3

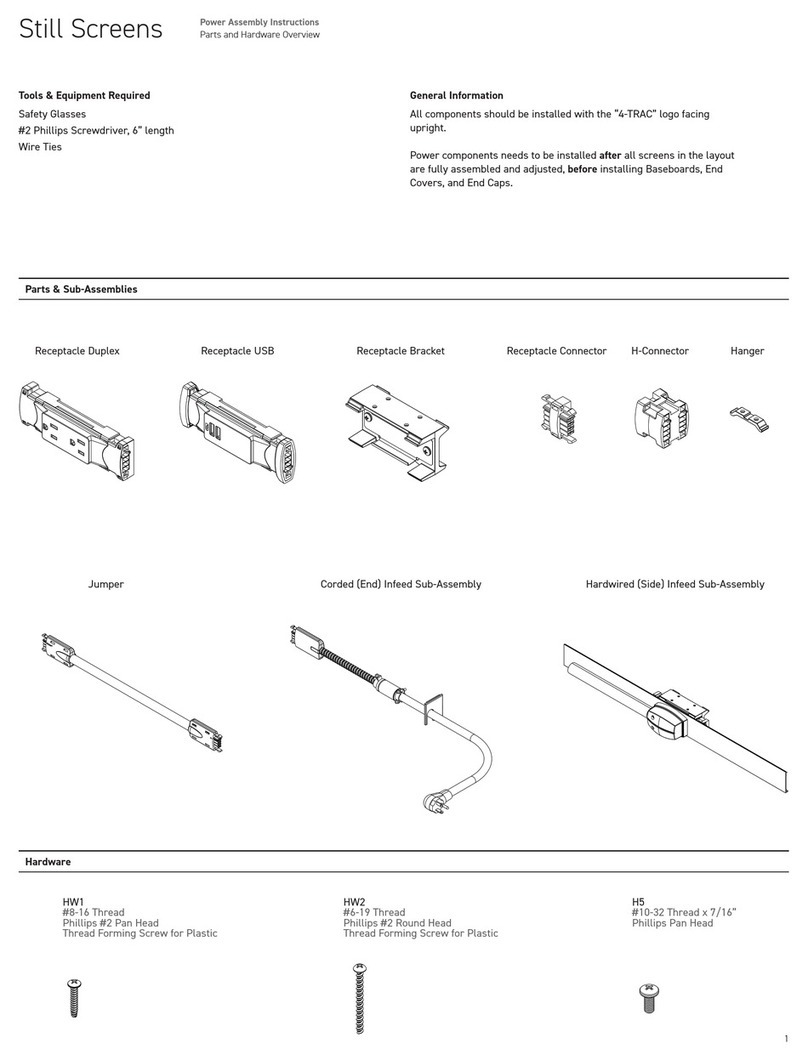

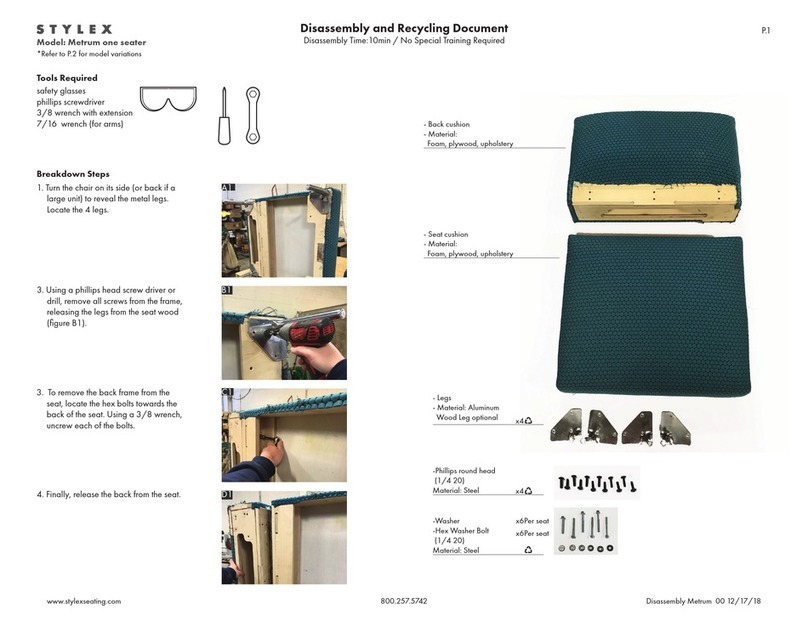

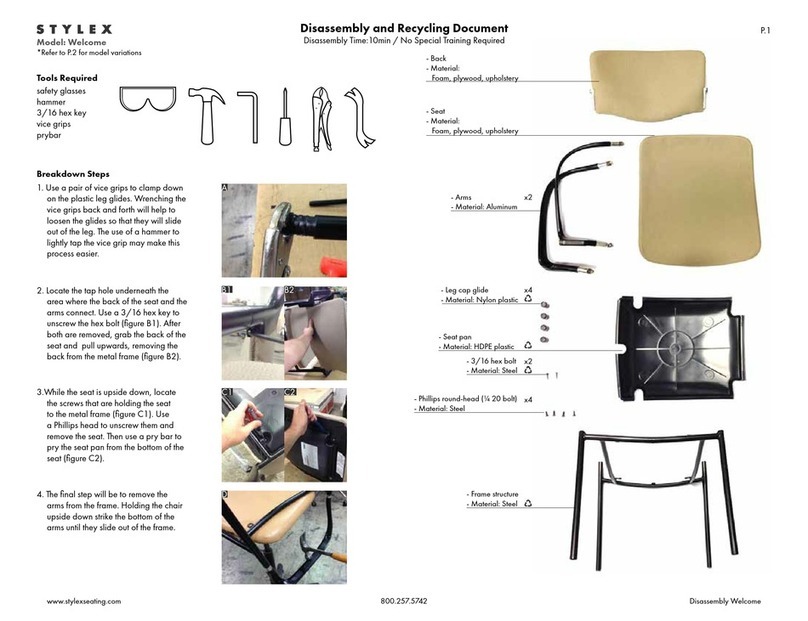

Still Screens

Screen Connector (Pre-Installed)

H4 #10-32 Thread x 5/8”Phillips Pan Head

H6 Leveling Glide 3/8” Hex Head

Assembly Instructions

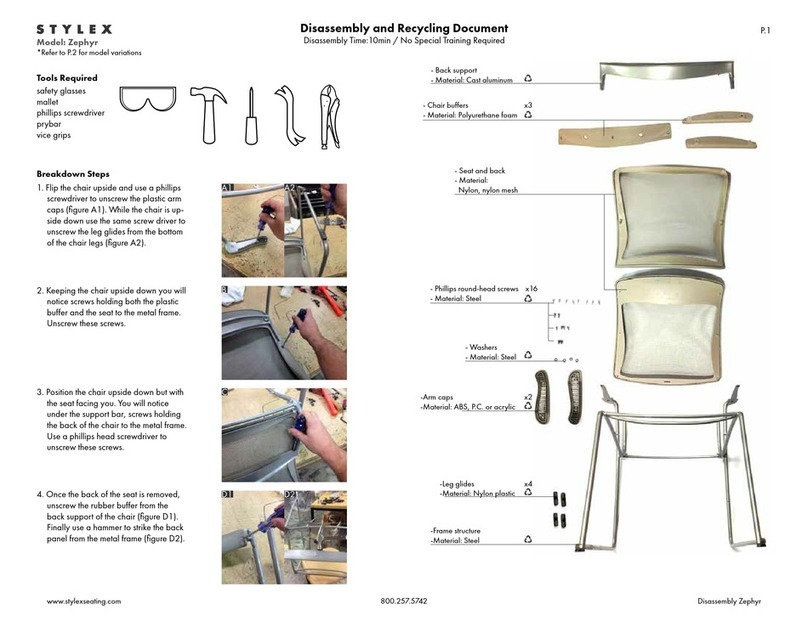

Screen to Screen Assembly

Do not assemble screens while laying flat, or lay assembled screen groups on the

floor.

1. For linear assemblies, installation should begin with one end of a layout (Image

A). If the layout has corners, begin with installation with one of the corners

(Image B). Ensure that the first screen is placed accurately within the room

before assembly the layout.

Note: If dual fabric screens are included, ensure textiles are facing the correct

side. If power is included in the system, ensure that receptacle brackets are

oriented in the correct direction.

2. The hook of the Upper Connector on an installed screen should face upqard,

while the connector on the screen to be installed should face downward. Follow

diretions in Detail A to flip upper connectors.

3. Position the next screen where it will be connected. Slightly lift the screen,

engage the upper connectors, and lower the screen (see Detail A below for

further instructions). If required, use a clean mallet or dead blow hammer to tap

the screen downward and fully engage.

4. Follow directions in Detail B to fasten and level each screen together.

5. When the layout is safely freestanding and with no more that 3 screens, double

check the screen locations within the room, and move if necessary. Do not move

assemblies of more than 3 screens.

When assembling larger layouts or when floors are irregular, it may be necessary to

raise all of the screens in order to allow for the adjust-ability to make all connections.

If glides cannot be adjusted high enough to account for irregularities, shims may be

installed underneath glides. Shims should not be used under Baseplates.

Assembling Layouts & Connecting Screens

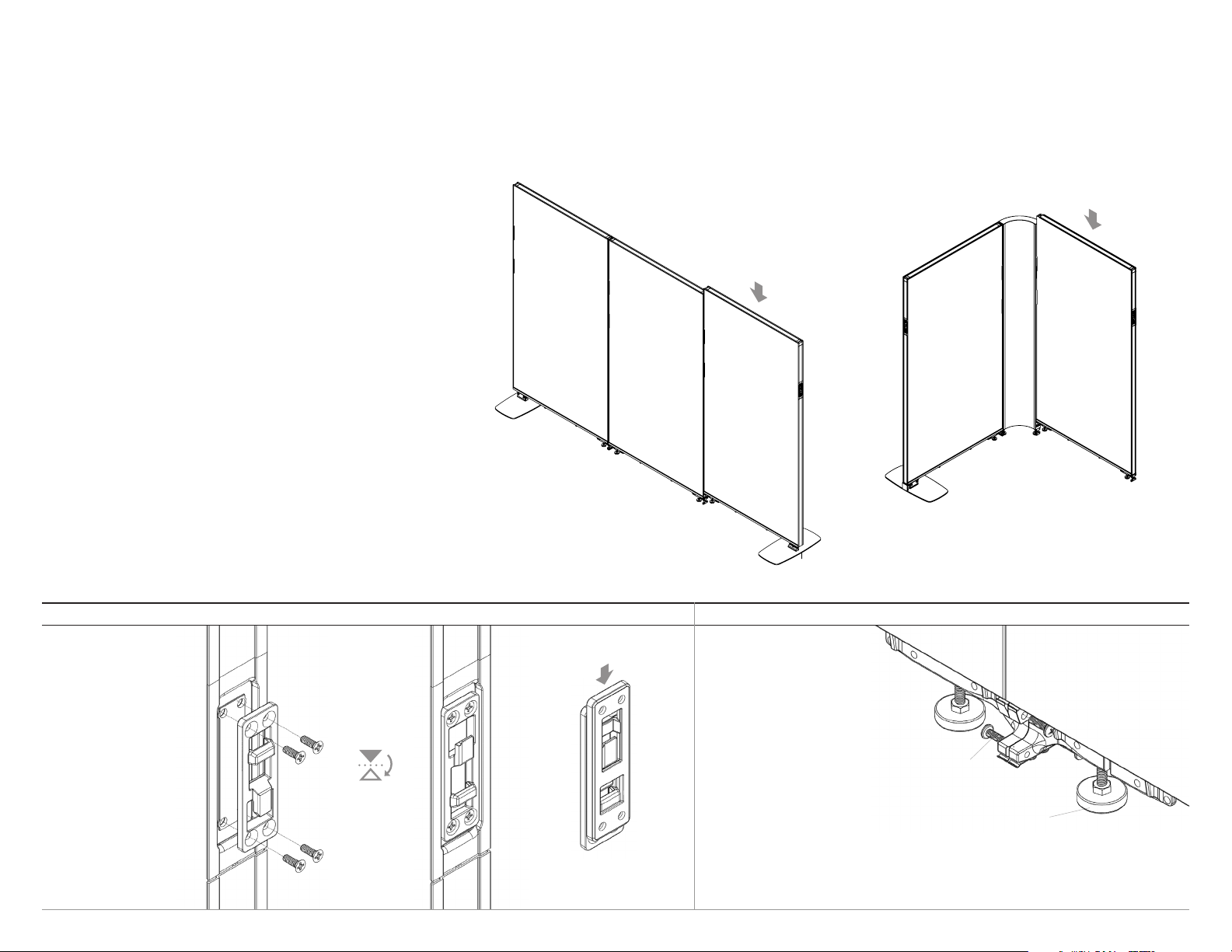

Detail A : Upper Connector Detail B : Base Connector Assembly

The direction of the

Upper Connector may

be flipped by removing

the four Phillips screws,

rotating, and reinstalling

the screws.

Image A Image B

Check that adjacent base

connectors are aligned before

installing screws. Do not force

alignment by installing screws

on an angle.

If necessary, raise or lower

each screen by rotating the

glides (H6) with a 3/8” wrench

or adjust the height of a

baseplate by loosening the two

hex screws (H3), adjusting the

leveling screw (H2) with a 3/8”

wrench, and re-tightening the

hex screws (H3).

To complete assembly, install

the (H4) screws with a long

Phillips screwdriver, 2 in each

direction (4 total for each

screen connection).

flip

If corner screens are in the layout, start assembly with a

corner screen.

Start assembly at end of run.

H6 x 2

H4 x 4

Parts Required

Safety glasses

#2 Phillips Screwdriver, 6” length

Tools Required