408- 8393

Housing Removal Tool 1338744- 1

Rev A2 of 2 Tyco Electronics Corporation

5. MAINTENANCE AND INSPECTION

5.1. Daily Maintenance

It is recommended that each operator of the removal

tool be made aware of, and responsible for, the

following steps of daily maintenance:

1. Remove dust, moisture, and other contaminants

with a clean brush or a soft, lint--free cloth.

2. Make sure all components are in place and

properly secured.

3. Actuate the removal tool to ensure all

mechanisms of the tool move smoothly.

5.2. Periodic Inspection

Regular inspections should be performed by quality

control personnel. A record of scheduled inspections

should remain with the removal tool or be supplied to

personnel responsible for the removal tool. Though

recommendations call for at least one inspection a

month, the inspection frequency should be based on

the amount of use, ambient working conditions,

operator training and skill, and established company

standards. These inspections should include a visual

inspection and should be performed in the sequence

listed:

1. Remove any accumulated dirt and debris that

could affect the operation of the removal tool.

2. Make sure all components are in place and are

properly secured.

3. Check for chipped, cracked, worn, or broken

areas. If damage is evident, repair is necessary.

See Section 6, REPLACEMENT AND REPAIR.

6. REPLACEMENT AND REPAIR

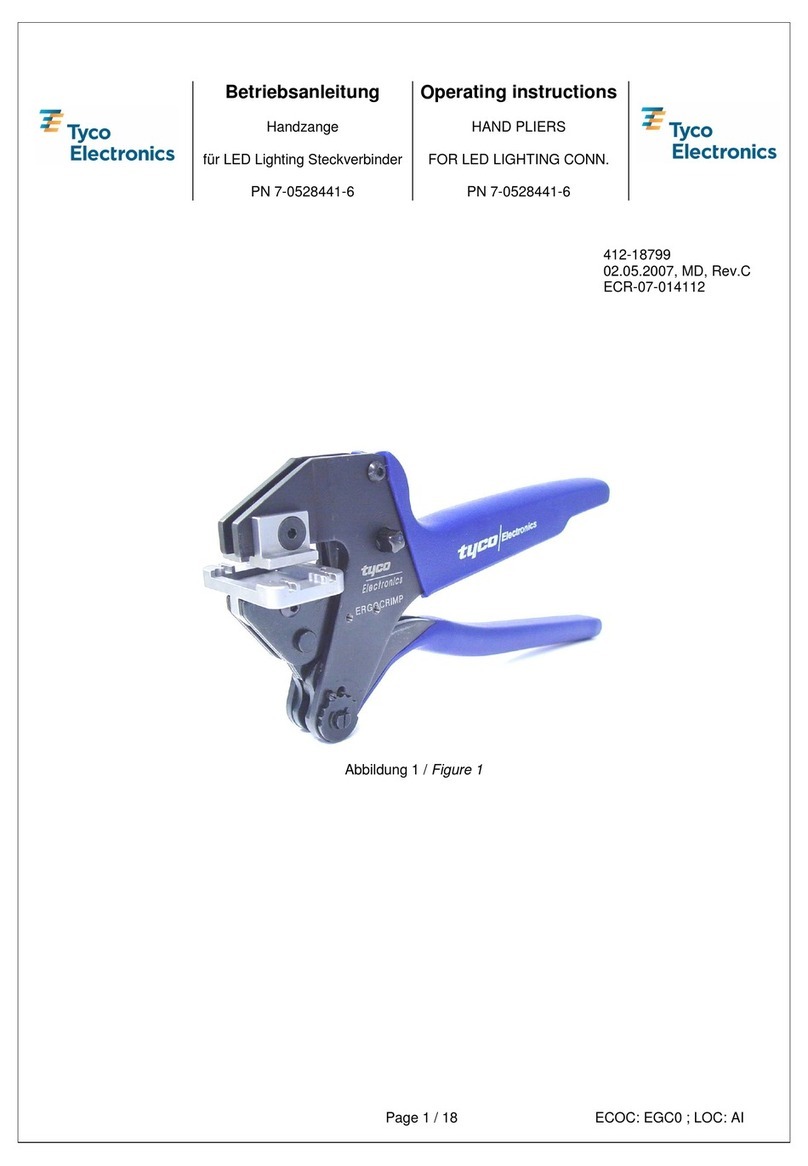

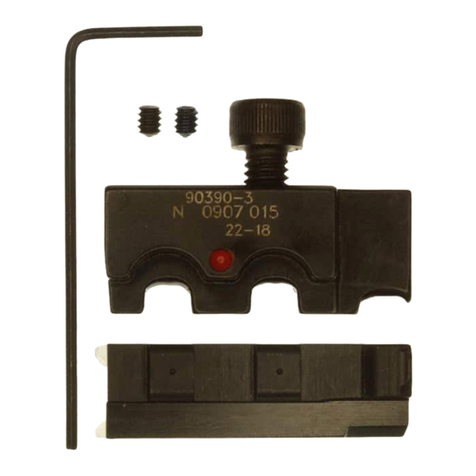

Replacement parts are listed in Figure 3. Parts other

than those listed in Figure 3 should be replaced by

Tyco Electronics to ensure quality and reliability of the

removal tool. Order replacement parts through your

representative, or call 1--800--526--5142, or send a

facsimile of your purchase order to 1--717--986--7605,

or write to:

CUSTOMER SERVICE (38--35)

TYCO ELECTRONICS CORPORATION

PO BOX 3608

HARRISBURG PA 17105--3608

For customer repair service, call 1--800--526--5136.

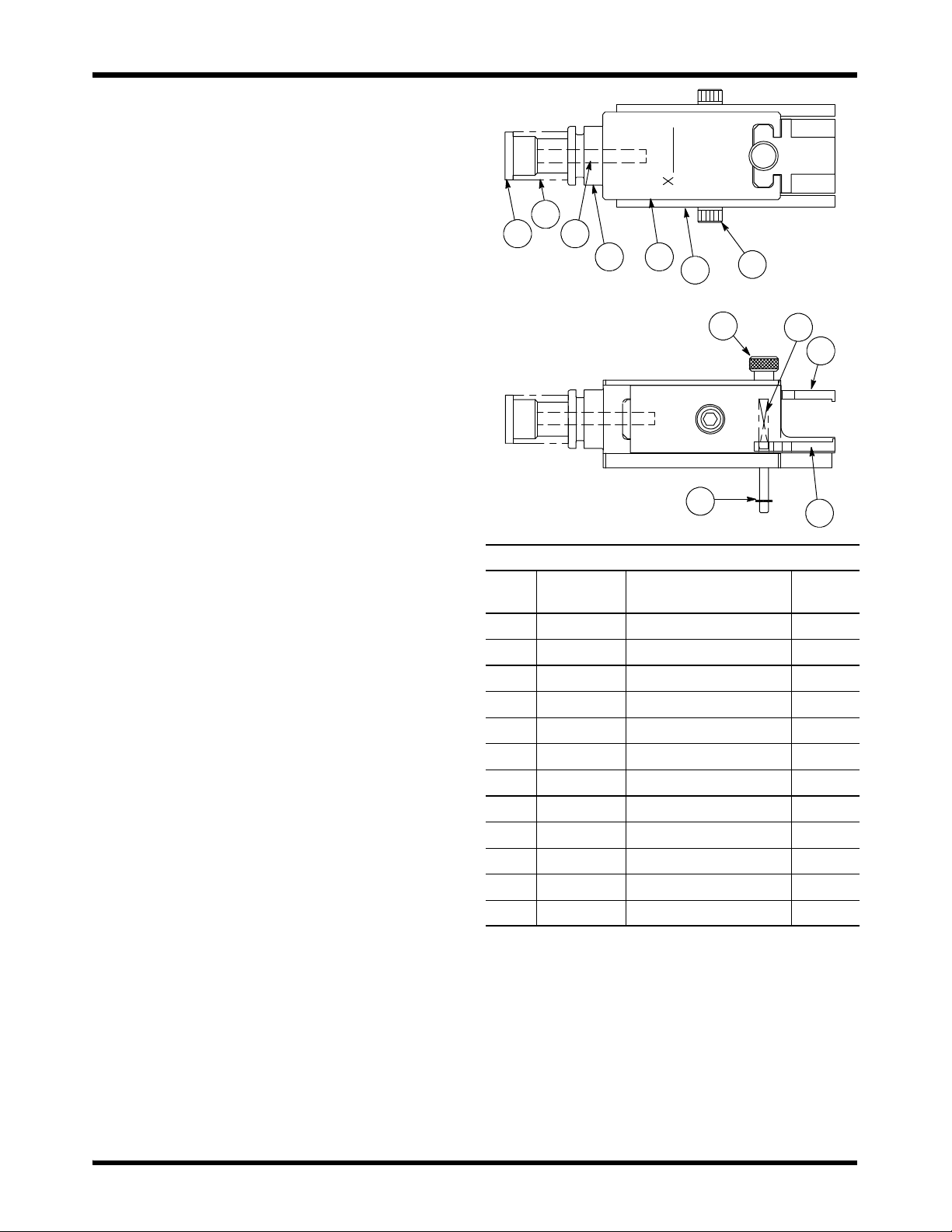

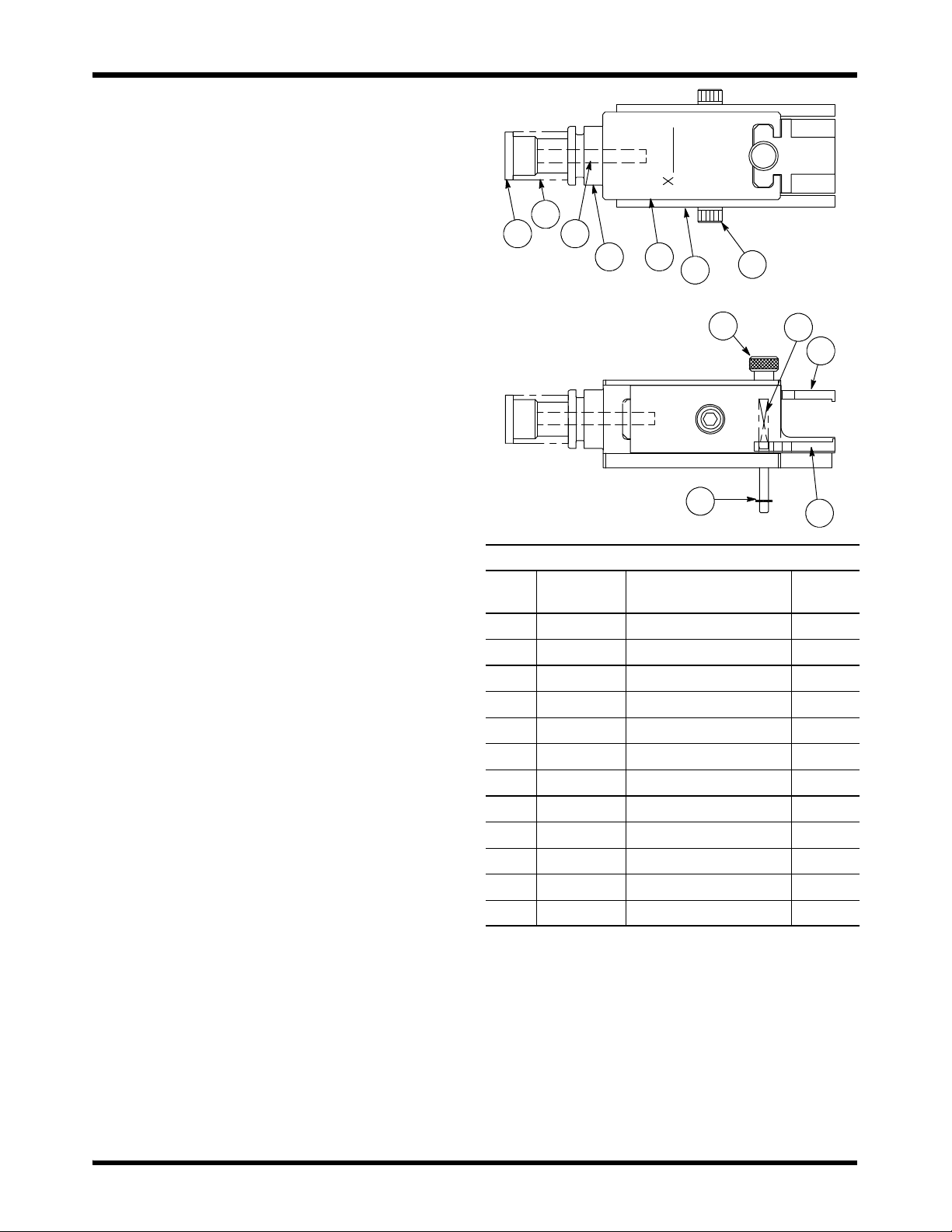

1

2

3

4 5 67

12

11

10

9

8

REPLACEMENT PARTS

ITEM PART

NUMBER DESCRIPTION QTY PER

TOOL

1-- 312149--1 ROD, Insertion Adjuster 1

2-- 0 22488--5 SPRING, Compression 1

31--21007--2 SCREW, Set 1

41320254--1 HEAD, Machined 1

51338748--1 BAR, Drive 1

61338749--1 BAR, Side Push 2

7-- 0 21000--7 SCREW, Socket Head Cap 2

8-- 21986--4 RING, Retaining 2

91320261--1 SCREW, Clamp 1

1002--22278--1 SPRING, Compression 2

1101338753--1 CLAMP, Upper 1

1201338754--1 CLAMP, Lower 1

Figure 3

7. REVISION SUMMARY

Revisions to this instruction sheet include:

SUpdated instruction sheet to corporate

requirements