Miller Weldmaster Triad Extreme User manual

Instruction Manual

Page 1

This instruction manual is intended to be a guide when operating the Triad Extreme Seam welder. To ensure optimal

performance from your welder, please follow the recommendations and specifications precisely.

For more technical information regarding this machine call our Resolution Center 1-855-888-WELD or email

service@weldmaster.com.

You can also subscribe to Miller Weldmaster Insiders to stay updated on tech tips, machine maintenance updates,

and more at www.weldmaster.com/insiders.

Instruction Manual

Page 2

Instruction Manual

Page 3

Chapter 1: Introduction

Chapter 2: Material Set-up

Chapter 3: Operating Instructions

Chapter 4: Material Guides

Chapter 5: Welding

Chapter 6: General Maintenance

Chapter 7: Wedge Cleaning and Honing

Chapter 8: Wedge Adjustment

Chapter 9: Wedge Replacement

Chapter 10: Wedge Installation

Chapter 11: Troubleshooting

Chapter 12: Schematics

Chapter 13: Commonly Used Parts

Page 4-5

Page6

Page 7

Page 8

Page 9-10

Pages 11

Pages 12

Page 13-16

Pages 17

Pages 18-19

Pages 20

Page 21-48

Page 49

Table of Contents

TABLE OF CONTENTS

Instruction Manual

Page 4

1.0 Introduction

The Triad Extreme Seam hot wedge welding machine is designed for in house fabrication of a wide

range of flexible membranes. This includes, but is not limited to, PVC, PP, PE, LDPE, Urethane, etc.

Thickness of material that can be welded will vary also with product. Normal range is 5-100 mil thick-

ness and can be supported or non-supported material.

The Triad comes complete with three different guides. This will allow you to perform the overlap weld,

hem weld, prayer weld and many more welding options.

The Triad uses a hot wedge as its heat source. This method will give you smokeless and quiet opera-

tion. The wedge also allows for welding thinner products without distortion.

The Triad can be used as a stationary welder or in an automatic mode. When using the Triad in an

automatic mode, a track system is suggested. Please refer to Track System Specifications.

We suggest that you make samples welds of your product to achieve the correct settings for heat,

speed and wedge alignment before you start welding

CHAPTER 1 INTRODUCTION

Instruction Manual

Page 5 CHAPTER 1 INTRODUCTION

1.1 Intended Use

The Triad Extreme Seam Welder is a hot wedge welding machine intended to heat-seal weld-

able thermal plastics such as:

•Vinyl (PVC) laminated and coated fabrics

•Vinyl (PVC) and Polyurethane (PU) films

•Polyurethane (PU) and Polypropylene (PP) coated fabric

•Polyethylene (PE)

•Thermoplastic rubber (TPR) film and fabrics Non-woven Polyester and Polypropylene Various

Weldable Webbing

The manufacturer does not approve of:

•Any other uses for these machines.

•The removal of any safety guards while in operation.

•Unauthorized modification of the machines.

•Using replacement parts that are not manufacturer-approved.

Only a properly-trained technician may operate and/or perform any routine maintenance or

repairs to the machines.

NOTE: The manufacturer will not be held liable for any damage or injuries occurring from

any inappropriate use of this machine.

Instruction Manual

Page 6CHAPTER 2 MATERIAL SET-UP

2.0 Material Setup

Material should be laid out as flat as possible, either on the floor or table depending on how you set

up your fabrication area. With most material and especially thinner goods, it is prefered to pull out

the wrinkles or pull taunt. The use of sheet metal in or next to the machine on the table, allows for

the use of magnets to position and hold the material. Taping material taunt is a good practice.

To perform overlap welds, always overlap material more than the final weld width. Example: With a

1-1/2” weld width, overlap the end of material or run 2 to 2 1/2”. The machine and front guides will

push the material to the desired overlap. If the material is not overlapped or positioned properly, the

machine will not make the desired overlap weld. See sample below.

Instruction Manual

Page 7 CHAPTER 3 OPERATING INSTRUCTIONS

3.0 Operating Instructions

The following procedures should be followed only after you have followed the Wedge Adjustment and

Guide adjustment procedures.

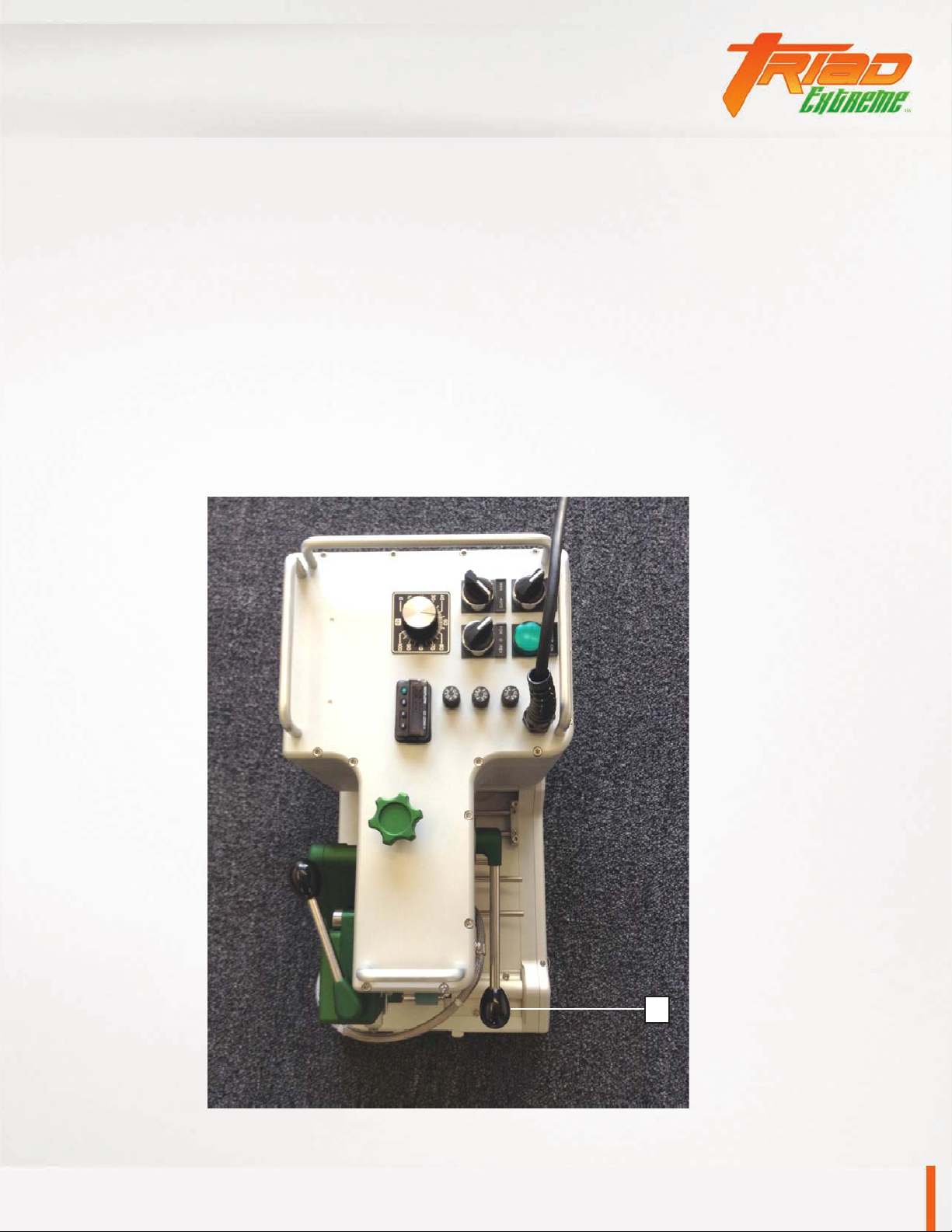

1. Pull up on Red Power Switch #3 to turn machine on. The Green Power Light #4 will go on with a

one second delay. The Green light will remain on as an indicator that you have power to the ma-

chine. (Push down on Red Power Switch #3 to turn machine off)

2. Temperature Controller #7 will come on with a 1-2 second delay after Green Power Light goes on.

Units are set in celsius at the factory. Press the Set Button and hold, now press the up or down

button until you reach your desired temperature. Heat up time is only one to two minutes. Do not

adjust heat over 510 degrees C. For sample welds, set controller to 400 degrees C. This may not

be your final setting.

3. Set For/Rev Switch #5 to Forward position. This indicates direction of machine and drive/pressure

roller movement.

4. Set Man/Auto Switch #2 to Auto position. This will engage or start Drive/Pressure rollers when

wedge is moved into welding position.

5. Swing Drive Wheel Assembly #10 under bottom Pressure Roller. This will make the machine move

or automatic. With Drive Wheel Assembly out, the machine can be used in a stationary mode.

6. #1 is the Speed Control. It is adjustable from 0-30 feet per minute. Normal setting will be in the

30 to 60 range, for 12-30 mil goods.

7. #8 is the Pressure Knob. It can be adjusted for more or less pressure, depending on the thickness

of material.

8. Insert material into the machine with proper guides installed and close Pressure Wheel Handle #9.

9. Swing Wedge Engagement Handle #11 in toward the machine, this will automatically start forward

motion of the Triad and engage wedge with material.

10. Adjust speed control up or down until you can verify you are getting a proper weld.

Instruction Manual

Page 8CHAPTER 4 MATERIAL GUIDES

4.0 Material Guides

All Guides shown below are included with the purchase of the standard machine. Each guide will give

you a specific type of weld and more. You can only use one guide system at a time.

The Top Guide will be used with all three different welding functions, overlap, hem and prayer

welds. All Guides are adjustable.

To achieve a precise weld with no loose flap on top or bottom of sheet, guides should be adjusted so

that they are even with the width of wedge, or welding area

Overlap Guide

Top Guide

Hem Guide

Prayer or Fin Guide

Instruction Manual

Page 9 CHAPTER 5 WELDING

5.0 Welding

5.1 Overlap Weld

Attach Overlap Guide #1 to base plate with the two screws provided. Loosen screw (A) to adjust bottom side

of overlap for proper alignment and re-screw.

5.2 Hem Weld

Slide Hem Guide #2 onto the three stainless rods up to the outer Horn Guide #3 (Diagram #1), leaving

enough area between the two so material will slide easily. Tighten thumbscrew (B) (Diagram #1), this will

allow the outer Horn guide and Hem guide to move as one. This dictates the size of the hem to be welded.

Push on Hem Slide #4 (Diagram #2) to achieve desired hem width or size. When this is done, tighten thumb-

screws (C) (Diagram #1) to lock in place.

Instruction Manual

Page 10

5.3 Prayer or Fin Weld

Position the Prayer Guide #5 under the Welding Horn, placing the key way into the slot. Fasten with screw

provided once proper alignment is completed.

5.4 Front Guides

Front Guides #6 are adjustable to pre-align material before you reach the welding process. This will help

the operator in feeding material into machine properly.

CHAPTER 5 WELDING

Instruction Manual

Page 11 CHAPTER 6 GENERAL MAINTENANCE

6.0 General Maintenance

General maintenance should be performed annually to your Triad Extreme Welder.

Chain tension should be checked to alleviate excessive wear to the chains and sprockets. Using a

foaming chain lubricant will cling to the chain and extend chain life.

The pinch rollers should be replaced if there are cuts, flat spots, burn marks etc.

Wedge adjustment should be checked daily before performing any welding. The operator should

be familiar with all wedge adjustments to get the best weld quality. Check for any loose hardware.

Loose hardware can alter the wedge adjustment with every engagement.

Instruction Manual

Page 12CHAPTER 7 WEDGE CLEANING AND HONING

7.0 Wedge Cleaning and Honing

For accurate welds and longer wedge life, the wedge should be cleaned and honed on a regular basis.

CLEANING: Wedge cleaning should be done daily. There are two ways to clean the wedge.

1. With the Pressure Rollers in the up position and the wedge in the weld position, use the Brass Brush

provided and clean wedge top and bottom. This can be done after every weld or as needed.

2. The second method of cleaning the wedge is to increase the temperature to 510 degrees C for 5-10

minutes. This will burn the residue on the wedge and it will flake off. Use the Brass Brush to re-

move.

HONING: Wedge Honing should be done if there are signs of wear on the wedge. This is evident with

uneven welds, rounding edges or corners on the wedge.

1. Install both smooth steel rollers on machine, (do not hone the wedge with the Silicone rollers on

machine).

2. Turn the forward/reverse switch to reverse position.

3. Swing wedge into weld position and close rollers.

4. Take the fine Emery Cloth provided, and run it back through the rollers on top of the wedge. Repeat

this step on the bottom of the wedge.

5. Repeat step 4 top and bottom until there is even wear the full length of wedge.

6. If Honing does not true up the wedge, refer to Wedge Adjustment section. A combination of honing

and adjustment may be necessary.

Emery Cloth

Instruction Manual

Page 13 CHAPTER 8 WEDGE ADJUSTMENT

8.0 Wedge Adjustment

Proper wedge alignment is essential to achieve a proper weld. Units are preset at the factory.

Sample welds should be made prior to actual use of the machine.

If sample welds are good only on one side or the other, or only partially welded, this means the

wedge is not aligned or square to the rollers, and alignment adjustment is needed.

Unplug unit from power source and make sure the wedge is cool before you work on the machine.

1. Pull Pressure Roller Handle #1 down. This will close Pressure Rollers.

1

Instruction Manual

Page 14

2. Swing Wedge Handle #2 in this will engage wedge with rollers. The wedge #4 should rest or

fit snug into the rollers #3 on both sides and should be centered.

CHAPTER 8 WEDGE ADJUSTMENT

4

2

3

8.0 Wedge Adjustment (Continued)

Instruction Manual

Page 15 CHAPTER 8 WEDGE ADJUSTMENT

3. To center wedge between rollers, turn screw #5, this will fine tune wedge up and down. Only a

1/8 or 1/4 turn is necessary. Do not overturn. Move Pressure Roller Handle up and down slowly

to check centering adjustment. Swing wedge handle in and out to ensure proper positioning.

5

4. Adjustment Screw #6 will move wedge on a center axis left and right. Loosen

Locking Screw #8 to make adjustment. Loosen Lock Nut #7, turn Adjustment

Screw clockwise to bring right side of wedge in and counterclockwise to bring left

side in. When adjusted properly, tighten Locking Screw and Lock Nut.

8

6

7

8.0 Wedge Adjustment (Continued)

Instruction Manual

Page 16

5. Wedge Stop Screw #9 will stop travel of wedge when positioning wedge in weld position.

Loosen Locknut #10 , turn Adjustment Screw in or out to proper position. The edge of the

wedge should fit snug and square into the rollers on each end.

Make a test weld before proceeding with job. Fine tuning your adjustments can be made while

wedge is hot. Do not run Hot Wedge into Silicone Rollers without material in machine for extended

periods, as it will distort the silicon.

Note: For thicker products (30mil and up) backing the wedge out may be necessary to allow room

for material.

10

9

CHAPTER 8 WEDGE ADJUSTMENT

8.0 Wedge Adjustment (Continued)

Instruction Manual

Page 17

9.0 Wedge Replacement

The wedge should be replaced when honing and adjustment is no longer effective. If heater failure occurs

after a period of time, the heaters may not be easily removed. The wedge and heater will most likely have

to be replaced together.

1. Unplug machine and make sure wedge is cool.

2. Remove Hanger Bracket Screw #11 and remove Wedge Housing Assembly #14.

3. Unscrew and detach Heater Connector #12.

4. Remove both Wedge Screws #13, and remove wedge.

5. Install new wedge with Wedge Screws. Attach Heater Connector and re-attach Wedge.

6. Center Housing with Screw #11 and tighten.

7. Wedge alignment may be necessary, please refer to Wedge Adjustment Section.

Note: Wedge Housing assembly will move back and forth in slot for #11 screw. Moving the Housing will

increase or decrease exposure of material to wedge for different preheat time or exposure. Thinner

products need little preheat, thicker material need more.

11

13

14

12

CHAPTER 9 WEDGE REPLACEMENT

Instruction Manual

Page 18

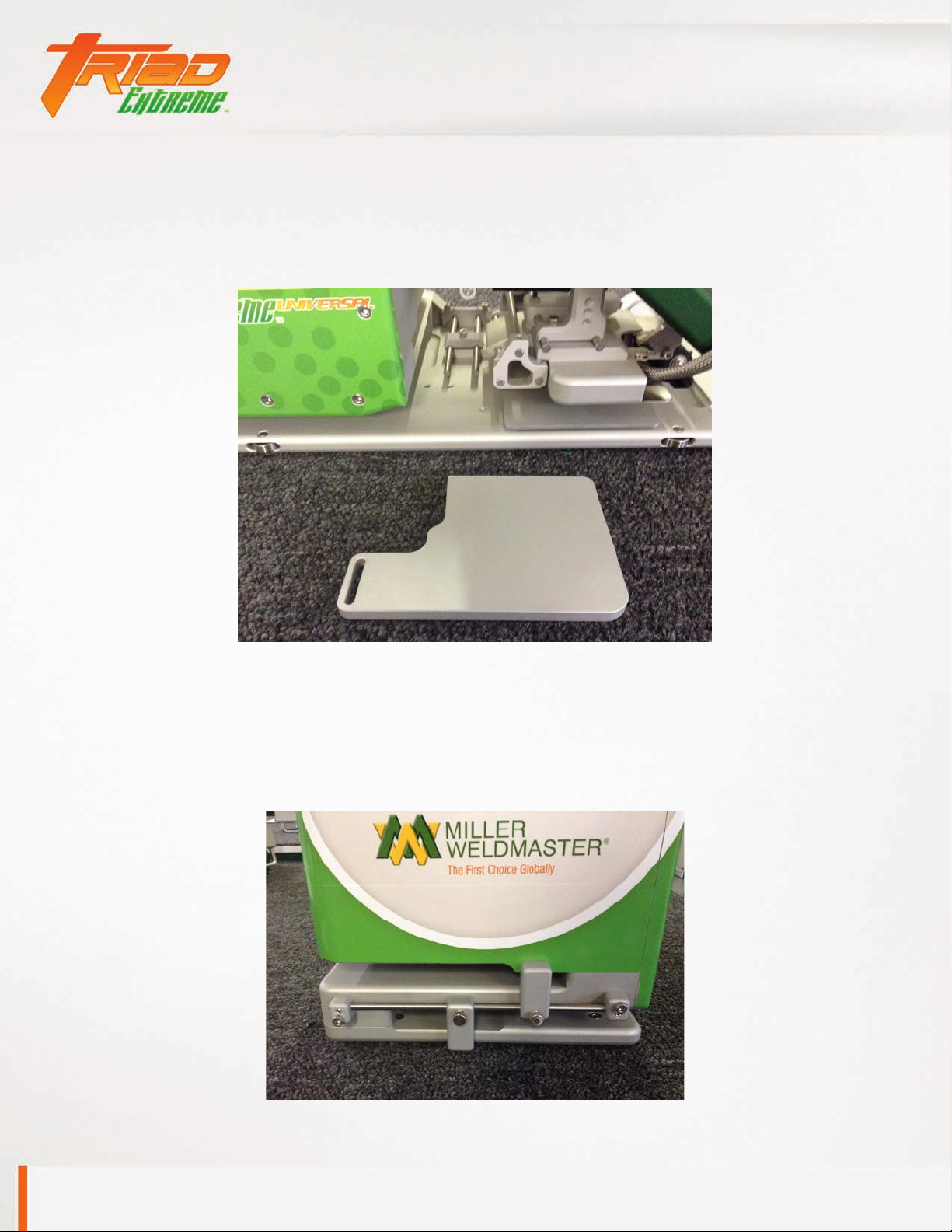

10.0 Wedge Installation

Install wedge on wedge mount

arm along with lead bracket

using two screws (note insert

photo). Position heater wires

properly on lead bracket and

gently close tabs to secure.

With wedge in engaged position,

use zip ties to collect heater

wires together. Note the wrap of

heater wires around upper pinch

roller arm and around back of

Triad.

CHAPTER 10 WEDGE INSTALLATION

Instruction Manual

Page 19

10.0 Wedge Installation (Continued)

CHAPTER 10 WEDGE INSTALLATION

Using clip & screw, attach

around heater wires and posi-

tion to body of Triad. Do not

fully tighten.

Electrically connect hot wedge

to receptacle on body of Triad.

When connected, make com-

fortable bend of heater wire and

position properly in clip. Swing

wedge in and out of welding po-

sition to make sure wrap around

back of Triad is comfortable.

When completed, tighten clip to

secure.

Instruction Manual

Page 20

11.0 Troubleshooting

Condition Possible Cause Corrective Action

Wedge doesn’t heat Fuse blown

Heater failed (220 Volt)

Control or relay failure

Loose wire

Diagnose wedge

Replace fuse

Replace wedge

Diagnose and replace control

Check wiring contacts

No drive, motor hums Chain break/binding

Pinch roller bearings

U joint shaft

Motor gears stuck (rare)

Find and repair or adjust failed chain

Replace bearings/shaft

Rebuild U joint shaft

Repair or replace motor

No drive, motor quiet Motor fuse failed caused by fabric or me-

chanical binding

Controller failure (usually associated with

control fuse blown)

Correct cause of binding

Replace fuse

Diagnose and replace controller

Wedge temp unsta-

ble

Controller programming

Heater failure (120 Volt)

Thermocouple failure

Reconfigure control.

Diagnose and replace wedge

Fuse blows (heater) Heater short or ground fault

Incorrect fuse value

Diagnose and replace wedge

Replace with correct fuse

Fuse blows (control) Controller failure

Short circuit or other wiring problem

Diagnose and replace failed control

Diagnose and correct wiring

Temp control display

blank, ER 4 (Triad) or ER in

(Spec)

No thermocouple signal

Thermocouple failure

Plug in and test wedge

Replace wedge

Check internal T/C wire

Temp control display

shows other ER code

Triad control (935) all errors are T/C based,

Spec control (SD) see control manual

Plug in and test wedge

Check control configuration

Only one pinch roller is

turning

Chain failure (Triad)

Belt failure (Spec)

Gear or sprocket spun

Repair or replace belt or chain

Replace shaft assembly

Pinch roller handle doesn’t

lift completely

Cam roller at apex of travel in cam plate Rotate wedge height adjustment bolt about

180° and readjust wedge center

CHAPTER 11 TROUBLESHOOTING

Table of contents

Other Miller Weldmaster Welding System manuals

Miller Weldmaster

Miller Weldmaster Impulse 3.0 Extreme User manual

Miller Weldmaster

Miller Weldmaster T600 Extreme User manual

Miller Weldmaster

Miller Weldmaster T-100 User manual

Miller Weldmaster

Miller Weldmaster 112 Extreme User manual

Miller Weldmaster

Miller Weldmaster 112 Extreme User manual

Miller Weldmaster

Miller Weldmaster Seamrover DD User manual

Miller Weldmaster

Miller Weldmaster T3 Extreme User manual

Miller Weldmaster

Miller Weldmaster Extreme T300 User manual