SULZ

ER

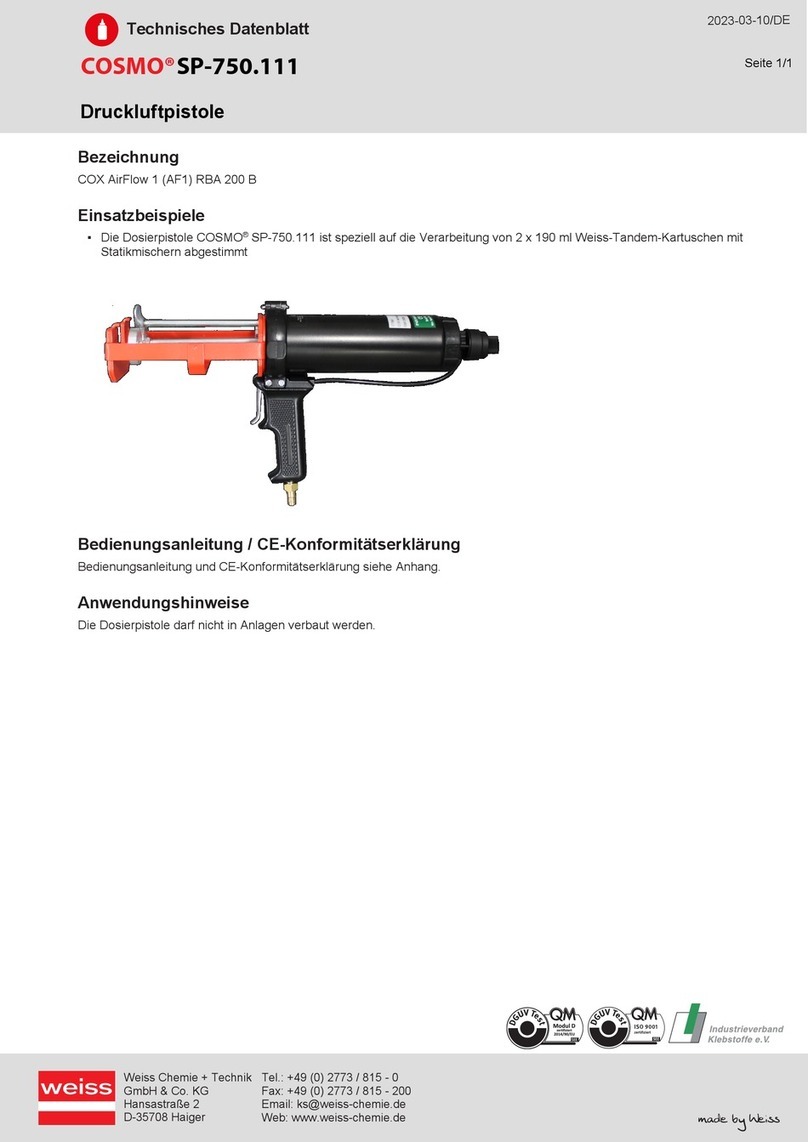

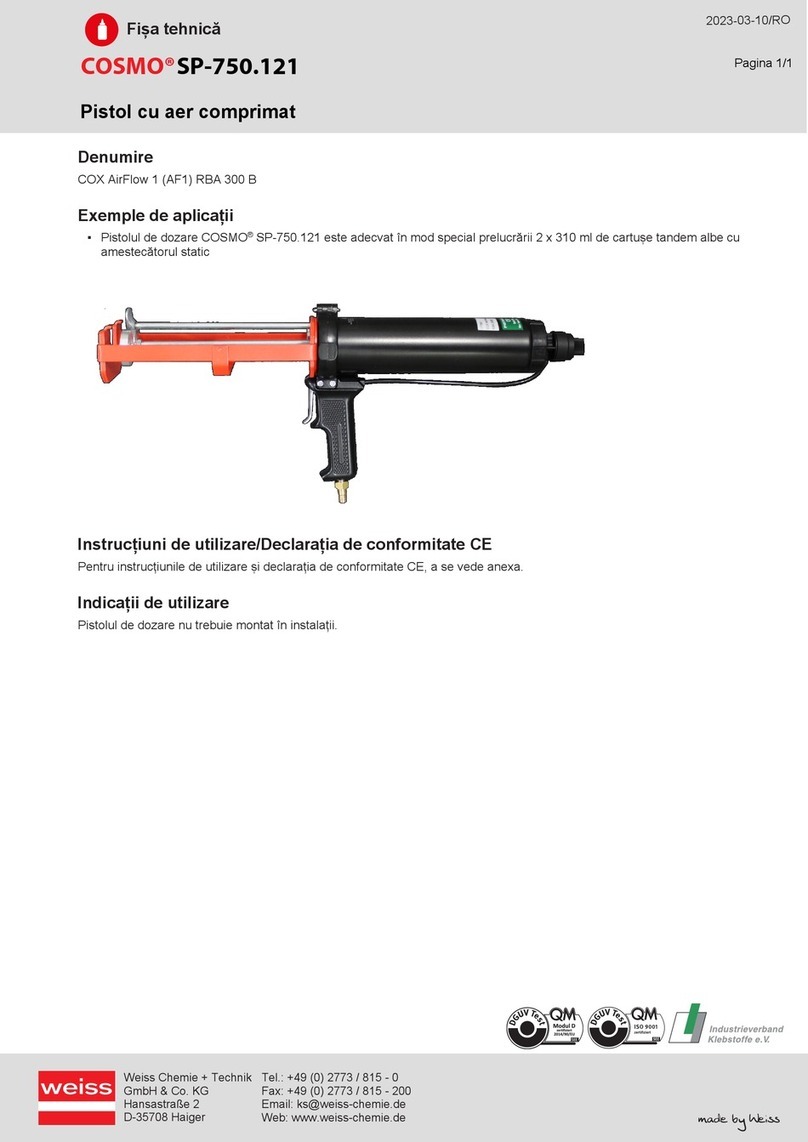

Dispenser DP

The following instructions must be read and strictly observed:

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

()

The user of the dispenser and any persans

.

.

~1.·

. standing in

th

e vicinity mustwear safety

1 goggles and gloves at all times during

operation of the dispenser.

The user should never point the barre! end of the dispenser at

hirnself or

in

the direction of bystanders [animals] or objects during

operation.

Never open the pneumatic drive or attempt to remove.

Handlethe

dispenser properly. Store

in

a cool dry place. Transport

it carefully, with minimal vibration. Do not drop it to the ground or

slam it

on

a bench or other workspace.

Safety devices must not be removed, worked around, bypassed or

deactivated during operation.

Always comply with the warnings and notices

on

the device. Never,

under any circumstances, remove these warnings and notices.

Replace them immediately if they become detached or illegible.

Do not remove, tamper or manipulate pressure limiting valve and

strictly respect pressure Iimits.

Check the dispenser for visible darnage and defects before each

use. The dispenser must only

be

used if it is

in

good working order.

lf you have any doubt about the condition of the dispenser, or if

there are any signs

of

breakage or other damage, immediately stop

using the device and send it for inspection and repair by a site

authorized by the manufacturer.

Keep the dispenser clean at any time. Failure

to

do so may result

in

malfunction of dispenser or bodily injury.

Do not attempt to modify or repair the dispenser. Maintenance and

repairs must

be

carried out exclusively by qualified specialists.

No

such work may be carried out while the dispenser

is

connected to

the compressed air supply.

Always follow safe workplace practices, such as making sure the air

hoses are carefully routed so that neither you nor any other person

can become entangled

in

the hoses or trip over them.

Be cautious connecting and disconnecting air pressure hose.

Always keep this instruction manual easily accessible to users of the

dispenser.

Only authentic Sulzer Mixpac spare parts may be used. Maltunetions

or accidents may result if spare parts of other manufacturers are

2010-01 (V 3.0) 4