Sumake SAF-100 User manual

Other Sumake Tools manuals

Sumake

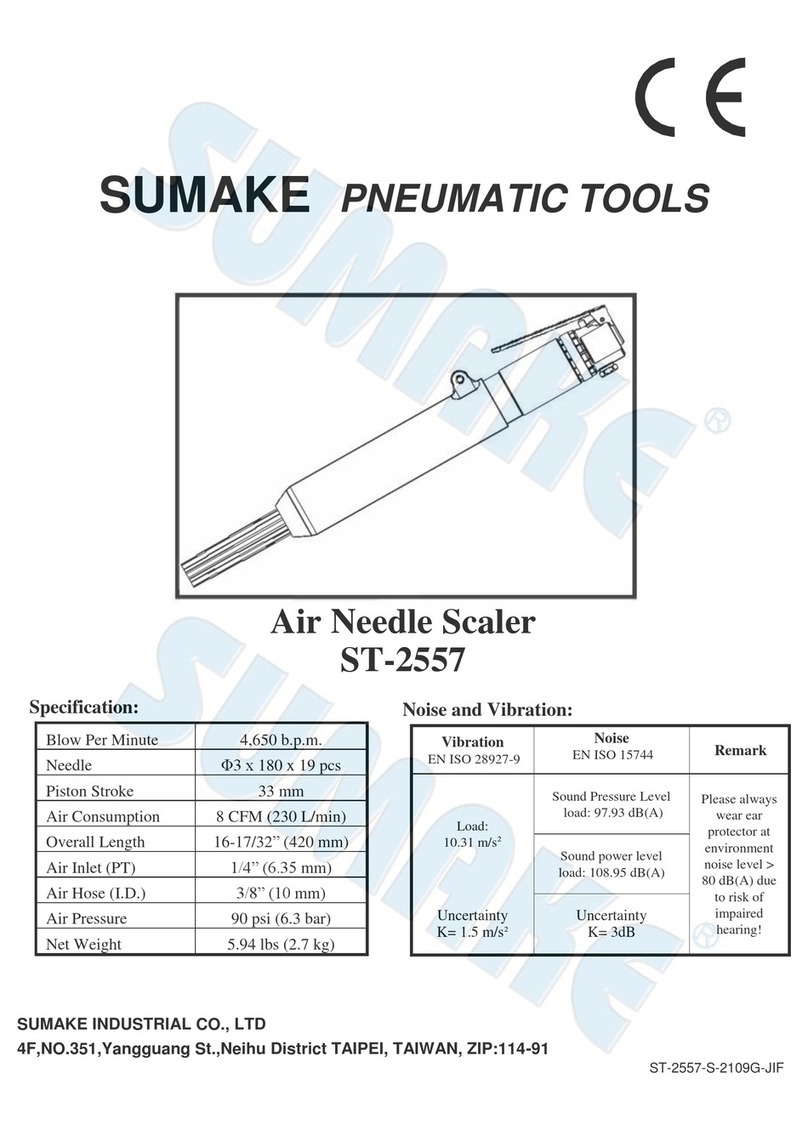

Sumake ST-2557 User manual

Sumake

Sumake SA-4013 User manual

Sumake

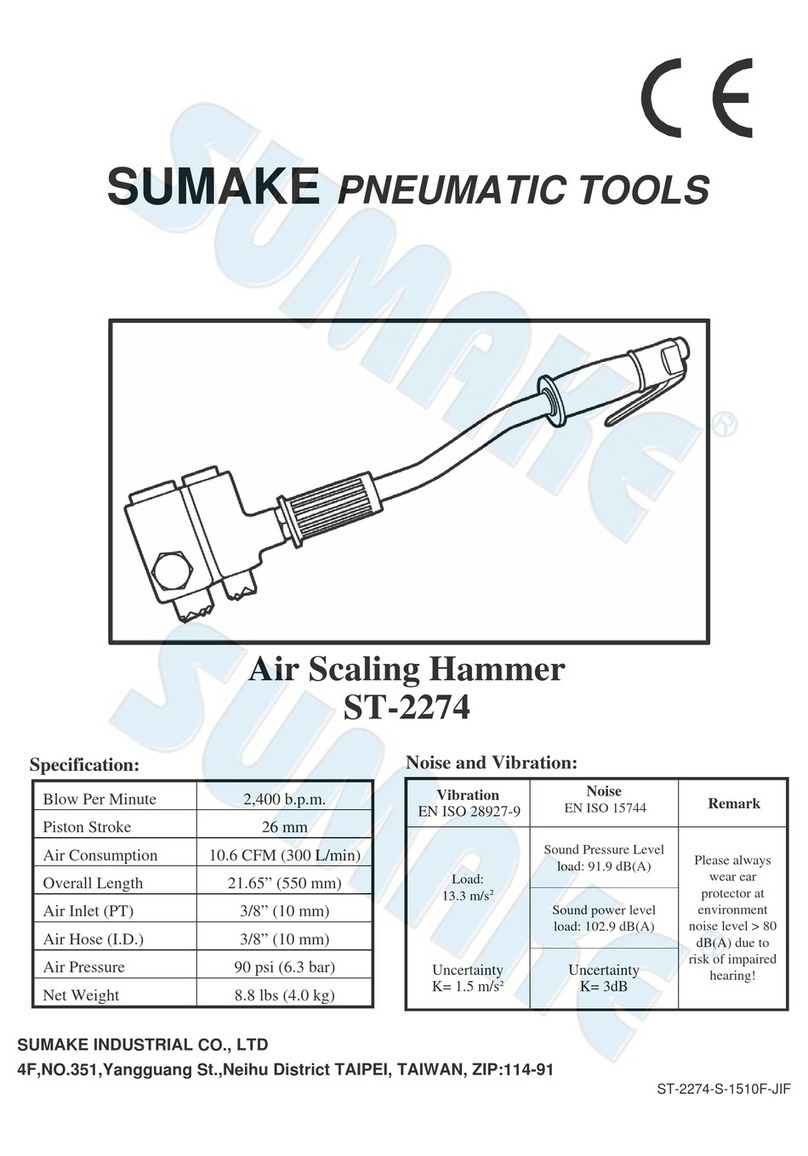

Sumake ST-2274 User manual

Sumake

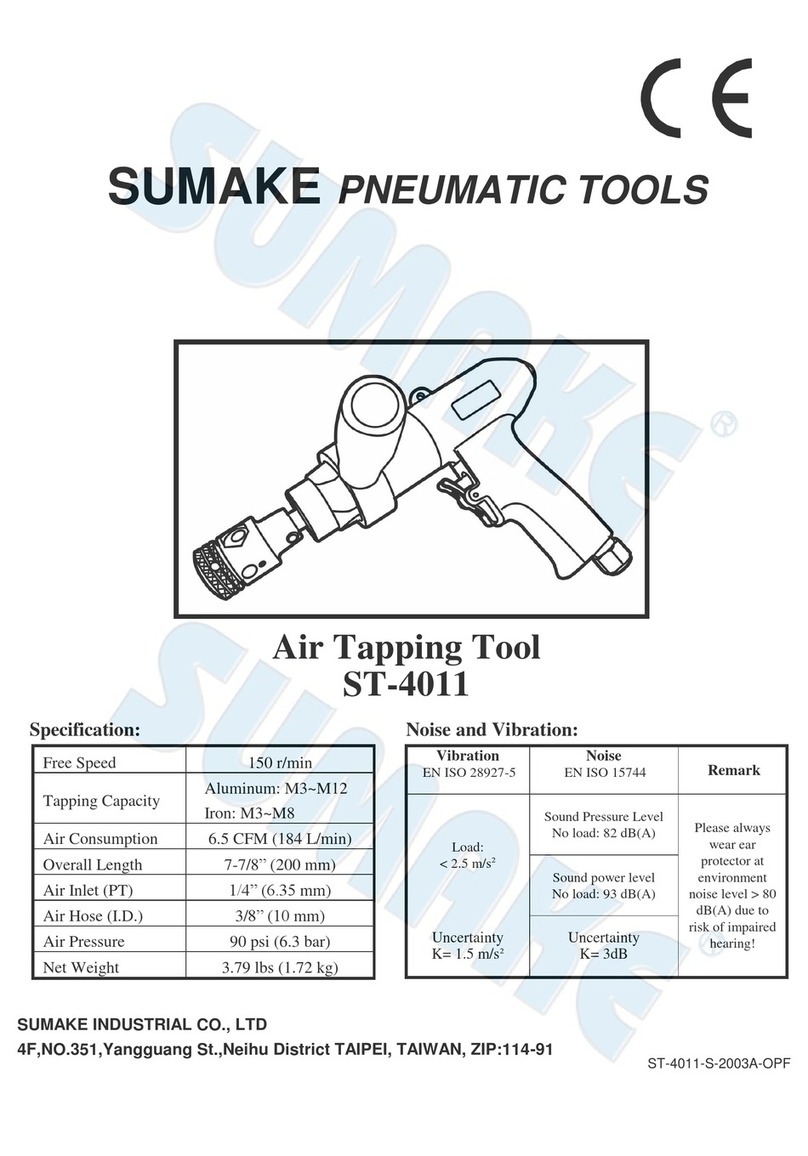

Sumake ST-4011 User manual

Sumake

Sumake ST-6410HR User manual

Sumake

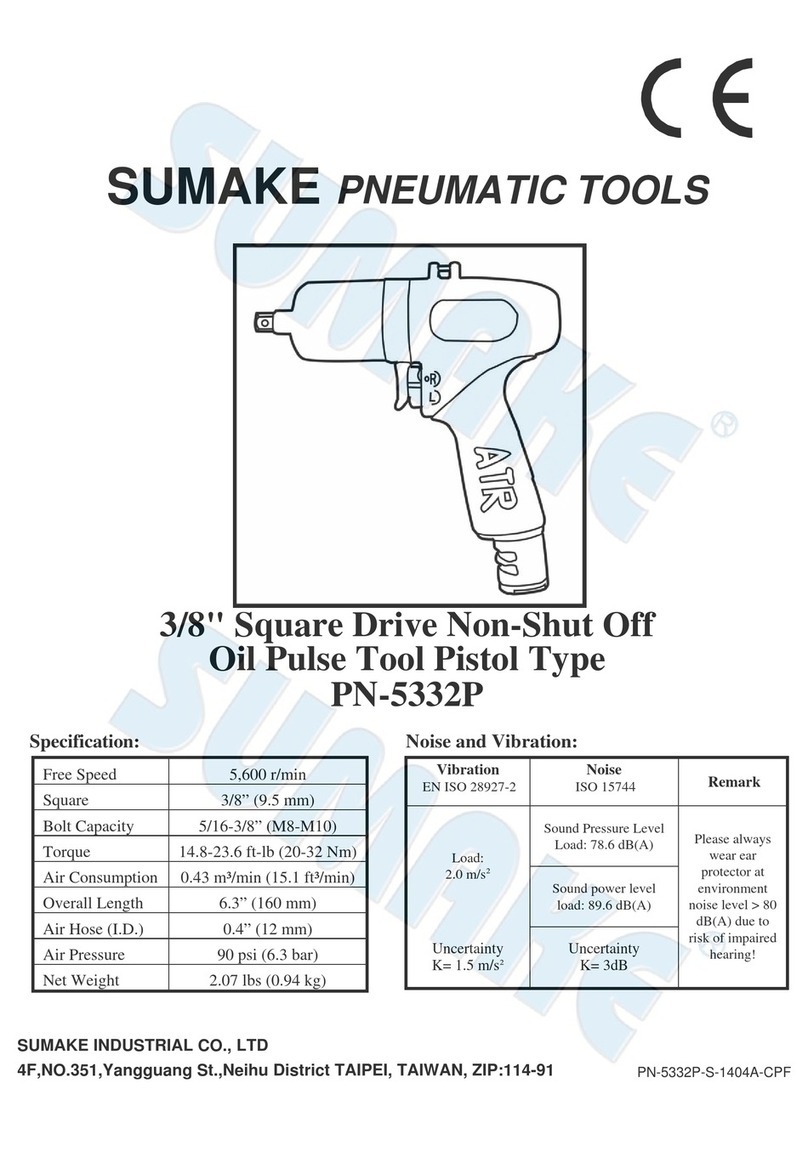

Sumake PN-5332P User manual

Sumake

Sumake ST-2510 User manual

Sumake

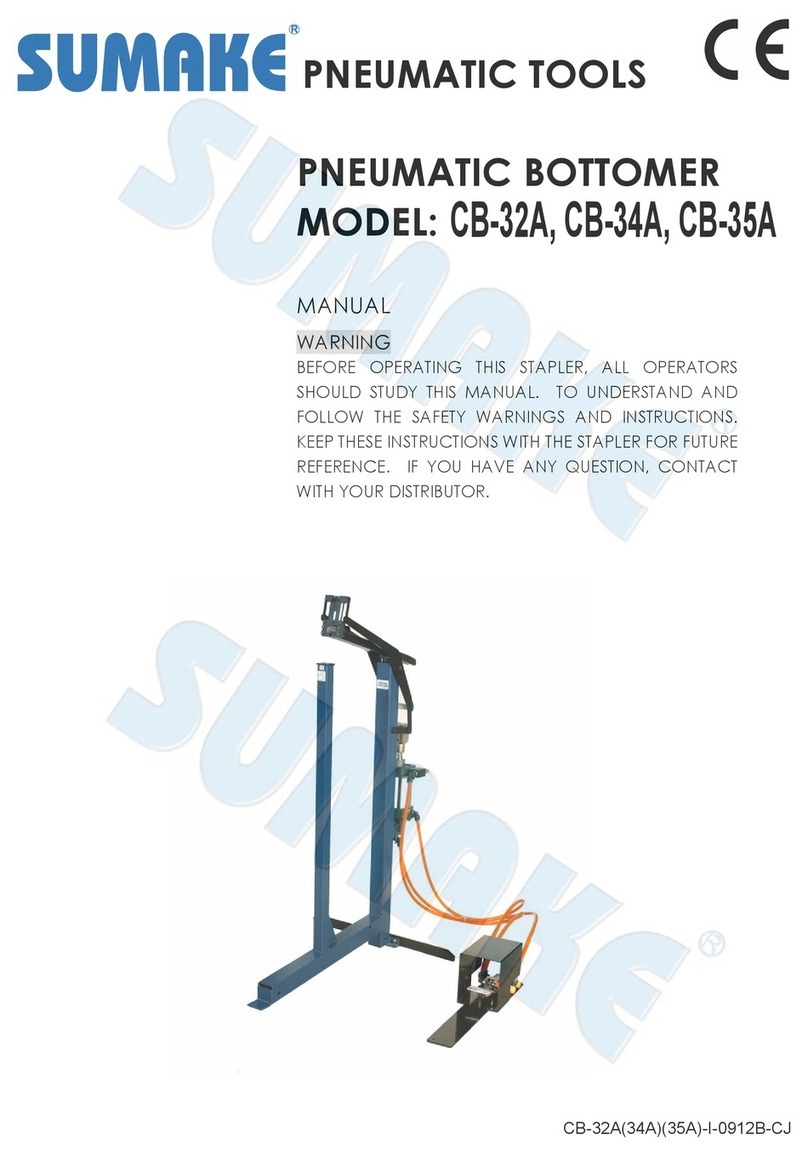

Sumake CB-32A User manual

Sumake

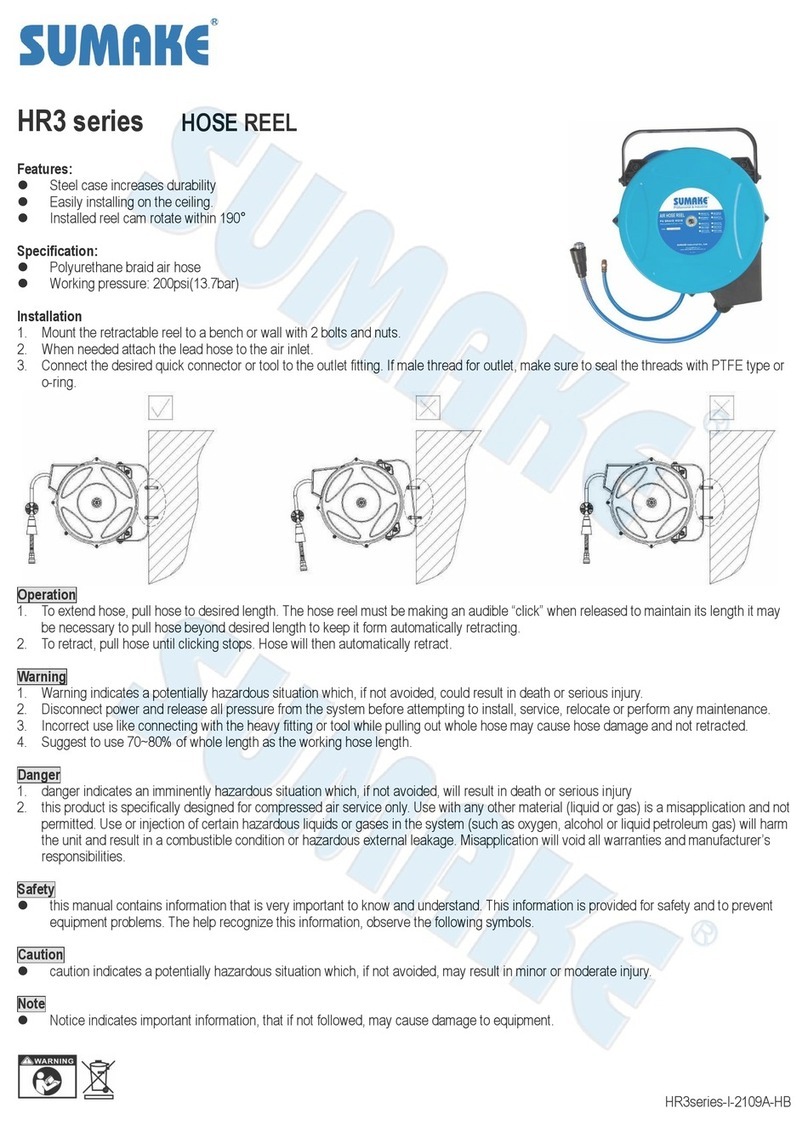

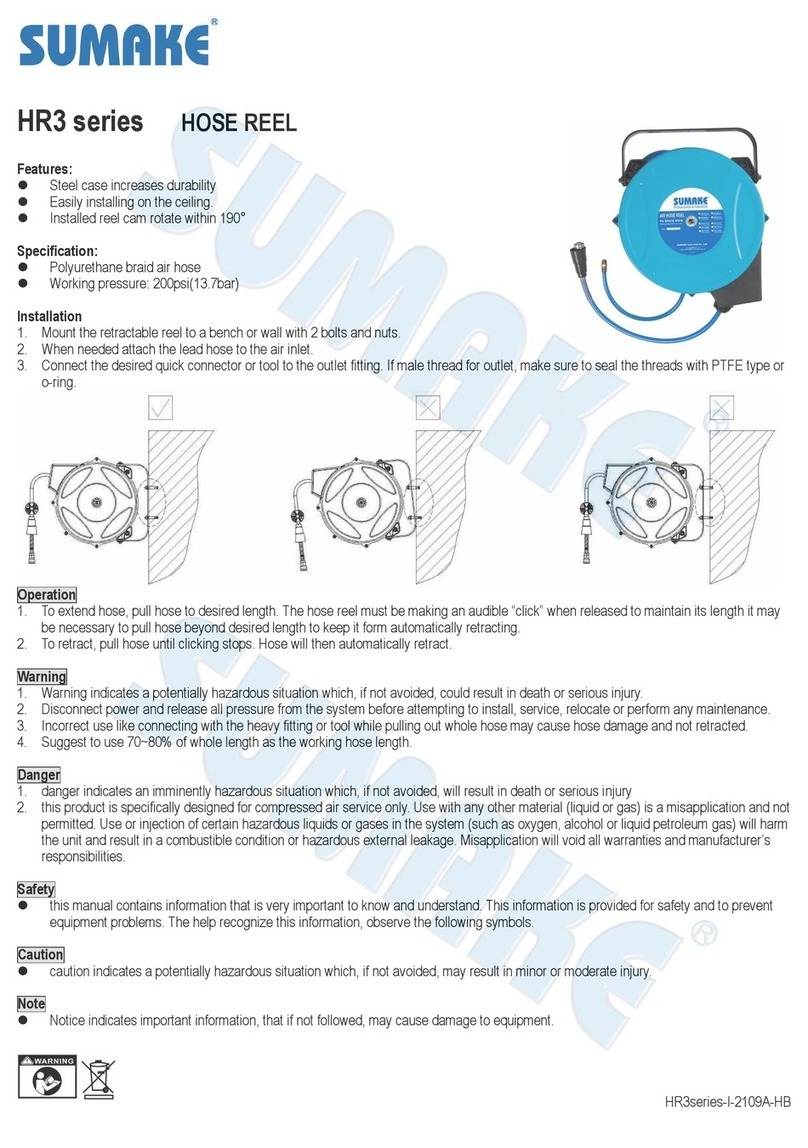

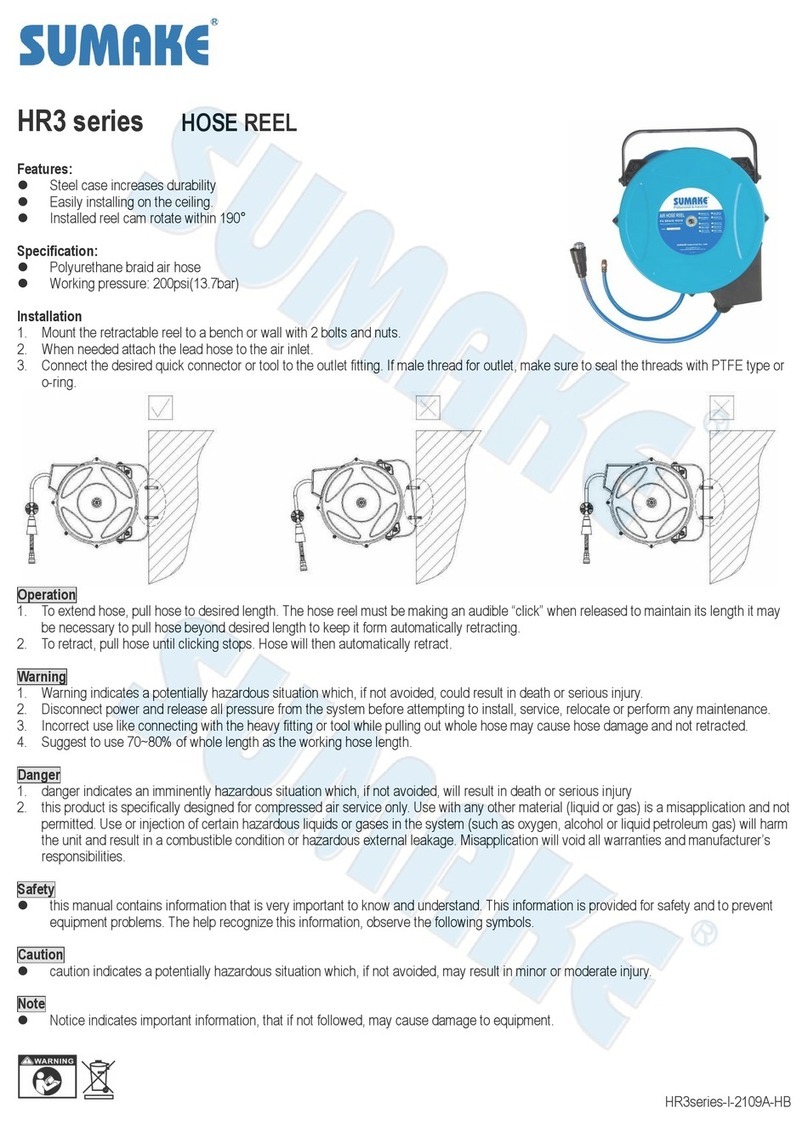

Sumake HR3 Series User manual

Sumake

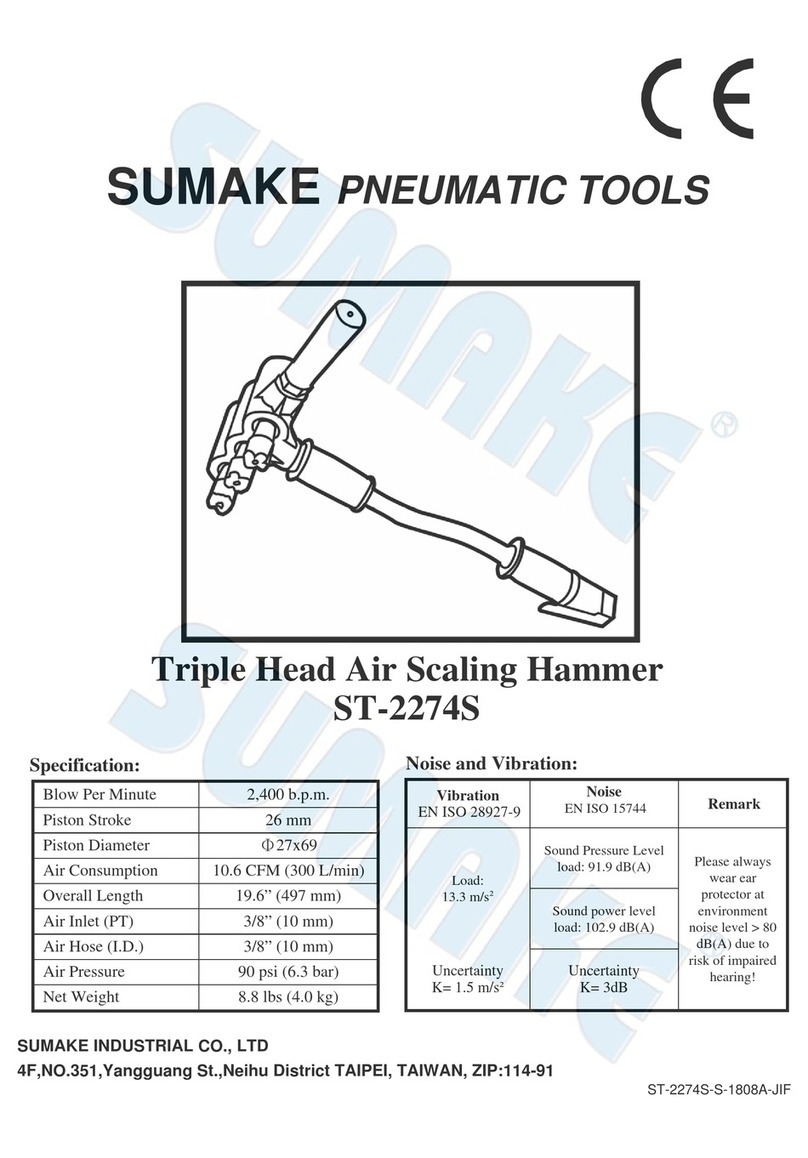

Sumake ST-2274S User manual

Sumake

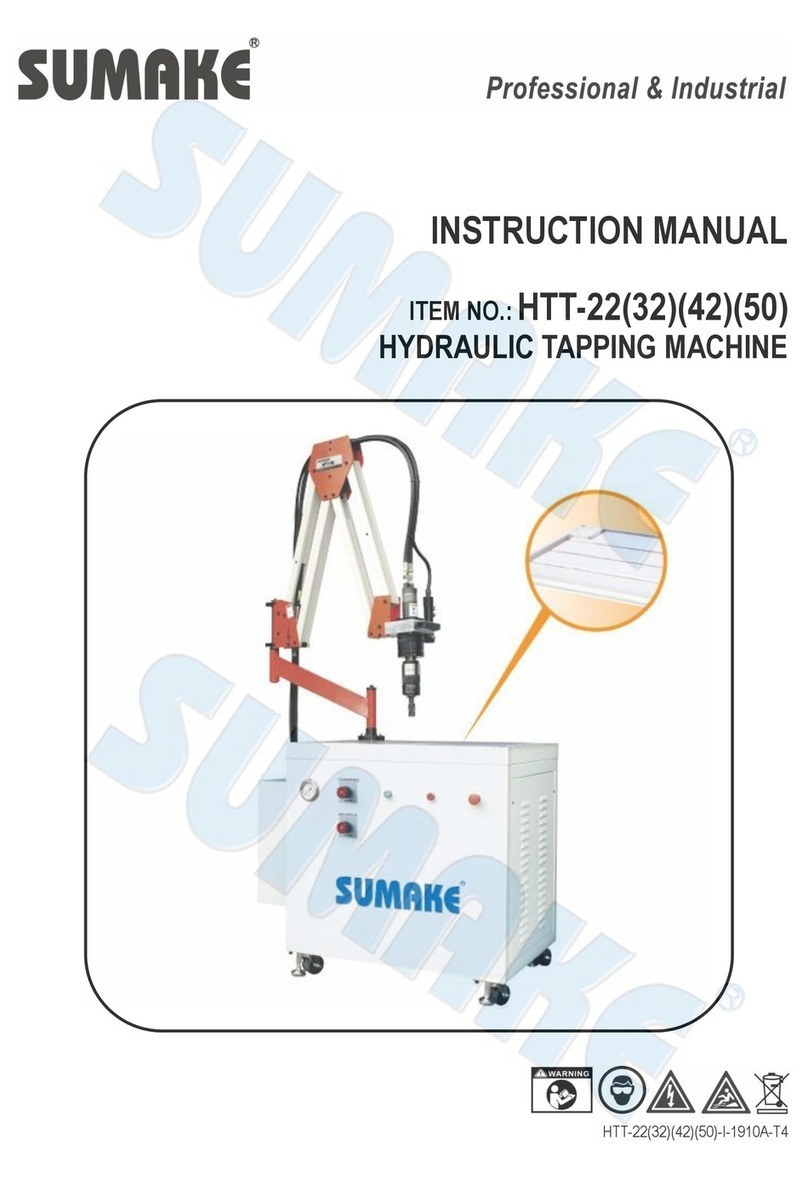

Sumake HTT-22 User manual

Sumake

Sumake HR3 Series User manual

Sumake

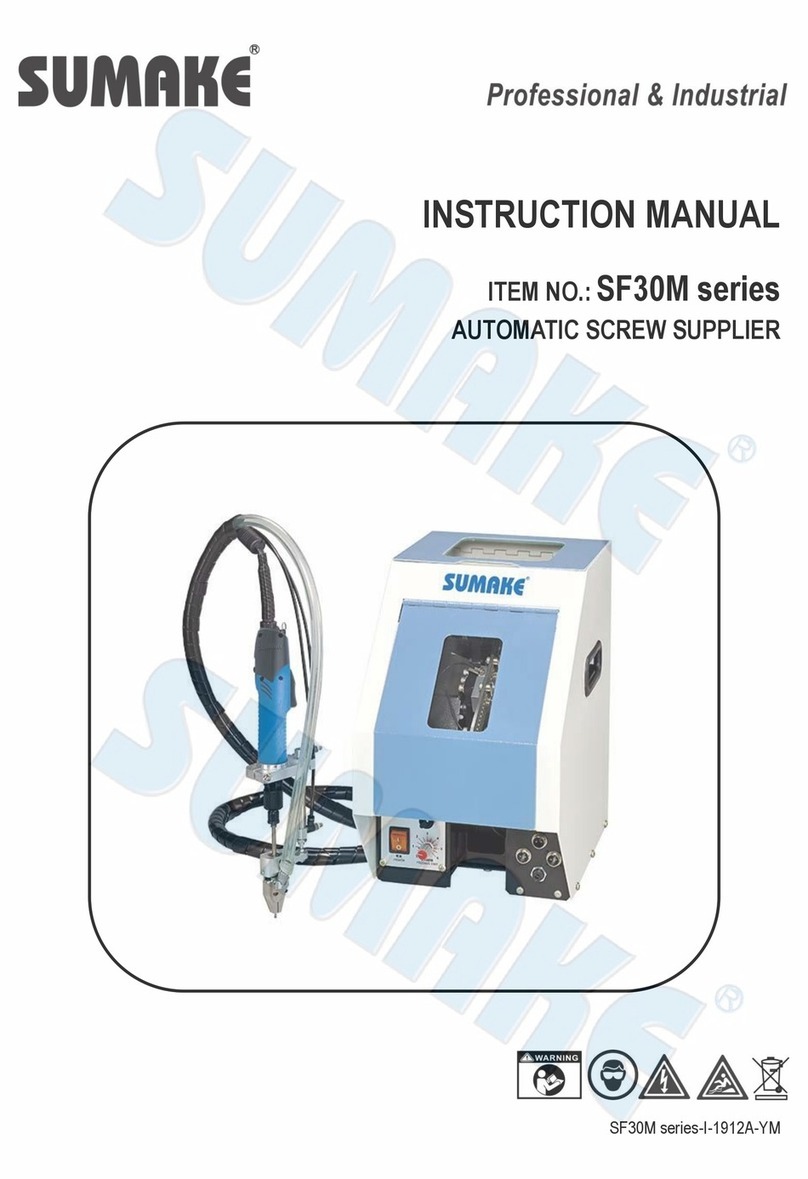

Sumake SF30M Series User manual

Sumake

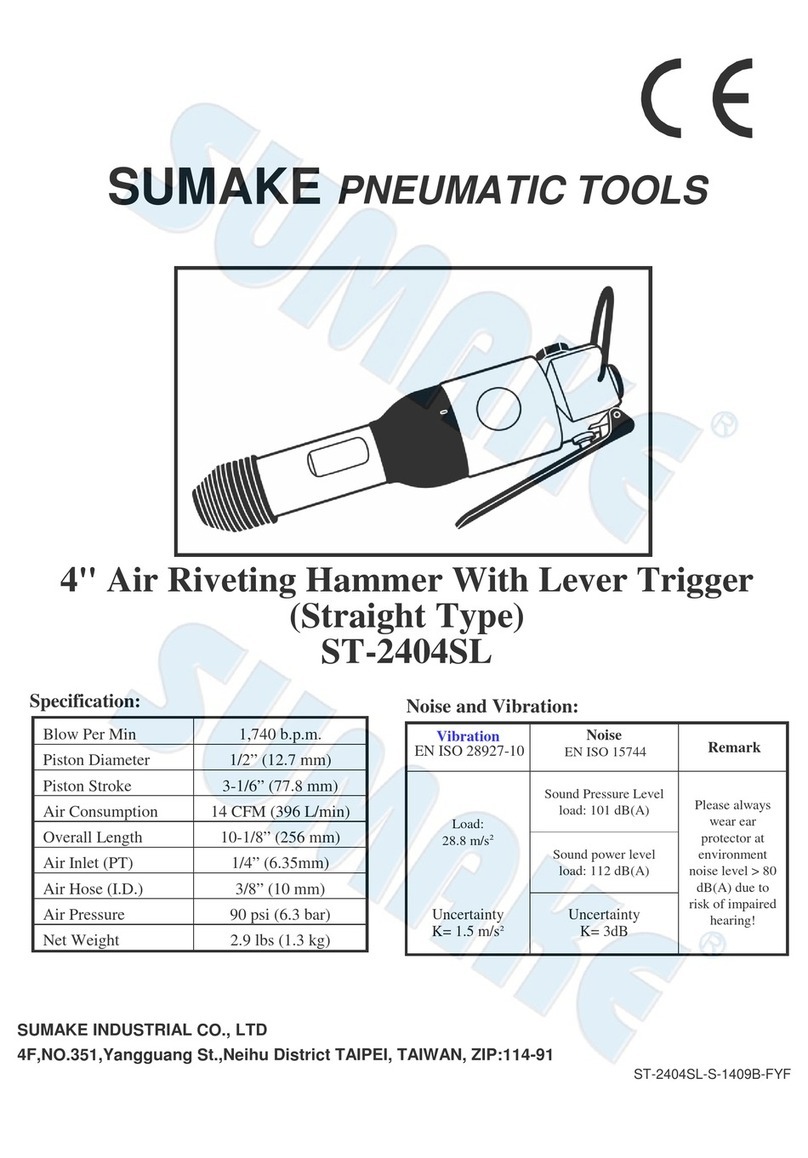

Sumake ST-2404SL User manual

Sumake

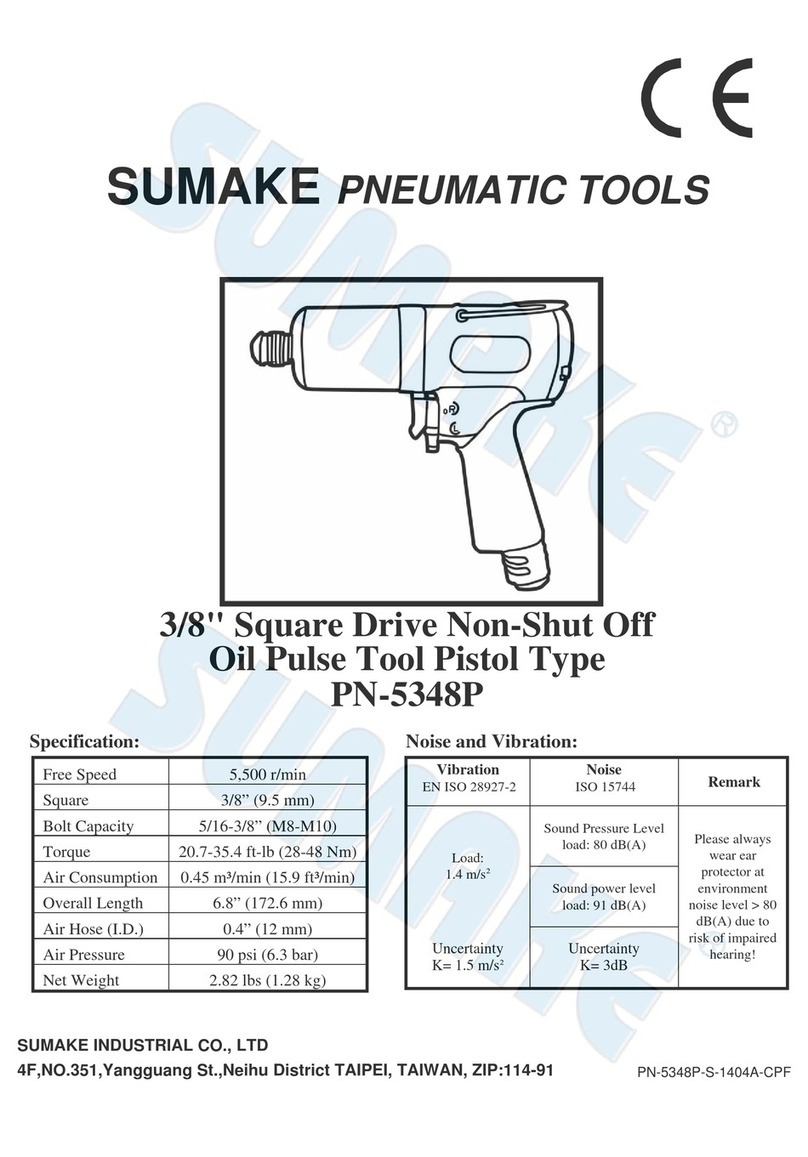

Sumake PN-5348P User manual

Sumake

Sumake ST-2002A User manual

Sumake

Sumake ST-2237/R User manual

Sumake

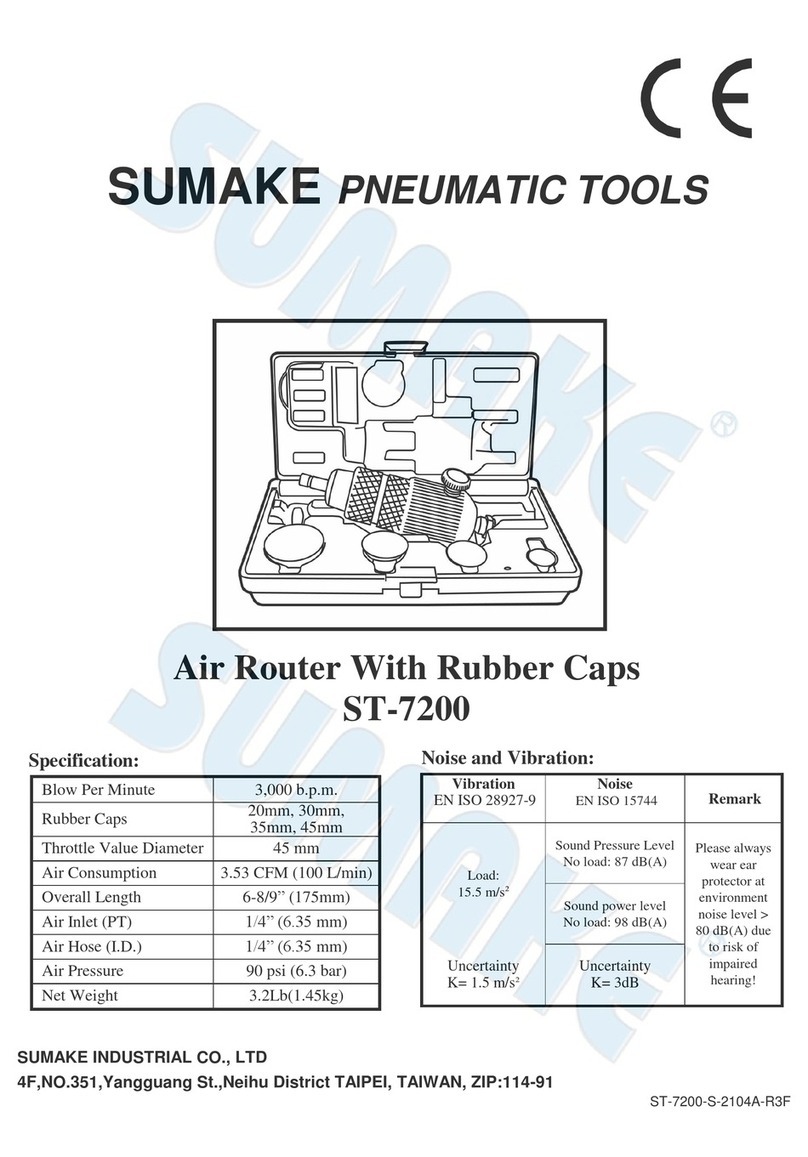

Sumake ST-7200 User manual

Sumake

Sumake HR3 Series User manual

Sumake

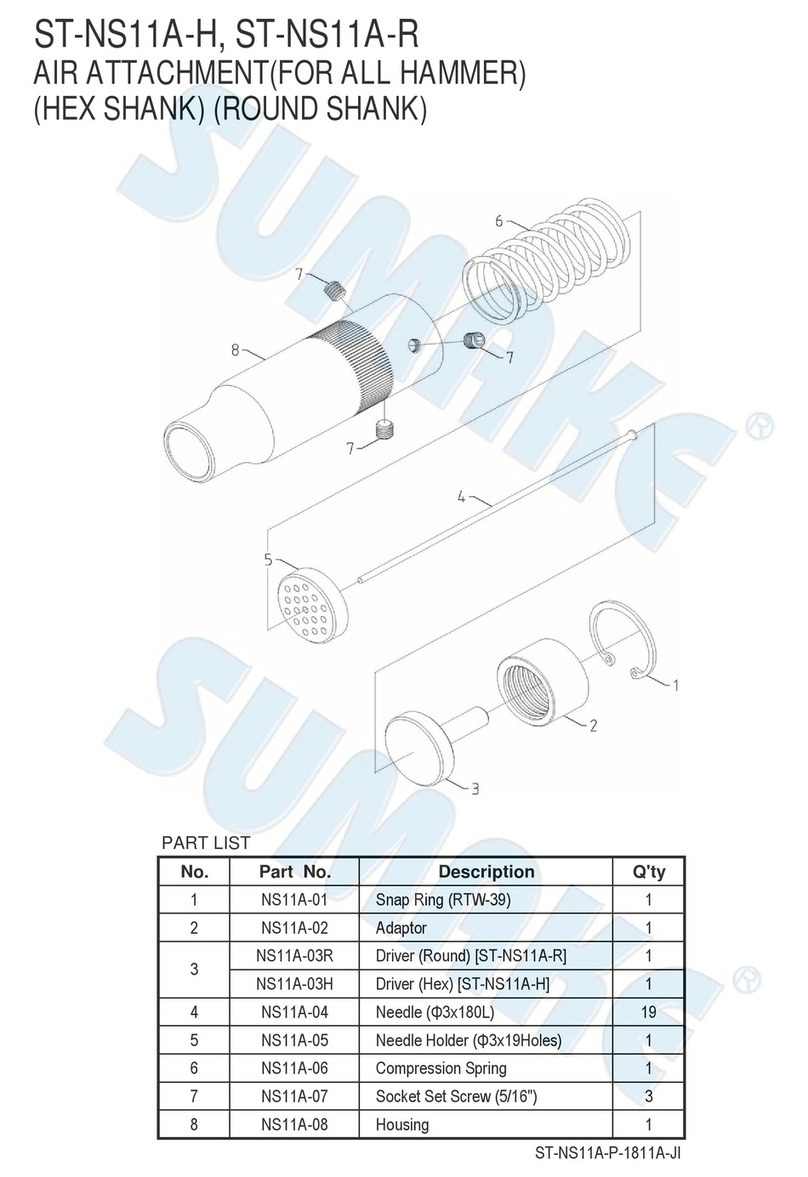

Sumake ST-NS11A-H User manual