Sulzer Sulzer MixCoat DPD 1500-01 manual

Article-No.: DKC-640059

EN - Instruction handbook

DE - Betriebsanleitung

FR - Manuel d’instructions

IT - Manuale di istruzioni

ES - Manual de instrucciones

PT - Manual de instruções

ZH - 使用说明书

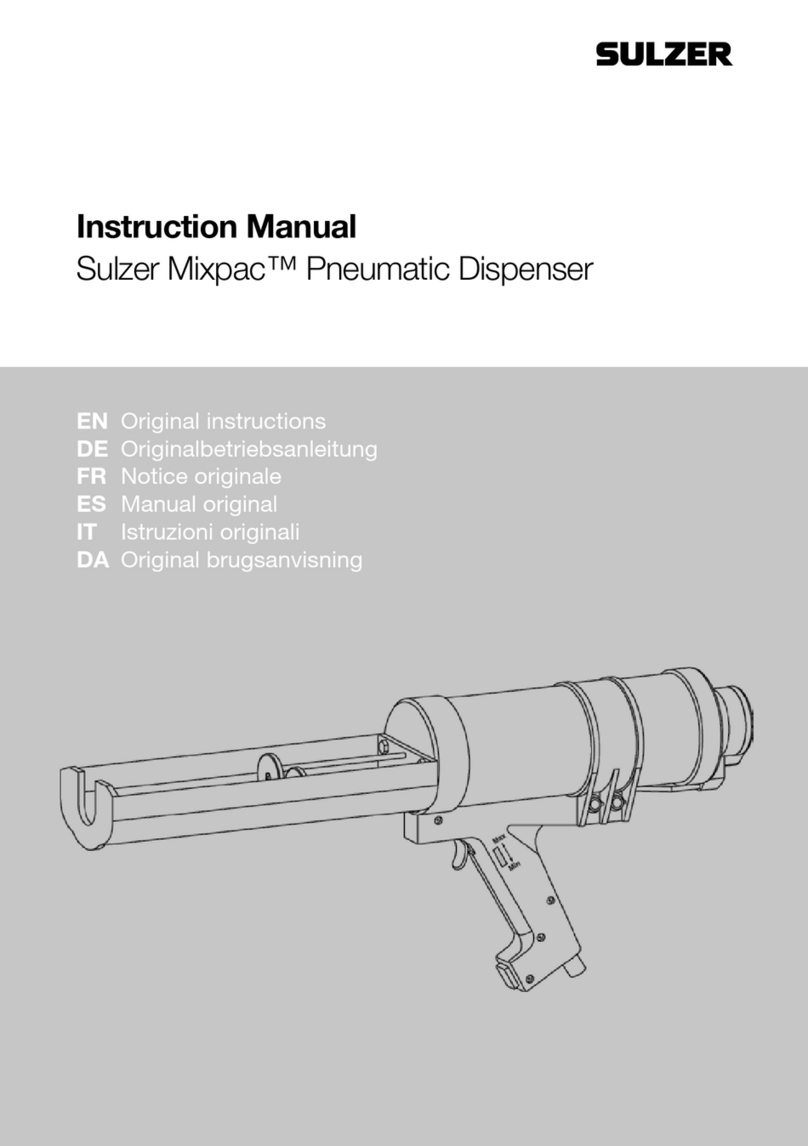

Sulzer MixCoat™

Pneumatic dispensers

DPD 1500-01 DPS 1500-01

Version 1.2 · 23.6.17

II

a

b

c16

A.

C.B.

D. F.E.

G.

25

910 1114121314 15

14

16

7*

17 18 19 20

21

24*

22

23

26

27

1

26* 7* 4

358

SW18

20

30*

31*

III

a

b

c

c

19 21

M.

0

I

II

2531*

21 24* 22

L.

30*

25 29

K.

31*

21 22 24*

J.

28

29

I.

17

H.

20

6*

29

20

1 of 14 Instruction handbook DPD/DPS

Version 1.2 · 23.6.17

EN

TABLE OF CONTENTS

1) General ......................................................2

Applicable standards .....................................2

Copyright ......................................................2

Guarantee .....................................................2

Typeplate and CE mark ..................................2

Additional system documentation ...................2

2) Safety regulations ....................................2

Symbols in the instruction handbook and

on the dispenser ...........................................2

Safety instructions that must be strictly

complied with: ...............................................4

Use in accordance with the instructions ..........5

Use not in accordance with the instructions .....5

3) Scope of delivery .....................................6

4) Product overview .....................................6

Safety instructions stickers DPS (12) ...............7

Safety instructions stickers DPD (12) ..............7

5) Functional description ............................7

Functional description, DPD ...........................7

Functional description, DPS ............................7

6) Preparing the dispenser for use ...........7

Instruction and reporting obligation .................7

Notices .........................................................7

Procedure .....................................................8

7) Operation ..................................................8

Inserting the cartridge ....................................8

Connect the dispenser to the compressed

air supply ......................................................9

Equalizing the cartridge materials ...................9

Fix the mixer onto the cartridge ......................9

Dispensing the materials DPD ........................9

Dispensing the materials DPS ........................9

Remove the used cartridges ...........................9

8) Troubleshooting .....................................10

9) Maintenance and repair .......................11

Notices .......................................................11

Spare part ordering information ...................11

10) Technical data ........................................11

11) Pneumatic diagram ..............................12

Pneumatic diagram DPD ..............................12

Pneumatic diagram DPS ..............................13

Article-No.: DKC-640059

2 of 14

Instruction handbook DPD/DPS

Version 1.2 · 23.6.17 EN

1) GENERAL

The original instruction handbook was compiled in

English. The other languages are based on the original

version.

Applicable standards

• 2006/42/EC: Machinery Directive

• EN ISO 8573-1:2010 Compressed air equipment

classes

• EN ISO 12100:2010 Safety of machinery

• EN ISO 4414:2010 Pneumatic fluid power - General

rules and safety requirements for systems and their

components

Copyright

All rights reserved. This manual may not be copied

either in part or as a whole nor reproduced in an elec-

tronic form without the previous written permission of

the manufacturer.

Guarantee

The manufacturer grants 24 months guarantee from

the date of delivery of the dispenser. Wearing parts are

excluded from the guarantee. Modifications to the

device as well as repair and service work may only be

carried out by the manufacturer or his service partner,

otherwise the warranty and liability rights are rendered

invalid.

Typeplate and CE mark

Additional system documentation

You can find additional information on our website at

www.sulzer.com.

2) SAFETY REGULATIONS

Symbols in the instruction handbook and

on the dispenser

Text that only refers to the dispenser DPS

1500-01 is marked with *, unmarked text

refers to both dispensers DPP 1500-01 and

DPS 1500-01.

Separate chapters are included where both

devices are fundamentally different.

Ensure that the instruction handbook is

always easily accessible for users.

We reserve the right to make changes as the

result of technical modifications.

Read this instruction handbook through care-

fully! Correct function and operational safety

can only be guaranteed when the users are

familiar with and comply with all safety regu-

lations in this instruction handbook.

Symbol Meaning

INFORMATION

Information on assembly, operation or

maintenance.

Immediate danger. If this danger is not

avoided, death or very serious, irre-

versible injuries will result.

Possibly dangerous situation. If this

danger is not avoided, death or very

serious, irreversible injuries can result.

Possibly dangerous situation. If this

danger is not avoided, slight or minor

irreversible injuries can result.

Situation that could cause damage to

equipment.

Generally dangerous situation.

DANGER

WARNING

CAUTION

NOTICE

3 of 14 Instruction handbook DPD/DPS

Version 1.2 · 23.6.17

EN

The dispenser may not be used before the operating

sequence and the instructions contained in this instruc-

tion handbook have been read and understood. The

device works at a high pressure, see "10) Technical

data" on page 11

If these instructions are not observed, high pres-

sures can be accidentally discharged from the

dispenser or the dispenser may burst,resulting in

serious injury to the user or persons in its vicinity

and also in damage to equipment.

Dangers/hazards that may result from

inhaling the fumes of caustic/corrosive

chemical substances.

Risk of explosion

Dangers/hazards that may result from

open fire

Dangers/hazards that may result from

skin contact with caustic/corrosive

chemical substances.

Dangers/hazards that may result from

flying parts.

Dangers/hazards that may result from

tripping over objects lying on the

ground.

Dangers/hazards that may result from

crushing of fingers.

Always read the instruction handbook

before using the product.

Dangers/hazards that may result from

opening the device. Never open the de-

vice; for maintenance and repair work

contact the local Sulzer service partner.

* Users of the dispenser must wear a

protective mask with P2 filter during

use.

* Users of the dispenser must wear an

overall during use.

Symbol Meaning

Persons using the dispenser,as well as

any persons within the vicinity, must

wear protective gloves during opera-

tion of the device.

Persons using the dispenser,as well as

any persons within the vicinity, must

wear protective goggles and ear pro-

tection during operation of the device.

CE

The dispenser bears the CE mark in

compliance with the respective Euro-

pean directives.

The following general safety instructions

inform you about the possible residual

dangers that exist even when the device is

used in accordance with the instructions, or

dangers that may arise unexpectedly.

In addition, the special safety instructions

must be complied with that are given directly

in the respective situations.

Furthermore the local statutory regulations on

accident prevention and environmental

protection applicable at the operating site

must be complied with.

Symbol Meaning

4 of 14

Instruction handbook DPD/DPS

Version 1.2 · 23.6.17 EN

Safety instructions that must be strictly

complied with:

WARNING Risk of injury and acci-

dents in the event of non-compliance

with the safety regulations

All safety regulations must be complied with; the

manufacturer is not liable for any damage resulting

from non-observance of safety regulations!

WARNING Risk of injury due to incor-

rect use, not wearing the personal pro-

tection equipment.

During use all users and all persons in the vicinity

must wear a protective mask with P2-filter*, overall*,

protective goggles, ear protection and safety gloves to

prevent inhalation of the fumes and skin contact with

the dispensed material.

The user is not permitted to point the mix tip at liv-

ing beings or objects during use.

Observe the safety instructions on the cartridge

WARNING Explosion and fire hazard

Never use the dispenser to spray on

open fire.

Never use the device near sources of

ignition or energy sources that constitute a

potential risk of combustion/explosion.

WARNING Risk of tripping over the

compressed air hose / due to lack of

cleanliness at the workplace!

Always ensure that the workplace is clean and tidy.

Lay compressed air hoses so that they do not cre-

ate a tripping hazard for the operator or bystanders.

• Only use the device when it is in a technically perfect

condition in accordance with its intended purpose

and in compliance with all safety regulations.

• In the event of defects or operational faults, stop op-

eration of the device immediately, remedy the faults

if possible and inform the manufacturer.

• The pneumatic driving unit of the dispenser may

never be opened or removed.

• Dispensers weighingmore than 5kg must be carried

with a shoulder strap.

• The dispenser must be handled carefully and stored

at a cool, dry place. The device must be transported

carefully. Shocks should be avoided as far as possi-

ble. Never drop the dispenser onto the floor or work-

bench. Prevent knocks at the workplace.

• It is not permitted to remove, circumvent, bridge or

take the safety devices out of operation when the

device is in use.

• Always comply with the warning and information

signs on the device. These warning and information

signs should never be removed. They must be re-

placed immediately if they become detached or are

illegible, see "4) Product overview" on page 6

• Pressure limits must be strictly adhered to.

• Before usage, always check the dispenser for any

visible signs of damage and faults. Only use the dis-

penser when it is in usable condition. If you are un-

sure of the usability of the device or if signs of

breakage or other damage become recognizable,

stop using the device immediately. Send the device

to an authorized agent of the manufacturer for in-

spection and repair (refer to the address list at the

back).

• Always keep the dispenser clean to prevent func-

tional fault or injury.

• Never attempt to make any repairs or modifications

to the device yourself. Maintenance and repairs

must be carried out exclusively by qualified special-

ist personnel. This work may never be carried out

when the dispenser is connected to the compressed

air supply.

• Always ensure that the workplace is safe.

• Take care when connecting and removing com-

pressed air hoses. Ensure that the air hoses are laid

so that you or other persons do not become tangled

in the hoses or can trip over them.

• Only original spare parts of Sulzer Mixpac may be

used. When using spare parts of other manufactur-

ers, all warranty rights towards the manufacturer

are rendered invalid and malfunctions or accidents

may occur.

5 of 14 Instruction handbook DPD/DPS

Version 1.2 · 23.6.17

EN

Manipulations or modifications to the device by

persons not authorized by the manufacturer as

well as non-compliance with the safety regula-

tions contained in the instruction handbook are

dangerous and can cause accidents with serious

injury and/or damage to materials.

Use in accordance with the instructions

The dispenser was developed for mixing and dispensing

materials of various combinations. Use in accordance

with the intended purpose requires compliance with the

instructions in the instruction handbook. The specifica-

tions in Chapter see "10) Technical data" on page 11

apply as the binding limits for use and technical data of

the device.

Use not in accordance with the instruc-

tions

These include:

• Any applications that deviate from the applications

listed in Chapter «Use in accordance with the in-

structions».

• Use of the dispenser without appropriate instruction

• Removing the warning plates on the device

• Careless handling near open fire or energy sources

• Changes to the device without the written permis-

sion of the manufacturer

• Use of cartridges or spare parts of a different man-

ufacturer without written consent of the manufac-

turer

WARNING Risk of injury and acci-

dents arising from use that is not in

accordance with its intended purpose

The manufacturer is not liable for damage resulting

from non-observance of the intended purpose

6 of 14

Instruction handbook DPD/DPS

Version 1.2 · 23.6.17 EN

3) SCOPE OF DELIVERY

Refer to the figure {A} on page II:

Remaining items see "Product overview", page 6.

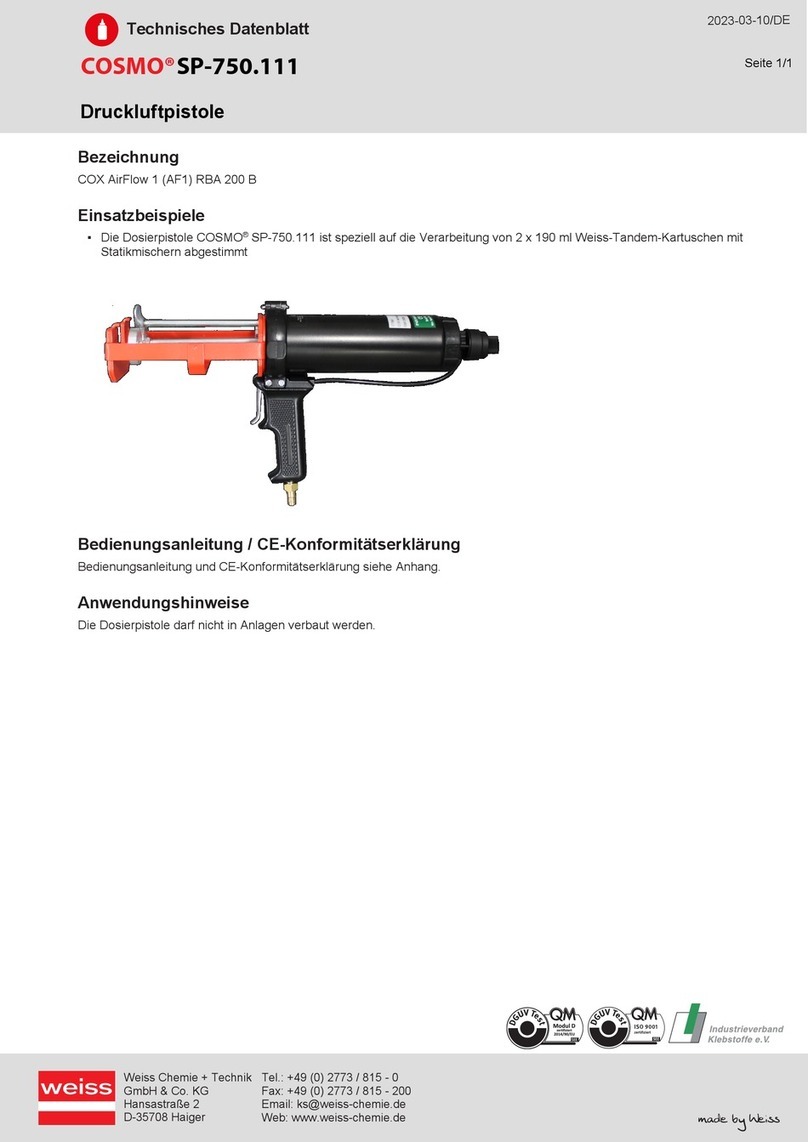

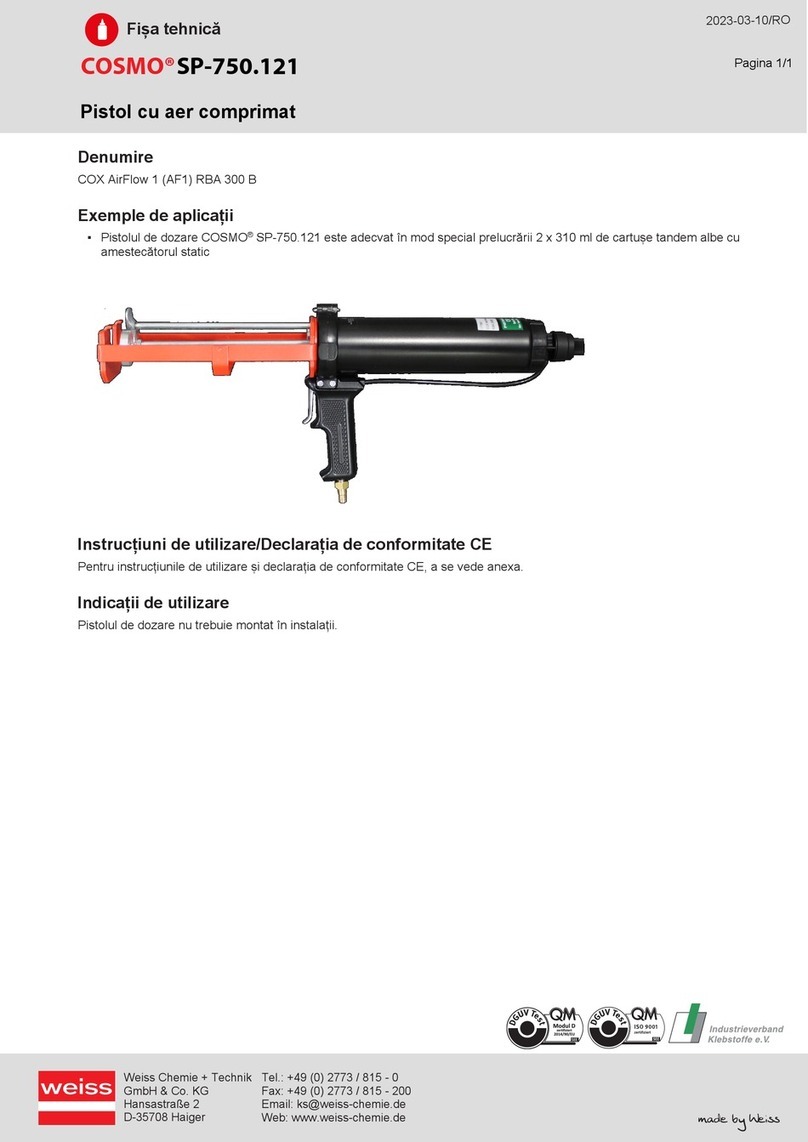

4) PRODUCT OVERVIEW

Refer to the figures on pages II and III:

1 Dispenser

2 Adjustable handle

3 Shoulder strap

4 Cartridge holder clips

5 Plunger disc set with tool set

6* Atomizing air hose

7* Plug coupling for atomizing air hose

8 Instruction handbook

The manufacturer is responsible for perfectly

safe technical delivery of the device,including

warning signs and instruction handbook, Any

missing or damaged warning signs must be

replaced immediately.

This instruction handbook must be kept ready

and within reach at all times to all persons

working with the dispenser.

9 Cartridge guide

10 Connection rod

11 Lower plunger disc (A-side)

12 Sticker with safety instructions

13 Pneumatic drive unit

14 Eye for shoulder strap

15 Piston rods

16 Adjustable handle

17 Cartridge holder clips

18 Cartridge detection

19 Red button (retract piston rod)

20 Compressed air connection, protective cap

21 Trigger

22 Adjustment wheel, pressure regulation valve for

piston speed

23 Type designation and serial number

24* Adjustment wheel for atomizing air regulation

25 Mixer

26 Upper plunger disc (B-side)

27 Lower plunger disc (A-side)

28 Cartridge stopper

29 Cap nut

30* Atomizing air line quick connector

31* Spraying head

7 of 14 Instruction handbook DPD/DPS

Version 1.2 · 23.6.17

EN

Safety instructions stickers DPS (12)

Safety instructions stickers DPD (12)

5) FUNCTIONAL DESCRIPTION

Functional description, DPD

Refer to figures {B}, {C}, {E} on page II:

• Press the trigger (21), the pneumatic driving unit

(13) is activated.

• The plunger discs (26+27) extend and are pressed

against the pistons of the cartridges.

• Dispensed material from the cartridges is transport-

ed at the same time into the mixer (25), adjust the

contact pressure with the adjustment wheel (22).

• Press button (19), the plunger is retracted and the

cartridges can be removed.

Functional description, DPS

Refer to figures {A}, {B}, {C}, {E} on page II:

• Press the trigger (21) up to its first stage (I). Atomiz-

ing air is transported through the atomizing air hose

(6) to the spraying head (31).

• Press the trigger (21) up to its second stage (II).The

piston of the drive unit (13) is activated, the plunger

discs (26+27) are extended and are pressed onto

the pistons of the cartridge.

• Dispensed material from cartridges (A) is transport-

ed at the same time into the mixer (25), adjust the

contact pressure with the adjustment wheel (22).

• The discharged atomizing air atomizes the previous-

ly mixed compound as it exits from the spraying

head (31).Adjust the discharged air volume with the

adjustment wheel (24).

• Press button (19), the plunger is retracted and the

cartridges can be removed.

WARNING Risk of serious injury

caused by discharge of high pressures

and/or bursting of the dispenser!

Always follow the instructions in this instruction

handbook exactly.

6) PREPARING THE DISPENSER

FOR USE

Instruction and reporting obligation

The operator ensures that all activities at the dispenser are

only carried out by authorized persons. He provides thor-

ough instruction for all persons working on the device, with

special emphasis on the residual dangers and safety regu-

lations, based on this instruction handbook.

The operator is obliged to report all defects occurring

during operation to the manufacturer if the instruction

handbook does not contain any information on how to

remedy these. Measures specified by the manufacturer

must be strictly complied with.

Notices

CAUTION Risk of crushing by extend-

ing plunger!

Only connect the dispenser to the com-

pressed air network after the cartridge has been

inserted correctly, see " Inserting the cartridge" on

page 8.

The cartridges (A),mixer (25), spray set (item

6* and 30*) and spraying head (31) are not

included in the scope of delivery.

For cartridges with mixing ratios 1:1, 2:1,3:1

and 4:1, the plunger discs (5) shown in figure

{A} are already included in delivery.

8 of 14

Instruction handbook DPD/DPS

Version 1.2 · 23.6.17 EN

Never put your hands or fingers between the pneu-

matic plunger and the cartridge.

CAUTION Risk of injury and poison-

ing by hazardous substances!

Always observe the safety regulations of

the manufacturer for the 2-component materials (refer

to the safety data sheets).

CAUTION Risk of injury in the event

of incorrect use of the cartridges /

plunger discs!

Refer to figure {E} on page II:

Always mount the right upper plunger disc (26) (B-

side).

Never use cartridges that are inappropriate for the

plunger.

Never replace the lower plunger disc (27) (A-side),

it remains firmly fixed in place.

Check the correct fixture of the plunger discs peri-

odically.

Procedure

Refer to figures {A}, {E}, {F}, {G} on page II:

1. Select an appropriate plunger disc (26) and fix in

place with socket head screws. Always use the

largest possible plunger disc.

2. Remove the protective cap from the compressed air

connection (20), connect the compressed air hose.

Never fit the compressed air hose on the protection

cap!

3. Install the correct adapter (1/4”) with internal thread

onto the compressed air connection (20) (not

included in the scope of delivery).

WARNING Risk of tripping over the

compressed air hose / due to lack of

cleanliness at the workplace!

Always ensure that the workplace is clean and tidy.

Lay compressed air hoses so that they do not cre-

ate a tripping hazard for the operator or bystanders.

4. Fix the atomizing air hose (6) on the plug connection

(7).

5. Adjust the handle (16):

a) Release the handle (16) (a)

b) Swivel the handle into the required position (b).

c) Fix the handle (c)

7) OPERATION

Inserting the cartridge

WARNING Risk of injury if the wrong

cartridges are used or used incorrectly!

Only use Sulzer Mixpac cartridges, oth-

erwise damage claims are forfeited.

Observe the safety instructions on the cartridge

Always place the cartridges with the largest vol-

umes at the bottom (A-side) when cartridges have dif-

ferent volumes.

Use Sulzer Mixpac spraying head (31), air hose (6)

and connector (30)

CAUTION Risk of crushing by extend-

ing plunger!

Never insert the cartridge when the dis-

penser is connected to the compressed air supply.

Refer to figure {H} on page III:

1. Insert the cartridge into the cartridge holder and

press downwards until it locks into the cartridge

holding clips (17). The cartridge detection feature

enables use of the device.

Before operation, always replace the upper

plunger disc with one suitable for the

cartridge used, see "6) Preparing the

dispenser for use" on page 7.

9 of 14 Instruction handbook DPD/DPS

Version 1.2 · 23.6.17

EN

Connect the dispenser to the compressed

air supply

Refer to figure {I} on page III:

NOTICE Risk of damage due to incorrect com-

pressed air supply!

Observe the requirements for the compressed air sup-

ply. Refer to Chapter "10) Technical data" on page 11.

Connection of an upstream compressed air main-

tenance unit is recommended

1. Connect the compressed air hose to the

compressed air connection (20) via the quick-

release coupling.

Equalizing the cartridge materials

Refer to figures {I} and {J} on page III:

1. Unscrew the cap nut (29).

2. Remove the cartridge stopper (28).

3. Only DPS: Connect the atomizing air regulator (24)

4. Set the pressure regulation valve (22) to the

minimum discharge quantity.

5. Press the trigger (21) until both components are

evenly pressed out of the cartridge. The trigger can

not be actuated if the cartridge has not been

inserted correctly.

Fix the mixer onto the cartridge

Refer to figure {K} on page III:

1. Remove any blockages in the cartridge and the

cartridge sleeve with a clean cloth.

2. Fix the mixer (25) with a cap nut (29) on the

cartridge outlet thread.

3. Only for DPS: Press the quick connector of the

atomizing air line (30) onto the spraying head (31)

until it locks into place.

Dispensing the materials DPD

Refer to figure {L} on page III:

1. Press the trigger (21). The dispensed materials are

pressed out of the cartridge and combined in the

mixer, the compound is discharged from the mix tip.

2. Adjust the dispensed quantity with the adjustment

wheel (22).

WARNING Risk of serious injury

caused by discharge of high pressures

and/or bursting of the dispenser!

Observe the maximum supply pressure of the com-

pressed air supply. Refer to Chapter "10) Technical

data" on page 11.

Dispensing the materials DPS

Refer to figure {L} on page III:

1. Press the trigger (21) up to its first stage (I). Atom-

izing air is transported through the atomizing air

hose (6) to the spraying head (31).

2. Press the trigger (21) up to its second stage (II).

Materials are pressed out of the cartridge and

combined in the mixer (25), the compound is atom-

ized with the atomizing air when it is discharged

from the spraying head (31).

3. Adjust the volume of atomizing air with adjustment

wheel (24) and the volume output with adjustment

wheel (22).

WARNING Risk of serious injury

caused by discharge of high pressures

and/or bursting of the dispenser!

Observe the maximum supply pressure of the com-

pressed air supply. Refer to Chapter "10) Technical

data" on page 11.

Remove the used cartridges

Refer to figures {L} and {M} on page III:

1. Release the trigger (21) and press the red button (19)

(a) until the plungers have moved to the rear stop.

2. Only DPS: Release the atomizing air line from the

spraying head (b).

3. Push out the cartridges from below and remove

upwards (c).

Dispose of the cartridge, mixer and atomizing

air line in accordance with the manufacturer’s

instructions.

10 of 14

Instruction handbook DPD/DPS

Version 1.2 · 23.6.17 EN

8) TROUBLESHOOTING

No. Fault Cause Remedy

1Plunger discs cannot en-

ter the cartridge

• Use of cartridges that are not sup-

plied by Sulzer Mixpac

• Cartridge not fully inserted in car-

tridge sleeve

• Incorrect plunger disc

• Check that there is no foreign mat-

ter in the cartridge sleeve.

• Push the cartridge fully down into

the cartridge sleeve.

2

The cartridge cannot be

removed from the dis-

penser

The plunger discs are still in position

inside the cartridge

• Press the red button (19) to fully re-

tract the plunger discs to the back

end-stop (see "Remove the used

cartridges", page 9)

3 Dispensing is interrupted Compressed-air supply has been in-

terrupted

• Check the compressed-air line

4Material discharge is in-

terrupted Material has hardened in the mixer • Replace the mixer (see "Fix the mi-

xer onto the cartridge", page 9)

5Spraying procedure is in-

terrupted

Atomizing air supply has been inter-

rupted

• Check the atomizing air line and the

quick connectors (see "Fix the mixer

onto the cartridge", page 9)

11 of 14 Instruction handbook DPD/DPS

Version 1.2 · 23.6.17

EN

9) MAINTENANCE AND REPAIR

Notices

WARNING Risk of injury due to acci-

dental actuation of the dispenser and/

or opening of the device!

Always disconnect the compressed air supply from

the dispenser during maintenance and repairs.

Never open or dismantle the device.

For maintenance and repair work, contact the local

Sulzer service partner.

CAUTION Risk of injury from incor-

rect maintenance/repair!

The pneumatic driving unit (item (13) in

figure {B} on page II) may never be opened. Contact the

service partners of Sulzer Mixpac for maintenance and

repair of the pneumatic driving unit (for address list

given at the back).

.

NOTICE Risk of damage due to incorrect mainte-

nance and cleaning!

Always keep the dispenser clean.

Never use any corrosive cleaning agents for clean-

ing the surface of the device (do not use products con-

taining silicone).

Spare part ordering information

When ordering spare parts,please provide the following

information:

• Serial number

• Device type

• Article description / spare parts number, see

"3) Scope of delivery" on page 6 and figure {A}

10) TECHNICAL DATA

For dimensions refer to figure {D} on page II:

All maintenance and repairs may only be

carried out by sites authorized by the manu-

facturer and exclusively by qualified and suit-

ably trained personnel (refer to the address

list at the back).

Operating pressure 700 kPa (7 bar) (100 psi) max.

Compressed air

supply 800 kPa (8 bar) (120 psi) max.

Compressed air

quality ISO 8573-1:2010 [2:4:2]

Sound level 107 dB(A)

Recommended op-

erating temperature +5°C to +40°C

Relative air humidity 30% to 80% RH

(non-condensing)

Transport and stor-

age temperature 0°C to +40°C

Pressure adjust-

ment Infinitely variable

Weight DPD: 4.2 kg

DPS: 4.0 kg

12 of 14

Instruction handbook DPD/DPS

Version 1.2 · 23.6.17 EN

11) PNEUMATIC DIAGRAM

Pneumatic diagram DPD

2

1

31

2

31

2

12354

7 6 58 9

1 Compressed air supply 700 kPa max.

2 Pressure regulation valve (integrated into the push switch)

3 Push switch, cylinder forwards

4 Push switch, cylinder backwards

5 Cartridge detection

6 Safety valve 700 kPa

7 Quick exhaust with silencer (integrated into the cylinder)

8 Cylinder

9 Leakage

13 of 14 Instruction handbook DPD/DPS

Version 1.2 · 23.6.17

EN

Pneumatic diagram DPS

2

1

33

1

2

2

1235 4

76 118 5

10 9

1 Compressed air supply 700 kPa max.

2 Pressure regulation valve (integrated into the push switch)

3 Push switch 1 (item 2) cylinder forwards

4 Push switch 2 cylinder backwards

5 Cartridge detection

6 Safety valve 700 kPa

7 Quick exhaust with silencer (integrated into the cylinder)

8 Cylinder

9 Leakage

10 Push switch 1 (item 1) Atomizing air on

11 Throttle check valve (integrated into the mixer)

14 of 14

Instruction handbook DPD/DPS

Version 1.2 · 23.6.17 EN

1 von 14 Betriebsanleitung DPD/DPS

Version 1.2 · 23.6.17

DE

INHALTSVERZEICHNIS

1) Allgemeines ..............................................2

Angewandte Normen .....................................2

Urheberrecht .................................................2

Garantiebedingungen .....................................2

Typenschild und CE-Kennzeichen ...................2

Zusätzliche Systemdokumentation ..................2

2) Sicherheitsvorschriften ...........................2

Symbole in dieser Betriebsanleitung und am

Austraggerät .................................................2

Sicherheitshinweise, die strikt zu

befolgen sind: ...............................................4

Bestimmungsgemässe Verwendung ...............5

Nicht bestimmungsgemässe Verwendung .......5

3) Lieferumfang ............................................6

4) Produktübersicht .....................................6

Sicherheitsaufkleber DPS (12) ........................6

Sicherheitsaufkleber DPD (12) ........................7

5) Funktionsbeschreibung ..........................7

Funktionsbeschreibung DPD ..........................7

Funktionsbeschreibung DPS ...........................7

6) Vorbereitung für den Betrieb .................7

Instruktion und Meldepflicht ...........................7

Hinweise .......................................................7

Vorgehensweise ............................................8

7) Betrieb .......................................................8

Kartusche einsetzen ......................................8

Austraggerät an das Druckluftnetz

anschliessen .................................................9

Abgleich Kartuschenkomponenten ..................9

Mischer auf Kartusche befestigen ...................9

Austragen der Materialien DPD ......................9

Austragen der Materialien DPS .......................9

Benutzte Kartuschen entnehmen ....................9

8) Störungsbehebung ...............................10

9) Wartung und Reparatur .......................10

Hinweise ....................................................10

Ersatzteilbestellinformation ..........................11

10) Technische Daten ..................................11

11) Pneumatikschema ................................12

Pneumatikschema DPD ...............................12

Pneumatikschema DPS ............................... 13

Artikel-Nr.: DKC-640059

2 von 14

Betriebsanleitung DPD/DPS

Version 1.2 · 23.6.17 DE

1) ALLGEMEINES

Die Originalbetriebsanleitung ist in englischer Sprache

verfasst, andere Sprachen sind davon abgeleitet.

Angewandte Normen

• 2006/42/EG: Maschinenrichtlinie

• EN ISO 8573-1:2010 Druckluft-Geräteklassen

• EN ISO 12100:2010 Sicherheit von Maschinen

• EN ISO 4414:2010 Sicherheit von Pneumatikanla-

gen

Urheberrecht

Alle Rechte vorbehalten. Diese Anleitung darf ohne

vorherige schriftliche Genehmigung des Herstellers

weder vollständig noch teilweise kopiert oder in elektro-

nischer Form reproduziert werden.

Garantiebedingungen

Der Hersteller gewährt ab Lieferung des Austraggeräts

24 Monate Gewährleistung, Verschleissteile sind davon

ausgeschlossen. Änderungen am Gerät, sowie Repa-

ratur- und Wartungsarbeiten dürfen ausschliesslich

vom Hersteller oder dessen Servicepartner durchge-

führt werden, andernfalls erlischt der Gewährleistungs-

und Haftungsanspruch.

Typenschild und CE-Kennzeichen

Zusätzliche Systemdokumentation

Weitere Informationen finden Sie auf unserer Website:

www.sulzer.com

2) SICHERHEITSVORSCHRIFTEN

Symbole in dieser Betriebsanleitung und

am Austraggerät

Textstellen, deren Inhalt sich nur auf das

Austraggerät DPS 1500-01 bezieht, sind mit

* gekennzeichnet, Textstellen ohne Kenn-

zeichnung beziehen sich auf beide Austrag-

geräte, DPP 1500-01 und DPS 1500-01.

Wo Beschreibungen der beiden Geräte sich

grundsätzlichen unterscheiden, sind separate

Kapitel angeführt.

Die Betriebsanleitung für den Benutzer stets

gut zugänglich aufbewahren.

Änderungen infolge technischer Modifikati-

onen vorbehalten.

Lesen Sie diese Betriebsanleitung sorgfältig

durch! Einwandfreie Funktion und Betriebssi-

cherheit sind nur dann gewährleistet, wenn

Benutzer alle Sicherheitsvorschriften in dieser

Betriebsanleitung kennen und beachten.

Symbol Bedeutung

INFORMATION

Informationen zu Montage, Betrieb

oder Unterhalt.

Unmittelbar drohende Gefahr. Wenn

sie nicht gemieden wird, sind Tod oder

schwerste irreversible Verletzungen die

Folge.

Möglicherweise gefährliche Situation.

Wenn sie nicht gemieden wird,können

Tod oder schwerste irreversible Verlet-

zungen die Folge sein.

Möglicherweise gefährliche Situation.

Wenn sie nicht gemieden wird,können

leichte oder geringfügige irreversible

Verletzungen die Folge sein.

Situation, die zu Sachschaden führen

könnte.

GEFAHR

WARNUNG

VORSICHT

ACHTUNG

3 von 14 Betriebsanleitung DPD/DPS

Version 1.2 · 23.6.17

DE

Das Austraggerät darf nicht benutzt werden, bevor der

Betriebsablauf, und die in dieser Betriebsanleitung

beschriebenen Anweisungen, gelesen und verstanden

wurden. Das Gerät arbeitet mit hohem Druck, siehe

siehe "10) Technische Daten" auf Seite 11

Werden diese Anweisungen nicht befolgt, kann

ein unbeabsichtigtes Entweichen hoher Drücke

am Austraggerät oder ein Bersten des Austragge-

räts zu schweren Verletzungen des Benutzers

oder Umstehender und zu Sachschäden führen.

Allgemein gefährliche Situation.

Gefahren, die durch Einatmen der

Dämpfe chemisch reizender Stoffe

auftreten können.

Explosionsgefahr

Gefahren, die durch offenes Feuer ent-

stehen

Gefahren, die durch Hautkontakt mit

chemisch reizenden Stoffe auftreten

können.

Gefahren, die durch herumfliegende

Teile entstehen können.

Gefahren, die durch Stolpern über am

Boden liegende Gegenstände auftreten

können.

Gefahren, die durch das Quetschen

von Fingern auftreten können.

Vor der Benutzung des Produktes, Be-

triebsanleitung lesen.

Gefahren, die durch Öffnen des Geräts

entstehen. Gerät keinesfalls öffnen, für

Wartungs- und Reparaturarbeiten lo-

kalen Sulzer-Servicepartner kontaktie-

ren.

* Benutzer des Austraggeräts müssen

während der Benutzung eine Schutz-

maske mit P2-Filter tragen.

Symbol Bedeutung

* Benutzer des Austraggeräts müssen

während der Benutzung einen Overall

tragen.

Benutzer des Austraggeräts, sowie in

der Nähe befindliche Personen müs-

sen während der Benutzung Schutz-

handschuhe tragen.

Benutzer des Austraggeräts, sowie in

der Nähe befindliche Personen müs-

sen während der Benutzung Schutz-

brille und Gehörschutz tragen.

CE

Das Austraggerät trägt das CE-Kenn-

zeichen in Übereinstimmung mit den

entsprechenden europäischen Richtli-

nien.

Die folgenden allgemeinen Sicherheitshin-

weise informieren über mögliche Restge-

fahren, die trotz bestimmungsgemässer

Verwendung des Geräts vorhanden sind,oder

unerwartet auftreten können.

Zusätzlich sind die speziellen Sicherheitshin-

weise zu beachten, welche direkt bei den

entsprechenden Situationen angeführt sind.

Des weiteren sind die lokalen gesetzlichen

Vorschriften zu Unfallverhütung und Umwelt-

schutz am Betriebsort des Geräts einzu-

halten.

Symbol Bedeutung

This manual suits for next models

1

Table of contents

Languages:

Other Sulzer Dispenser manuals