2

Caution

Do not use the unit with any other voltage than AC

220V.

*There is risk of electric shock or fire

caused by a short circuit.

If the unit is not working properly,

pull the plug immediately and

turn it in for service or repair.

*There is risk of electric

shock or fire caused by a

short circuit.

Do not obstruct the suction inlet or the exhaust air

vent while the unit is in operation.

*The motor can otherwise overheat and

break down.

Do not use the unit in places where it can be ex-

posed to rain or other water.

*Contact with water can damage the insu-

lation and cause electric shock, short cir-

cuit, fire and other accident and injuries.

Do not use the unit in places with high concentration

of dust in the air.

*If there are high levels of dust in the air,

dust can enter into the motor, causing it

to overheat and can result in a fire.

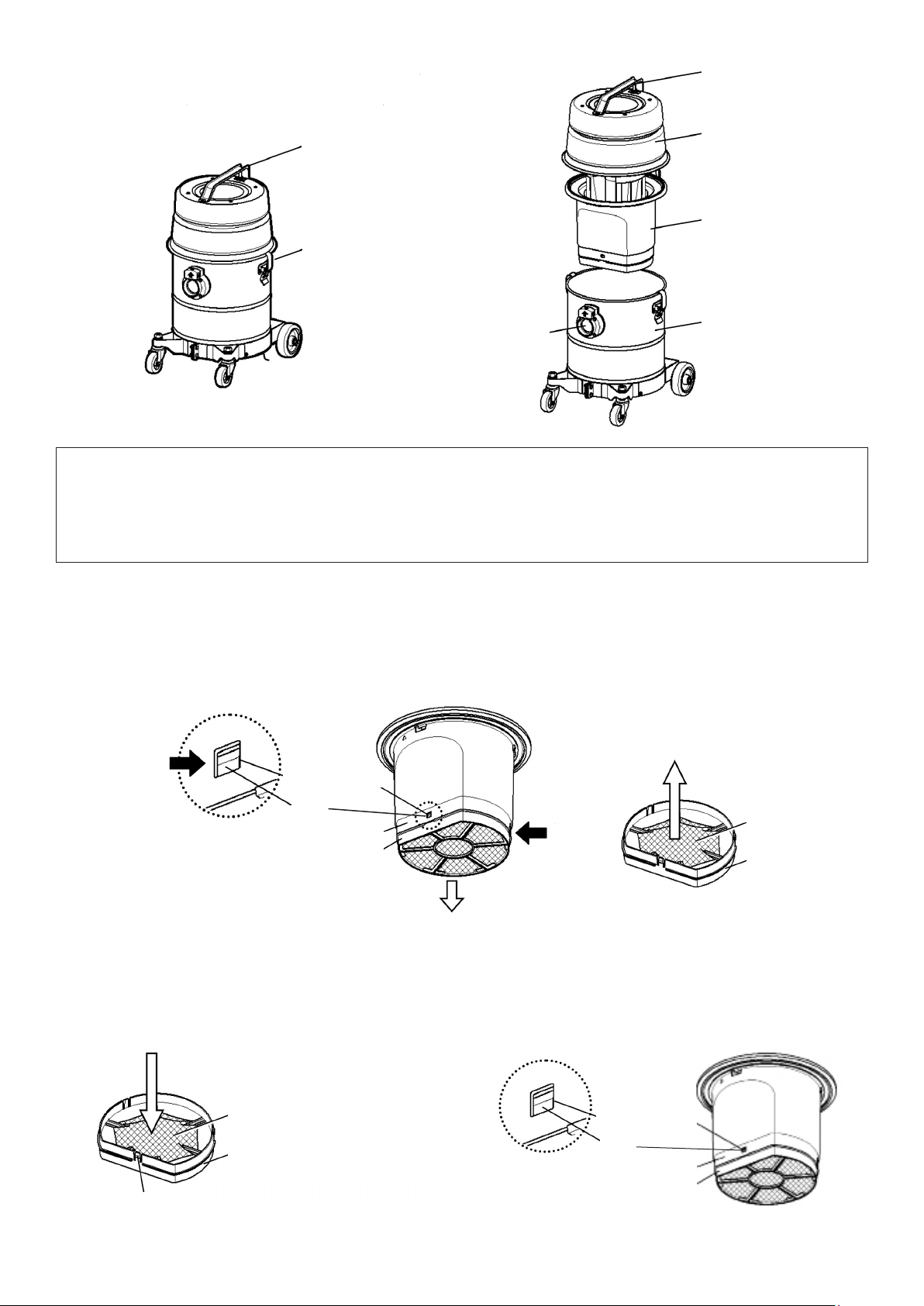

Never use the unit to clean metal chips or swarf

without the support lter.

*Without the support filter, the normal

filter can get damaged by the metal chips

and swarf, which can lead to accidents

and malfunction.

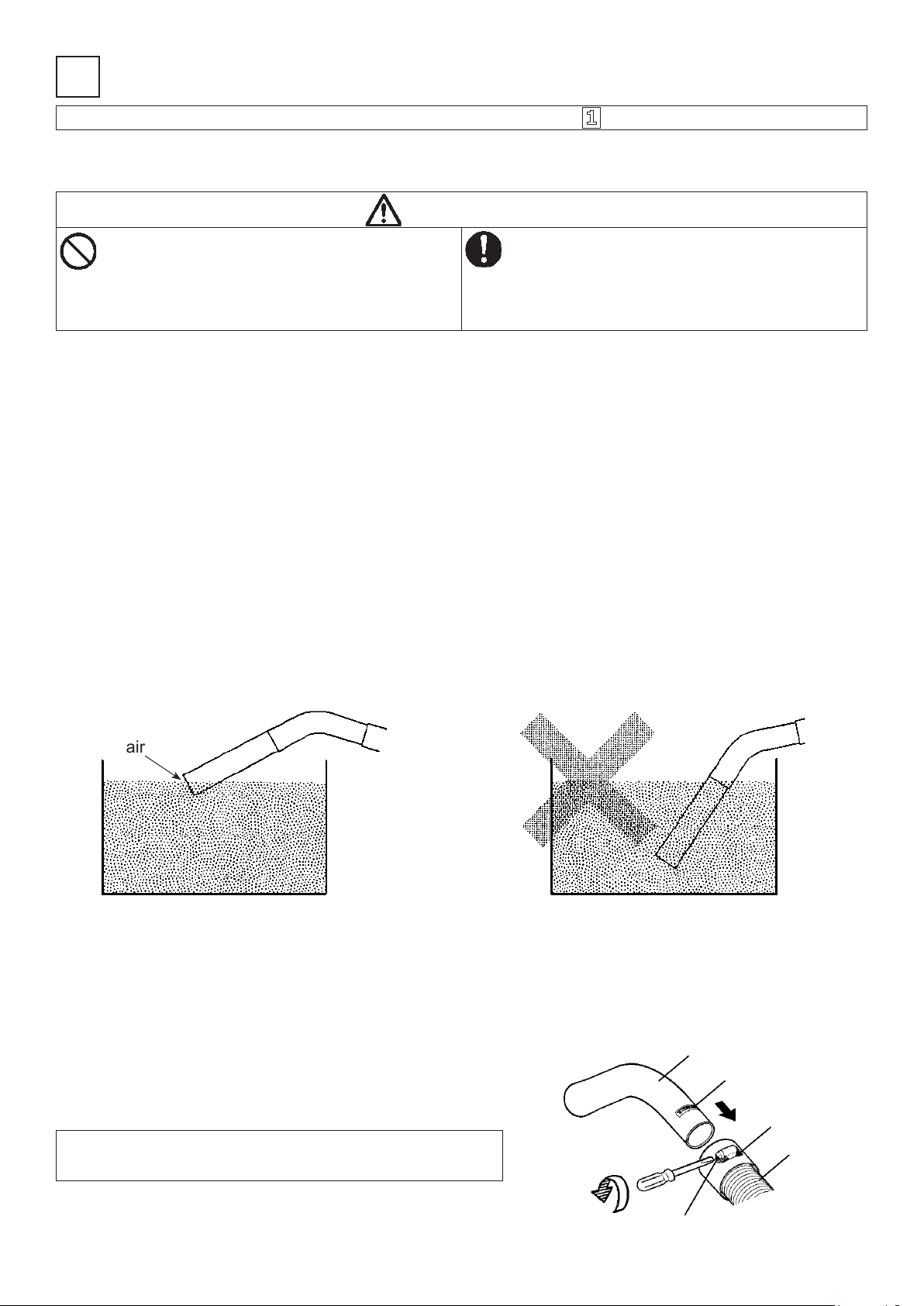

If the suction of the unit if obstructed by something

getting stuck inside the tube or hose, or if the oat

device has been risen, you must turn off the power

immediately.

*The motor can otherwise overheat and

break down.

Keep away from re.

*The unit can become deformed, causing

short circuit and possibly fire.

Do not clean solidied cement dust, synthetic resin

dust, metal dust, carbon dust, conductive ne dust

or pharmaceuticals.

*This could cause fire from short circuit or

electric shock.

Do not clean thinner or other solvents, volatile or

explosive gases or dust, lit cigarettes or other hot or

burning substances.

*This could cause explosions, fires or the

filter to get burned and damaged.

Earth the unit securely with earth clip at the end of

the electric cord. Especially if you are cleaning a

place with wet oors.

*If the unit is not earthed, there is risk of

electric shock.

Do not use in areas with mist or smoke from chlo-

rine-based cutting oil.

*This can lead to a chemical reaction that

makes the resin parts break, which can

lead to injuries as well as damage to the

unit. Do not use the unit at high humidity.

*This could cause fire, short circuit or mal-

function.

*The humidity should be below 80%.

Do not use at temperatures higher than 40ºC.

*This could cause fire.

*The unit can be used within the tempera-

ture range 0-40ºC.

Do not clean any substance, liquid or dust that

foams.

*Foam can cause the float device to not

work properly, causing the vacuum clean-

er to overfill and leak from the exhaust

vent. This could cause short circuit, mo-

tor malfunction, or stain your clothes.

Do not put hands or ngers into

the air suction inlet holes or the

nozzles.

*There is risk of injury.

Do not step on the hose or pull it recklessly.

*The hose can get damaged and start leak-

ing into the environment where the vacu-

um cleaner is being used.

Do not tip the unit over during or after cleaning

liquids.

*This could cause the motor to overheat or

malfunction, or cause an accident.

Never use the unit while it is tipped over on its side.

*The content of the tank might spill out.

Do not use the unit if the cord or plug is damaged,

or if the plug is loose in the socket.

*Electric shock or fire caused by a short

circuit can occur.

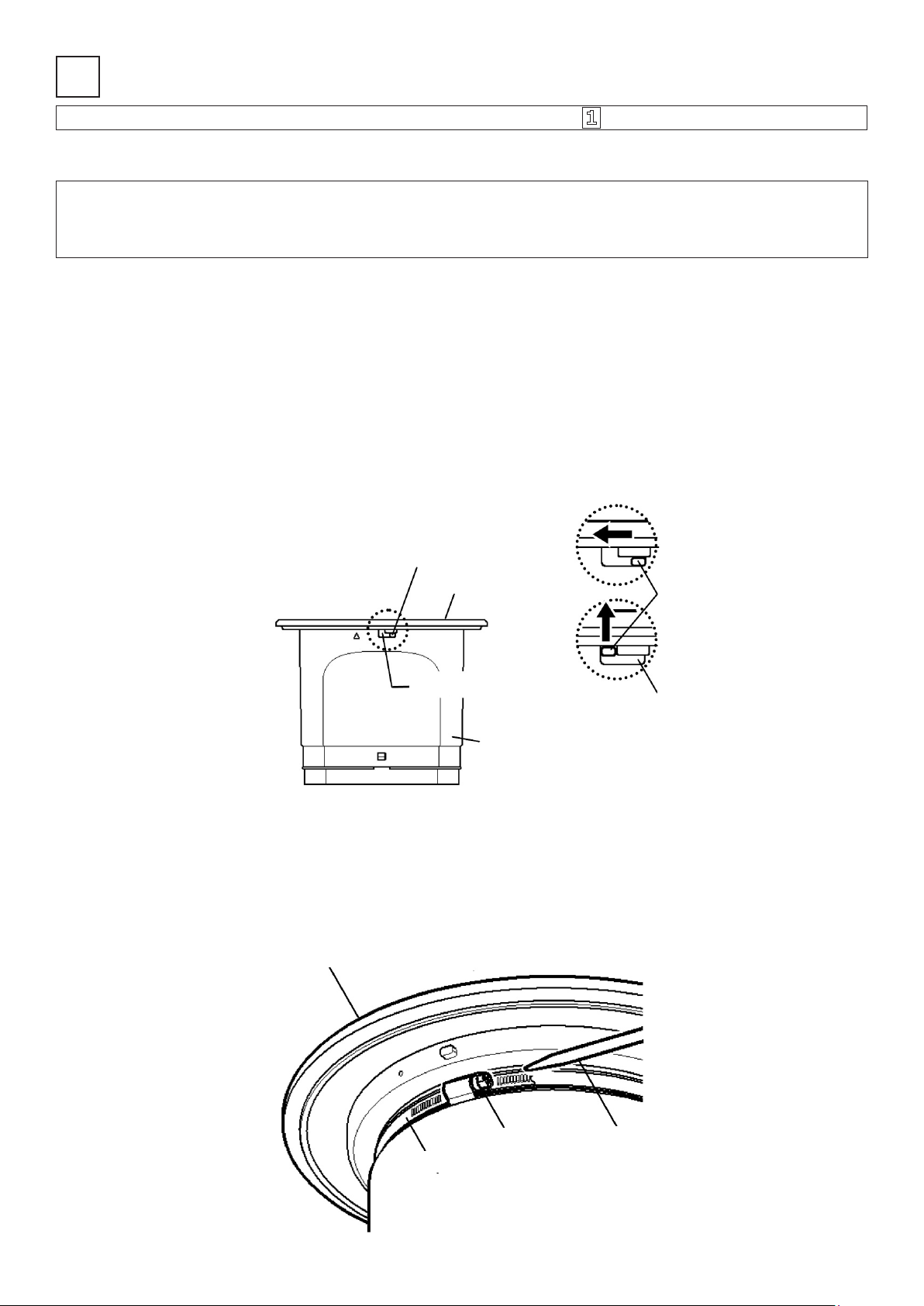

If you use an extension cord, make sure to use one

that meets the specied requirements.

*There is risk of the cord overheating and

catching fire.

Do not use the unit when the cord is coiled or bun-

dled together.

*There is risk of the cord overheating and

catching fire.

*Make sure that the cord is extended be-

fore use.

Do not move the unit by pulling the electric cord or

hose.

*The cord or hose can get damaged, cause

electric shock, short circuit, fire or leak-

age.

Do not damage, extend, nor excessively bend, pull, twist, bundle, squeeze or put heavy objects on the cord.

*If the cord gets damaged, there is risk of electric shock or fire.

Do not clean sea water or other

corrosive liquids or powder.

*This can cause the motor

to catch fire, malfunction

or cause and accident.