2

Be prepared for job

Wear proper apparel. Do not wear loose clothing, gloves, neckties, rings, bracelets or other jewelry which may get

caught in moving pasts of machine.

Wear protective hair covering to contain ling hair.

Wear safety glasses (not everyday glasses) and shoes with non-slip soles.

Wear dust mask and dustless clothes if operation is dusty.

Wear ear protection if the work area may include exposure to excessive noise levels.

Keep work area ventilation and clean. It should be properly lighted. Cluttered work areas invite accidents.

Do not use the tools in dangerous environments or wet locations. Do not expose it t rain.

Always disconnect tool from air supply when servicing or adjusting tool and when tool is not in use.

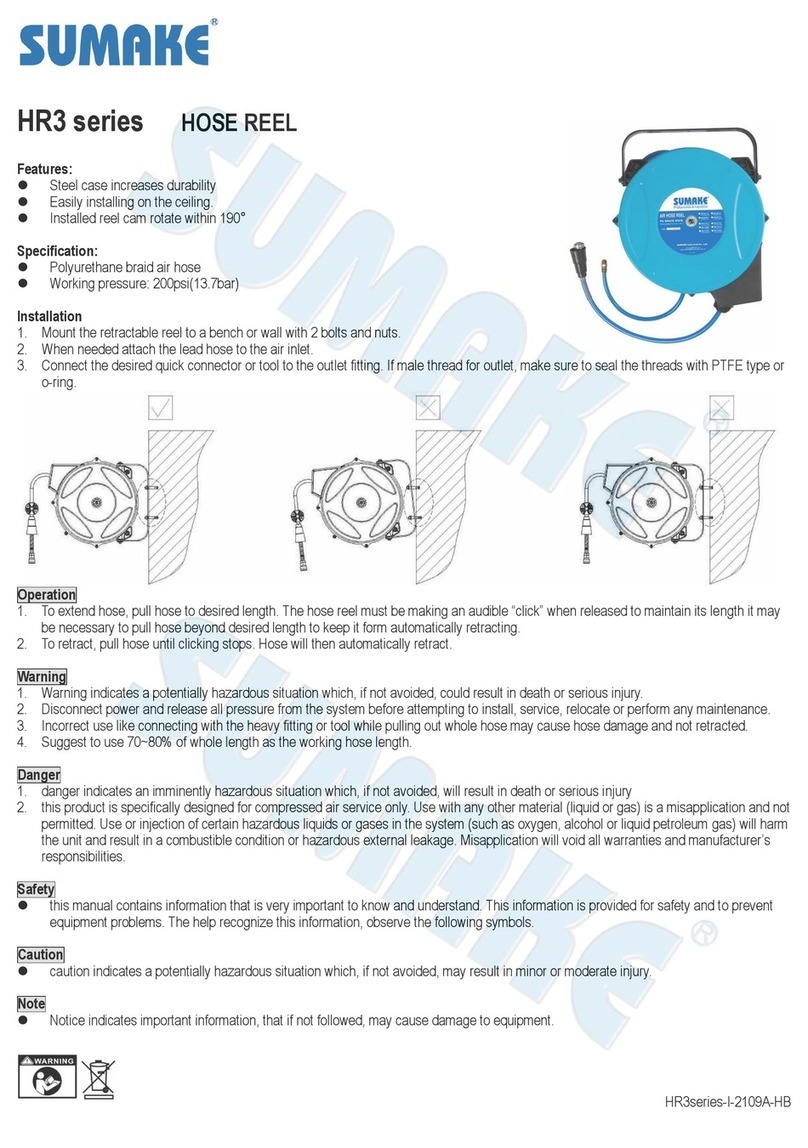

Preparation before operation

1. the pneumatic tapping tool operates on compressed air at pressure from 7 to 9 kgf/cm2

2. Never exceed maximum pressure.

3. Air operated tools require clean, dry, lubricated, compressed air t ensure top performance, low maintenance and long

life.

4. Moisture will reduce tool performance and life if not removed from compressed air.

5. Lubricate tool with quality pneumatic tapping tool oil is required.

Note: recommend to use light and heat-resistant oil.

If a filter-regulator-lubricator system us used, please keep 3-5 drops/minute while operating.

If no air line lubricator is used, place five to six drops of oil into the tool body before operating. (add quality

pneumatic oil from parts no. 22 and 23)

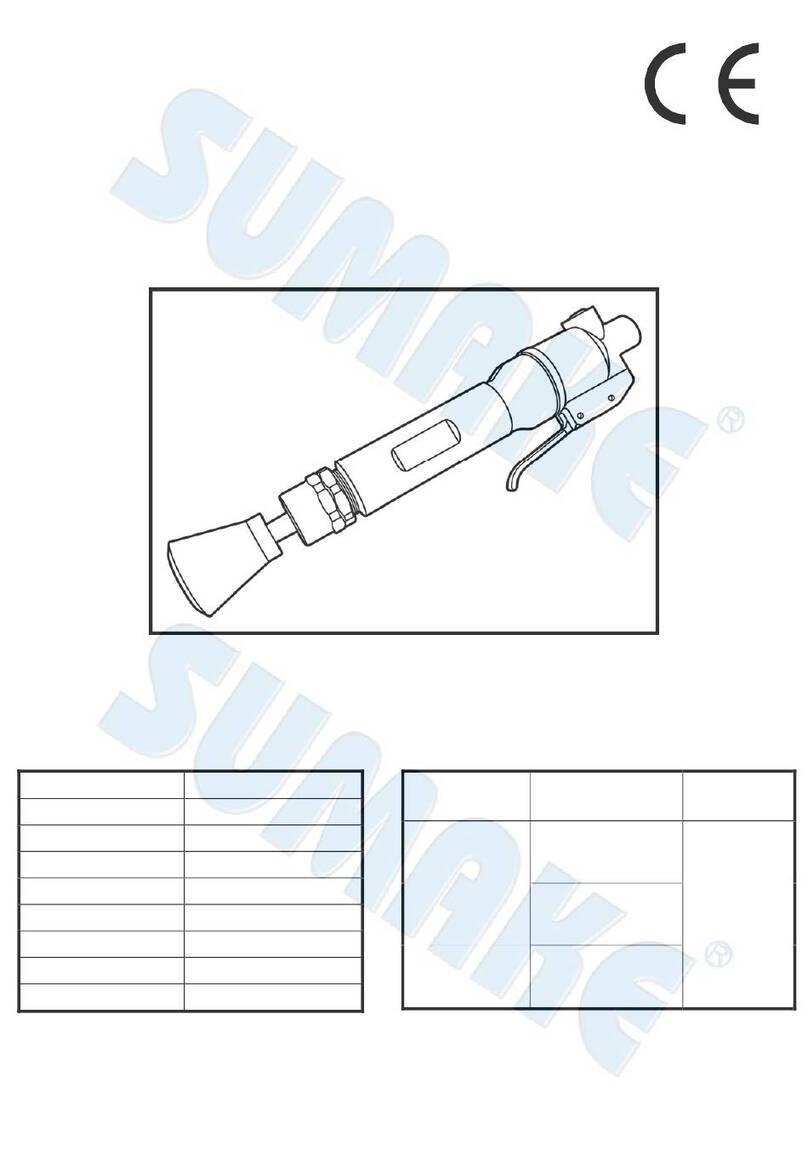

Assembly

STH-12A, STH-12B

1. Assembly the wrench (refer part no.1 and 2) from the front of tap to the tool body.

2. Position wrench at 90∘to the left of body (see figure 1) and tighten wrench in position by turning handle clockwise.

(Position wrench to the right if you are left handed.)

3. Insert tap (not included) into tap chuck tightening by screws to ensure the tap is tight in chuck.

STH-12A: by using hex wrench to adjust the screw.

STH-12B: by using the wrench (included) to adjust the gear.

STH-12C

1. Slide wrench (refer part no. 1 and 2) from the front of tap to the tool body.

2. Position wrench at 90∘to the left of body (see figure 1) and tighten wrench in position by turning handle clockwise.

(Position wrench to the right if you are left handed.)

3. Slide tap (not included) into tap holder until tap licks in place, tap can be removed by simultaneously depressing flange

and pulling out tap.

4. Insert collet with tap into chuck. Pull back chuck sleeve, insert collet with tabs aligned to slots in chuck sleeve, and then

release sleeve (see figure 3)

Operation

1. Take the spindle with tap to the hole to be tapped and place the tip of the tap in the hole.

2. Press the [ L] operation lever (refer part no. 57). The tap will self-center and begin tapping.

3. After tapping to the required depth, press the [ R ] reverse button (refer part no. 57).The tap will reverse out from the

hole.

Note:

The signs of [ L] and [ R ] show on the tool body

Use only enough air pressure to perform the operation.Air pressure in excess of that which is required will make

the operation inefficient and may cause premature wear or damage to the tool.