10

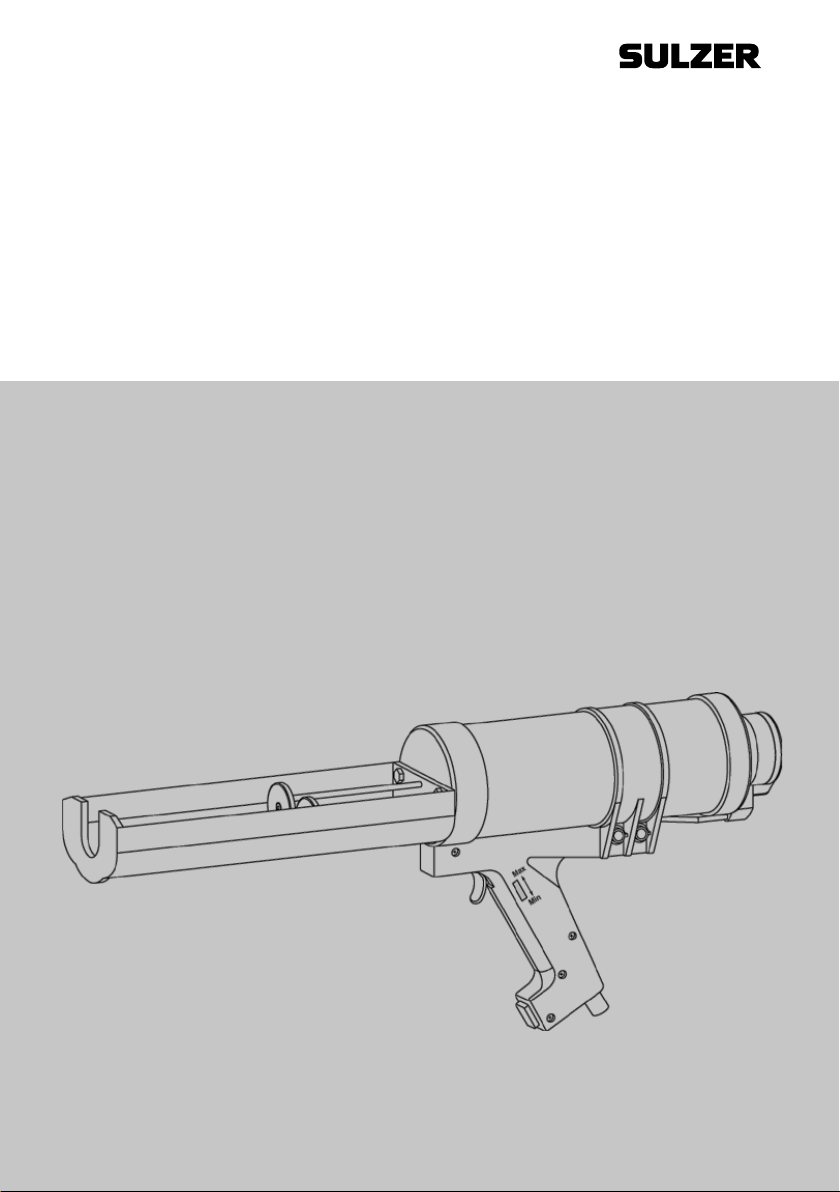

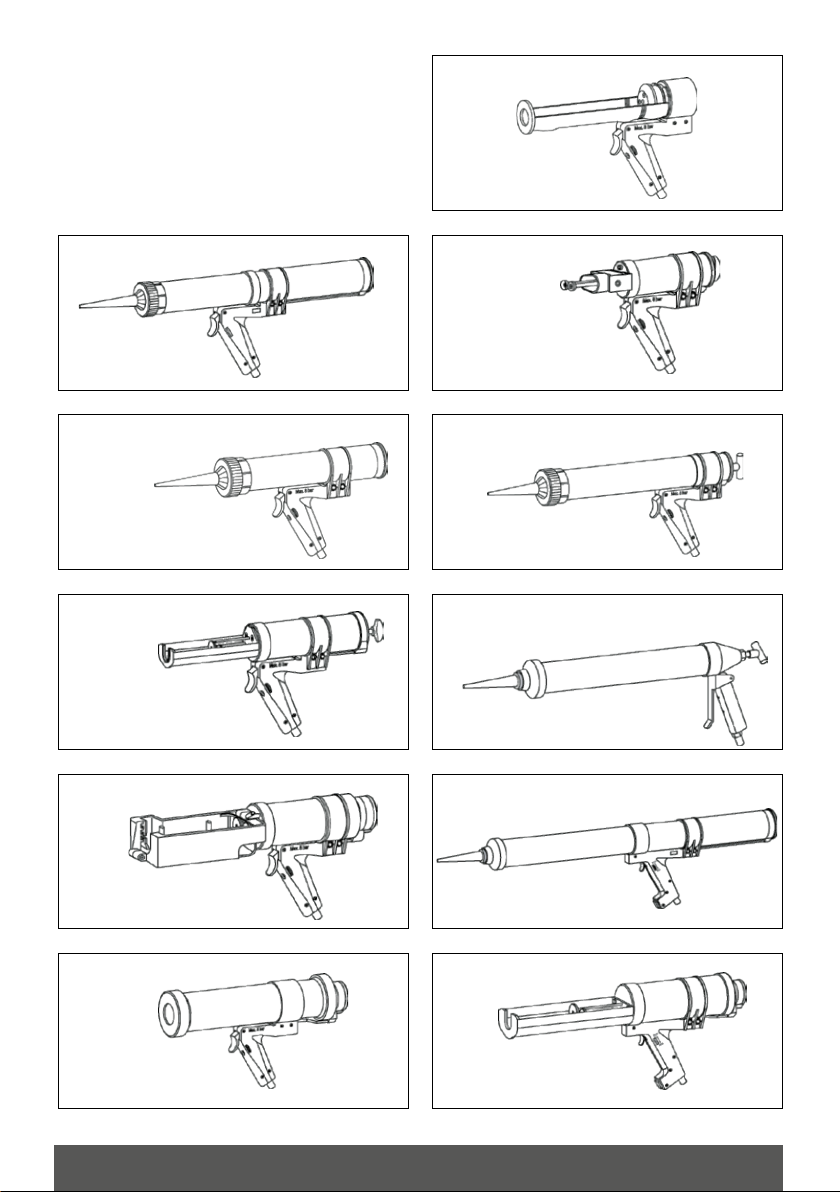

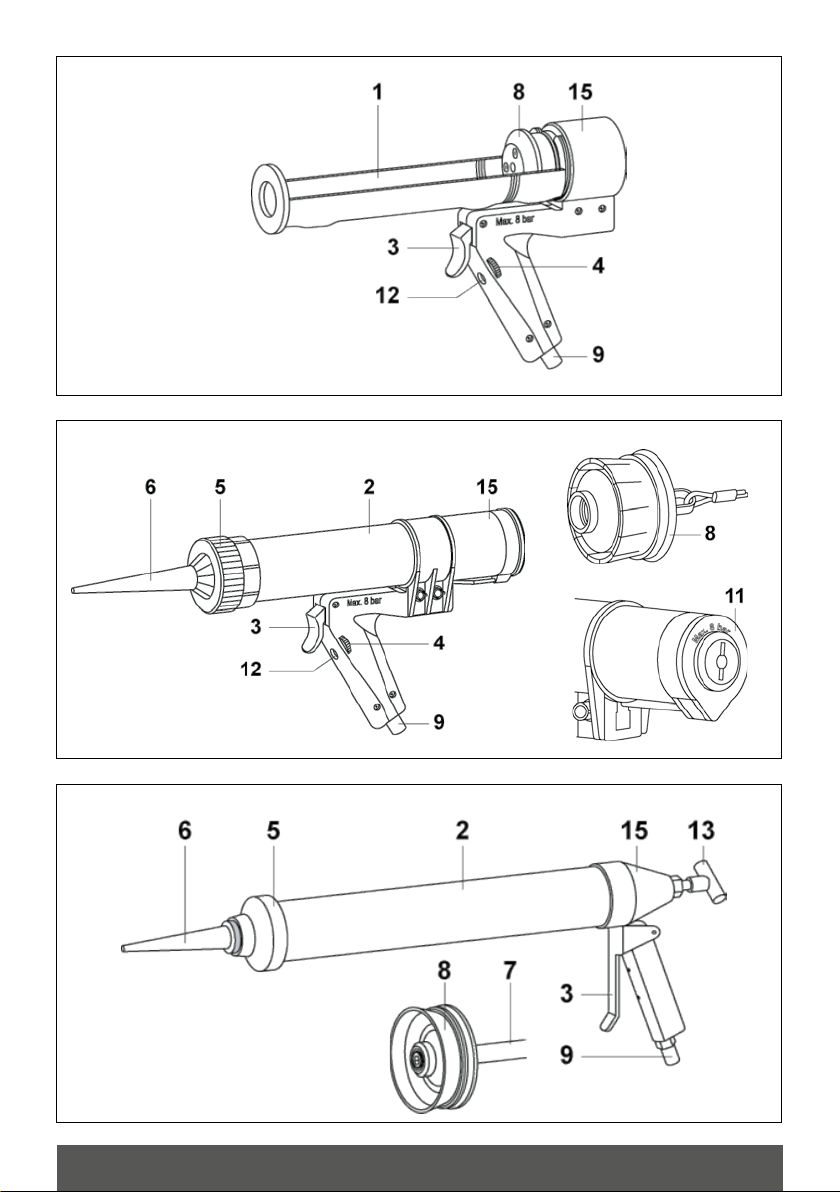

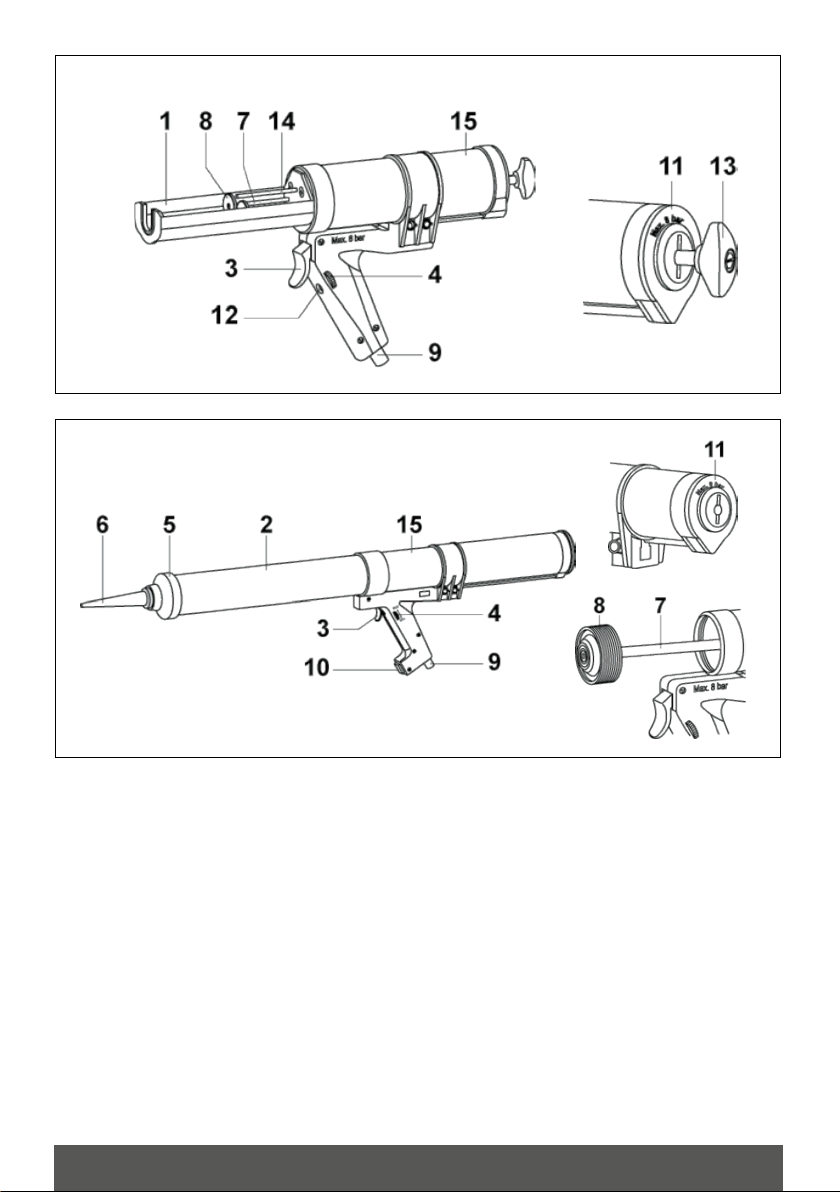

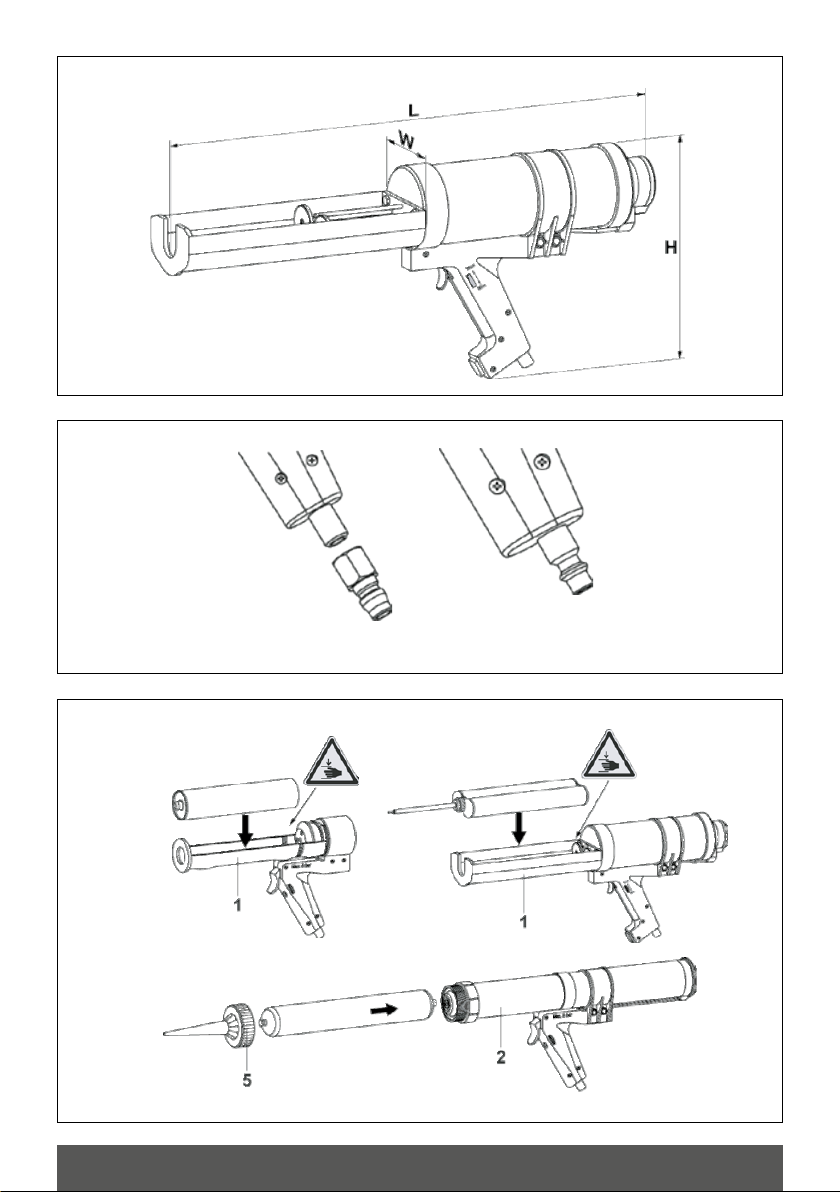

EN Some illustrations may deviate from your dispenser, as these instructions cover all

pneumatic dispensers The operating instruction is available for download on the websi-

te www.sulzerchemtech.com

Always keep this instruction manual easily accessible to users. Subject to change as a result of technical modifications.

DE Einige Abbildungen können mit Ihrem Austraggerät nicht übereinstimmen, weil diese

Betriebsanleitung alle pneumatischen Austraggeräte betrifft. Die Betriebsanleitung ist

auf der Website zum Download verfügbar www.sulzerchemtech.com

Die Betriebsanleitung muss für alle Benutzer leicht zugänglich sein. Die Betriebsanleitung kann infolge technischer Mo-

difikationen geändert werden.

FR Certaines illustrations peuvent différer de votre distributeur, car ces instructions s’appli-

quent à tous les distributeurs pneumatiques. Ce mode d’emploi est téléchargeable sur

le site www.sulzerchemtech.com

Gardez toujours ce mode d’emploi à la portée des opérateurs. Il peut être sujet à changement suite à des modifications

techniques.

ES Algunas ilustraciones pueden desviarse de su dispensador, ya que estas instrucciones

se refieren a todos los dispensadores neumáticos El manual de instrucciones está

disponible para su descarga en el sitio web www.sulzerchemtech.com

Mantenga siempre este manual de instrucciones de fácil acceso para los usuarios. Puede estar sujeto a cambios, como

resultado de modificaciones técnicas.

IT Alcune illustrazioni possono differire dal vostro erogatore poiché queste istruzioni

riguardano tutti gli erogatori pneumatici. Le istruzioni di funzionamento sono disponibili

per il download sul sito www.sulzerchemtech.com

Fate in modo che il presente manuale di istruzioni sia sempre facilmente accessibile agli utenti. Potrebbe essere soggetto

a cambiamenti a seguito di modifiche tecniche.

DA Enkelte illustrationer kan afvige fra din dispenser, da denne vejledning dækker alle

trykluft dispensere. Betjeningsvejledningen kan også hentes på vores hjemmeside

www.sulzerchemtech.com

Hav altid denne betjeningsvejledning let tilgængelig for alle brugere. Med forbehold for ændringer i vejledningen som følge

af tekniske ændringer.