Sua ionMig 250 User manual

ionMig 250

Copyright © Mundaka Welding & Gases, Inc.

ionMig 250

INVERTER IBGT –MIG WELDING MACHINE

OPERATION MANUAL

IMPORTANT: Read this Owner’s Manual Completely before attempting to use this

equipment. Save this manual and keep it handy for quick reference. Pay particular

attention to the safety instructions we have provided for your protection. Contact your

distributor if you do not fully understand this manual.

ionMig 250

Copyright © Mundaka Welding & Gases, Inc.

2

CONTENT

1. SAFETY ...................................................................................................................................3

2. GENERAL DESCRIPTION.......................................................................................................5

3. CIRCUIT DIAGRAM.................................................................................................................6

4. MAIN PARAMETER.................................................................................................................7

5. PANEL INSTRUCTION ............................................................................................................8

5.1 Front panel instruction.........................................................................................................8

5.2 Back panel instruction .......................................................................................................10

5.3 Middle panel instruction .................................................................................................... 11

6. INSTALLATION & OPERATION ............................................................................................12

6.1 Input cable connection.......................................................................................................12

6.2.1 Arc welding installation...................................................................................................12

6.2.2 Sketch map of installation:..........................................................................................13

6.2.3 Operation .........................................................................................................................14

6.3.1 MIG welding installation..................................................................................................14

6.3.2 Sketch map of installation:..........................................................................................15

6.3.3 Operation:.....................................................................................................................15

6.4.1 No gas, self-protection welding installation:.................................................................16

6.4.2 Sketch map of installation:..........................................................................................17

6.4.3 Operation: ........................................................................................................................17

7. CAUTION ...............................................................................................................................18

7.1 Working Environment ........................................................................................................18

7.2 Good Ventilation .................................................................................................................18

7.3 Over-voltage is forbidden ..................................................................................................18

7. 4 Over-load is forbidden ......................................................................................................19

7. 5 Over-heating Protection....................................................................................................19

8. MAINTENANCE .....................................................................................................................19

9. TROUBLESHOOTING ...........................................................................................................20

ionMig 250

Copyright © Mundaka Welding & Gases, Inc.

3

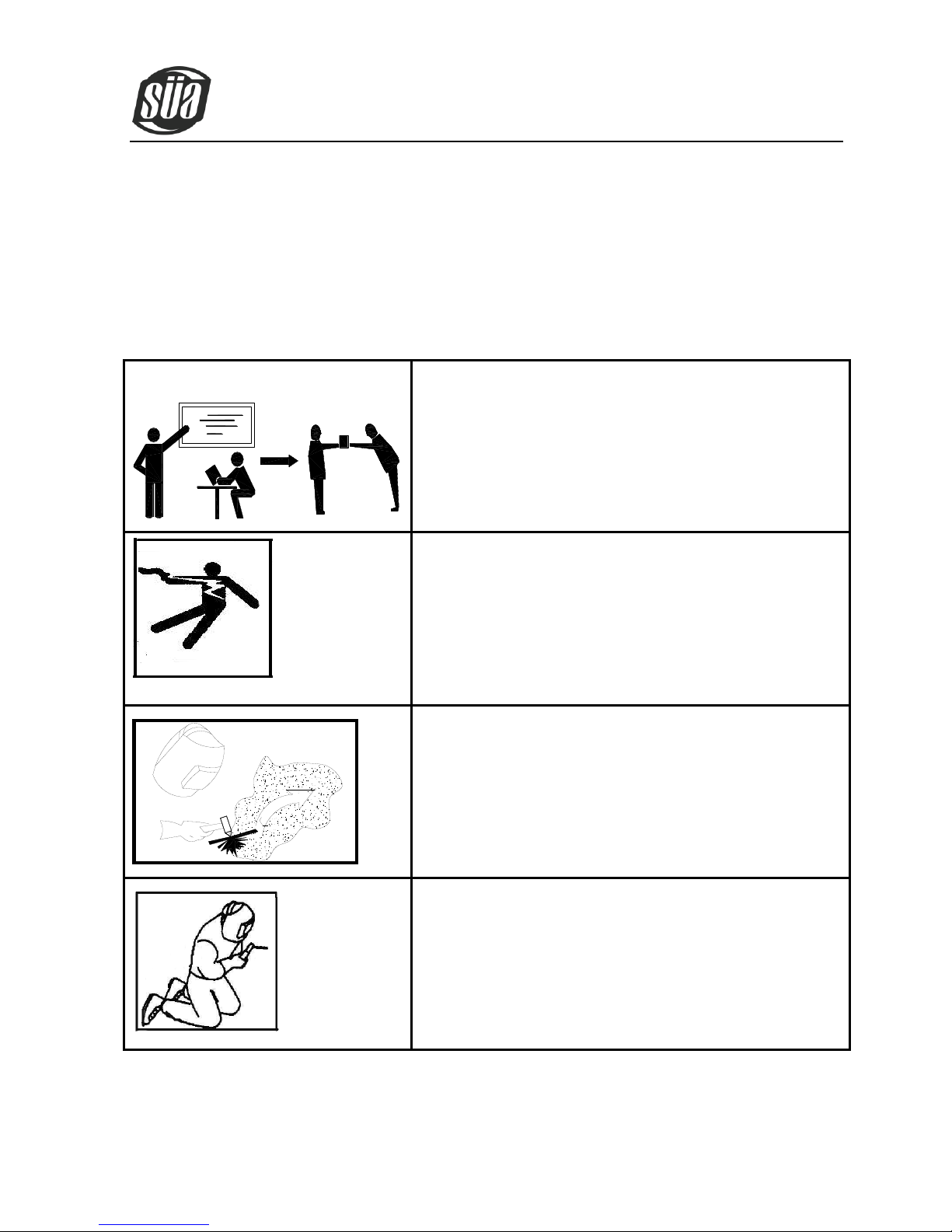

1. SAFETY

Welding is dangerous, and may cause damage to you and others, so take good protection when welding.

For details, please refer to the operator safety guidelines in conformity with the accident prevention

requirements of the manufacturer.

Professional training is needed before operating the

machine.

·Use labor protection welding supplies authorized by national

security supervision department.

·The operator must be special personnel with a valid "metal

welding (OFC) operations" operation certificate.

·Cut off power before maintenance or repair.

Electric shock—may lead to serious injury or even

death.

·Install grounding device according to the application criteria.

·Never touch the live parts when skin bared or wearing wet

gloves/clothes.

·Make sure that you are insulated from the ground and

workpiece.

·Make sure that your working position is safe.

Smoke& gas—may be harmful to health.

·Keep the head away smoke and gas to avoid inhalation of

exhaust gas from welding.

·Keep the working environment in good ventilation with

exhaust or ventilation equipment when welding.

Arc radiation—may damage eyes or burn skin.

·Wear Suitable welding masks and protective clothing to

protect your eyes and body.

·Use suitable masks or screens to protect spectators from

harm.

ionMig 250

Copyright © Mundaka Welding & Gases, Inc.

4

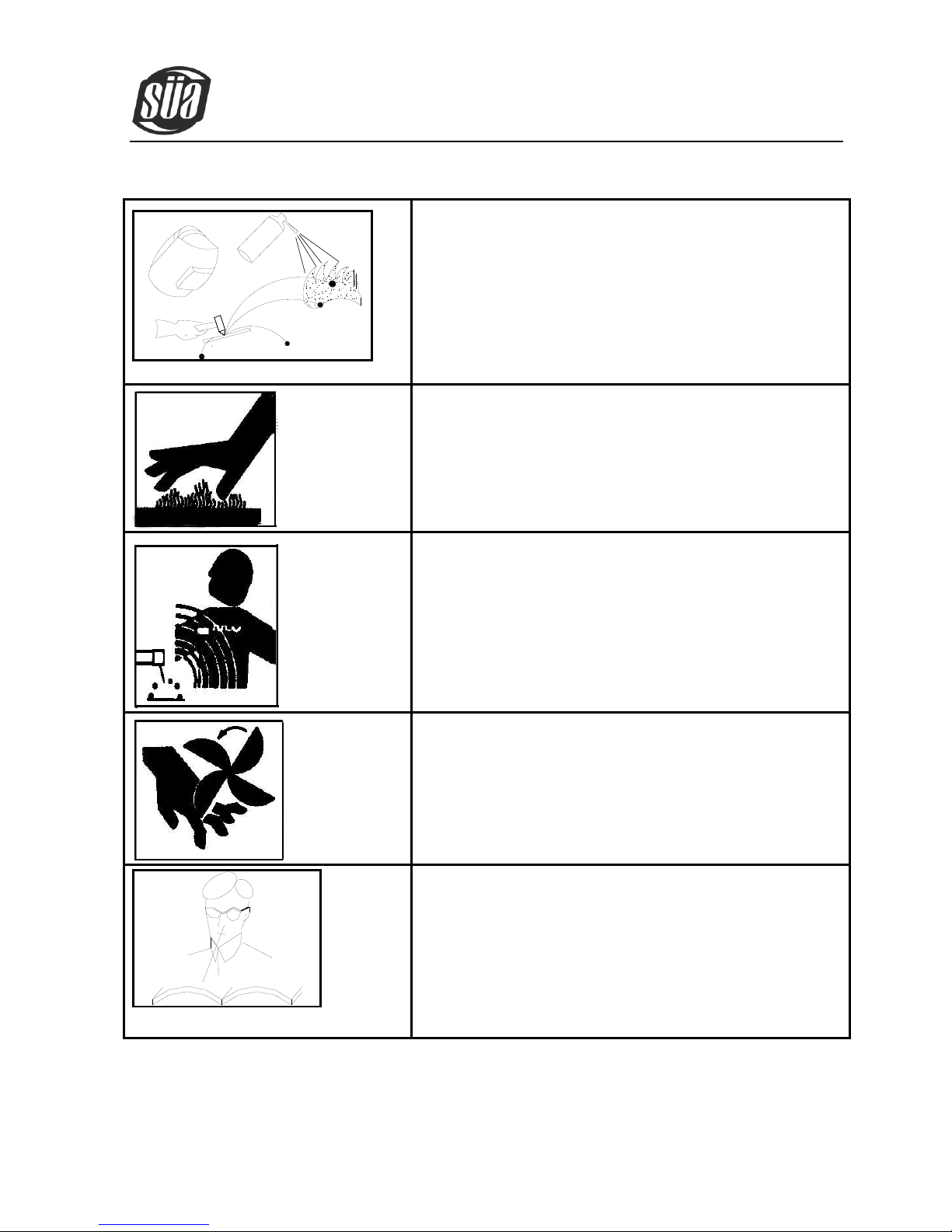

Improper operation may cause fire or explosion.

·Welding sparks may result in a fire, so please make sure no

combustible materials nearby and pay attention to fire

safety.

·Have a fire extinguisher nearby, and have a trained person to

use it.

·Airtight container welding is forbidden

·Pipe thaw with this machine is forbidden.

Hot workpiece may cause severe scalding.

·Don’t contact hot workpiece with bare hands.

·Cooling is needed during continuous use of the welding

torch.

Magnetic fields affect cardiac pacemaker.

·Pacemaker users should be away from the welding spot

before medical consultation.

Moving parts may lead to personal injury.

·Keep yourself away from moving parts such as fan.

·All doors, panels, covers and other protective devices should

be closed and in place.

Machine fault—seek professional help when

encountering any difficulties.

·Consult the relevant contents of this manual If you encounter

any difficulties in installation and operation.

·Contact the service center of your supplier to seek

professional help If you still cannot fully understand after

reading the manual or still cannot solve the problem

according to the manual.

ionMig 250

Copyright © Mundaka Welding & Gases, Inc.

5

2. GENERAL DESCRIPTION

Triple function machine that contain MIG welding, arc welding and no gas self-protection

welding.

Use IGBT with unique control method as inverter power device for increase the reliability

of welding machine.

The duty cycle is so high that can weld long time.

Closed loop feedback control, constant voltage output, fit for wide voltage range (±15%)

Adjustable welding voltage and current, excellent welding characteristics.

MIG welding use the unique welding dynamic characteristic control circuit, stable welding

arc, and little splash, beautiful shaping, high welding efficiency.

Function of removing the molten ball after welding available, high no-load, slow wire

feeding, high successful rate of arc starting.

The current of arc welding is stable, lift arc performance is excellent, and any model

welding rod is available.

Inverter frequency is 20 KHz, greatly reducing the volume and weight of the welder.

Great reduction in metal loss obviously enhances the welding efficiency and energy

saving effect.

Switching frequency is beyond audio range, which almost eliminates noise pollution.

ionMig 250

Copyright © Mundaka Welding & Gases, Inc.

6

3. CIRCUIT DIAGRAM

A

ionMig 250

Copyright © Mundaka Welding & Gases, Inc.

7

4. MAIN PARAMETER

TYPE

MIG200

MIG250

MIG200MY

MIG250MY

Input voltage (V)

Single-phase

AC230V±15%,50/60Hz

3-phase

AC410V±15%,50/60Hz

Rated input current (A)

33

45

16

22

Rated power supply capacity

(KVA)

7.5

10.4

6.6

9.2

Recommended fuse capacity

(A)

60

70

70

70

Arc welding current adjustment

range (A)

10~200

10~250

10~200

10~250

Gas protection welding current

adjustment range (A)

25~200

25~250

25~200

25~250

Gas protection welding voltage

adjustment range (V)

11~27

11~29

11~27

11~29

No-load voltage (V)

52

54

52

54

Feed speed adjustment range

(m/min)

1.5~16

1.5~16

1.5~16

1.5~16

Welding wire diameter

applicable (mm)

0.6/0.8/0.9 /1.0

0.6/0.8/0.9 /1.0

0.6/0.8/0.9 /1.0

0.6/0.8/0.9 /1.0

Rated duty cycle 40 °C

35% @ 250 Amp

Efficiency (%)

85

85

85

85

Power factor

0.75

0.75

0.85

0.85

Protection class

IP21S

Insulation class

F

Size (mm)

880×296×616

880×296×616

880×296×616

880×296×616

Weight (Kg)

75

77

75

77

ionMig 250

Copyright © Mundaka Welding & Gases, Inc.

8

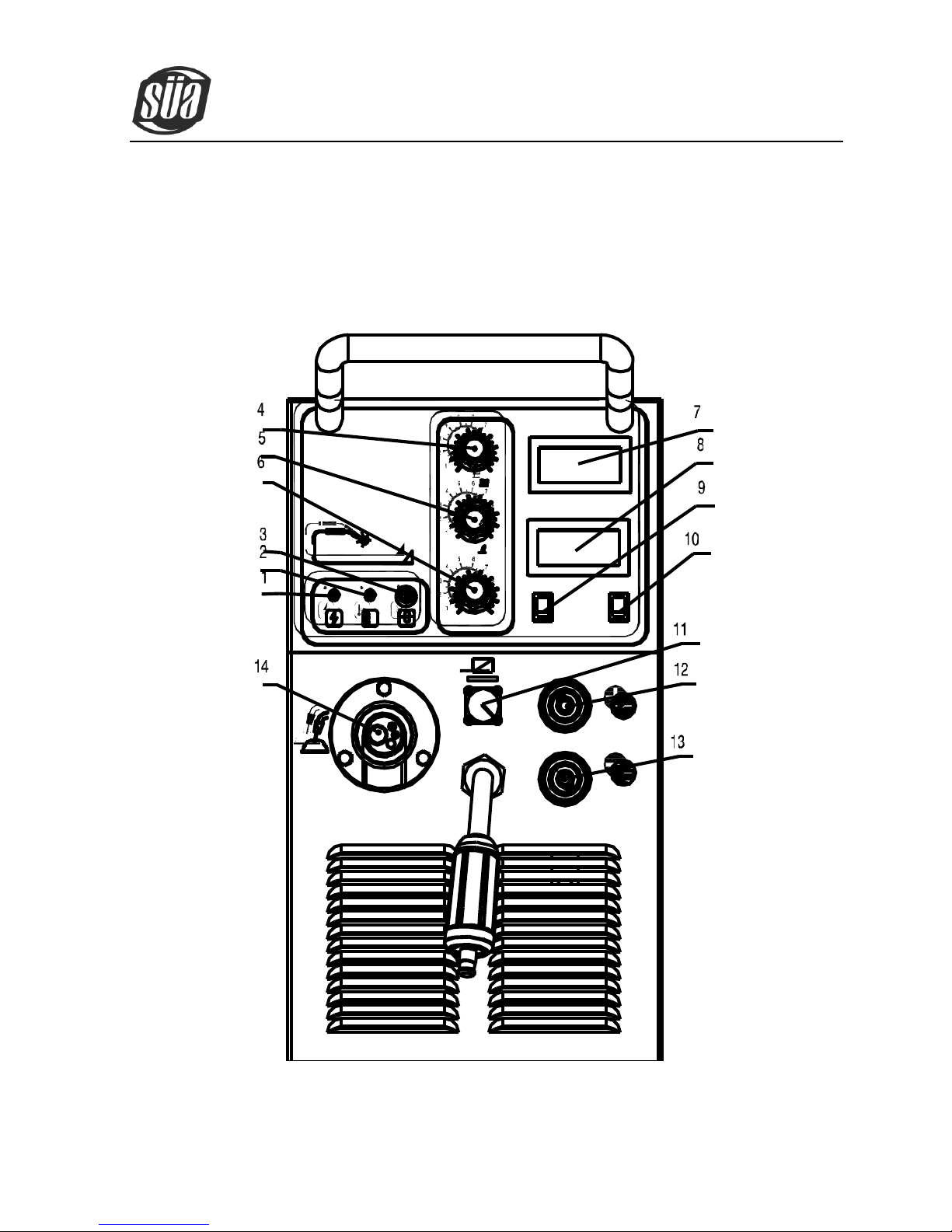

5. PANEL INSTRUCTION

5.1 Front panel instruction

MIG 250

ARC

MIG

Pull

Push

ionMig 250

Copyright © Mundaka Welding & Gases, Inc.

9

(1) Power LED

(2) Over-heating LED

(3) Wire feeding switch

(4) Arc welding current adjustment

(5) Gas protection welding voltage adjustment

(6) The wire feeding speed of gas protection welding adjustment

(7) Voltmeter

(8) Ammeter

(9) Function switch of MIG welding and arc welding

(10)Function switch of wire feeding torch

(11)Socket of wire feeding torch control cable

(12) “+”output terminal

(13) “-”output terminal

(14) Euro-style welding torch connection of MIG welding

ionMig 250

Copyright © Mundaka Welding & Gases, Inc.

10

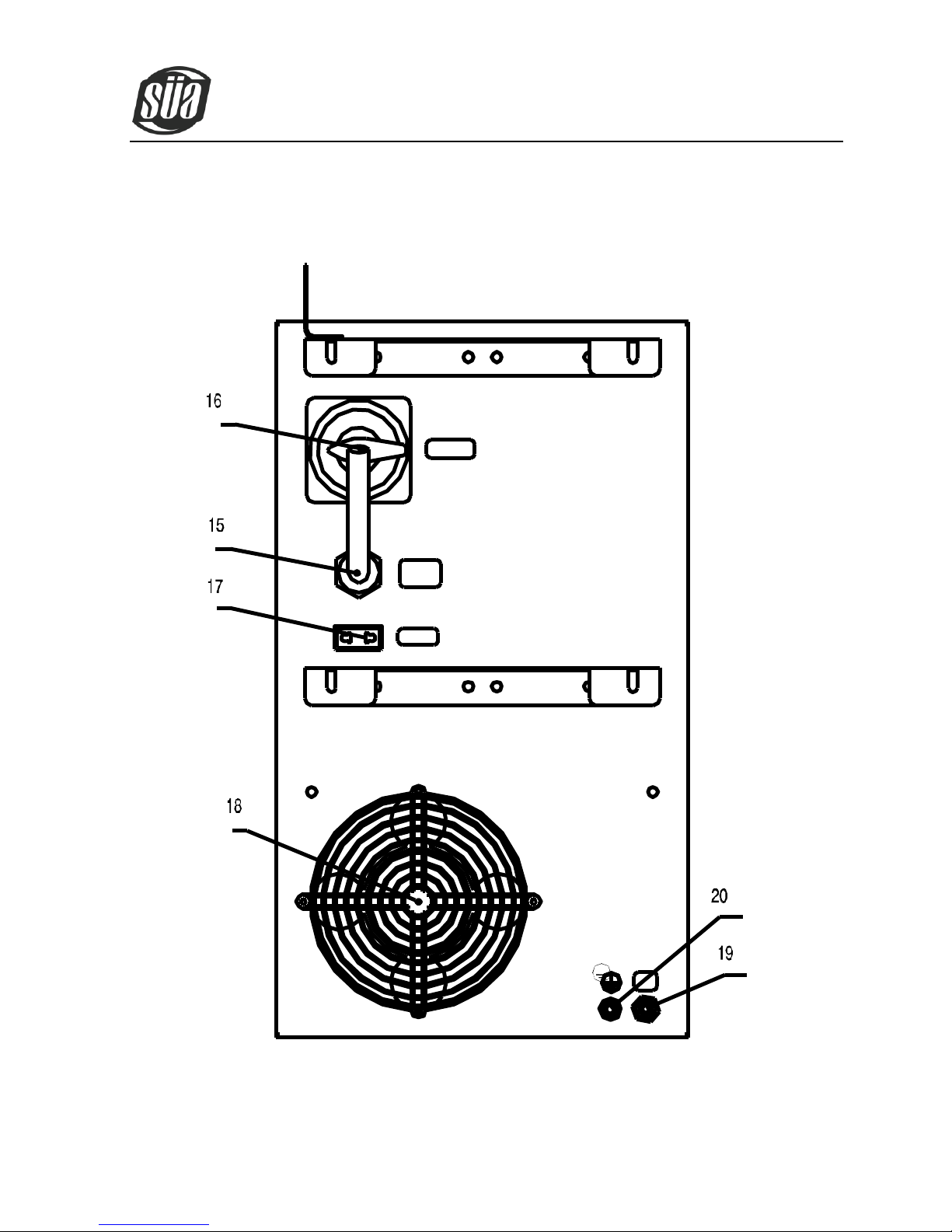

5.2 Back panel instruction

ionMig 250

Copyright © Mundaka Welding & Gases, Inc.

11

(15) Input power cable

(16) Power switch

(17) Power socket

(18) Fan

(19) Gas hose connector

(20) Grounding screw

5.3 Middle panel instruction

(21)Burn back time adjustment

ionMig 250

Copyright © Mundaka Welding & Gases, Inc.

12

6. INSTALLATION & OPERATION

Note: ·Please install the machine strictly according to the following steps.

·Electric connection operation should be after turning off the power supply switch of the

switch box.

·The protection class of this machine is IP21S, so avoid using it in rain.

6.1 Input cable connection

A. Every machine has input cable, connecting them with the corresponding voltage class according to

the input voltage of welding machines. Please don’t connect with wrong voltage class. (Notice: when

connection the welding machine should be earthed reliably.)

B. The input cable should be connected well with the corresponding power supply connection pole or

socket, avoid oxidation.

C. Check if the input voltage within the fluctuation range.

6.2.1 Arc welding installation

A. Every welding machine matches two plugs. Insert the plug into the socket at the bottom of the front

panel, and tighten it, ensure contact good. Otherwise if the working time is long and the working

current is big, it will burn the pin and socket. Please treat it seriously.

B. Insert the welding clamp cable into the “+” socket at the bottom of the front panel, workpiece connect

with the“-”.

C. It should be pay attention to the wire’s polarity. Generally, DC welding machines have two connection

methods: positive connection and negative connection. Positive connection: insert the welding clamp

into the “-” and the workpiece into the “+”; Negative connection: insert the workpiece into the “-”

ionMig 250

Copyright © Mundaka Welding & Gases, Inc.

13

and the welding clamp into the “+”. Choose which connection method when welding should according

to workpiece metal and craft requirements. If select inappropriately, the electric arc will not stable,

also have some spatter, stick the welding rod and so on. In this case, you can replace the plug

conveniently to change the polarity.

D. If the distance between workpiece and welder is too far (50-100m), the welding cable and earth cable

are long, in this case, the cross-sectional area of wire should big enough to reduce the cable voltage

falling.

6.2.2 Sketch map of installation:

SWITCHING BOX

ionMig 250

Copyright © Mundaka Welding & Gases, Inc.

14

6.2.3 Operation

A. After installing the machine according to the above steps, set the power switch of the back panel in

the “on” position, and the machine will be started. The power supply LED lights, the fan begins to turn.

B. Select the arc welding through the function switch at the bottom of front panel. According to the

thickness of workpiece, adjust the “welding current adjustment knob”, let the welding performance

reach to the requirements.

C. General speaking, welding rod corresponding to the welding current as below:

Φ2.5:70-100A; Φ3.2 : 110-160A; Φ4.0 : 170-220A; Φ5.0 : 230-280A

6.3.1 MIG welding installation

A. Plug the welding torch into the “ ” output socket at the front panel of the machine, and tighten it.

Meanwhile, let the welding wire penetrate into the torch by hand.

B. Insert the cable plug with earth clamp into the “-” socket at the front panel of the machine, and tighten

it clockwise.

C. Insert the quick plug of wire feeder into the “+” socket at the front panel of the machine, and tighten it

clockwise.

D. Fix the wire reel to the wire feeding rack axis, matching the groove position of the wire feeding wheel

with the contact tip of the welding torch and the welding wire diameter.

Meanwhile, loosen the strut bracing, and make the wire into the glove of the wire feed wheel, press

the wire tightly, but not too tight, and then thread the wire into the torch. Press the” wire feeding”

button to feed the wire out of the welding torch.

E. Connect the air inlet at the back panel of machine to the gas bottle with gas reduced pressure

flowmeter by gas hose.

ionMig 250

Copyright © Mundaka Welding & Gases, Inc.

15

6.3.2 Sketch map of installation:

GAS HOSE

SWITCHING BOX

6.3.3 Operation:

A. After installing the machine according to the above steps, set the power switch of the back panel in

the “on” position, and the power supply LED lights, the fan begins to turn. Open the gas bottle and

adjust the flow meter on the gas meter to get the desired gas flow volume.

B. Set the function switch of the front panel in the gas protection welding status, and adjust the gas

ionMig 250

Copyright © Mundaka Welding & Gases, Inc.

16

protection welding voltage and wire feeding speed knobs, opt the suitable welding voltage and

current.

C. Press the welding torch switch to start working.

D. According to the requirements, adjust the burn back potentiometer in the middle panel to change the

length of welding wire extend contact tip after welding.

E. The gas will be cut off 1s after the arc stops.

6.4.1 No gas, self-protection welding installation:

A. Plug the welding torch into the “ ” output socket at the front panel of the machine, and tighten it.

Meanwhile, let the welding wire penetrate into the torch by hand.

B. Insert the cable plug with earth clamp into the “+” socket at the front panel of the machine, and tighten

it clockwise.

C. Insert the handle wire quick plug of wire feeder into the “-” socket at the front panel of the machine,

and tighten it clockwise.

D. Fix the wire reel to the wire feeding rack axis, matching the groove position of the wire feeding wheel

with the contact tip of the welding torch and the welding wire diameter.

Meanwhile, loosen the strut bracing, and make the wire into the glove of the wire feed wheel, press

the wire tightly, but not too tight, and then thread the wire into the torch. Press the” wire feeding”

button to feed the wire out of the welding torch.

ionMig 250

Copyright © Mundaka Welding & Gases, Inc.

17

6.4.2 Sketch map of installation:

SWITCHING BOX

6.4.3 Operation:

A. After installing the machine according to the above steps, set the power switch of the back panel in

the “on” position, and the power supply LED lights, the fan begins to turn.

B. Set the function switch of the front panel in the gas protection welding status, and adjust the gas

protection welding voltage and wire feeding speed knobs, opt the suitable welding voltage and

current.

ionMig 250

Copyright © Mundaka Welding & Gases, Inc.

18

C. According to the requirements, adjust the burn back potentiometer in the middle panel to change the

length of welding wire extend contact tip after welding.

D. Press the welding torch switch to start working.

7. CAUTION

7.1 Working Environment

A. Welding should be carried out in a relatively dry environment with its humidity of 90% or less.

B. The temperature of the working environment should be within -10C to 40C.

C. Avoid welding in the open air unless sheltered from sunlight and rain, and never let rain or water

filters the machine.

D. Avoid welding in dusty area or environment with corrosive chemical gas.

E. Avoid gas shielded arc welding in environment with strong airflow.

7.2 Good Ventilation

This welding machine has so big welding current when working that nature ventilation cannot meet the

cooling demand, while the inner fan enables the machine to work steadily by its effective cooling.

Operator should make sure the louvers are uncovered and unblocked. The minimum distance between

the machine and nearby objects should be 30cm. Good ventilation is of critical importance to the normal

performance and service life of the machine.

7.3 Over-voltage is forbidden

The power supply voltage has been showed in the main parameter table. General speaking, the voltage

in the welding machine will compensate the circuit automatically, for ensuring the welding current in the

permitted range. If the voltage exceeds the permitted limit, the machine will be damaged. The users

should know this situation, and take the corresponding measures. So pay attention to the changes in

ionMig 250

Copyright © Mundaka Welding & Gases, Inc.

19

voltage. Once over-voltage occurs, stop welding and switch off the power.

7. 4 Over-load is forbidden

The users should check the max permitted load current at any time (relatively the fixed duty cycle). The

welding current can’t exceed the max permitted load current. Over-loaded current will cut the welding

machine use life remarkably, and maybe burn the welding machine.

7. 5 Over-heating Protection

Over-heating protection appears while the machine is of overload status because of continuous welding

for a long time, and a sudden halt of welding occurs. In this case, it is unnecessary to restart the

machine, but just wait for the over-heating LED to go out, and welding can be recovered.

8. MAINTENANCE

WARNING: The following operation requires sufficient professional knowledge on

electric aspect and comprehensive security knowledge. Operators should be holders of

valid qualification certificates which can prove their skills and knowledge. Make sure the

input cable of the machine is cut off from the electricity before uncovering the welding

machine.

A. Check periodically whether inner circuit connection is ok (esp. plugs). Tighten the loose connection. If

there is oxidization, remove it with sandpaper and then reconnect.

B. Keep hands, hair and tools away from the moving parts such as the fan to avoid personal injury or

machine damage.

C. Clean the dust periodically with dry and clean compressed air. If welding in environment with heavy

smoke and pollution, the machine should be cleaned daily. The pressure of compressed air should

ionMig 250

Copyright © Mundaka Welding & Gases, Inc.

20

be at a proper lever lest the small parts inside the machine be damaged.

D. Avoid rain, water and vapor filters the machine. If there is, dry it and check the insulation with a

megger (including that between the connections and that between the connection and the case).

Only when there is no abnormal phenomena can welding be continued.

E. Check periodically whether the insulation skin of all cables are perfect. If there is any dilapidation,

wrap it or replace it.

F. Check periodically whether the gas hose has any cracks. If any, get them replaced.

G. Put the machine into the original packing in dry location if it is not to be used for a long time.

9. TROUBLESHOOTING

WARNING: The following operation requires sufficient professional knowledge on

electric aspect and comprehensive security knowledge. Operators should be

holders of valid qualification certificates which can prove their skills and

knowledge. Make sure the input cable of the machine is cut off from the

electricity before uncovering the welding machine.

Common Malfunction Analysis and Solution

Malfunction phenomena

Solution

1. The overheating protection

LED turns on.

A. Check the welding current and welding time. Operate according to the

requirement referring to the instruction manual.

B. Check the fan’s running status when welding. If the fan does not work,

check if there is a power supply of 230V: If the power supply is normal,

Table of contents

Other Sua Welding System manuals

Popular Welding System manuals by other brands

Miller

Miller Augmented Arc owner's manual

Lincoln Electric

Lincoln Electric SPEEDTEC 405S Operator's manual

ArcOne

ArcOne Inverter Power Sources User instruction manual

Miller Weldmaster

Miller Weldmaster Triad Extreme manual

K.C.D. STUDWELDING

K.C.D. STUDWELDING CD1000 instruction manual

Draper

Draper MPW190 instructions