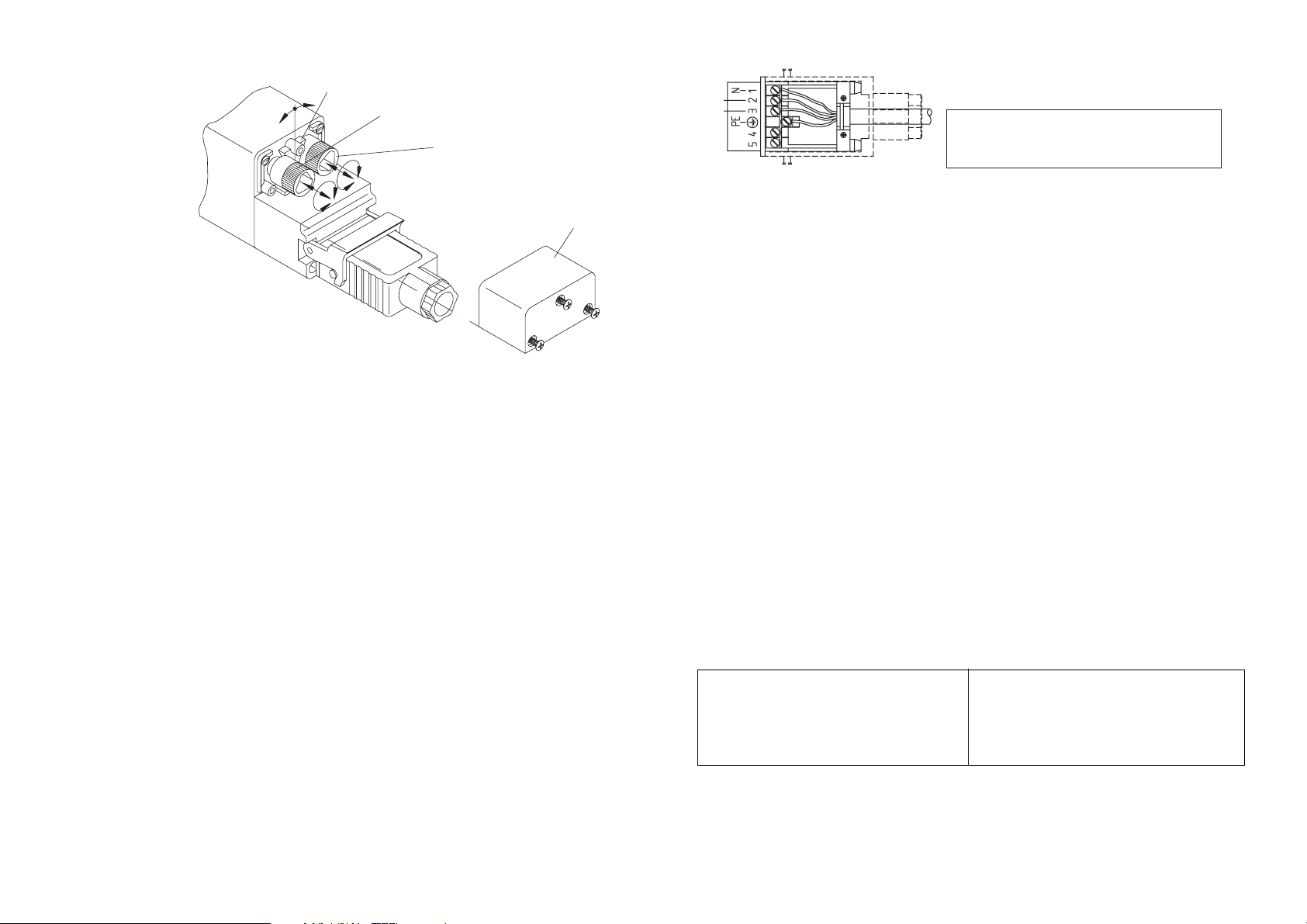

Data motor plug: Technical data:

type TK3 = 4 pole voltage rating 230 V 110 V

TK5 = 6 pole nominal rating abt 30 W 30 W

voltage 230 VAC rated current 0,13 A 0,26 A

fuse protection 10 A frequency 50 Hz 60 Hz

system of protection IP 30 operation mode S3 50 % S3 50%

group of isolation B direction of rotation ri + le ri + l

for dry rooms only

*) test cable type A1 order No. 206 820

test cable type A2 order No. 206 821

No warranty if these instructions are not followed. Subject to technical modifications.

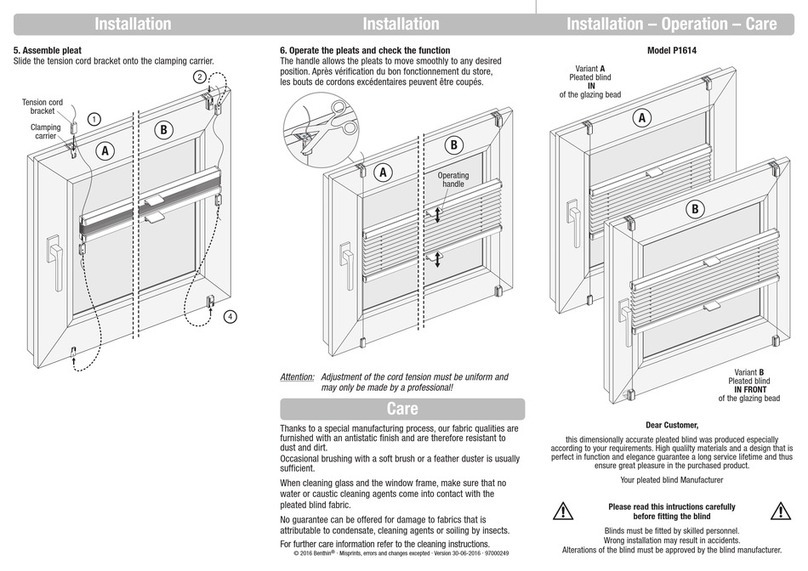

End position installation of assembled sundrape electro drives

Drive runner approximate-

ly in centre of rail. Release

screws in cover lid and

remove them in direction

of arrow. Now you can see

the two buttons for the

end positions.

1. Push safety clip to the

back and press button I

down. Turn button I (both

directions possible) until

all three grooves of index

rings are visible in one line

and switch noise of the microswitch becomes audible.

2. Connect test cable* and switch on for the inactive direction of movement. When the motor starts

going, choose other switching position at the test cable.

ATTENTION!

Setting of the end positions is made with buttons I and II only - Turn button I by hand (both direc-

tions possible) until motor starts running. Hold button I until runners have assembled to a distance

between each other of abt. 10 mm. Attention: with Corvus blinds it is essential to watch a

safety distance of 10 mm (side of stack). First end position is set.Turn off operating switch

3. Pull out button I carefully without turning and let it click into place.

4. To set second end position, push safety handle across centre position, press button II. Turn but-

ton II (both directions possible) until all three grooves of index rings are visible in one line and switch

noise of microswitch is heard.

5. Turn on operating switch for opposite running direction. Turn button II by hand (both directions

possible) until motor starts running. Hold button II until first runner has reached a distance of half the

width of a louvre to the end of the blind. Attention: with Corvus blinds drive onto the snapper

and do not go beyond this position. Second end position is reached. Switch off operating switch.

6. Pull out carefully button II without turning it and let it engage.

7. Shift safety handle precisely to the middle and fix lid.

8. Test both setting and re-adjust, if necessary.

Attention: with tandem blinds one motor only is set.

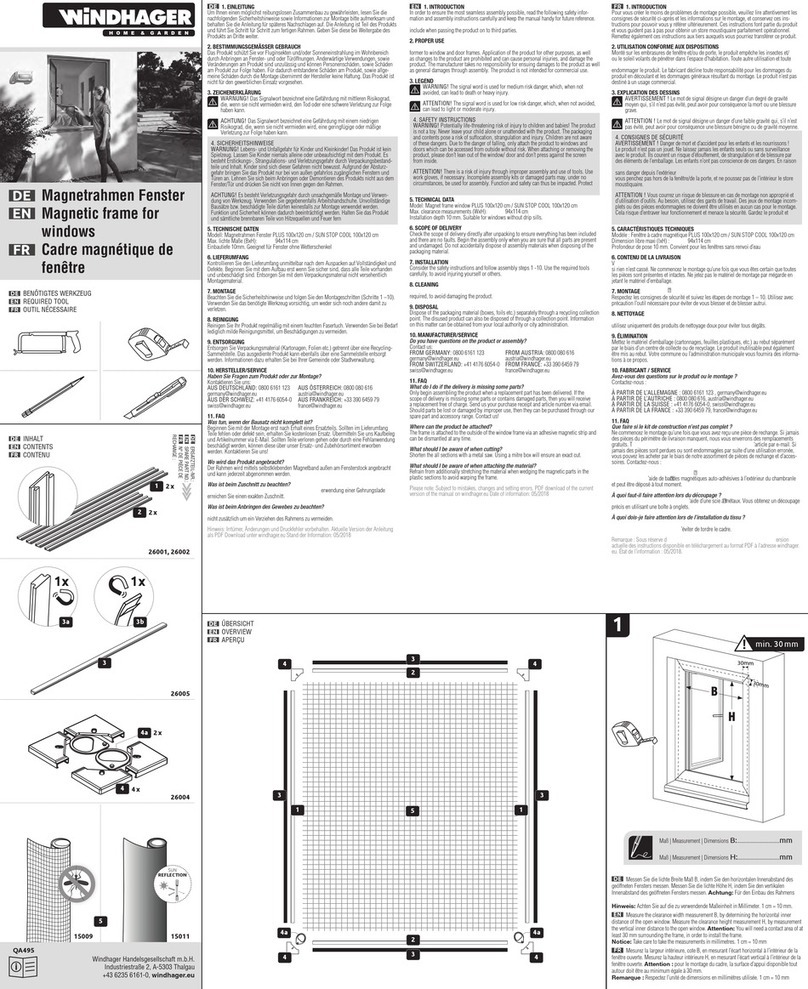

N = neutral conductor (neutral blue)

right-handed rotation = control wire (right brown)

left-handed rotation = control wire (left black)

PE = protective conductor (PE yellow/ green)

Instruction for electrical connection of

sundrape® electric vertical blinds

Before installation of the electric drive, all unne-

cessary wires are to be taken away and existing

installations which are not necessary for a use

with electric supply are to be deactivated. When

mounting electric drives which are operated by

touch contact switch, the touch contact switch

has to be installed near the system, however at a

safety distance to moving parts and above a

height of 1,5 m. For drives delivered without

moving parts, the reference turning moment and

the reference working duration have to be com-

patible with the characteristics of the running

part.. Do not exceed the maximum turning

moment. In case you need more detailed infor-

mation, please contact the manufacturer.

Connections and supply lines to be installed at

the building-site by authorized electro-firms in

compliance with offical regulations. In order to

avoid backing ups of currents in the condensers

of running motors, operate the motors separate-

ly. A separate contact for each rotation direction

of the motors is required (for decoupling purpo-

ses). For controls of more than 2 motors a group

control is required. . Control types for sundrape

electro blinds:

single

in groups with central control

by radio remote control

automatic and central control

Cable laying plans and wiring diagrams are sub-

mitted on request.

3/right-handed rotation

2/left-handed rotation

safety clip

button I

button II

cover