- 5 -

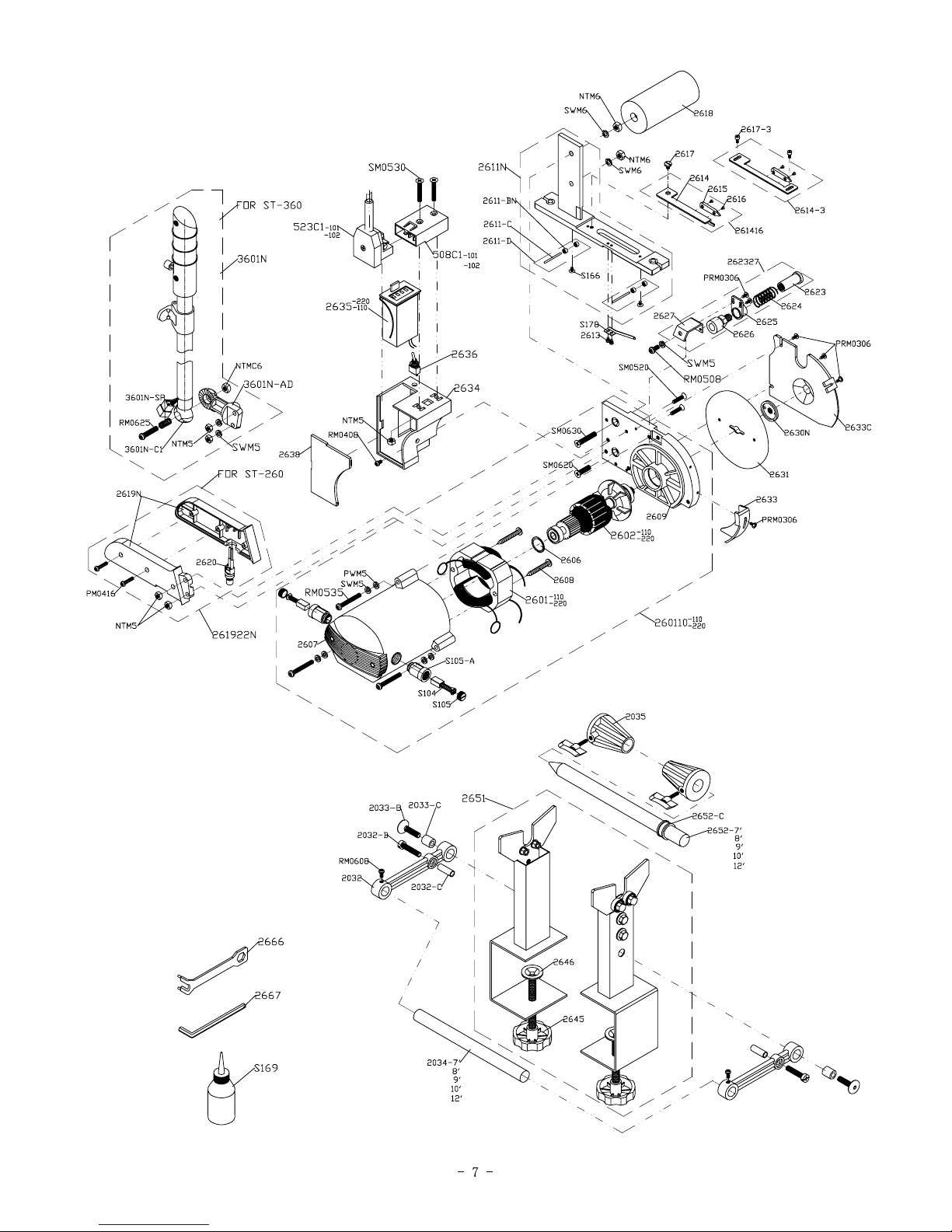

CHECKING (Release connecting plugs)

3.1 Every 24 hours, Clean the Rail bar.

3.2 Every 200 hours, Give oil to roller 2611-BN

3.3 Adjustment of Re-sharpener:

While the grinding wheel wears ,loosen stop nut of collar holder and rectify the re-sharpener

position so as to the grinding wheel keeps proper contact with the knife edge.

3.4 Replacement of Grinding wheel,See Grinding wheel Replacement Guide.

3.5 Replacement of knife:

1. Remove the knife guard 2633 and knife cover 2633C.

2. Lock the knife to the Standard 2609,insetting 2.5mm spanner 2666 to hole in the knife.

The corresponding hole for locking knife is also provided in the standard ,Remove knife

lock hut 2630N

by turning it left Use the wrench 2666 attached.

3. Remove knife.

4. Be sure the front face of the knife when re-setting the knife “SU LEE ST-260”markde face

is the front face.

5. Adjust the position of re-sharpener 2626 after each replacement of knife.

3.6 Replacement of Carbon Brush

1. Too much weaving of carbon brush will cause motor troubles. Carbon brush must be

replaced when it wears to 5-6mm.

2. Carbon brush cap S105 is replaced by turning it left by attached wrench.

3. Always replace right and lift carbon brushes simultaneously.

4. Be sure to hold metallic part of the brush , keep fingers away from carbon.

保養與檢修(注意:將插頭拔掉)

3.1 每使用 24 小時,清理軌道內部之棉布絮.

3.2 每使用 200 小時,請於滑輪 2611-BN 處加少許潤滑油.

3.3 磨刀石的調整:

當刀片磨損時,將磨刀石螺絲放鬆,調整磨刀石位置,使砂輪與刀片的邊緣保持正確的接觸面,在

將螺絲旋緊即可.

3.4 砂輪的更換請看圖解所示.

3.5 刀片的更換:

1.將前護片 2633 及刀片護蓋 2633C 取下.

2.使用內六角扳手 2667 插入刀片孔內,使刀片卡鎖在馬達座 2609 上,不會轉動,再使用鎖刀扳

手2666 將鎖刀螺帽 2630N 依反時針方向轉開.

3.取下刀片.

4.裝刀片時請確定刀片上印有“SU LEE ST-260”字樣的一面,即正面朝向外面,人可看到.

5.每次更換刀片後,須將磨刀石 2626 重新調整至適當位置.

3.6 碳刷的更換:

1.碳刷磨損太多時,可能損壞馬達,當碳刷磨損到長度剩下 5~6MM 即可更換.

2.只須將碳刷蓋 S105 轉開即可取出舊碳刷,再將新碳刷置入,將碳刷蓋旋上即可.

3.通常更換碳刷時,請將左右兩個同時更換.

4.裝入時,請確認碳刷有接觸在金屬整流子上,勿用手碰碳刷.