screw

out

screw

in

*In ordering parts and components, give each part

number, name and quantity.

Warning

1. This tool is not insulated for coming into contact

Foreword

We are a manufacturer and exporter of air tools

since established. We have devote all our efforts

in im

rovin

ualit

and tools’ life. As well as the

mechanism, and may cause trouble. So, install a

air filter and an oiler between the compressor an

the tool. Use a 3 HP or larger compressor for eac

sander.

chisel

screw

out

screw

in gun body

retainer

2-2 On-off device

Please note that the tool never running unless the

insert tool is properly fixed on the gun body. To

operate this tool, just push the trigger, which is on

*In ordering parts and components, give each part

number, name and quantity.

Warning

1. This tool is not insulated for coming into contact

with electric power source.

2. It is forbidden to use this tool in explosive

atmospheres and do not put any combustible

material near the workpiece since it might emit

sparks when working on hard material.

3. Check the wear of the insert tool and the retainer

before operating this tool.

Foreword

We are a manufacturer and exporter of air tools

since established. We have devote all our efforts

in improving quality and tools’ life. As well as the

noise and vibration of tools. Bring all of you

working efficiences, profits, and enjoy using the

tool is our principle.

Features

This air tool is a

neumatic tool that in

ects hi

h

mechanism, and may cause trouble. So, install a

air filter and an oiler between the compressor an

the tool. Use a 3 HP or larger compressor for eac

sander.

1-3 Air hose

Clean the hose with a blast of compressed ai

efore connecting the hose to air tool. This will

revent both moisture and dust within the hose

from entering the tool and causing possible rust o

malfunction. To compensate for unusually long

hose (over 25 ft), the line pressure should be

chisel

screw

out

screw

in gun body

retainer

2-2 On-off device

Please note that the tool never running unless the

insert tool is properly fixed on the gun body. To

operate this tool, just push the trigger, which is on

the grip, down. The tool continuously reciprocating

as one push the trigger down and it stops running as

thetriggerisreleased.

For the sake of safety, put it on hanger or on a soft

flat pad when not in use.

2-3 Replace and adjusting

*In ordering parts and components, give each part

number, name and quantity.

Warning

1. This tool is not insulated for coming into contact

with electric power source.

2. It is forbidden to use this tool in explosive

atmospheres and do not put any combustible

material near the workpiece since it might emit

sparks when working on hard material.

3. Check the wear of the insert tool and the retainer

before operating this tool.

4. Working with this tool will generate dust,

depending on the material being worked on,

couldbe harmful to the operator

5. This tool can cause the ejection of particles at

chipping or demolishing work, hence the

operator shall wear appropriate protective device

Foreword

We are a manufacturer and exporter of air tools

since established. We have devote all our efforts

in improving quality and tools’ life. As well as the

noise and vibration of tools. Bring all of you

working efficiences, profits, and enjoy using the

tool is our principle.

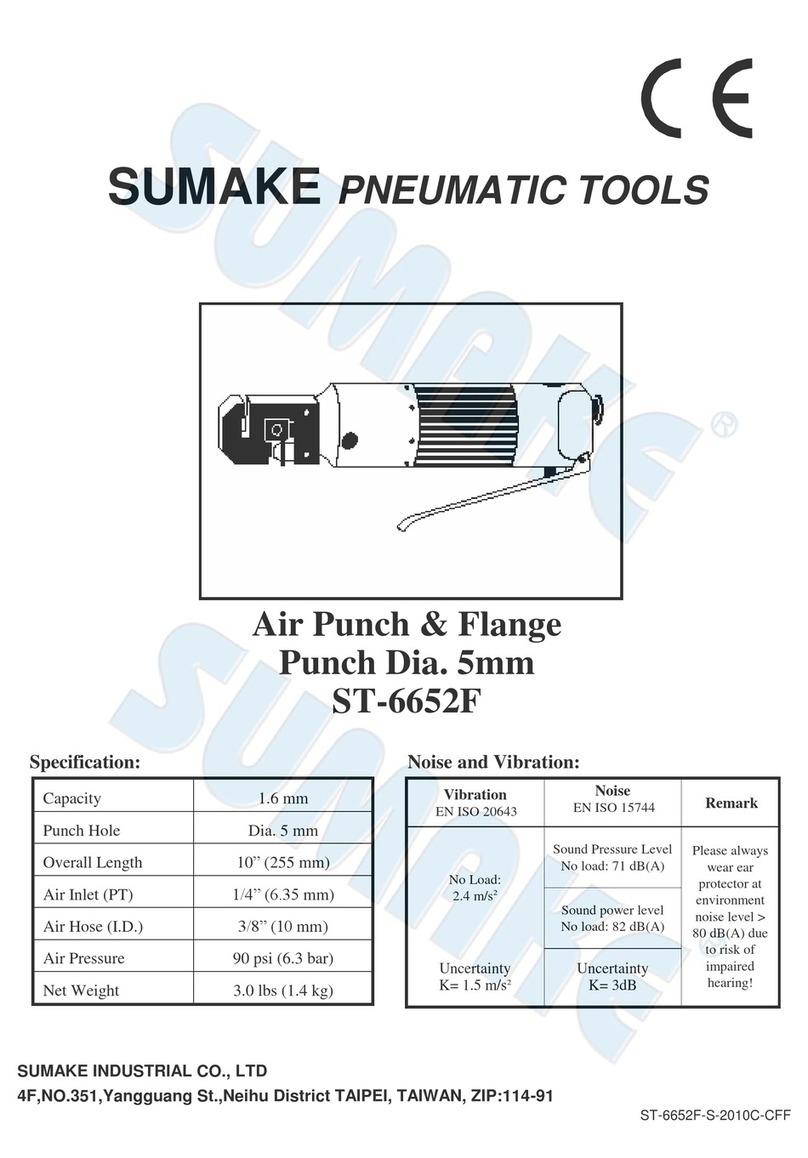

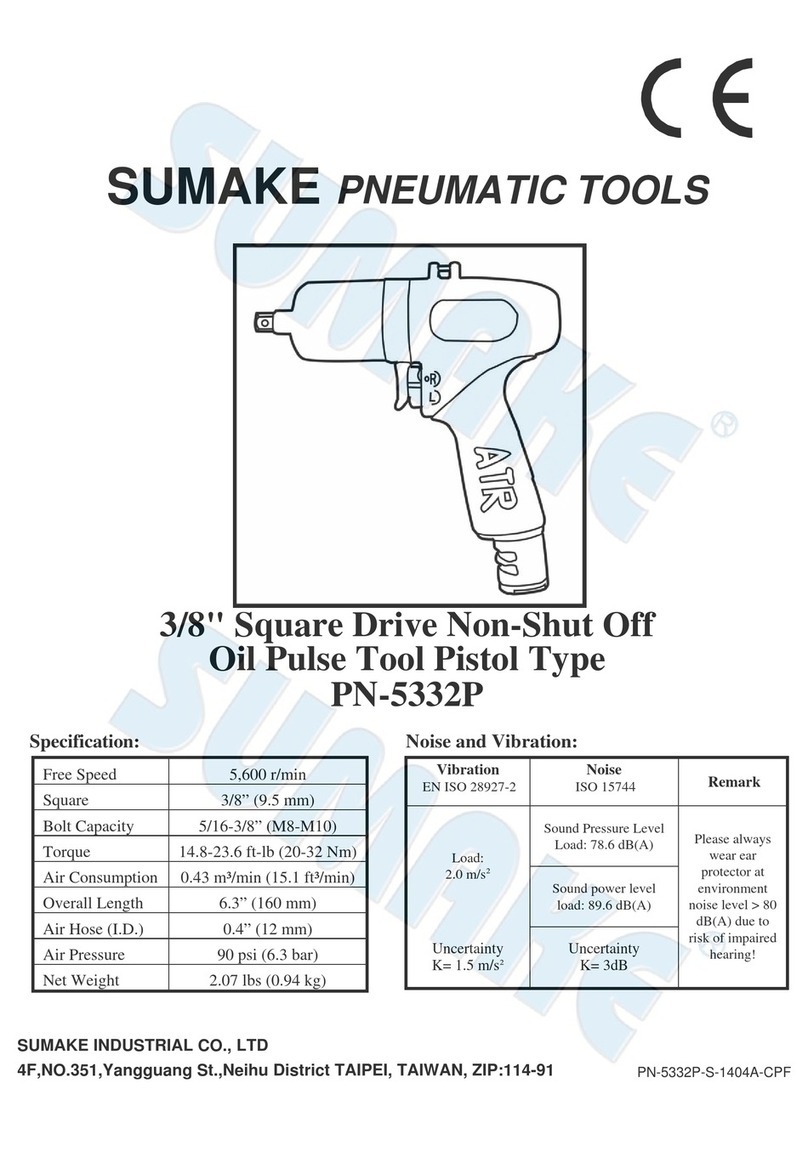

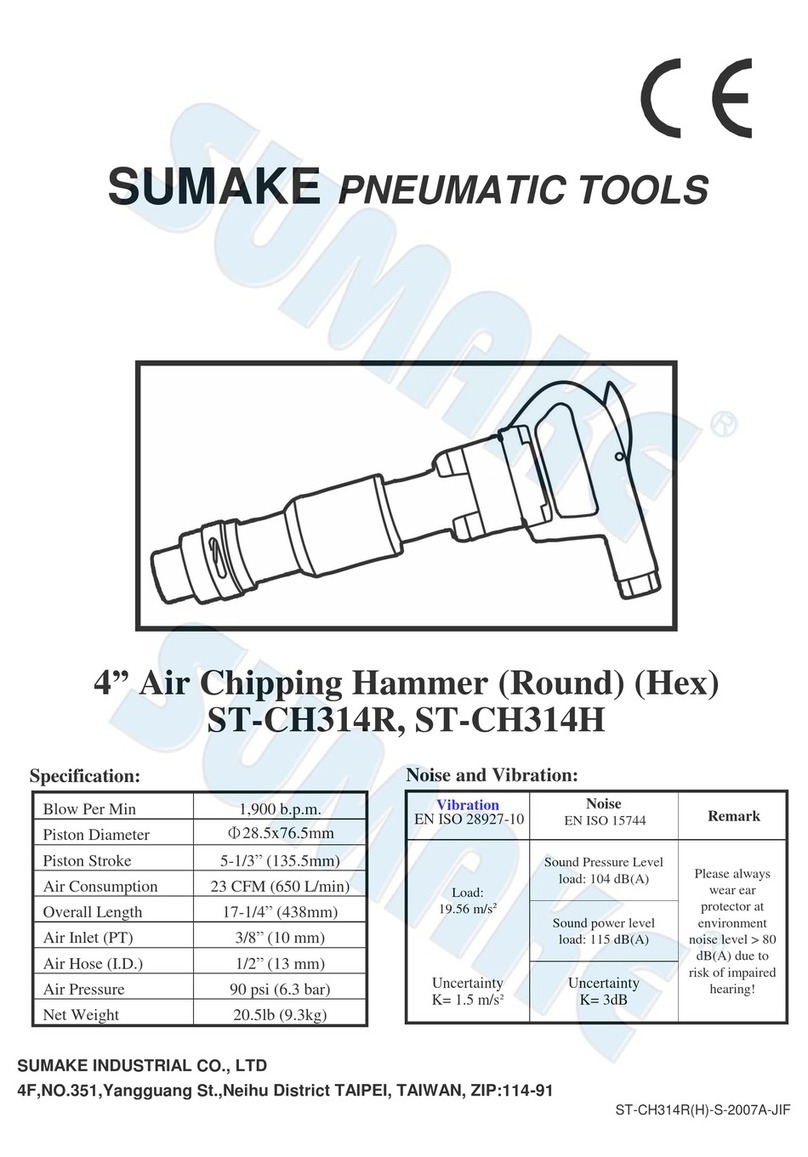

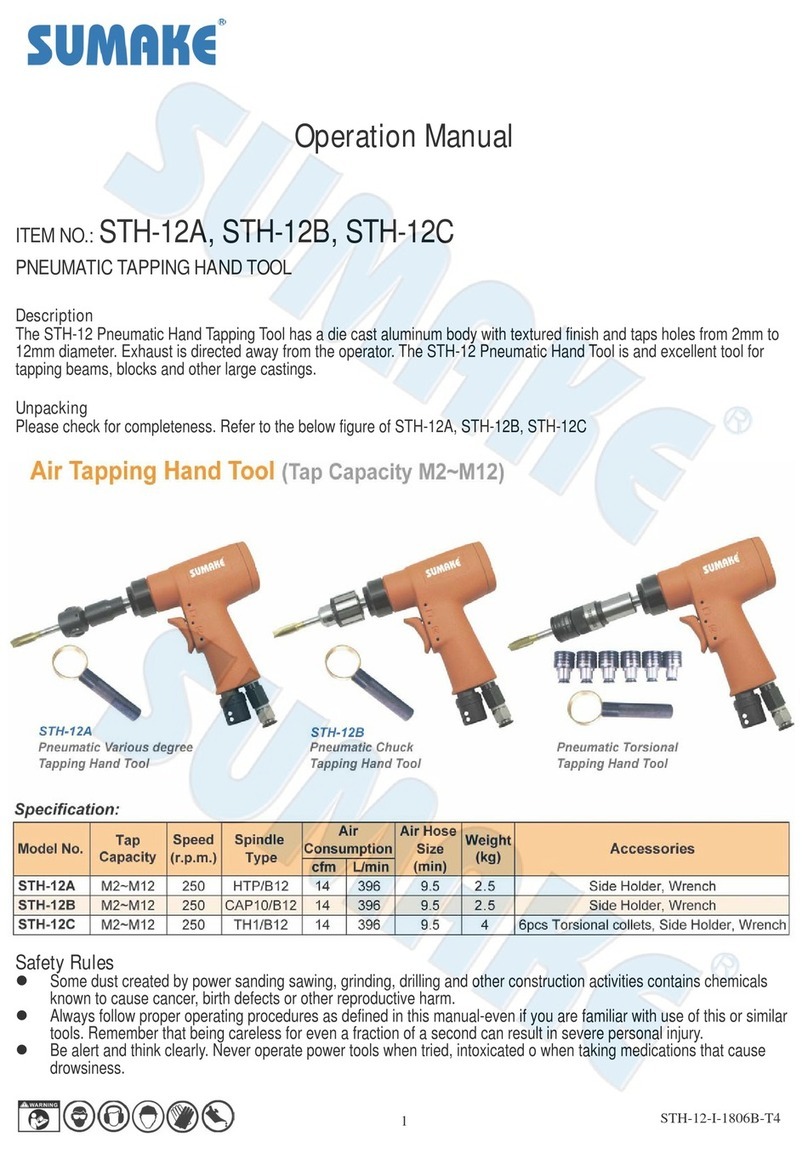

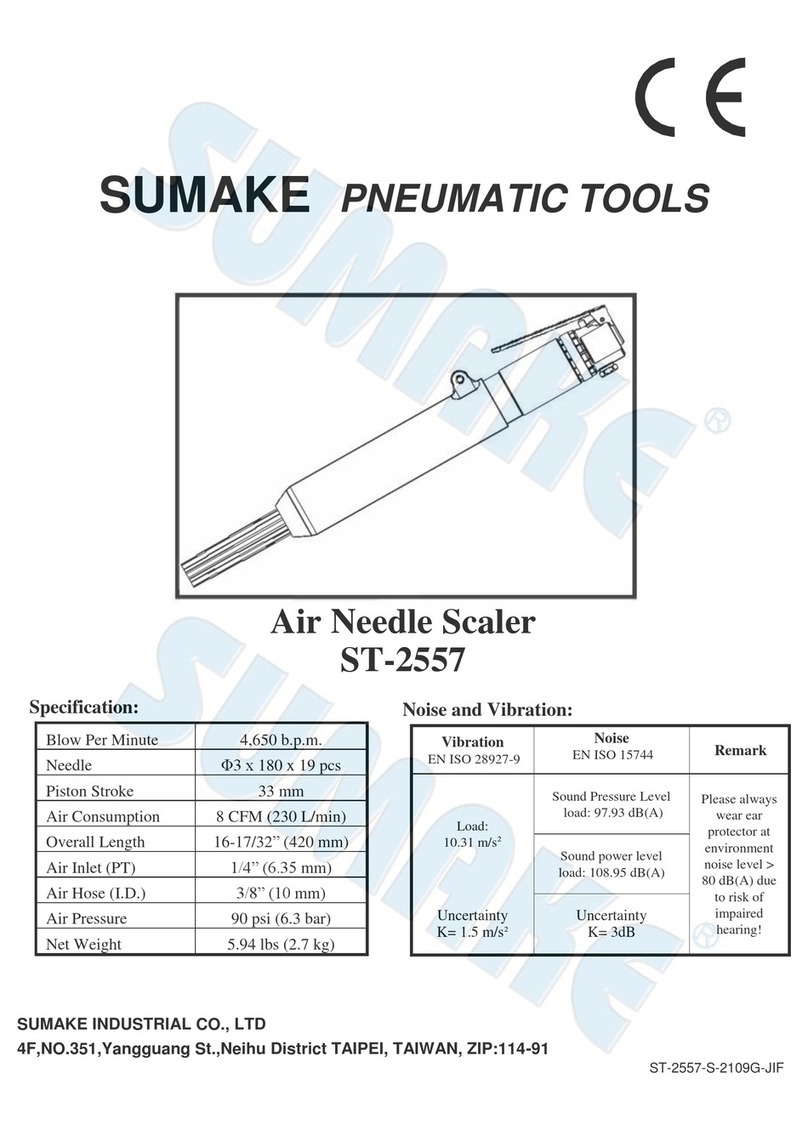

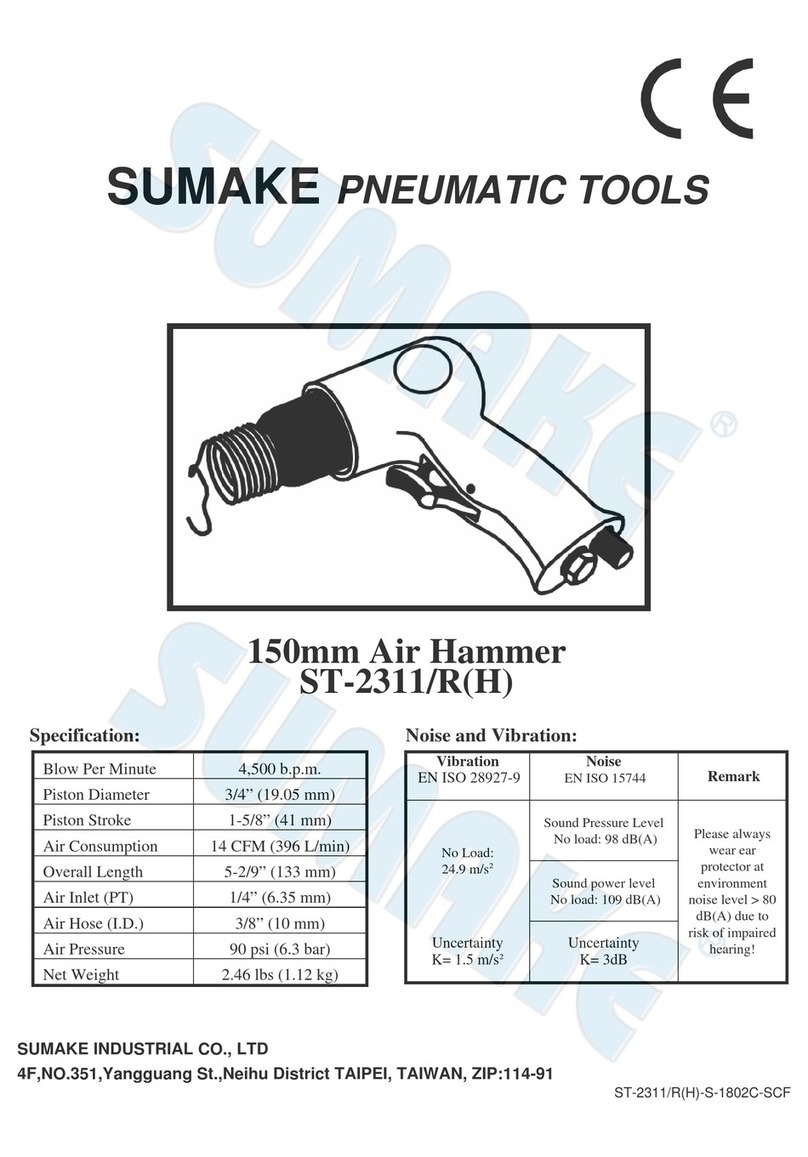

Features

This air tool is a pneumatic tool that injects high

efficiency into manual chipping, riveting, breaking

of concrete and asphalt etc. Your care in handling it

is, however, important if performance is to be

realized over a long period of time. This booklet is

prepared to equip you with the knowledge

necessar

to kee

it on the

ob efficientl

.

mechanism, and may cause trouble. So, install a

air filter and an oiler between the compressor an

the tool. Use a 3 HP or larger compressor for eac

sander.

1-3 Air hose

Clean the hose with a blast of compressed ai

efore connecting the hose to air tool. This will

revent both moisture and dust within the hose

from entering the tool and causing possible rust o

malfunction. To compensate for unusually long

hose (over 25 ft), the line pressure should be

increased accordingly.

Drainage

chisel

screw

out

screw

in gun body

retainer

2-2 On-off device

Please note that the tool never running unless the

insert tool is properly fixed on the gun body. To

operate this tool, just push the trigger, which is on

the grip, down. The tool continuously reciprocating

as one push the trigger down and it stops running as

thetriggerisreleased.

For the sake of safety, put it on hanger or on a soft

flat pad when not in use.

2-3 Replace and adjusting

There isno user serviceable part inside this tool.

Please send the tool to a qualified personnel orour

service section to repair or/and replaceworn parts.

3. Maintenance

3-1 Lubrication

hose apply 4 or 5 drops of

*In ordering parts and components, give each part

number, name and quantity.

Warning

1. This tool is not insulated for coming into contact

with electric power source.

2. It is forbidden to use this tool in explosive

atmospheres and do not put any combustible

material near the workpiece since it might emit

sparks when working on hard material.

3. Check the wear of the insert tool and the retainer

before operating this tool.

4. Working with this tool will generate dust,

depending on the material being worked on,

couldbe harmful to the operator

5. This tool can cause the ejection of particles at

chipping or demolishing work, hence the

operator shall wear appropriate protective device

and do not let other person near the work area.

6. The insert tool and the retainer on heavy types

are exposed to heavystrains and can after a long

periodof use break due to fatigue.

7. Keep your body balance and beware of the break

of the severed workpiece.

8. If one needs to use the free hand, although it is a

source of vibration damage we suggest place the

Foreword

We are a manufacturer and exporter of air tools

since established. We have devote all our efforts

in improving quality and tools’ life. As well as the

noise and vibration of tools. Bring all of you

working efficiences, profits, and enjoy using the

tool is our principle.

Features

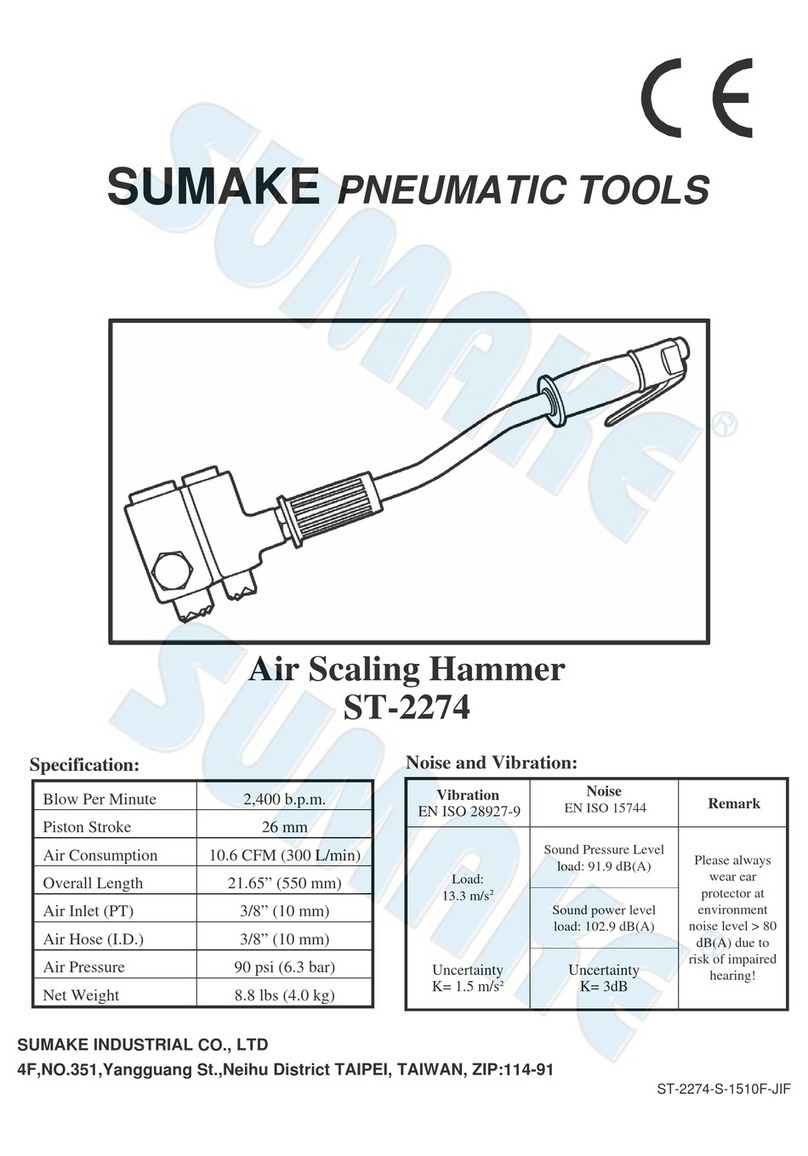

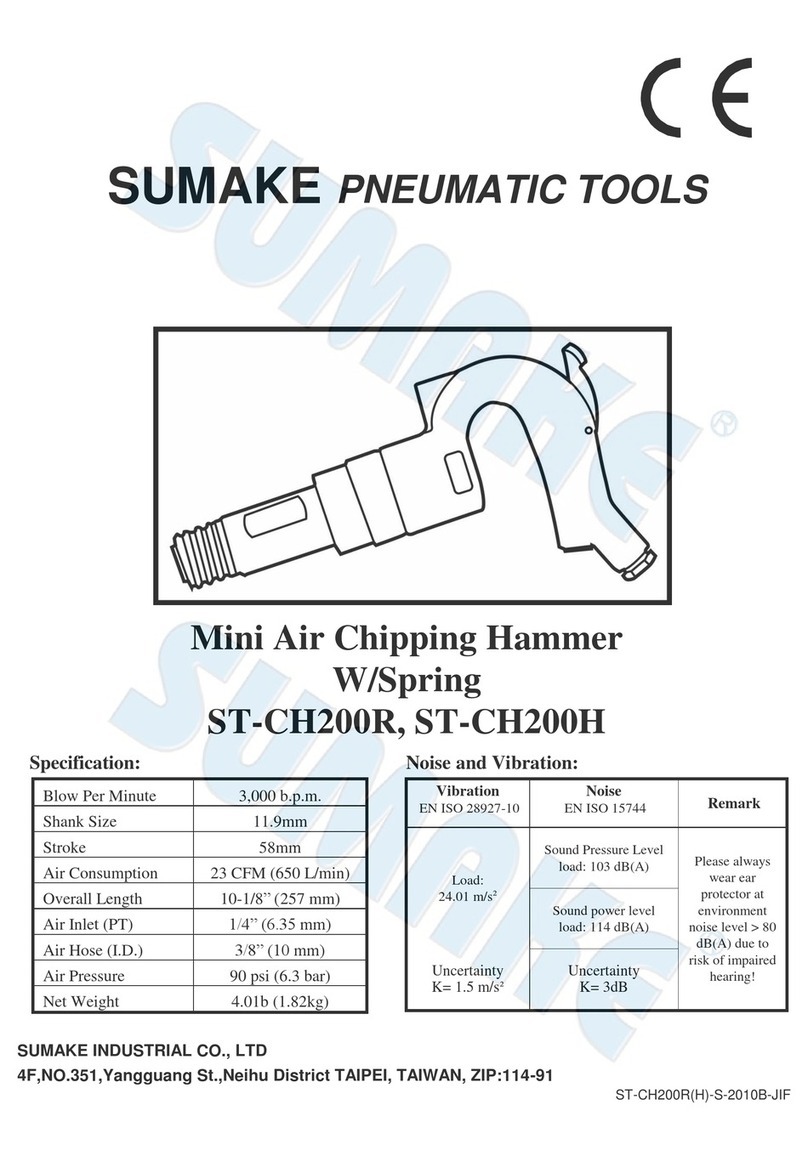

This air tool is a pneumatic tool that injects high

efficiency into manual chipping, riveting, breaking

of concrete and asphalt etc. Your care in handling it

is, however, important if performance is to be

realized over a long period of time. This booklet is

prepared to equip you with the knowledge

necessary to keep it on the job efficiently.

Operator‘s instruction

1. Cautions for Use

1-1 Air pressure

Maximum performance is displayed at the proper

able at a gauge pressure of

mechanism, and may cause trouble. So, install a

air filter and an oiler between the compressor an

the tool. Use a 3 HP or larger compressor for eac

sander.

1-3 Air hose

Clean the hose with a blast of compressed ai

efore connecting the hose to air tool. This will

revent both moisture and dust within the hose

from entering the tool and causing possible rust o

malfunction. To compensate for unusually long

hose (over 25 ft), the line pressure should be

increased accordingly.

Drainage

1-4 The approved eye protector, ear-muff,

mouth-muffle, and gloves should be worn whe

chisel

screw

out

screw

in gun body

retainer

2-2 On-off device

Please note that the tool never running unless the

insert tool is properly fixed on the gun body. To

operate this tool, just push the trigger, which is on

the grip, down. The tool continuously reciprocating

as one push the trigger down and it stops running as

thetriggerisreleased.

For the sake of safety, put it on hanger or on a soft

flat pad when not in use.

2-3 Replace and adjusting

There isno user serviceable part inside this tool.

Please sendthe tool to a qualified personnel or our

service section to repair or/and replaceworn parts.

3. Maintenance

3-1 Lubrication

Before connecting the hose , apply 4 or 5 drops of

SAE #10 spindle oil at the air inlet. Use of a thicker

oil can lead to reduced performance or malfunction.

If a thicker oil is used by accident, wipe it away

immediately. Also, every 3 or 4 hours of operation,

oiling is necessary.

*In ordering parts and components, give each part

number, name and quantity.

Warning

1. This tool is not insulated for coming into contact

with electric power source.

2. It is forbidden to use this tool in explosive

atmospheres and do not put any combustible

material near the workpiece since it might emit

sparks when working on hard material.

3. Check the wear of the insert tool and the retainer

before operating this tool.

4. Working with this tool will generate dust,

depending on the material being worked on,

couldbe harmful to the operator

5. This tool can cause the ejection of particles at

chipping or demolishing work, hence the

operator shall wear appropriate protective device

and do not let other person near the work area.

6. The insert tool and the retainer on heavy types

are exposed to heavystrains and can after a long

periodof use break due to fatigue.

7. Keep your body balance and beware of the break

of the severed workpiece.

8. If one needs to use the free hand, although it is a

source of vibration damage, we suggest place the

hand by holding the tool in the part between the

retainer and the grip and do not place the hand

on the rear part by pushing the tool. The former

posture provides the operator more balance than

the latter one.

Always disconnect the tool from the air power

Foreword

We are a manufacturer and exporter of air tools

since established. We have devote all our efforts

in improving quality and tools’ life. As well as the

noise and vibration of tools. Bring all of you

working efficiences, profits, and enjoy using the

tool is our principle.

Features

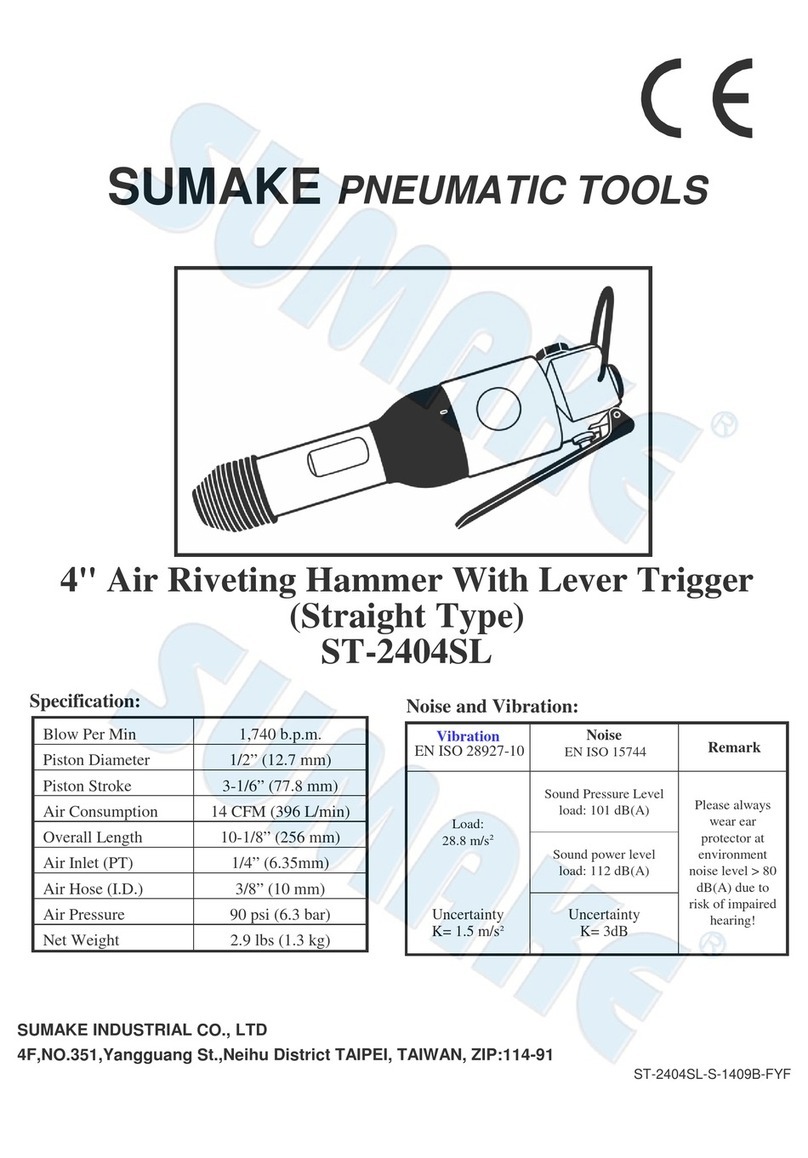

This air tool is a pneumatic tool that injects high

efficiency into manual chipping, riveting, breaking

of concrete and asphalt etc. Your care in handling it

is, however, important if performance is to be

realized over a long period of time. This booklet is

prepared to equip you with the knowledge

necessary to keep it on the job efficiently.

Operator‘s instruction

1. Cautions for Use

1-1 Air pressure

Maximum performance is displayed at the proper

sanding speed, obtainable at a gauge pressure of

6.2 bar. Range-wise, this is an air pressure from 5

to 7 bar (70 to 100 psi)

57

mechanism, and may cause trouble. So, install a

air filter and an oiler between the compressor an

the tool. Use a 3 HP or larger compressor for eac

sander.

1-3 Air hose

Clean the hose with a blast of compressed ai

efore connecting the hose to air tool. This will

revent both moisture and dust within the hose

from entering the tool and causing possible rust o

malfunction. To compensate for unusually long

hose (over 25 ft), the line pressure should be

increased accordingly.

Drainage

1-4 The approved eye protector, ear-muff,

mouth-muffle, and gloves should be worn whe

operate this tool.

1-5 The working place shall be well ventilated.

1-6 Release the on-off device in the case o

energy supply failure.

2. Operation, Adjusting And Replacing

chisel

screw

out

screw

in gun body

retainer

2-2 On-off device

Please note that the tool never running unless the

insert tool is properly fixed on the gun body. To

operate this tool, just push the trigger, which is on

the grip, down. The tool continuously reciprocating

as one push the trigger down and it stops running as

thetriggerisreleased.

For the sake of safety, put it on hanger or on a soft

flat pad when not in use.

2-3 Replace and adjusting

There isno user serviceable part inside this tool.

Please sendthe tool to a qualified personnel or our

service section to repair or/and replaceworn parts.

3. Maintenance

3-1 Lubrication

Before connecting the hose , apply 4 or 5 drops of

SAE #10 spindle oil at the air inlet. Use of a thicker

oil can lead to reduced performance or malfunction.

If a thicker oil is used by accident, wipe it away

immediately. Also, every 3 or 4 hours of operation,

oiling is necessary.

3-2 Storage

Avoid storing the tool in a location subject to high

humidity. If the tool is left as it is used , the

residual moisture inside the tool can cause rust.

Before storing and after operation, oil the tool at

the air inlet with spindle oil and run it for a short

time.

*In ordering parts and components, give each part

number, name and quantity.

Warning

1. This tool is not insulated for coming into contact

with electric power source.

2. It is forbidden to use this tool in explosive

atmospheres and do not put any combustible

material near the workpiece since it might emit

sparks when working on hard material.

3. Check the wear of the insert tool and the retainer

before operating this tool.

4. Working with this tool will generate dust,

depending on the material being worked on,

couldbe harmful to the operator

5. This tool can cause the ejection of particles at

chipping or demolishing work, hence the

operator shall wear appropriate protective device

and do not let other person near the work area.

6. The insert tool and the retainer on heavy types

are exposed to heavystrains and can after a long

periodof use break due to fatigue.

7. Keep your body balance and beware of the break

of the severed workpiece.

8. If one needs to use the free hand, although it is a

source of vibration damage, we suggest place the

hand by holding the tool in the part between the

retainer and the grip and do not place the hand

on the rear part by pushing the tool. The former

posture provides the operator more balance than

the latter one.

9. Always disconnect the tool from the air power

source when maintenance, placing any insert

tool, and not in use.

10.

Never carry the tool by hose and beware of a

whippingcompressedairhose.

11.

The workpiece shall be fixed by proper device.

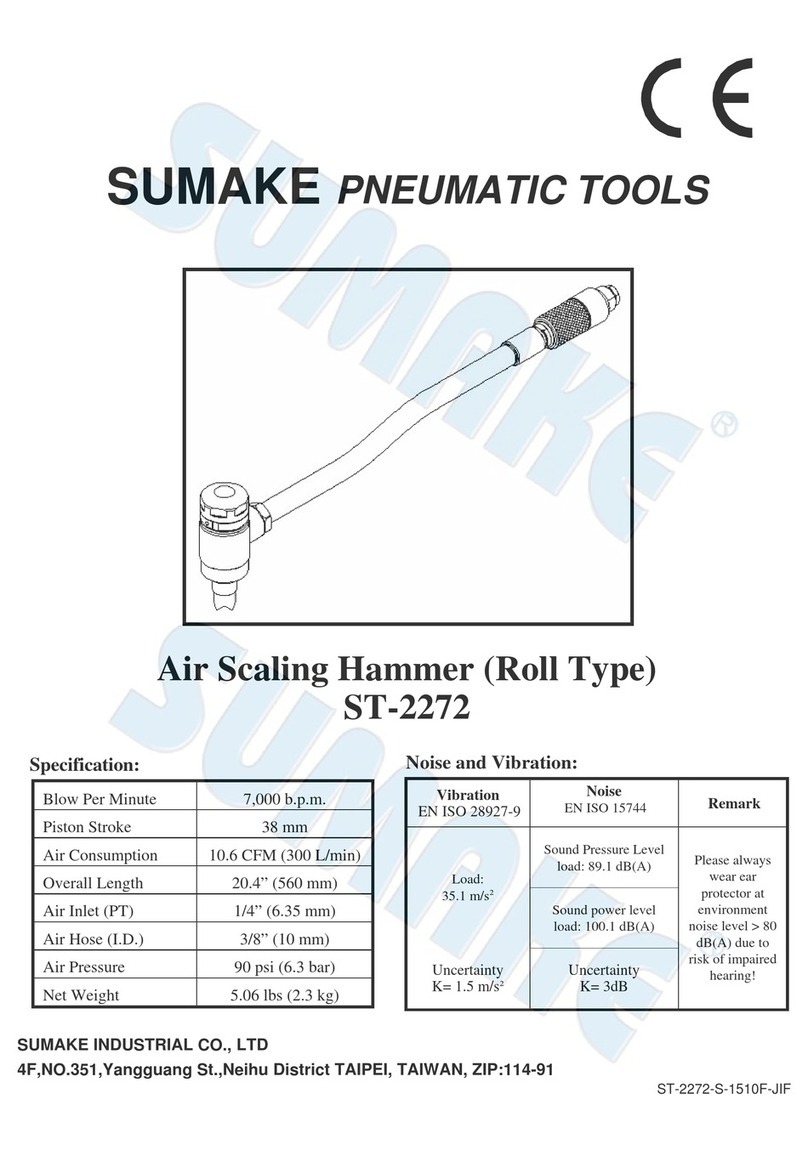

Foreword

We are a manufacturer and exporter of air tools

since established. We have devote all our efforts

in improving quality and tools’ life. As well as the

noise and vibration of tools. Bring all of you

working efficiences, profits, and enjoy using the

tool is our principle.

Features

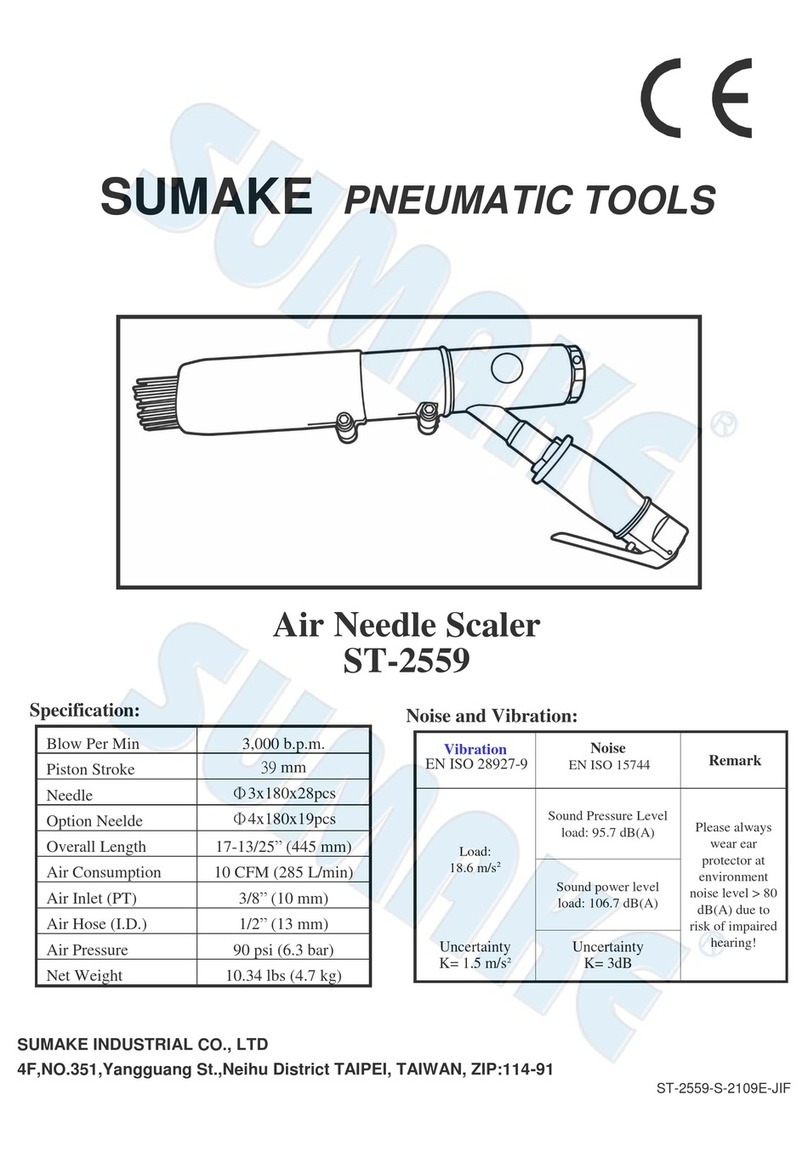

This air tool is a pneumatic tool that injects high

efficiency into manual chipping, riveting, breaking

of concrete and asphalt etc. Your care in handling it

is, however, important if performance is to be

realized over a long period of time. This booklet is

prepared to equip you with the knowledge

necessary to keep it on the job efficiently.

Operator‘s instruction

1. Cautions for Use

1-1 Air pressure

Maximum performance is displayed at the proper

sanding speed, obtainable at a gauge pressure of

6.2 bar. Range-wise, this is an air pressure from 5

to 7 bar (70 to 100 psi)

57

1-2 Air line

Use a 3/8“ air hose between the compressor and

the tool . Compressed air is cooled and its water

mechanism, and may cause trouble. So, install a

air filter and an oiler between the compressor an

the tool. Use a 3 HP or larger compressor for eac

sander.

1-3 Air hose

Clean the hose with a blast of compressed ai

efore connecting the hose to air tool. This will

revent both moisture and dust within the hose

from entering the tool and causing possible rust o

malfunction. To compensate for unusually long

hose (over 25 ft), the line pressure should be

increased accordingly.

Drainage

1-4 The approved eye protector, ear-muff,

mouth-muffle, and gloves should be worn whe

operate this tool.

1-5 The working place shall be well ventilated.

1-6 Release the on-off device in the case o

energy supply failure.

2. Operation, Adjusting And Replacing

Method

2-1 Inserting a chisel

First disconnect the air horse from this tool. Inser

the desired chisel from the open end of the quic

change retainer so that the retainer could hold the

rotuberance on the chisel shank. Secure the

retainer and the chisel to the gun body by scre

th t i th l d d i th l k i

chisel

screw

out

screw

in gun body

retainer

2-2 On-off device

Please note that the tool never running unless the

insert tool is properly fixed on the gun body. To

operate this tool, just push the trigger, which is on

the grip, down. The tool continuously reciprocating

as one push the trigger down and it stops running as

thetriggerisreleased.

For the sake of safety, put it on hanger or on a soft

flat pad when not in use.

2-3 Replace and adjusting

There isno user serviceable part inside this tool.

Please sendthe tool to a qualified personnel or our

service section to repair or/and replaceworn parts.

3. Maintenance

3-1 Lubrication

Before connecting the hose , apply 4 or 5 drops of

SAE #10 spindle oil at the air inlet. Use of a thicker

oil can lead to reduced performance or malfunction.

If a thicker oil is used by accident, wipe it away

immediately. Also, every 3 or 4 hours of operation,

oiling is necessary.

3-2 Storage

Avoid storing the tool in a location subject to high

humidity. If the tool is left as it is used , the

residual moisture inside the tool can cause rust.

Before storing and after operation, oil the tool at

the air inlet with spindle oil and run it for a short

time.

3-3 Disposal

If the tool is too seriously damaged to be used

anymore, drop it in a resource recycling can. Never

drop it into fire.

3-4 Ordering serviceParts

For further o

erational and handlin

information o

*In ordering parts and components, give each part

number, name and quantity.

Warning

1. This tool is not insulated for coming into contact

with electric power source.

2. It is forbidden to use this tool in explosive

atmospheres and do not put any combustible

material near the workpiece since it might emit

sparks when working on hard material.

3. Check the wear of the insert tool and the retainer

before operating this tool.

4. Working with this tool will generate dust,

depending on the material being worked on,

couldbe harmful to the operator

5. This tool can cause the ejection of particles at

chipping or demolishing work, hence the

operator shall wear appropriate protective device

and do not let other person near the work area.

6. The insert tool and the retainer on heavy types

are exposed to heavystrains and can after a long

periodof use break due to fatigue.

7. Keep your body balance and beware of the break

of the severed workpiece.

8. If one needs to use the free hand, although it is a

source of vibration damage, we suggest place the

hand by holding the tool in the part between the

retainer and the grip and do not place the hand

on the rear part by pushing the tool. The former

posture provides the operator more balance than

the latter one.

9. Always disconnect the tool from the air power

source when maintenance, placing any insert

tool, and not in use.

10.

Never carry the tool by hose and beware of a

whippingcompressedairhose.

11.

The workpiece shall be fixed by proper device.

Foreword

We are a manufacturer and exporter of air tools

since established. We have devote all our efforts

in improving quality and tools’ life. As well as the

noise and vibration of tools. Bring all of you

working efficiences, profits, and enjoy using the

tool is our principle.

Features

This air tool is a pneumatic tool that injects high

efficiency into manual chipping, riveting, breaking

of concrete and asphalt etc. Your care in handling it

is, however, important if performance is to be

realized over a long period of time. This booklet is

prepared to equip you with the knowledge

necessary to keep it on the job efficiently.

Operator‘s instruction

1. Cautions for Use

1-1 Air pressure

Maximum performance is displayed at the proper

sanding speed, obtainable at a gauge pressure of

6.2 bar. Range-wise, this is an air pressure from 5

to 7 bar (70 to 100 psi)

57

1-2 Air line

Use a 3/8“ air hose between the compressor and

the tool . Compressed air is cooled and its water

content separated, as soon as the air leaves the

compressor.

Coupler Recoil

hose

Leader

hose Water

separation Air

supply

mechanism, and may cause trouble. So, install a

air filter and an oiler between the compressor an

the tool. Use a 3 HP or larger compressor for eac

sander.

1-3 Air hose

Clean the hose with a blast of compressed ai

efore connecting the hose to air tool. This will

revent both moisture and dust within the hose

from entering the tool and causing possible rust o

malfunction. To compensate for unusually long

hose (over 25 ft), the line pressure should be

increased accordingly.

Drainage

1-4 The approved eye protector, ear-muff,

mouth-muffle, and gloves should be worn whe

operate this tool.

1-5 The working place shall be well ventilated.

1-6 Release the on-off device in the case o

energy supply failure.

2. Operation, Adjusting And Replacing

Method

2-1 Inserting a chisel

First disconnect the air horse from this tool. Inser

the desired chisel from the open end of the quic

change retainer so that the retainer could hold the

rotuberance on the chisel shank. Secure the

retainer and the chisel to the gun body by scre

the retainer on the closed end in the clockwise

direction . Loose the retainer and the chisel fro

the gun body by screw the retainer on the ope

end in the reverse direction.

chisel

screw

out

screw

in gun body

retainer

2-2 On-off device

Please note that the tool never running unless the

insert tool is properly fixed on the gun body. To

operate this tool, just push the trigger, which is on

the grip, down. The tool continuously reciprocating

as one push the trigger down and it stops running as

thetriggerisreleased.

For the sake of safety, put it on hanger or on a soft

flat pad when not in use.

2-3 Replace and adjusting

There isno user serviceable part inside this tool.

Please sendthe tool to a qualified personnel or our

service section to repair or/and replaceworn parts.

3. Maintenance

3-1 Lubrication

Before connecting the hose , apply 4 or 5 drops of

SAE #10 spindle oil at the air inlet. Use of a thicker

oil can lead to reduced performance or malfunction.

If a thicker oil is used by accident, wipe it away

immediately. Also, every 3 or 4 hours of operation,

oiling is necessary.

3-2 Storage

Avoid storing the tool in a location subject to high

humidity. If the tool is left as it is used , the

residual moisture inside the tool can cause rust.

Before storing and after operation, oil the tool at

the air inlet with spindle oil and run it for a short

time.

3-3 Disposal

If the tool is too seriously damaged to be used

anymore, drop it in a resource recycling can. Never

drop it into fire.

3-4 Ordering serviceParts

For further operational and handling information or

for replacement of parts and components, contact

the sale agent fromwhom you purchased the tool or

the service division of our company.

*In ordering parts and components, give each part

number, name and quantity.

Warning

1. This tool is not insulated for coming into contact

with electric power source.

2. It is forbidden to use this tool in explosive

atmospheres and do not put any combustible

material near the workpiece since it might emit

sparks when working on hard material.

3. Check the wear of the insert tool and the retainer

before operating this tool.

4. Working with this tool will generate dust,

depending on the material being worked on,

couldbe harmful to the operator

5. This tool can cause the ejection of particles at

chipping or demolishing work, hence the

operator shall wear appropriate protective device

and do not let other person near the work area.

6. The insert tool and the retainer on heavy types

are exposed to heavystrains and can after a long

periodof use break due to fatigue.

7. Keep your body balance and beware of the break

of the severed workpiece.

8. If one needs to use the free hand, although it is a

source of vibration damage, we suggest place the

hand by holding the tool in the part between the

retainer and the grip and do not place the hand

on the rear part by pushing the tool. The former

posture provides the operator more balance than

the latter one.

9. Always disconnect the tool from the air power

source when maintenance, placing any insert

tool, and not in use.

10.

Never carry the tool by hose and beware of a

whippingcompressedairhose.

11.

The workpiece shall be fixed by proper device.

Foreword

We are a manufacturer and exporter of air tools

since established. We have devote all our efforts

in improving quality and tools’ life. As well as the

noise and vibration of tools. Bring all of you

working efficiences, profits, and enjoy using the

tool is our principle.

Features

This air tool is a pneumatic tool that injects high

efficiency into manual chipping, riveting, breaking

of concrete and asphalt etc. Your care in handling it

is, however, important if performance is to be

realized over a long period of time. This booklet is

prepared to equip you with the knowledge

necessary to keep it on the job efficiently.

Operator‘s instruction

1. Cautions for Use

1-1 Air pressure

Maximum performance is displayed at the proper

sanding speed, obtainable at a gauge pressure of

6.2 bar. Range-wise, this is an air pressure from 5

to 7 bar (70 to 100 psi)

57

1-2 Air line

Use a 3/8“ air hose between the compressor and

the tool . Compressed air is cooled and its water

content separated, as soon as the air leaves the

compressor.

Tool

Nipple

Coupler Recoil

hose

Leader

hose

Oiler Regulator

Water

separation Air

supply

Drain

daily

A portion of the water content, however, is

condensed in the piping and can enter the tool

mechanism, and may cause trouble. So, install a

air filter and an oiler between the compressor an

the tool. Use a 3 HP or larger compressor for eac

sander.

1-3 Air hose

Clean the hose with a blast of compressed ai

efore connecting the hose to air tool. This will

revent both moisture and dust within the hose

from entering the tool and causing possible rust o

malfunction. To compensate for unusually long

hose (over 25 ft), the line pressure should be

increased accordingly.

Drainage

1-4 The approved eye protector, ear-muff,

mouth-muffle, and gloves should be worn whe

operate this tool.

1-5 The working place shall be well ventilated.

1-6 Release the on-off device in the case o

energy supply failure.

2. Operation, Adjusting And Replacing

Method

2-1 Inserting a chisel

First disconnect the air horse from this tool. Inser

the desired chisel from the open end of the quic

change retainer so that the retainer could hold the

rotuberance on the chisel shank. Secure the

retainer and the chisel to the gun body by scre

the retainer on the closed end in the clockwise

direction . Loose the retainer and the chisel fro

the gun body by screw the retainer on the ope

end in the reverse direction.

chisel

screw

out

screw

in gun body

retainer

2-2 On-off device

Please note that the tool never running unless the

insert tool is properly fixed on the gun body. To

operate this tool, just push the trigger, which is on

the grip, down. The tool continuously reciprocating

as one push the trigger down and it stops running as

thetriggerisreleased.

For the sake of safety, put it on hanger or on a soft

flat pad when not in use.

2-3 Replace and adjusting

There isno user serviceable part inside this tool.

Please sendthe tool to a qualified personnel or our

service section to repair or/and replaceworn parts.

3. Maintenance

3-1 Lubrication

Before connecting the hose , apply 4 or 5 drops of

SAE #10 spindle oil at the air inlet. Use of a thicker

oil can lead to reduced performance or malfunction.

If a thicker oil is used by accident, wipe it away

immediately. Also, every 3 or 4 hours of operation,

oiling is necessary.

3-2 Storage

Avoid storing the tool in a location subject to high

humidity. If the tool is left as it is used , the

residual moisture inside the tool can cause rust.

Before storing and after operation, oil the tool at

the air inlet with spindle oil and run it for a short

time.

3-3 Disposal

If the tool is too seriously damaged to be used

anymore, drop it in a resource recycling can. Never

drop it into fire.

3-4 Ordering serviceParts

For further operational and handling information or

for replacement of parts and components, contact

the sale agent fromwhom you purchased the tool or

the service division of our company.

*In ordering parts and components, give each part

number, name and quantity.

Warning

1. This tool is not insulated for coming into contact

with electric power source.

2. It is forbidden to use this tool in explosive

atmospheres and do not put any combustible

material near the workpiece since it might emit

sparks when working on hard material.

3. Check the wear of the insert tool and the retainer

before operating this tool.

4. Working with this tool will generate dust,

depending on the material being worked on,

couldbe harmful to the operator

5. This tool can cause the ejection of particles at

chipping or demolishing work, hence the

operator shall wear appropriate protective device

and do not let other person near the work area.

6. The insert tool and the retainer on heavy types

are exposed to heavystrains and can after a long

periodof use break due to fatigue.

7. Keep your body balance and beware of the break

of the severed workpiece.

8. If one needs to use the free hand, although it is a

source of vibration damage, we suggest place the

hand by holding the tool in the part between the

retainer and the grip and do not place the hand

on the rear part by pushing the tool. The former

posture provides the operator more balance than

the latter one.

9. Always disconnect the tool from the air power

source when maintenance, placing any insert

tool, and not in use.

10.

Never carry the tool by hose and beware of a

whippingcompressedairhose.

11.

The workpiece shall be fixed by proper device.

SST-2280-I-1706A-FY

Foreword

We are a manufacturer and exporter of air tools

since established. We have devote all our efforts

in improving quality and tools’ life. As well as the

noise and vibration of tools. Bring all of you

working efficiences, profits, and enjoy using the

tool is our principle.

Features

This air tool is a pneumatic tool that injects high

efficiency into manual chipping, riveting, breaking

of concrete and asphalt etc. Your care in handling it

is, however, important if performance is to be

realized over a long period of time. This booklet is

prepared to equip you with the knowledge

necessary to keep it on the job efficiently.

Operator‘s instruction

1. Cautions for Use

1-1 Air pressure

Maximum performance is displayed at the proper

sanding speed, obtainable at a gauge pressure of

6.2 bar. Range-wise, this is an air pressure from 5

to 7 bar (70 to 100 psi)

57

1-2 Air line

Use a 3/8“ air hose between the compressor and

the tool . Compressed air is cooled and its water

content separated, as soon as the air leaves the

compressor.

Tool

Nipple

Coupler Recoil

hose

Leader

hose

Oiler Regulator

Water

separation Air

supply

Drain

daily

A portion of the water content, however, is

condensed in the piping, and can enter the tool

mechanism, and may cause trouble. So, install a

air filter and an oiler between the compressor an

the tool. Use a 3 HP or larger compressor for eac

sander.

1-3 Air hose

Clean the hose with a blast of compressed ai

efore connecting the hose to air tool. This will

revent both moisture and dust within the hose

from entering the tool and causing possible rust o

malfunction. To compensate for unusually long

hose (over 25 ft), the line pressure should be

increased accordingly.

Drainage

1-4 The approved eye protector, ear-muff,

mouth-muffle, and gloves should be worn whe

operate this tool.

1-5 The working place shall be well ventilated.

1-6 Release the on-off device in the case o

energy supply failure.

2. Operation, Adjusting And Replacing

Method

2-1 Inserting a chisel

First disconnect the air horse from this tool. Inser

the desired chisel from the open end of the quic

change retainer so that the retainer could hold the

rotuberance on the chisel shank. Secure the

retainer and the chisel to the gun body by scre

the retainer on the closed end in the clockwise

direction . Loose the retainer and the chisel fro

the gun body by screw the retainer on the ope

end in the reverse direction.