Sumake HTT-22 User manual

Other Sumake Tools manuals

Sumake

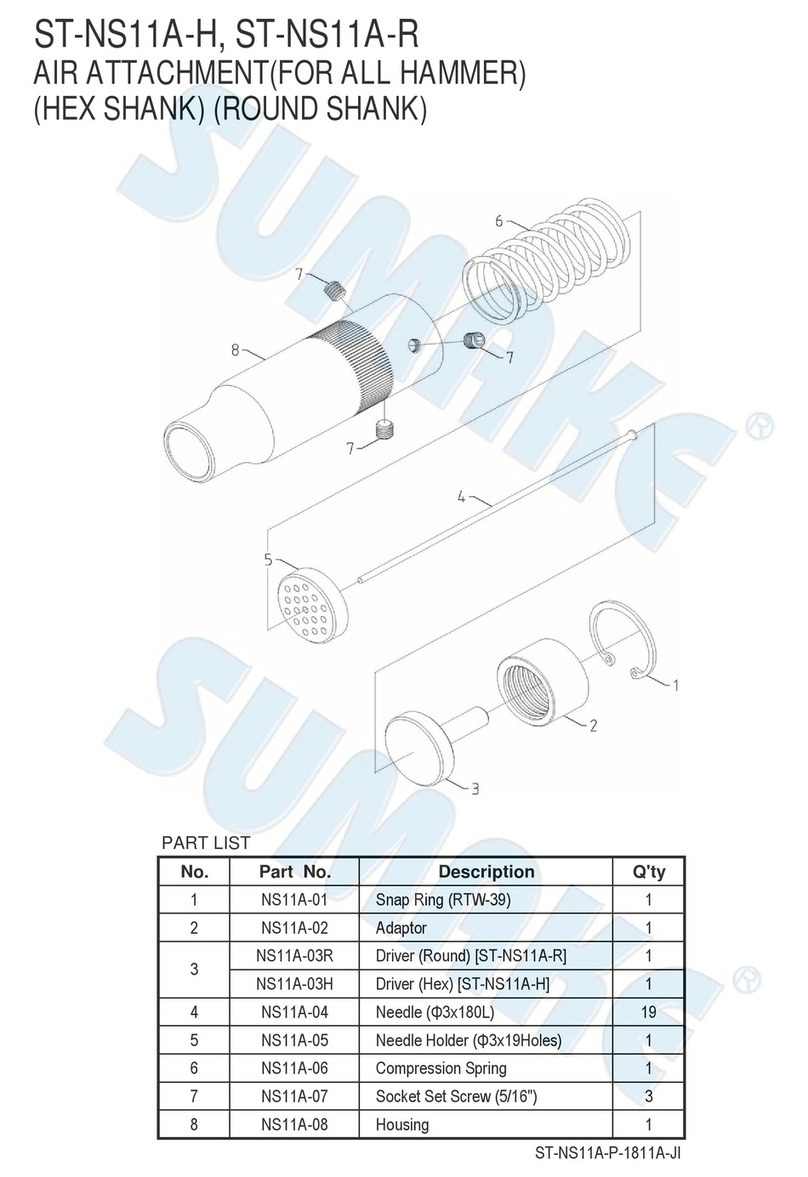

Sumake ST-NS11A-H User manual

Sumake

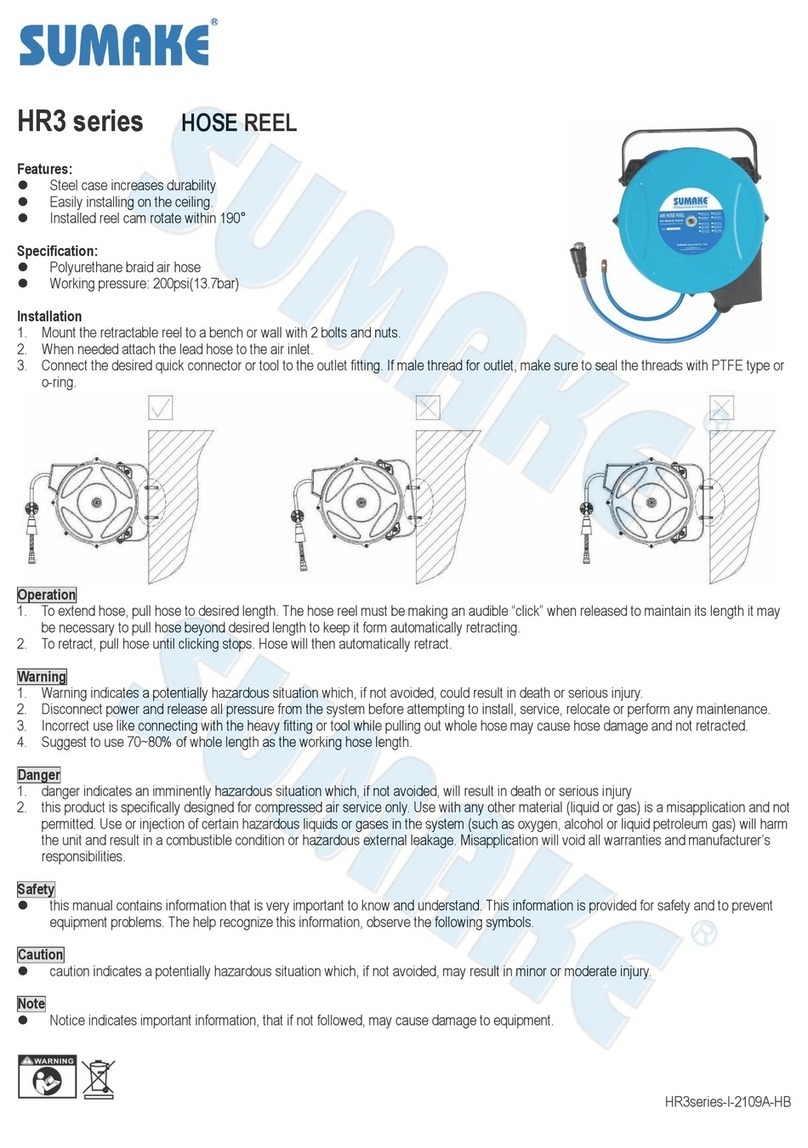

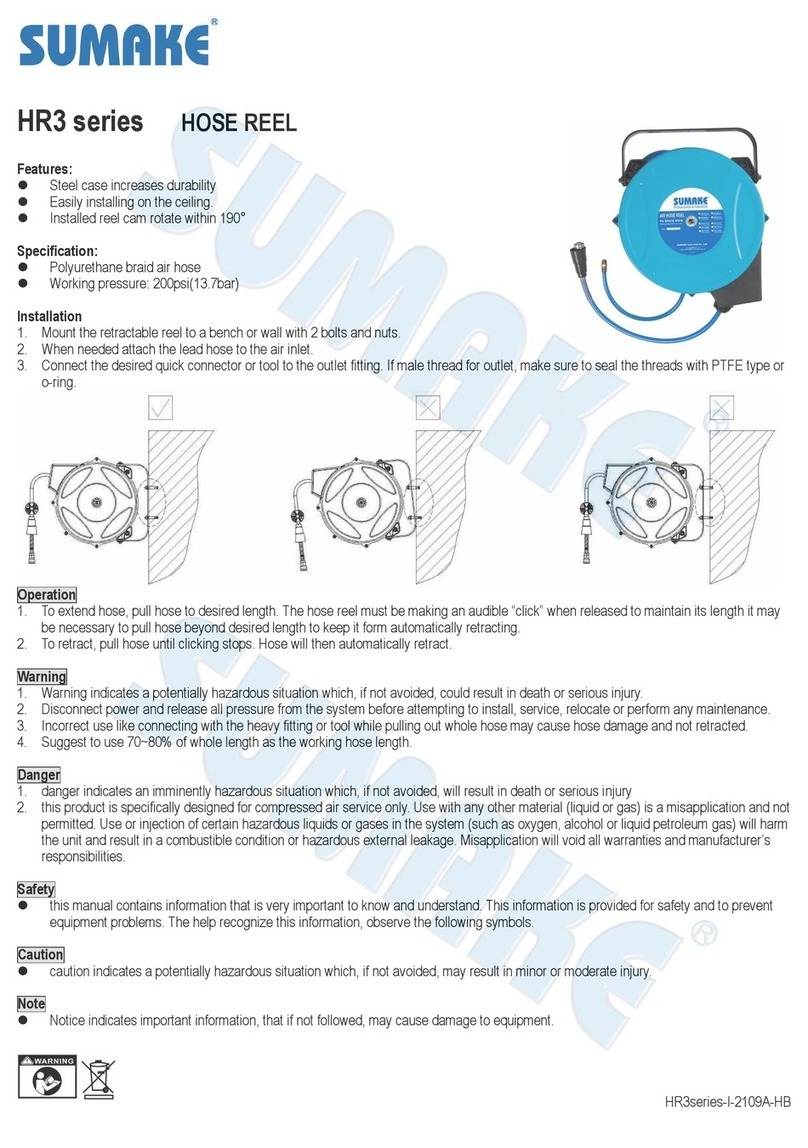

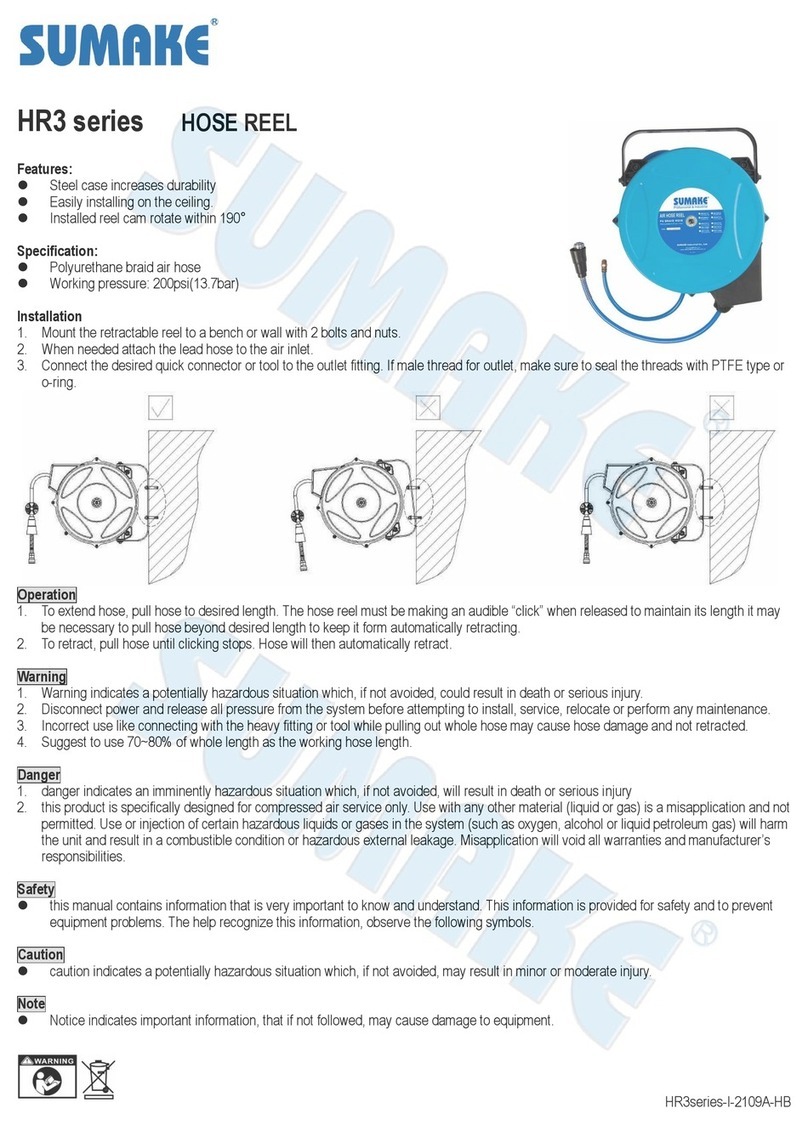

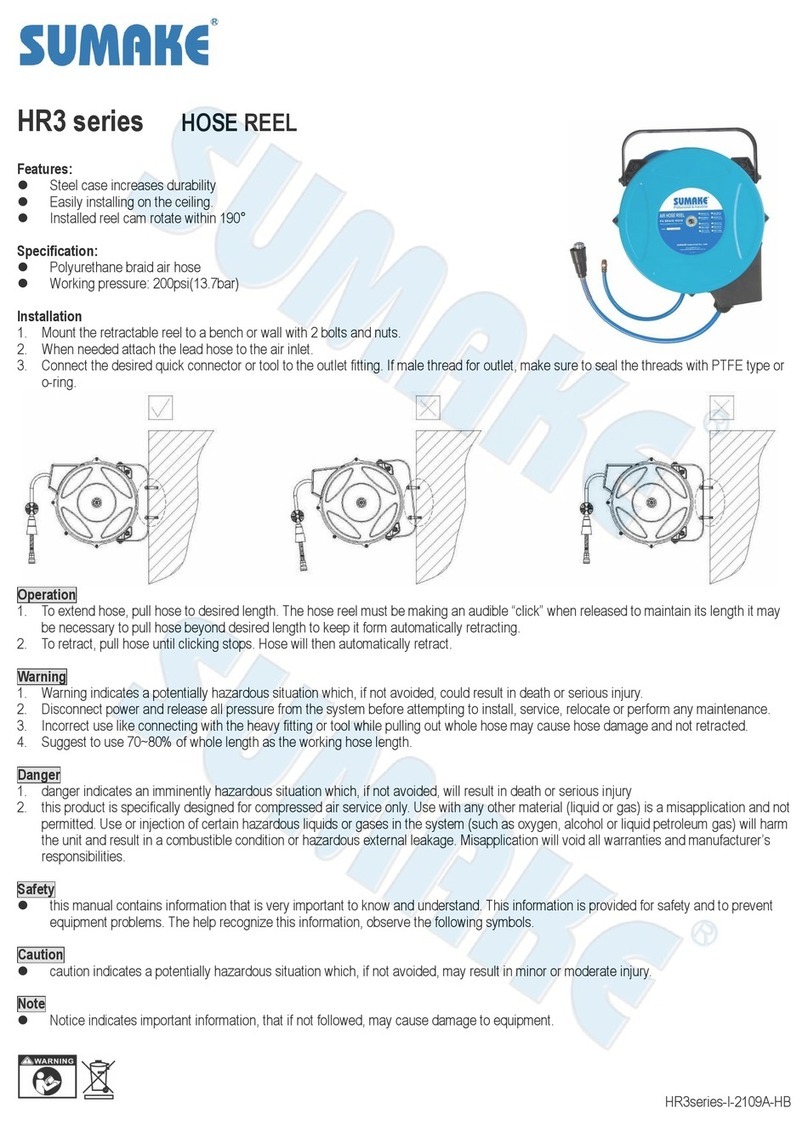

Sumake HR3 Series User manual

Sumake

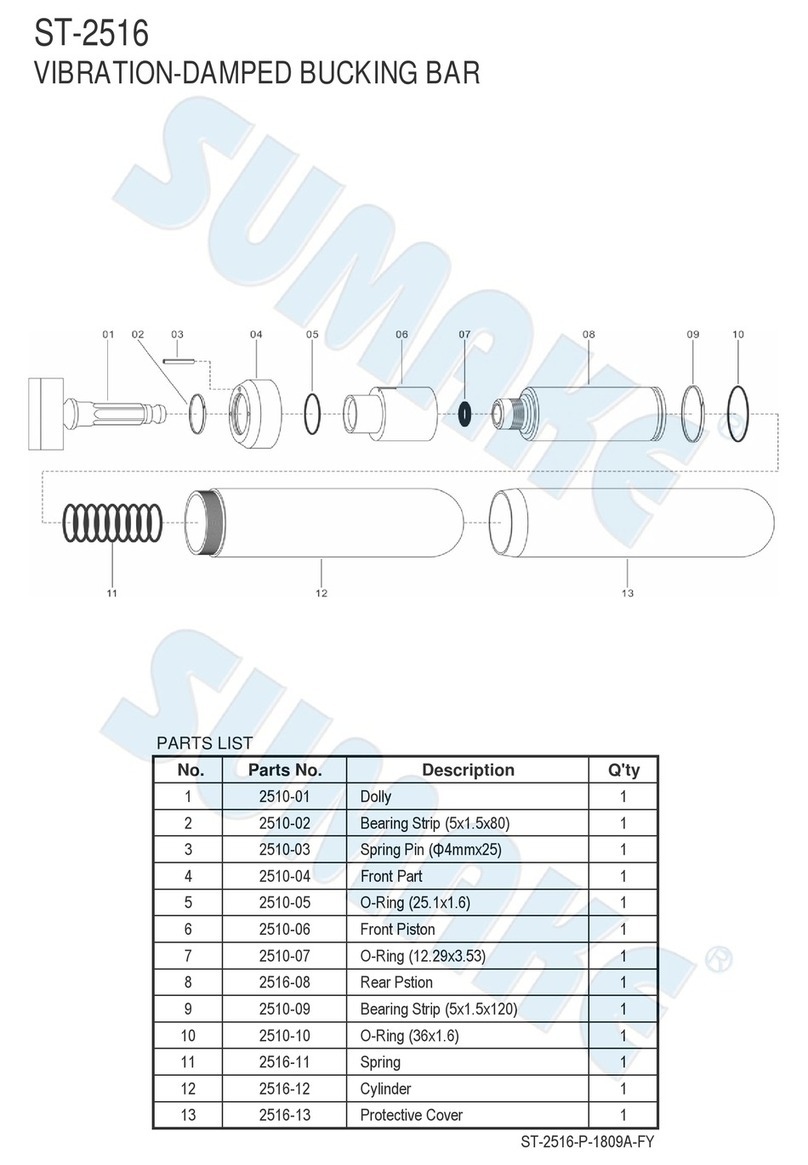

Sumake ST-2516 User manual

Sumake

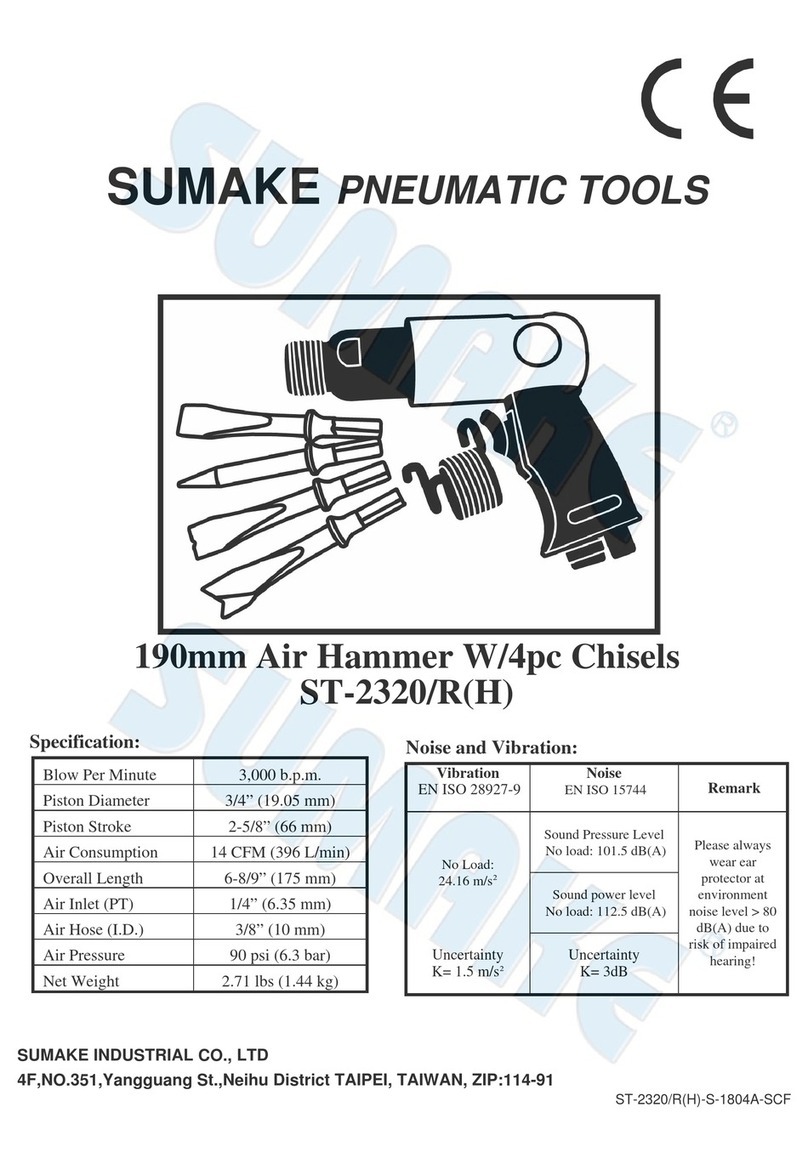

Sumake ST-2320/R Specifications

Sumake

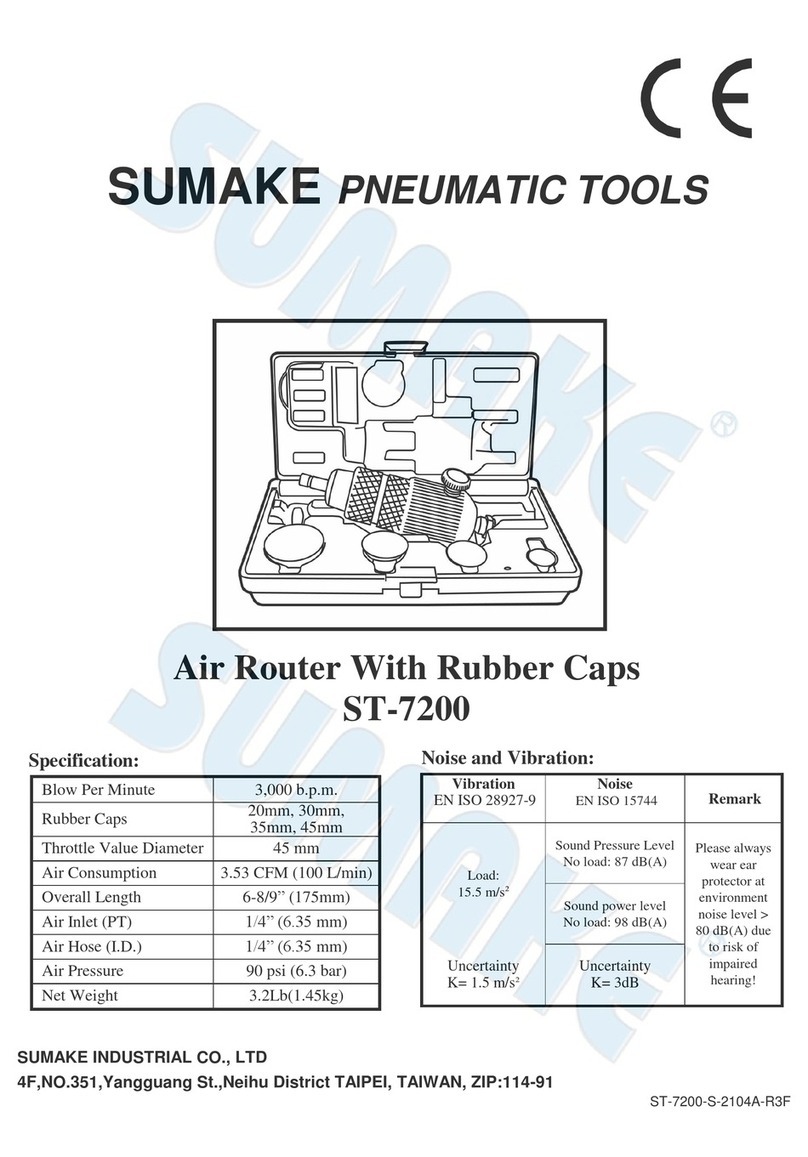

Sumake ST-7200 User manual

Sumake

Sumake HR3 Series User manual

Sumake

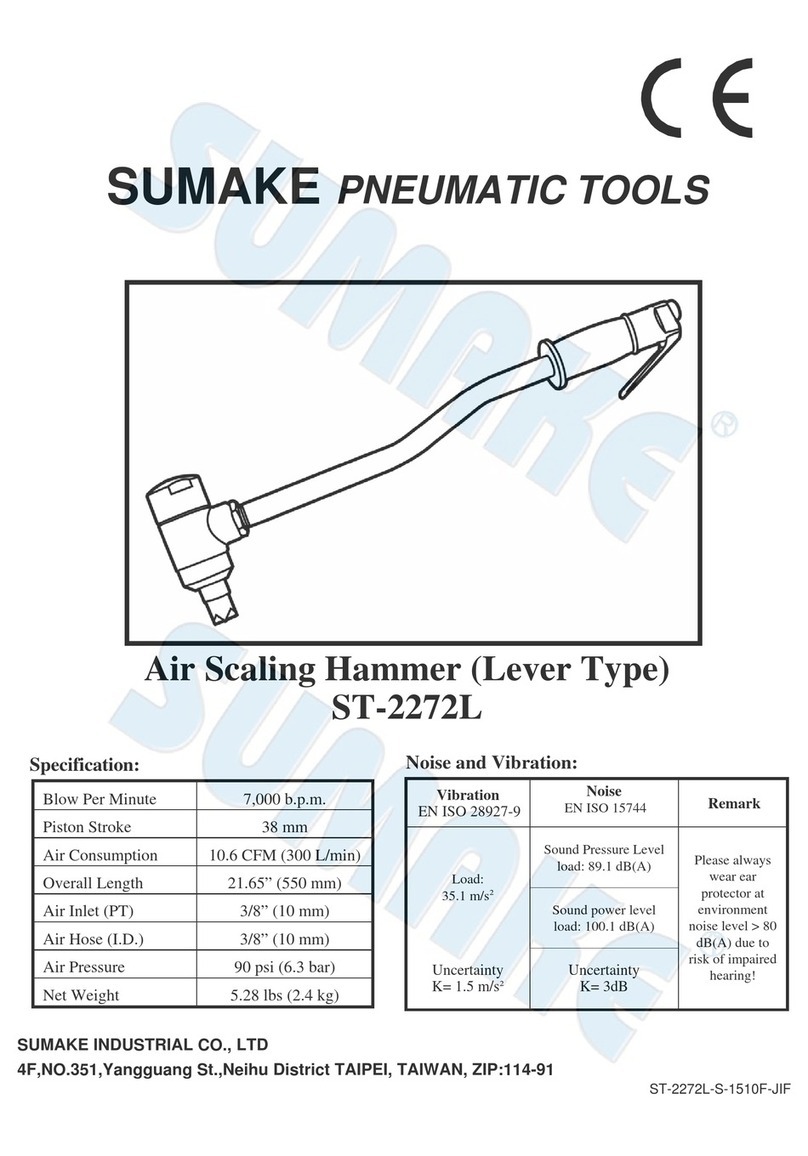

Sumake ST-2272L User manual

Sumake

Sumake ST-6410HR User manual

Sumake

Sumake HR3 Series User manual

Sumake

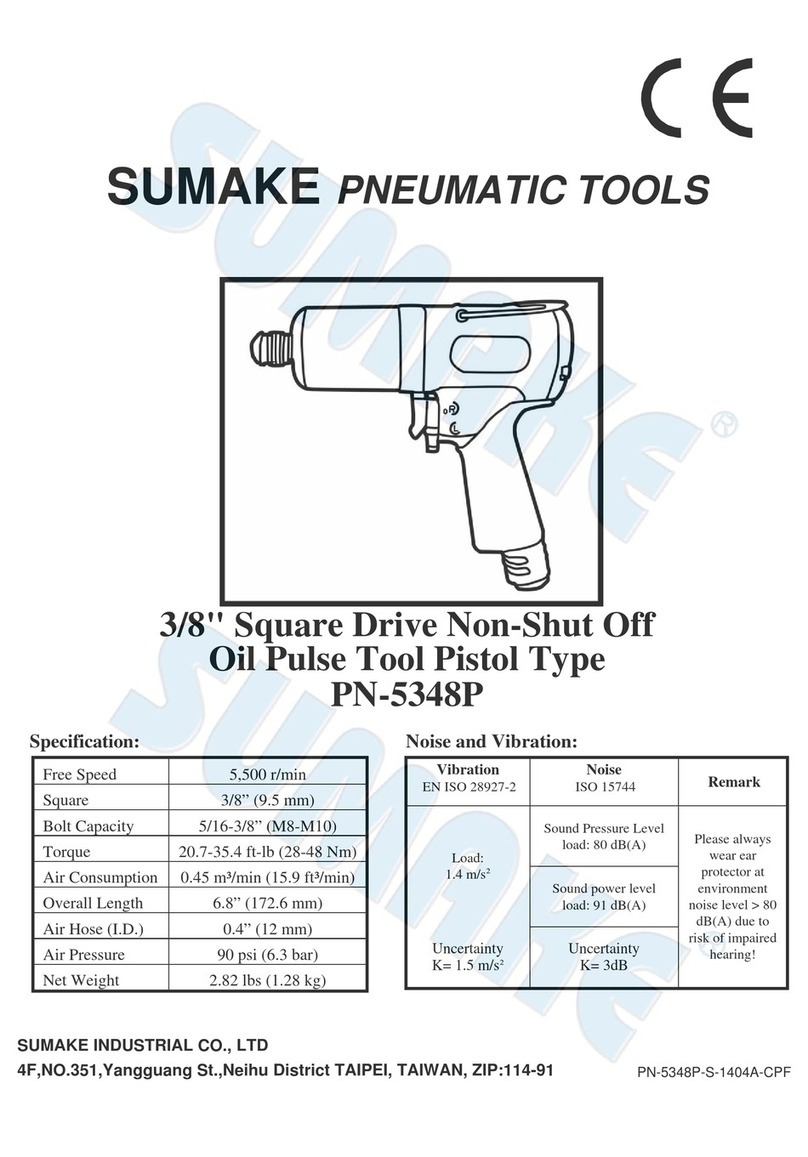

Sumake PN-5348P User manual

Sumake

Sumake HR3 Series User manual

Sumake

Sumake ST-P6634 User manual

Sumake

Sumake ST-2280 User manual

Sumake

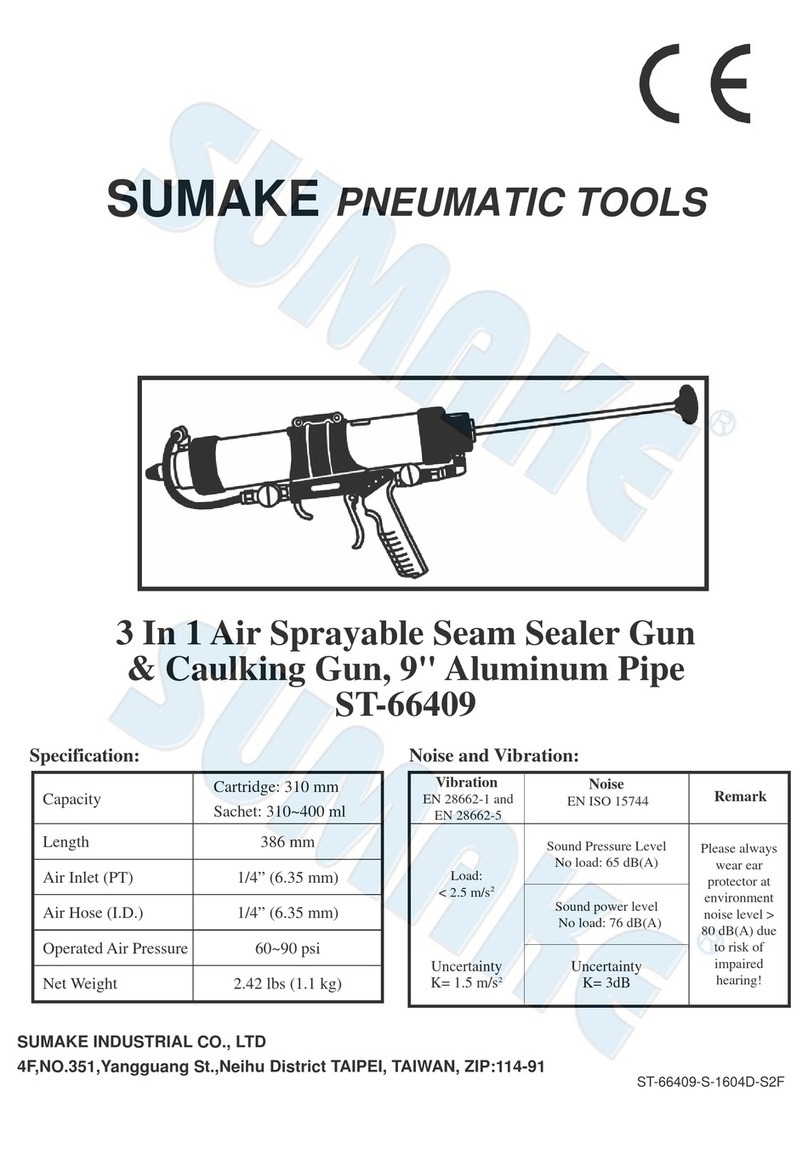

Sumake ST-66409 User manual

Sumake

Sumake SF501 User manual

Sumake

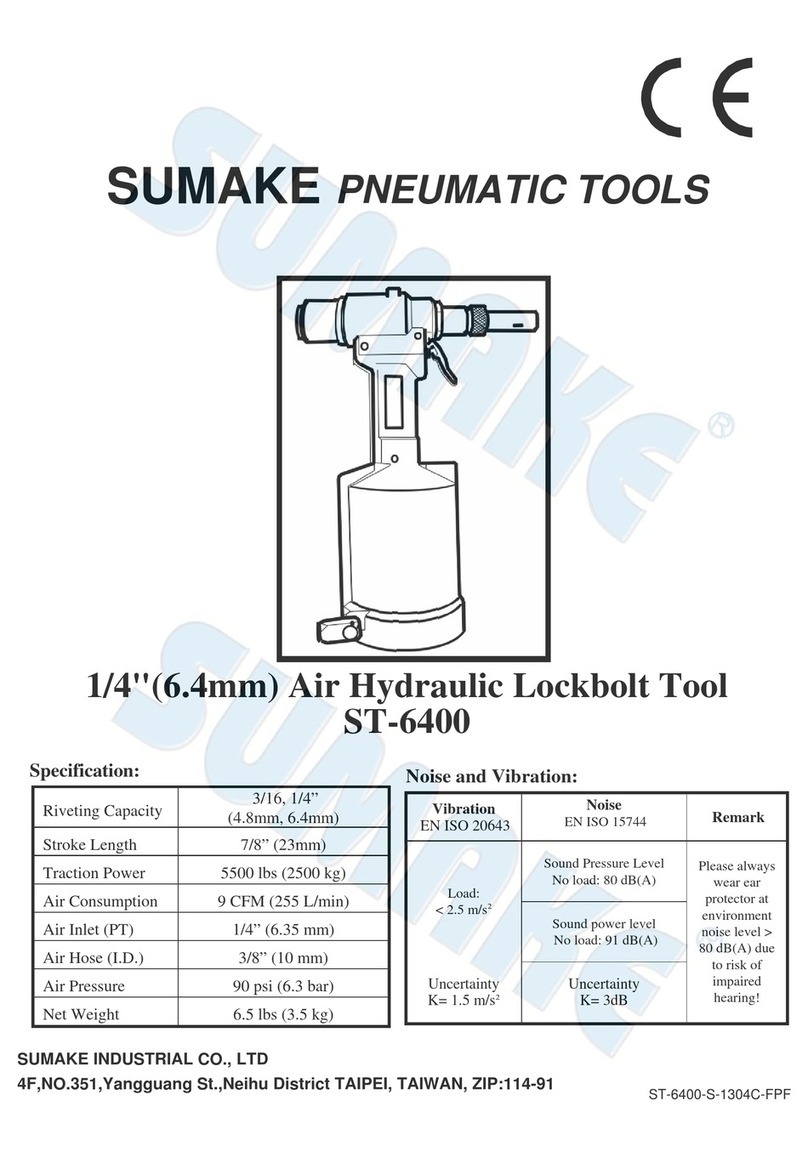

Sumake ST-6400 User manual

Sumake

Sumake ST-P6634SA User manual

Sumake

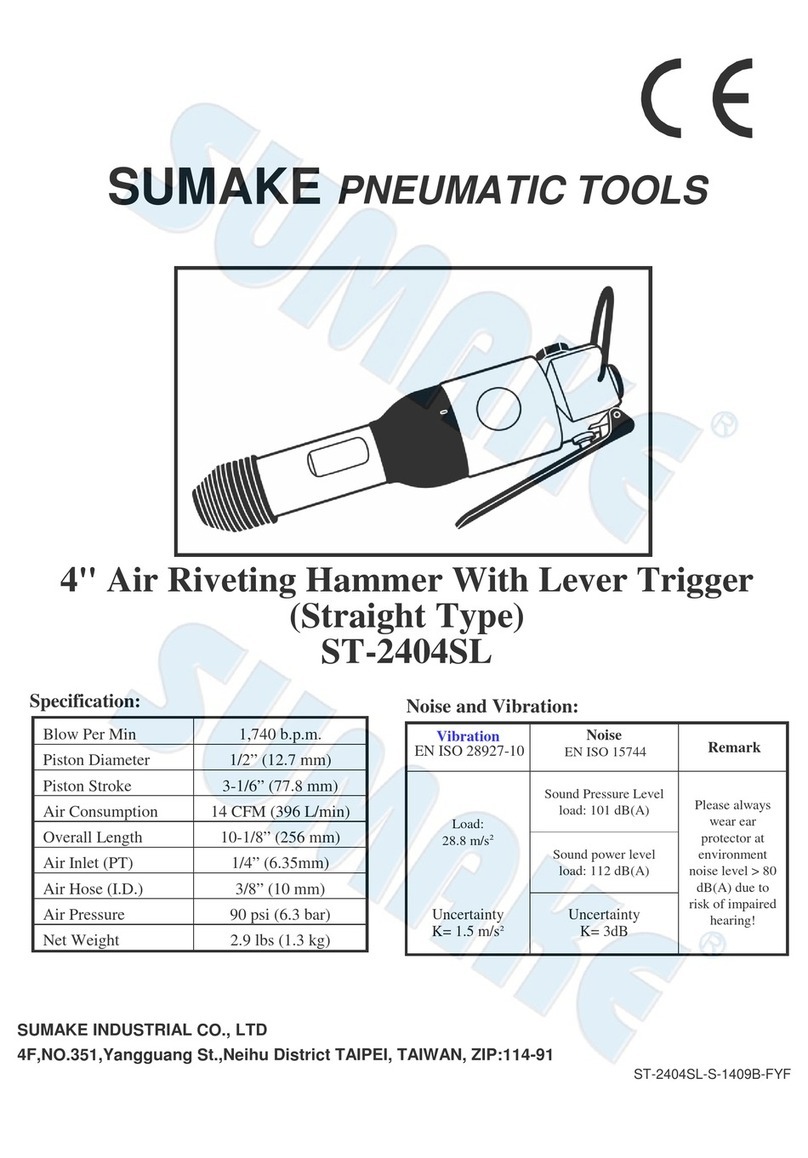

Sumake ST-2404SL User manual

Sumake

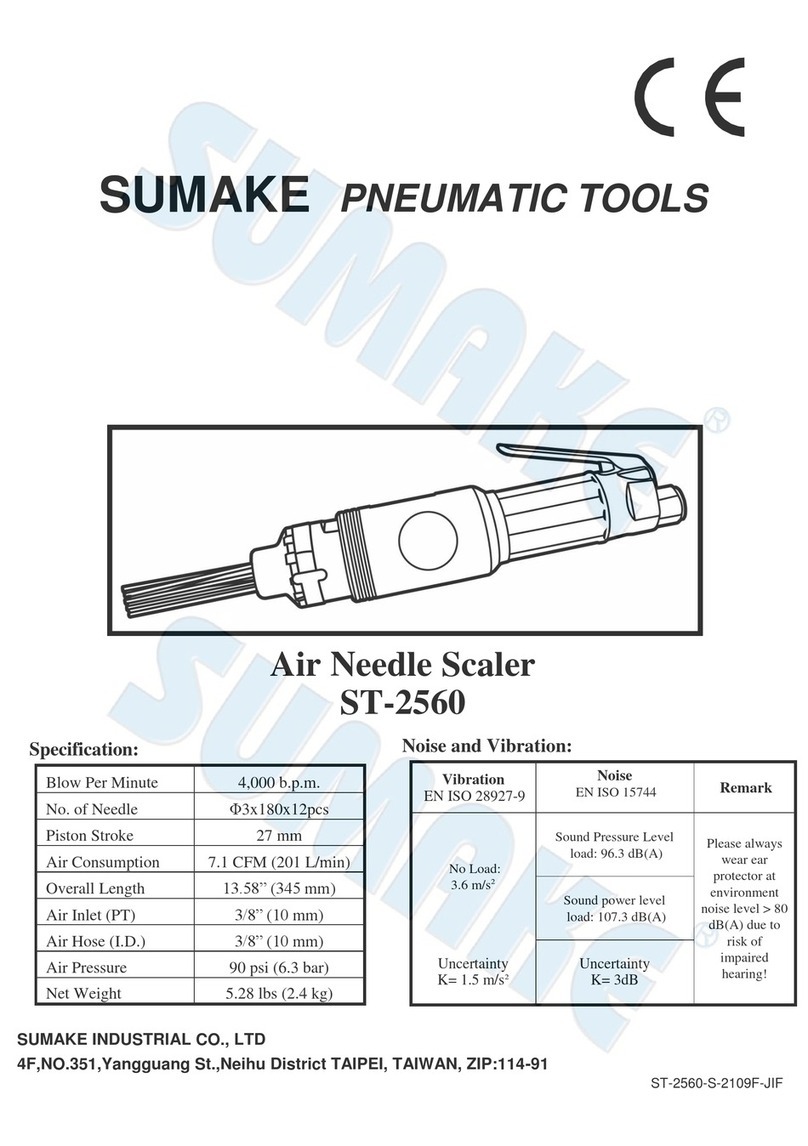

Sumake ST-2560 User manual

Sumake

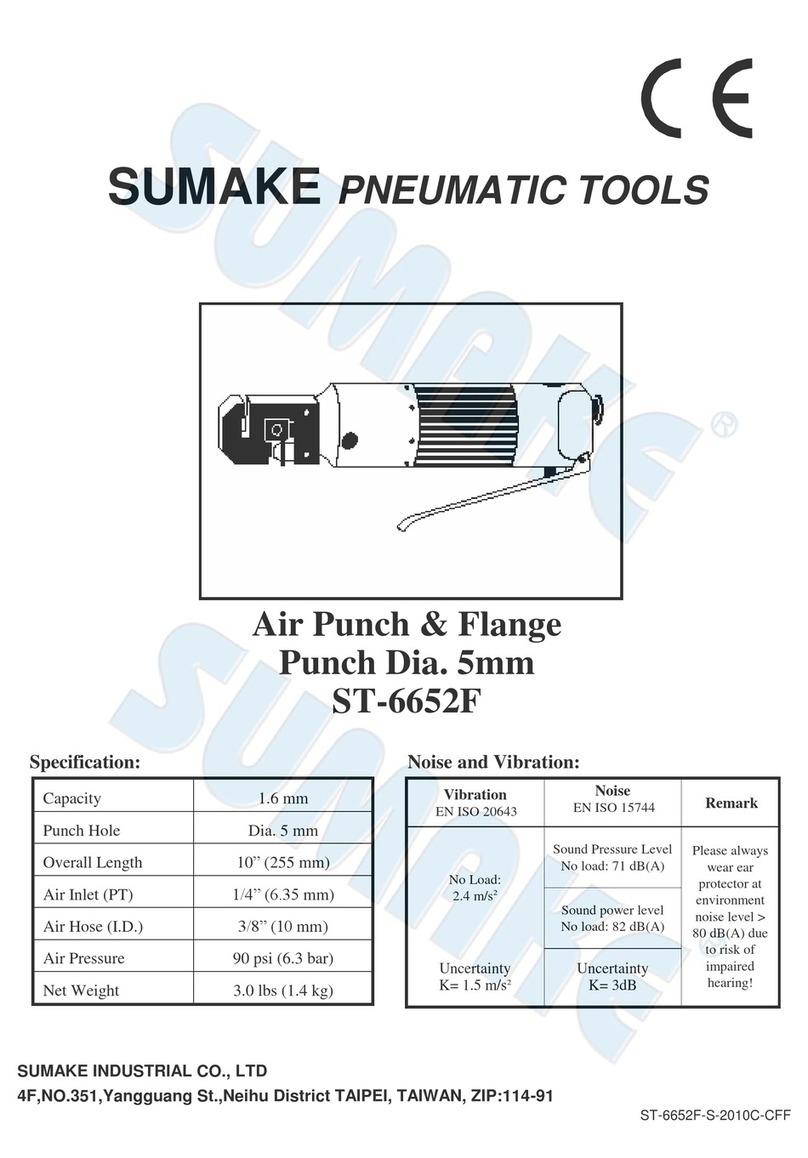

Sumake ST-6652F User manual