforthehighlightedP-SetandreturntotheIdleScreenusing

thosesettings.

•Press"atanytimetoescapewithoutretrievingaP-Set.

•WhenaP-Sethasbeenretrieved,theP-SetnumberappearsontheIdleScreeninsteadofthe

icon.AssoonasasettinginthatP-Sethasbeenchanged,theiconreplacestheP-Setnumber

ontheIdleScreentodenotethattheP-Setisnolongerineffect.

DeleteP-Set

P-SetscanonlybedeletedusingDTCConnect.WhenaP-Setisdeleted,itisreplacedbyaPxxFREEentry

intheSAVEPSETlist,andnolongerappearsintheSELECTPSETlist.

DataCapture

DataabouteachrecordedtorqueeventisstoredtoalogthatmayberetrievedusingDTCConnect.The

logcontainsthefollowingdataforeachrecordedevent:SequenceNumber,Date,Time,P-Set,Mode,

Units,TorqueDirection,FinalTorque,ResidualTorque,FinalAngle,DoubleHitAngle,EventStatus,

TorqueStatus,AngleStatus,TargetDirection,TargetTorque,MinimumTorque,MaximumTorque,Snug

Torque,MinimumAngle,MaximumAngle,ToolSerialNumber,ToolName,ToolModel,andBattery

Level.MoredetailonthesefieldsisprovidedintheToolResultsLogsectionbelow.

MODES

SettingsPerMode

Themeaningofsomesettingsmaychangedependingonmode.Thefollowingaresettingsrelevantto

eachmode.Ifasettingisnotavailablethroughamenuscreenonthetool,itmaybepossibletomodify

thevalueusingDTCConnect.

TrackMode

Trackmodeconstantlyshowsthecurrenttorqueonthewrench,andthecurrentanglerelativetothe

startoftrackmodewhen4%offullscaletorqueisapplied.Onlytwosettingsareused:

•MinimumTorque–ThegreenLEDlightswhileabovethistorqueandbelowMaximumTorque.

- SELECT PSET -

P61

Sturtevant Richmont P/N 857421 Rev A - 08/9/19 Page 11

•MaximumTorque–TheredLEDlightswhileabovethistorque.

Theanglemeasurementmaybeclearedbypressing".

PeakMode

Peakmodeshowsthecurrentpeaktorqueonthewrenchuntiltorqueisreleased.Torquedisplaybegins

at4%offullscaletorque.YellowLEDslightupinsequenceasminimumtorqueisapproached.

•TargetTorque–PulltothisvaluetogetagreenLED.

•MinimumTorque–StatusisOKbetweenminimumandmaximumtorque.ThegreenLEDturns

onwhentorqueisreleasedifpeaktorqueisbetweenminimumandmaximumtorque.

•MaximumTorque–TheredLEDlightsandthestatusisHIifthepeakvalueexceedsthistorque.

•YellowTorque–PercentofMinimumTorqueatwhichthethirdyellowLEDlightsup.(Allthree

yellowLEDslightupinequalstepsoftorque.)Thedefaultvalueis90%.

•IgnorableTorque–PercentofMinimumTorquebelowwhichafinalpeaktorqueisignored(not

printedandnotlogged).Thedefaultvalueis90%.Anotherlikelyvaluetouseis0%(logall

events).

ResidualMode

Residualmodeshowszerotorqueonthewrenchuntilresidualtorqueisdetected,thenitshowsthe

residualtorqueuntiltorqueisreleased,withanOKstatus.

•TargetAngle–Thedefaultis3°.Thismaybemodifiedthroughthekeypad.Tolookforthe

torquediponly,setthetargetangleto0°.OthersettingscanbetunedasneededusingDTC

Connect.

Twomethodsmaybeappliedtodetectresidualtorque.

•Onasoftjoint,apullthroughasmallprescribedangledenotesthatresidualtorquehasbeen

reached.Thevalueatthatexactanglerepresentstheresidualtorquethatwasinthejoint.A

minimumof3°isrecommended.

•Onahardjoint,adipintorquemaybedetectedwhenappliedtorquebreaksthejointloose

momentarily.Thevalueatthebottomofthediprepresentstheresidualtorquethatwasinthe

joint.

Boththeresidualtorque(“asfound”)andthefinaltorque(“asleft”)arelogged.

T2AMode

InTorquetoAnglemode,ajointistightenedtoaprescribedtargettorque;thenthefasteneristurned

throughanadditionalangle,intendedtostretchthefastenerandthusapplyclamploadbyanamount

proportionaltotheangle.

Astorqueisapplied,itisdisplayedinlargedigits,withanangleof0°.WhentheTargetTorqueis

reached,ayellowLEDlightsandthedisplaychangestoangleinthelargedigits,startingat0°.Asangle

approachesitstarget,theotheryellowLEDslightup.

Sturtevant Richmont P/N 857421 Rev A - 08/9/19 Page 12

•TargetTorque–PulltothisvaluetogetayellowLEDandstartcountingangle.Thisistypically

thesnugpointonthejoint,thepointatwhichtheheadofthefastenerhasbottomedout.

•TargetAngle–PulltothisangletogetagreenLEDandanOKstatus.

•MaximumAngle–TheredLEDlightsandthestatusisHIifangleexceedsitsmaximum.

•MaximumTorque–Whilefinalangleisofprimaryinterest,acheckonfinaltorquemaybe

warrantedaswell,e.g.,todetectafastenerthatistoohardtostretchenough(100%offullscale

torquebydefault).Forthisreason,minimumtorqueandmaximumtorquemayalsobe

specified.Finaltorquemustfallwithinthisrangetobeacceptable.

TAMMode

TorquewithAngleMonitoringisanextensionofPeakmode,addingtheabilitytodetectcross-threaded

fasteners,doublehitsonajoint,andthelike.Primarily,itaddstheconstraintthatafastenermustturn

throughaminimumanglebeforeminimumtorqueisreached.

TAMmodeusesthesamesettingsasPeakmode,plus:

•TargetAngle–Thisistheminimumangleneededbeforeminimumtorqueisreached.

CALIBRATION

CalibrationScreen

IfconfiguredtodisplaytheCALIBRATEWRENCHscreen,calibrationcanbeinitiatedthroughthekeypad

duringacoldstart.ThefollowingscreenappearsaftertheIdentificationScreen,andthennotagainuntil

thenextcoldstart.

•Press#toentercalibrationmode.TheCalibrationPasswordscreenappears.

•Press$toskiptonormaloperation.

CalibrationPasswordScreen

A4-digitpasswordmustbeenteredcorrectlybeforethewrenchcanbecalibrated.

•TheCalibrationPasswordScreenisanalogoustotheUnlockPasswordScreendescribed

previously.Thefactorydefaultpasswordis3112.ItcanbechangedusingDTCConnect.

oIfthepasswordisincorrect,theCalibrationScreenisredisplayed.

oIfthepasswordiscorrect,theCalibrationHeadLengthScreenisdisplayed.

•Press"toreturntotheCALIBRATEWRENCHScreen.

CalibrationHeadLengthScreen

Thecalibratorwillhavetheabilitytomodifythecalibrationheadlengthfromitsdefaultvalue(36.51).

CALIBRATE WRENCH

NO

YES

CAL HEAD LENGTH

MM

36.51

Sturtevant Richmont P/N 857421 Rev A - 08/9/19 Page 13

•Press!or#toincrement/decrementby1intherightmostdigit.Unitsarealwaysmillimeters.

Decrementingstopsat0andincrementingstopsat99.99.

•Pressandhold!or#toaccelerateincrementing/decrementing.

•Press$toproceedtotheTorqueCalibrationscreen.

TorqueCalibrationScreen

Calibrationbeginsatclockwise0%.

•Astorqueisapplied,atorquevaluewillreplacethetargetvalue,andtheiconwilldisappear.

•Press#tosaveacalibrationpoint.ThegreenLEDwillflashtoshowacceptanceofthepoint.

Repeatasoftenasnecessaryuntilsatisfied.

•Press!togoontothenextcalibrationpoint.Thefullsequenceisclockwise(CW)0%,100%,

60%,and20%,followedbycounterclockwise(CCW)0%,100%,60%,and20%.

•Afterthelastpointissaved,thefollowingoptionsare:

oPress!torepeatthesequencetoallowtouchups.

oPress$toenteranglecalibration.

oPress#tosetcaldateandnextcaldate.Onthenextscreen:

!Press$toacceptthedateshownandenteranglecalibration.

!Press!toreturntotorquecalibration.

AngleCalibrationScreen

•Placewrenchonananglecalibrationfixturewithhandletotherightofthehead.

•Pressthe“SET0°!“arrowkeyonwrenchtosavethe0°value.

•SwingthewrenchCCW180°,pressthe“CCW180°#”arrowkeyonthewrenchtosavethe180°

value.

•SwingthewrenchCW180°.Theanglereadingshoulddisplay0°.Ifnot,pressthe“SET0°!“to

savethe0°value.

•ThesequenceofCCW180°andCW180°mayberepeatedtoallowtouchupstotherecorded

values.

•Press$toexitcalibration.

CAL

FT IN

LB

1.23

CAL 0%

IN

LB

0.0

CAL 100%

IN

LB

300.0

CAL

FT IN

LB

1.23

CAL ANGLE SET 0°

DONE

CCW 180°

180

Sturtevant Richmont P/N 857421 Rev A - 08/9/19 Page 14

DTCCONNECT

DTCConnectisasoftwareprogramthatprovidesameansofcustomizingtheSturtevantRichmontDTC

Wrenchandretrievingdatafromthetool.

Installation

RuntheDTCConnectinstallationfile.ThiswillinstalltheDTCConnectapplicationand

theWindowsdriverforthetoolifneeded.AshortcutwillbecreatedonthePCdesktop.

ConnectingTheTool

PlugtheUSBcableintothePC.Poweronthetool.SlideopenthedoorcoveringtheUSBplugonthe

tool.PlugtheUSBcableintotheportonthetool.StarttheDTCConnectprogram.

Click“PollPortNames”toquerytheactive

COMportsonthePC.TheCOMPortdrop

downmenuwillbeupdatedwithdetailsofthe

equipmentconnectedtotheactiveCOMports.

Clickthe“COMPort:”dropdownmenuand

selecttheCOMportthattheDTCtoolis

connectedto.

Click“ConnecttoDevice”toopen

communicationwiththeDTCtool.

Thebuttonsontheleftsideofthewindowwill

beactivated.

Sturtevant Richmont P/N 857421 Rev A - 08/9/19 Page 15

Selectionsavailablefromthehomescreen

include:

•ToolResultsLog–view,save,orclearthe

resultsstoredonthetool.

•Parameters(P-Sets)–view,edit,orsave

theparametersettingsonthetool.

•ToolConfiguration–view,edit,orsavethe

generalsettingsforthetool.

General

Returnstothepreviousscreen.

Updatesthecurrentinformationbeingdisplayed.

ToolResultsLog

Thisscreendisplaystheresultsstoredintoolmemory.Ifnoresultsarestored,thewindowwilldisplay

“THEREARENORESULTSINTHELOG”.Optionsavailablefromthisscreeninclude:

•ClearReadings–deletesallrecordsintheresultslog.(Note:Allrecordswillbeerasedfrom

memoryandcannotberetrieved.)

•SaveReadings–savestheresultslogtoaCSVorTXTfile.Allfieldsareincludedregardlessofthe

PrintFieldsettings.

•PrintFields–selectthefieldstobedisplayedintheToolResultsLogwindow.Checktheboxesto

displayfields.Unchecktheboxestohidefields.Click“SaveChanges”whencompletetoreturn

totheToolResultsLogscreen.(Note:“RESERVED”fieldsareforfutureuseandcannotbe

selected.)

Sturtevant Richmont P/N 857421 Rev A - 08/9/19 Page 16

ThefollowingtableprovidesadescriptionofthePrintFieldsthatareavailable:

Field

Descriptionorrangeofvalues

SequenceNumber

Numberoftheevent

Date

Date

Time

Time

P-SetNumber

P-Setused(blankifnoP-Setwasselected)

Mode

Toolmode

Units

Unitsofmeasure

Direction

+,-(+=clockwise,-=counterclockwise)

Torque

Finalpeaktorque

ResidualTorque

Residualtorque

Angle

Finalpeakangle

Status

OK,NOK,NA

TorqueStatus

OK,LO,HI,NA,OVL

AngleStatus

OK,LO,HI,Tb4A,NA

TargetDirection

+,-,+/-(“+”=clockwise,”-“=counterclockwise,“+/-“=both)

TargetTorque

Targettorque

MinTorque

Minimumacceptabletorque

MaxTorque

Maximumacceptabletorque

SnugTorque

Torquevaluewhereanglestartstobemeasured

MinAngle

Minimumacceptableangle

MaxAngle

Maximumacceptableangle

SerialNumber

Toolserialnumber

Name

Toolname

Model

Toolmodel

Battery

Toolbatterypercentageremaining

Parameters(P-Sets)

Thisscreendisplaystheparametersettings(P-Sets)storedintoolmemory.Optionsavailablefromthis

screeninclude:

•EditP-Sets–view,create,modify,ordeleteparametersettingsonthetool.

•WritetoTool–savedisplayedparametersettingstothetool.

•OpenP-SetFile–openapreviouslysavedP-Setfile.

•SavetoFile–savedisplayedparametersettingstoaCSVorTXTfile.

Sturtevant Richmont P/N 857421 Rev A - 08/9/19 Page 17

EditP-Sets

TodeleteaP-Set,highlighttheP-Setinthelistandclick“Delete”.

TomodifyanexistingP-Set,highlighttheP-Setinthelist.TocreateanewP-Set,click“New”.

Modifythesettingsasneeded.Dependingonthemode,somefieldswillbelocked/fixed.Somefields

willhaverestrictionsonvaluesthatcanbeenteredbasedonotherfields(ie.MaxTorquecannotbeless

thanMinTorque).

AdditionalP-Setsmaybemodifiedorcreatedbyrepeatingthestepsabove.

Click“SaveP-Sets”tosavethemodifications.

Note:“WritetoTool”fromtheParameters(P-Sets)Readingspagemustbeclickedtosavethe

modificationstothetoolmemory.

ThefollowingtableprovidesadescriptionoftheParameterSettingsthatareavailable:

Field

Descriptionorrangeofvalues

Name

NameofP-Set(16charactersfrom“A”thru“Z”,“0”thru“9”,“.”,“-“)

Mode

ToolMode(TRACK,PEAK,RESIDUAL,T2A,TAM)

Units

ToolUnitsofmeasure(IN.LB,FT.LB,CNM,NM,C.MKG,MKG)

TargetTorqueValue

Targettorque

TargetTorqueDirection

Clockwise(CW),Counterclockwise(CCW),Both

MinTorque

Minimumacceptabletorque

Sturtevant Richmont P/N 857421 Rev A - 08/9/19 Page 18

MaxTorque

Maximumacceptabletorque

AutoClearTime(s)

Numberofsecondsthatthedisplaywillclearafteraresultisrecorded

Number

NumberofP-Set

SnugTorque

Torquevaluewhereanglestartstobemeasured

IgnorableTorque

Percentageofminimumtorquebelowwhichresultsarenotstored/printed

AngleTarget(°)

Targetangle

HighAngle(°)

Maximumacceptableangle

HeadLength(mm)

Lengthoftheinterchangeablehead

DwellTime(s)

Numberofsecondsbeforetheresultisrecorded(thisallowsforratcheting

orrepositioningthetool.

ToolConfiguration

Thisscreendisplaysthesettingsforthetool.Optionsavailablefromthisscreeninclude:

•EditSettings–view,modify,orsaveconfigurationsettingsonthetool.

•WritetoTool–savedisplayedsettingstothetool.

•OpenConfigFile–openapreviouslysavedToolConfigurationfile.

•SavetoFile–savedisplayedconfigurationsettingstoaTXTfile.

EditSettings

Modifythesettingsasneeded.Click“ChangeFields”tomodifythedisplayedPrintFields(functionalityis

thesameasthe“PrintFields”buttonontheToolResultsLogpage).

Click“SaveSettings”tosavethemodifications.

Note:“WritetoTool”fromtheToolConfigurationpagemustbeclickedtosavethemodificationstothe

tool.

Sturtevant Richmont P/N 857421 Rev A - 08/9/19 Page 19

AppendixA–SettingsviaUSBConnectiontoaPC

TheDTChasmanysettingsthatarenotaccessibleviathewrenchkeypad.

•Allofthese

settingsaresupportedviatextualcommandswithparametersreceivedthroughthe

serial(USB)portfromaterminalemulatorlikeHyperTerminal,TeraTerm,or

PuTTY.

•MostofthesesettingsarealsosupportedviatheDTCConnectsoftware.

Thetypicalcomman

dformatis:COMMAND<SPACE>VALUE(ie.“LOG0”).

General

SettingsandCommands

Thetablebelowlistssettingsthat

applytoawrenchasawhole.

Setting

Command

Range

ofValues

Description

SerialNumber

SN

-

Showthewrenchserialnumber.Alphanumeric,8

charactersmax.

ProductID

E

-

Showthewrenchmodelandcapacity.

Firmware

Version

V

-

Showthewrenchfirmwareversion,e.g.,v1.0.

LastCalibration

Date

CD

MMDDYYYY

Show/setthelastcalibrationdate.

NextCalibration

Date

CDN

MMDDYYYY

Show/setthenextcalibrationdate.

WrenchName

NM

ABCDEFGH

12345678

Show/settheowner-assignednameofthewrench,

upto16characters;spaces&punctuationare

allowed.

Locality

@F

UorE

Show/setthetypeofformatting:USorEuropean.

(See@U&@E.)

U.S.Date&

Time

@U

MM/DD/YY,

HH:MM:SS

Show/setcurrentdateandtimeinU.S.format.

Ineithercase,setdecimalseparatorto“.”andfield

separatorto“,”.

EuroDate&

Time

@E

DD/MM/YY,

HH:MM:SS

Show/setcurrentdateandtimeinEuropean

format.

Ineithercase,setdecimalseparatorto“,”andfield

separatortotab.

Logging

LOG

0-1

Turntorqueloggingon(1)oroff(0).

DumpRecords

DR

-

Printareportofstoredtorquerecords.Fieldsto

printandtheirorderareselectedviathePF

command.PrintatmostDRLrecords.

NumberofDR

Lines

DRL

1-999

Show/setthenumberof(themostrecent)linesto

putintoaDRreport.PrintCurrentRecord.

PrintCurrent

Record

P

-

Print(butdon’tsave)atorquerecordforthe

currenttorque.

RecordCount

F

-

Showthecurrentnumberofrecordsstoredin

memory.(Response:decimal0-999).

Print1Record

F

1-999

Printtherecordselectedbythedecimalvalue,in

theformatdefinedbythePFcommand.

ThefollowingtableprovidesadescriptionoftheToolConfigurationSettingsthatareavailable:

Field

Descriptionorrangeofvalues

ToolUnits

Toolunitsofmeasure(IN.LB,FT.LB,CNM,NM,C.MKG,MKG)

ToolName

Customerassignednameforthetool(16charactersfrom“A”thru“Z”,“0”thru

“9”,“.”,“-“)

DisplayedMode

ToolMode(TRACK,PEAK,RESIDUAL,T2A,TAM)

PrintFieldSelection

Specifiesthefieldstoprintforarecord(refertoToolResultsLogsection)

YellowTorque

PercentageofminimumtorqueatwhichthelastyellowLEDturnsoninPEAK

andTAMmodes

YellowAngle

NumberofdegreesbeforetargetangleatwhichthelastyellowLEDturnsonin

T2Amode

BacklightTime(s)

Numberofsecondsafterwhichthebacklightwillturnoff(0=nobacklight)

SleepDelay(min)

Numberofminutesofidletimeafterwhichthetoolwillenterlow-power

mode

UnlockingPassword

Passwordtounlockthetoolkeypad,P-Sets,ortoenablethetool

CalibrationPassword

Passwordtounlockthetoolforcalibration

UnitRestriction

LimitstheunitsthataredisplayedforselectioninDTCConnect

Imperial–IN.LB,FT.LB

SI–CNM,NM

Metric–C.MKG,KG

*Thisdoesnotlimittheunitsdisplayedonthetool.

ToolModes

CheckthemodestoappearontheModeselectionscreen

LockStatus

Checktolockthekeypad,P-Sets,and/ortool(DisableToolblockstheuseof

thedisplay/keypadandpreventsdatalogging.Thiscanonlybeunlockedusing

DTCConnect.)

DisplayedFeatures

Selectwhichfeaturesappearinthetoolmenuforselection

ToolDateandTime

CheckNowtousedate&timefromthePC;unchecktospecifythedate&time

CheckUSforUSformat:MM/DD/YYYY,HH:mm:SS

CheckEUforEuropeanformat:DD/MM/YYYYHH:mm:SS

Where“MM”isthe2-digitmonth,“DD”isthe2digitday,“YYYY”isthe4-digit

year,“HH”isthe2-digithours(24-hourformat),“mm”isthe2digitminutes,

and“SS”isthe2-digitseconds.

Sturtevant Richmont P/N 857421 Rev A - 08/9/19 Page 20

ThefollowingcopyrightnoticeappliestotheUSBfeatureoftheDTCwrench.

(USBsoftwareisbeingredistributedinbinaryform.)

/* --COPYRIGHT--,BSD

* Copyright (c) 2016, Texas Instruments Incorporated

* All rights reserved.

*

* Redistribution and use in source and binary forms, with or without

* modification, are permitted provided that the following conditions

* are met:

*

* * Redistributions of source code must retain the above copyright

* notice, this list of conditions and the following disclaimer.

*

* * Redistributions in binary form must reproduce the above copyright

* notice, this list of conditions and the following disclaimer in the

* documentation and/or other materials provided with the distribution.

*

* * Neither the name of Texas Instruments Incorporated nor the names of

* its contributors may be used to endorse or promote products derived

* from this software without specific prior written permission.

*

* THIS SOFTWARE IS PROVIDED BY THE COPYRIGHT HOLDERS AND CONTRIBUTORS "AS IS"

* AND ANY EXPRESS OR IMPLIED WARRANTIES, INCLUDING, BUT NOT LIMITED TO,

* THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

* PURPOSE ARE DISCLAIMED. IN NO EVENT SHALL THE COPYRIGHT OWNER OR

* CONTRIBUTORS BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL, SPECIAL,

* EXEMPLARY, OR CONSEQUENTIAL DAMAGES (INCLUDING, BUT NOT LIMITED TO,

* PROCUREMENT OF SUBSTITUTE GOODS OR SERVICES; LOSS OF USE, DATA, OR PROFITS;

* OR BUSINESS INTERRUPTION) HOWEVER CAUSED AND ON ANY THEORY OF LIABILITY,

* WHETHER IN CONTRACT, STRICT LIABILITY, OR TORT (INCLUDING NEGLIGENCE OR

* OTHERWISE) ARISING IN ANY WAY OUT OF THE USE OF THIS SOFTWARE,

* EVEN IF ADVISED OF THE POSSIBILITY OF SUCH DAMAGE.

* --/COPYRIGHT--*/

Table of contents

Other Sturtevant Richmont Power Tools manuals

Sturtevant Richmont

Sturtevant Richmont SDR Series User manual

Sturtevant Richmont

Sturtevant Richmont exacta 2 Programming manual

Sturtevant Richmont

Sturtevant Richmont exacta 2 User manual

Sturtevant Richmont

Sturtevant Richmont exacta 2 3000 series Service manual

Sturtevant Richmont

Sturtevant Richmont SLTC-FM 2.4GHz Series User manual

Sturtevant Richmont

Sturtevant Richmont SD Series User manual

Sturtevant Richmont

Sturtevant Richmont SLTC Series Operating instructions

Sturtevant Richmont

Sturtevant Richmont LTCR Series User manual

Sturtevant Richmont

Sturtevant Richmont EXACTA 1350-TD Series User manual

Sturtevant Richmont

Sturtevant Richmont SLTCR-FM 2.4GHz 3000I User manual