Suncast Brilliant by Design Vista BMS7702 User manual

Register

your

product

for

Limited

Warranty!

Must

register

product

within

90

days

of

purchase

for

limited

warranty

Register

Scan

for

updated

Limited

Warranty

Warranty

www.suncast.com/warranty

or

call

US

1 (

800)

846-2345

Have

Questions?

We

are

here

to

help.

Check

out

our

resource

library

along

with

helpful

tips,

videos

and

FAQ's.

You

may

call

the

Contact

Center

directly

at:

1 (

800)

846-2345

or

write

Suncast

Corporation,

Contact

Center,

701

N.

Kirk

Road,

Batavia,

IL

60510 (

USA)

To

purchase

Suncast

replacement

parts

and

learn

about

other

Suncast

products

visit

us

online

or

call.

www.suncast.com

1-800-846-2345

or

1-630-381-6309

A

Before

You

Begin...

•

Consult

your

local

authorities

for

any

permits

required

to

construct

shed.

Prior

to

the

construction

of

your

shed,

check

with

the

local

building

code

official

to

review

any

required

permits

or

building

limitations.

• A

level

and

sturdy

foundation

is

required

before

shed

construction

can

begin.

Site

preparation

information

is

available

on

pages

11-12.

A

foundation

that

differs

from

the

suggestions

within

this

manual

could

prevent

proper

assembly

and

may

damage

parts.

•

Read

instructions

thoroughly

prior

to

assembly.

This

kit

contains

parts

that

can be

damaged

if

assembled

incorrectly

or

in

the

wrong

sequence.

•

Please

follow

instructions.

Suncast

is

not

responsible

for

replacing

parts

lost

or

damaged

due

to

incorrect

assembly.

•

Assistance

is

required

during

entire

assembly.

[

I]

IMPORTANT

OPEN

ALL

BOXES

FIRST

AND

NEATLY

LAYOUT

PARTS.

SMALL

PARTS

MAY

BE

CONTAINED

IN

EACH

BOX.

PLEASE

REFERENCE

PARTS

LIST

WITHIN

THIS

MANUAL

TO

VERIFY

ALL

PARTS

ARE

PRESENT.

COMPLETE

SITE

PREPARATION

AND

FOUNDATION

CONSTRUCTION

BEFORE

UNPACKING

ALL

PARTS.

A

CAUTION

•

Proper

site

preparation

required.

•

Shed

not

intended

for

use

in

extreme

weather

conditions.

•

Shed

not

intended

for

storage

of

flammable

or

caustic

chemicals.

•

Store

heavy

items

near

the

bottom

of

shed.

•

Shed

not

intended

for

use

by

children.

•

DO

NOT

stand,

sit,

or store

items

on

storage

shed

roof.

•

Treat

carefully

in

extreme

temperatures.

•

Repair

or

replace

broken

parts

immediately.

•

Suncast

is

not

responsible

for

damage

caused

by

weather

or

misuse.

•

At

regular

intervals,

inspect

your

shed

to

make

sure

that

assembly

integrity

has

been

maintained.

•

Periodically

check

that

the

location

you

have

chosen

to

set

your

shed

is

still

level.

•

This

kit

contains

parts

with

metal

edges.

Please

be

careful

when

handling.

3

A

Shed

Safety

and

Care

•

Hot

items,

such

as

recently

used

grills,

blowtorches,

etc.,

must

not

be

stored

in

the

shed.

•

Heavy

articles

should

not

be

leaned

against

the

walls,

as

this

may

cause

panel

distortion

and

permanent

damage.

•

Keep

roof

clean

of

snow

and

leaves.

•

The

shed

walls

and

roof

sections

have

a

textured

exterior,

much

like

vinyl

home

siding.

Over

time,

dust

may

accumulate

in

the

texture.

When

combined

with

moisture,

this

could

encourage

the

growth

of

moss

or

mold on

the

shed.

To

maintain

the

look

of

your

shed,

we

recommend

cleaning

it

each

year

with

mild

soap and

water.

DO

NOT

use

bleach,

ammonia,

or

other

caustic

cleaners,

and

DO

NOT

use

stiff

bristle

brushes.

Failure

to

perform

annual

cleaning

could

result

in

permanent

staining of

the

plastic.

This

is

not

a

manufacturing

defect

and

is

not

covered

under

warranty.

Assembly

Day

Tips

•

Complete

site

preparation

and

foundation

construction

before

unpacking

parts

and

beginning

assembly.

•

DO

NOT

attempt

to

assemble

on

a

day

with

strong

winds.

•

DO

NOT

attempt

to

assemble

on days

when

temperature

is

below

32 degrees

Fahrenheit.

•

Set

aside

appropriate

amount

of

time

to

completely

assemble

shed.

•

Make

sure

you

have

assistance

nearby

to

lift

and

secure

parts

in

place.

•

Wear

light

duty

work

gloves

while

assembling

shed.

•

Once

roof

is

assembled,

a

flashlight

may

be

of

use

when

assembling

smaller

components

inside

shed.

•

DO

NOT

use

a

torque

wrench

or

hand

drill

to

tighten

provided

Easy

bolts.

Use

010210410

Easy

Bolt

Easy

Driver

tool (

provided)

ONLY.

•

Suncast

provides

extra

hardware

for

small

fasteners

for

customer

convenience.

In

some

cases,

there

will

be

extra

small

fasteners

once

the

assembly

is

complete.

Note:

This

product

contains

parts

that

are

used

in

different

orientations

to

construct

the

shed.

Please

take

note

of

the

orientation

of

the

parts

shown

throughout

this

instruction

manual.

Failure

to

follow

instructions

could

result

in

damage

to parts.

Suncast

is

not

responsible

for

replacing

parts

lost

or

damaged

due

to

incorrect

assembly.

4

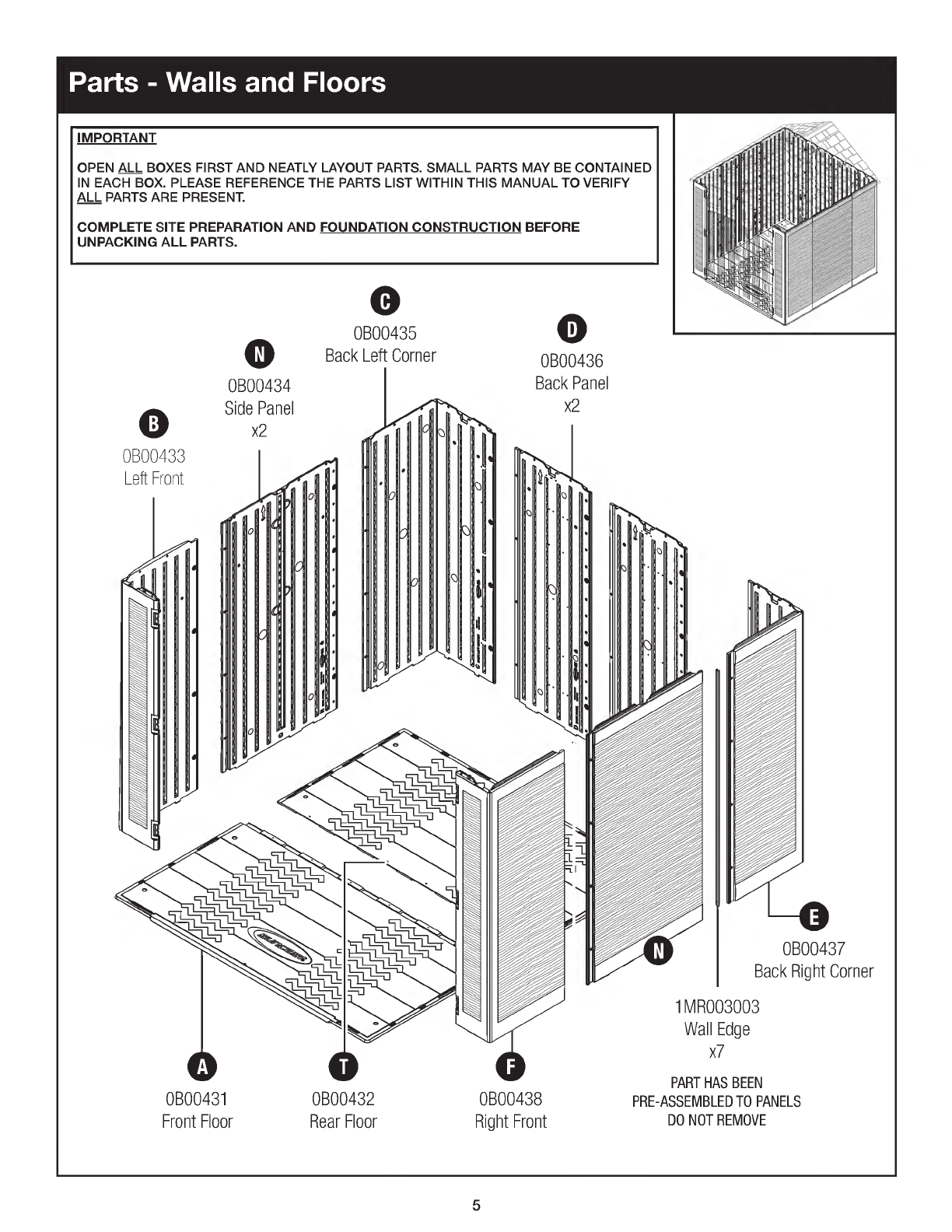

Parts -

Walls

and

Floors

-

IMPORTANT

OPEN

ALL

BOXES

FIRST

AND

NEATLY

LAYOUT

PARTS.

SMALL

PARTS

MAY

BE

CONTAINED

IN

EACH

BOX.

PLEASE

REFERENCE

THE

PARTS

LIST

WITHIN

THIS

MANUAL

TO

VERIFY

ALL

PARTS

ARE

PRESENT.

COMPLETE

SITE

PREPARATION

AND

FOUNDATION

CONSTRUCTION

BEFORE

UNPACKING

ALL

PARTS.

0

OB00433

Left

Front

o

OB00435

0

Back

Left

Corner

OB00434

Side

Panel

x2

OB00431

Front

Floor

OB00432

Rear

Floor

o

OB00436

Back

Panel

x2

OB00438

Right

Front

OB00437

Back

Right

Corner

1M

R003003

Wall

Edge

x7

PART

HAS

BEEN

PRE-

ASSEMBLED

TO

PANELS

DO

NOT

REMOVE

5

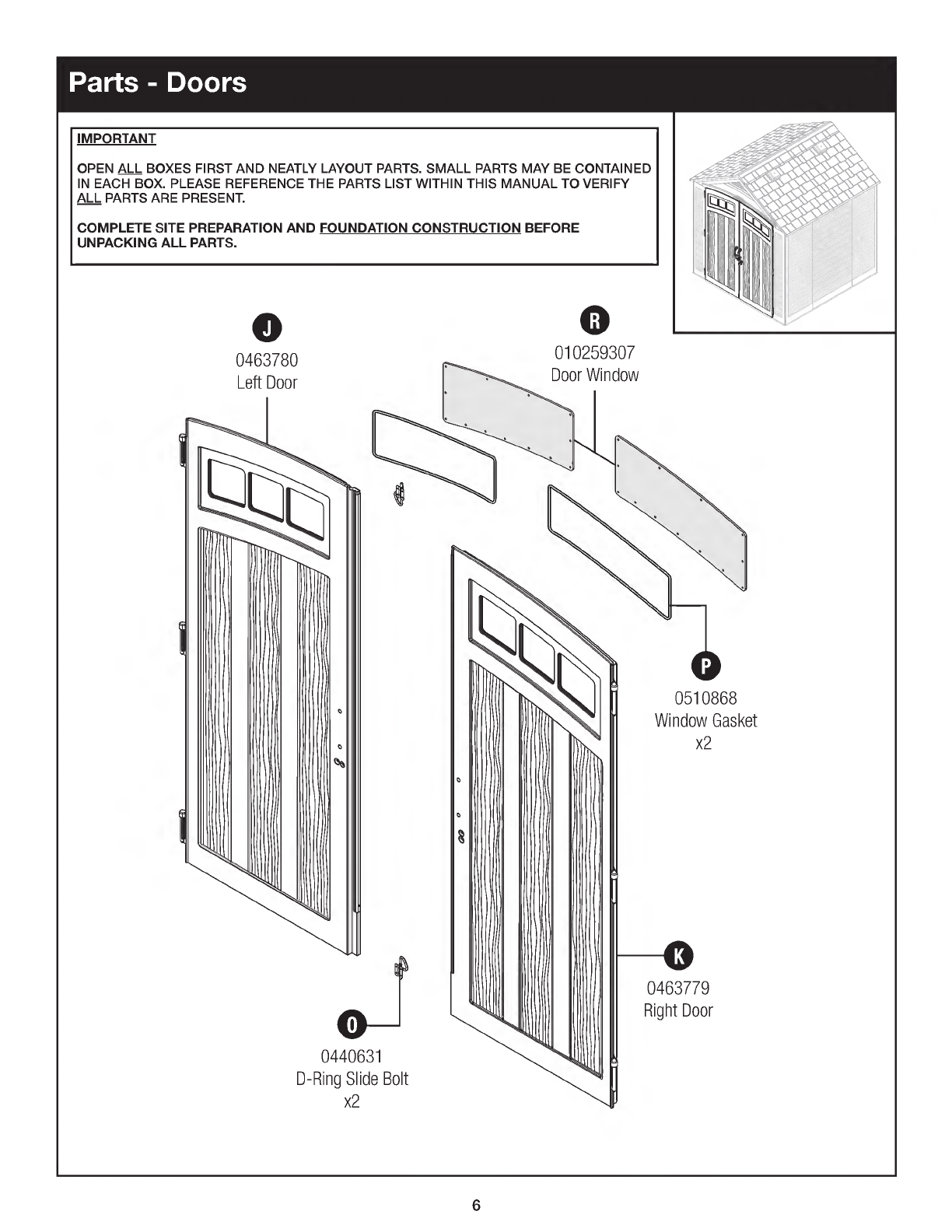

Parts -

Doors

IMPORTANT

OPEN

ALL

BOXES

FIRST

AND

NEATLY

LAYOUT

PARTS.

SMALL

PARTS

MAY

BE

CONTAINED

IN

EACH

BOX.

PLEASE

REFERENCE

THE

PARTS

LIST

WITHIN

THIS

MANUAL

TO

VERIFY

ALL

PARTS

ARE

PRESENT.

COMPLETE

SITE

PREPARATION

AND

FOUNDATION

CONSTRUCTION

BEFORE

UNPACKING

ALL

PARTS.

o

0463780

Left

Door

0440631

D-

Ring

Slide

Bolt

x2

o

010259307

Door

Window

0510868

Window

Gasket

x2

0463779

Right

Door

6

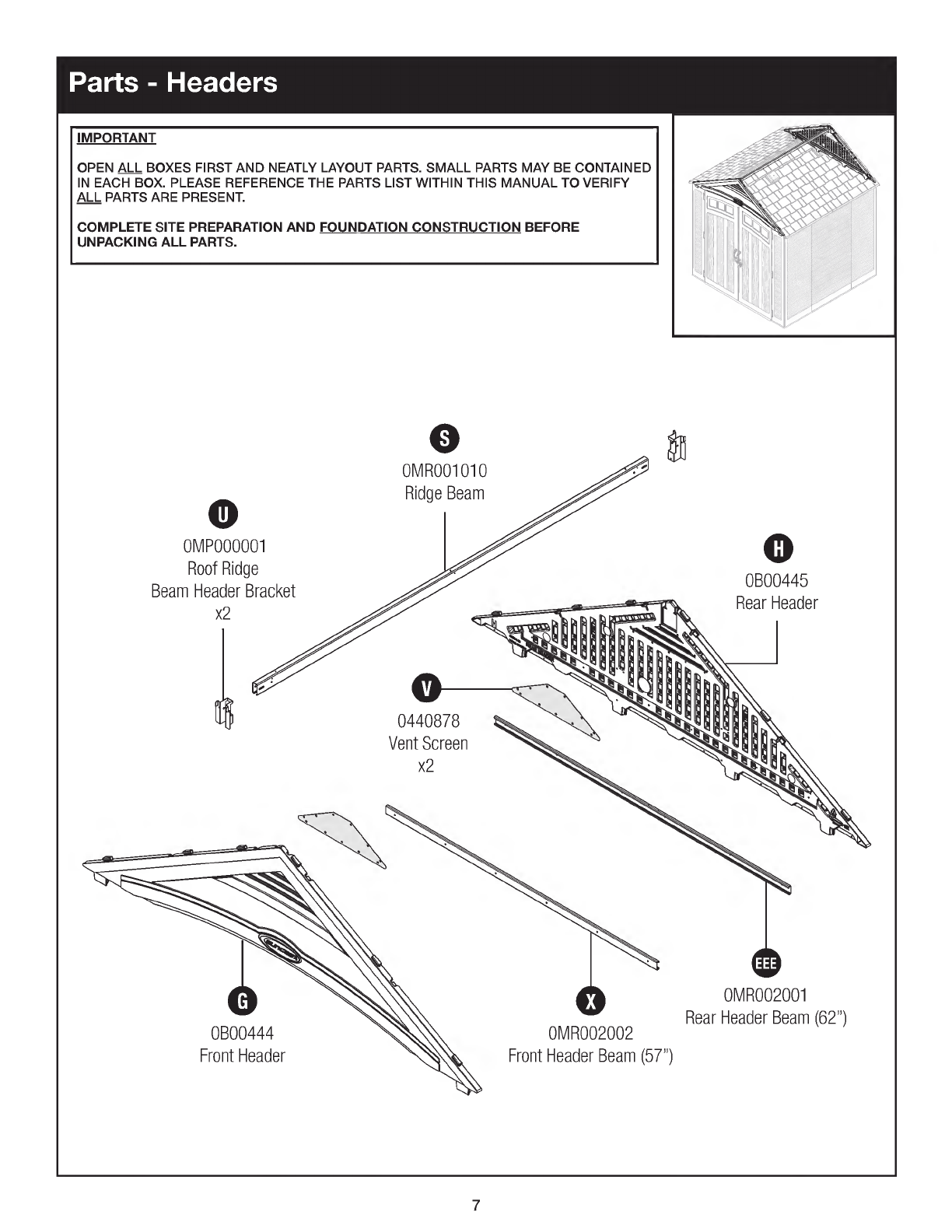

Parts -

Headers

-

IMPORTANT

OPEN

ALL

BOXES

FIRST

AND

NEATLY

LAYOUT

PARTS.

SMALL

PARTS

MAY

BE

CONTAINED

IN

EACH

BOX.

PLEASE

REFERENCE

THE

PARTS

LIST

WITHIN

THIS

MANUAL

TO

VERIFY

ALL

PARTS

ARE

PRESENT.

COMPLETE

SITE

PREPARATION

AND

FOUNDATION

CONSTRUCTION

BEFORE

UNPACKING

ALL

PARTS.

,

o

0M

P000001

Roof

Ridge

Beam

Header

Bracket

x2

OB00444

Front

Header

o

OMR001010

Ridge

Beam

0440878

Vent

Screen

x2

OMR002002

Front

Header

Beam (

57")

o

OB00445

Rear

Header

OMR002001

Rear

Header

Beam (

62")

7

Parts -

Roof

Truss

IMPORTANT

OPEN

ALL

BOXES

FIRST

AND

NEATLY

LAYOUT

PARTS.

SMALL

PARTS

MAY

BE

CONTAINED

IN

EACH

BOX.

PLEASE

REFERENCE

THE

PARTS

LIST

WITHIN

THIS

MANUAL

TO

VERIFY

ALL

PARTS

ARE

PRESENT.

COMPLETE

SITE

PREPARATION

AND

FOUNDATION

CONSTRUCTION

BEFORE

UNPACKING

ALL

PARTS.

41)

--

OMR005004

Truss

Leg

x2

OM

R004002

Side

Adapter

x2

0

OMP000003

Truss

Bracket

0

OMR009012

Roof

Support

Bar

x8

OMR006001

Truss

Cross

Beam

x2

0M

P000004

Truss

Strap

x2

s-

8

Parts -

Roof

IMPORTANT

OPEN

ALL

BOXES

FIRST

AND

NEATLY

LAYOUT

PARTS.

SMALL

PARTS

MAY

BE

CONTAINED

IN

EACH

BOX.

PLEASE

REFERENCE

THE

PARTS

LIST

WITHIN

THIS

MANUAL

TO

VERIFY

ALL

PARTS

ARE

PRESENT.

COMPLETE

SITE

PREPARATION

AND

FOUNDATION

CONSTRUCTION

BEFORE

UNPACKING

ALL

PARTS.

o

OB00442A

Left

Roof

x2

ED

0102231

Skylight

x2

OB00443A

Front

Roof

Peak

o

0464402

Skylight

Gasket

x4

010247607

lllumiventTM

Base

x2

o

OB00452A

Rear

Roof

Peak

44_

010247507

lllumiventTM

Cover

x2

OB00441A

Right

Roof

x2

9

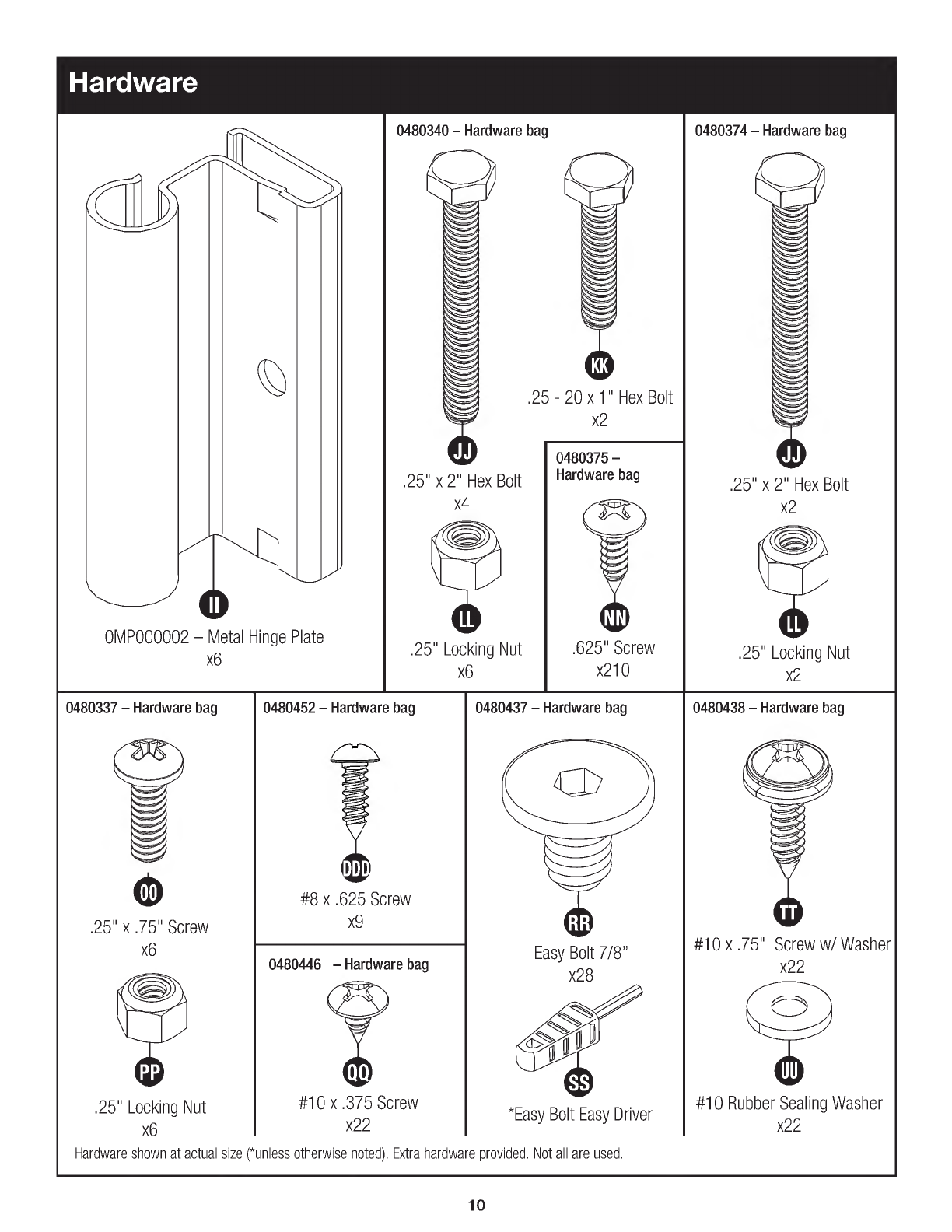

OMP000002 —

Metal

Hinge

Plate

x6

Hardware

0480340 —

Hardware

bag

.25"

x

2"

Hex

Bolt

x4

.25"

Locking

Nut

x6

.25 -

20

x

1"

Hex

Bolt

x2

0480375 —

Hardware

bag

.625"

Screw

x210

0480374

—

Hardware

bag

.25"

x

2"

Hex

Bolt

x2

.25"

Locking

Nut

x2

0480337 —

Hardware

bag

o

.25"

x .

75"

Screw

x6

("3

o

.25"

Locking

Nut

x6

Hardware

shown

at

actual

size (*

0480452 —

Hardware

bag

#8

x .

625

Screw

x9

0480446

—

Hardware

bag

#10

x .

375

Screw

x22

unless

otherwise

noted).

Extra

hardwa

0480437 —

Hardware

bag

Easy

Bolt

7/8"

x28

*Easy

Bolt

Easy

Driver

re

provided.

Not

all

are used.

0480438 —

Hardware

bag

#10

x .

75"

Screw

w/

Washer

x22

#10

Rubber

Sealing

Washer

x22

10