7 8

toggled in before delivery, if need to change the input voltage, please

toggle the switch cap into correct position before power on .

The 24V DC brushless/servo motor has 8 wires connected to control board.

Power supplies output 24/12V DC to control board, one is supply power to

motor, one is supply power to control unit.

7.1.4. R&G (LED) light power supply:

There is power supply specially for R&G light, if you connect to 24V or

12V power supply, the R&G light input should be consistent.

7.1.5. R&G light interface:

When boom falling down to horizontal position, red light will

keep lighting; when boom lifting up to vertical position, green light will

keep lighting. During the boom falling down or lifting up, the red light will

keep lighting. (Please refer to Appendix III for wire diagram)

The interface also can be used to output open limit signal and close limit

signal, Please check wiring Figure 4 for reference(Optional output).

7.1.6. Wire control signal input interface:

This interface is dry contact input signal, UP/ DOWN / STOP connect

with “COM ”, the control board will respond accordingly. User can use

this interface to connect with parking system, and it can

also wiring connected to button switch to control the barrier. (Please refer

to Figure 4 for for main control board wire control)

7.1.7. Photocells interface:

This interface is dry contact input signal, only for responding opening

when shorts circuit the terminal “Photocells” during closing. This is

mostly use for prevent damage when boom falling. So normally

photocells are installed paralleled and under the arm. Boom will keep

open, or will auto-reverse when there are obstacles between photocells.

7.1.8. Loop detector interface:

This interface is dry contact input signal, only for responding to auto

cl o s ing after signal in put an d then di s a ppeared. So fi rs t it

should received dr y con ta ct or re lay input , after th e input

signa l di sappear ed, boom will auto fal ling to clo s ed

This interface is used for communication between computer and

SFMCU control unit. We provide SDK for customers to develop

software to receive barrier gate status and control barrier gate

7.1.10. Battery interface:

This interface is used for battery, the battery can be used to keep

barrier gate working normal when power off.

7.1.11. Other interface(Arm detection):

Currently it’s used for arm detection. This function is not open

unless needed, you can open this function from menu settings.

Please see Appendix VI for reference.

3 buttons for menu setting, INC, SET, DEC, setting guidance please refer

7.1.13. Manual control button

‘UP’, ‘DOWN’, ‘STOP’ , these 3 buttons allow you to control barrier

gate open, close and stop by manual. The stop button also used as save

7.2. Controller auto-detect after power-on description.

When the arm is in open position, the controller should re-confirm the close

position of boom after power-on or resume power: The barrier gate will

auto close slowly one time by default. This require the boom are installed,

if not controller can not close to right position. During the re-confirming

process, it detects all open and anti-bumping signal interface, and it will

stop learning if there is signal. After finish leaning, the boom stays at the

down limit position and Buzzer will beep one time.

If spring installed but no boom, or there is obstacles on the boom during

down process, or the spring and boom in serious imbalance, need to

remove the obstruction or adjust the spring, then power-on again.

If boom is in closing position when, please do not hold or stop the arm

move, the barrier gate will confirm it’s close position very soon.

8. Boom horizontal and vertical fine adjustment

8.1 Horizontal adjustment:

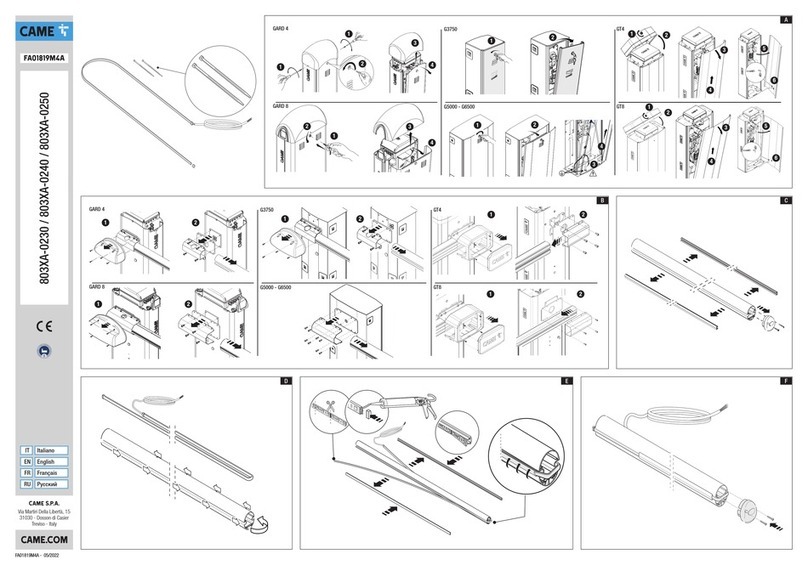

Power off first. And loosen the two

screws(see figure 5) on balance

rotating arm a little but not totally

loosed, then rotate barrier arm to

make the active swing arm to

mechanical limit position. In this

situation, keep the arm in

horizontal status, and fasten the