LAS ER C HI LLER OP ER AT ORS MAN UA L LAS ER C HI LLER OP ER AT ORS MAN UA L LAS ER C HI LLER OP ER AT ORS MAN UA L

712

Warning: please cut off the power before installation!!

3.2 Site requirements:

Ambient temperature and relative humidity (RH)

Our chiller suitable for install indoors, ambient temp. from 5℃ to 35℃, RH

less than 80%(No condensation) .

Location

The chiller should be installed on solid horizontal surface, the closer to the

laser equipment, the better cooling performance will achieve; keep the

chiller off the heating source at least 4inch (1.4meters), such as heating tube

and boiler.

Please install the chiller at place where drainage system is available in order to

keep the installation place clean in case of any leakage occurs, please don't

install the chiller in erosive gas, humidity, dusty places or indoors with high

temp..

Our chiller is equipped with wheel, which makes it easier for installation and

operation; the front wheel could be locked to secure the unit. Avoid

voltage drops by using properly grounded power outlets wired with 14 gauges

or larger diameter wire. If possible, be close to the power distribution panel.

Using an extension cord may cause low line voltage problems, the voltage

loss should be with 10 % from the extension cord if this is inevitable.

The heating discharged by the fan is 1.4 times than the rated cooling capacity,

so the air- draft and air discharge side shouldn't be too close to wall. The air

discharge side should reserve at least 0.8m, the installation site should

ventilate well, the air-draft and air discharge volume of the site should be

a bit large than the chiller, or use air-condition with larger cooling

capacity than the heat discharge of the chiller to cool the installation site.

3.3 Power connection

Make sure the power wire rightly connected and current, frequency should be

match with the requirements marked on the label which was pasted on the back

of the chiller.

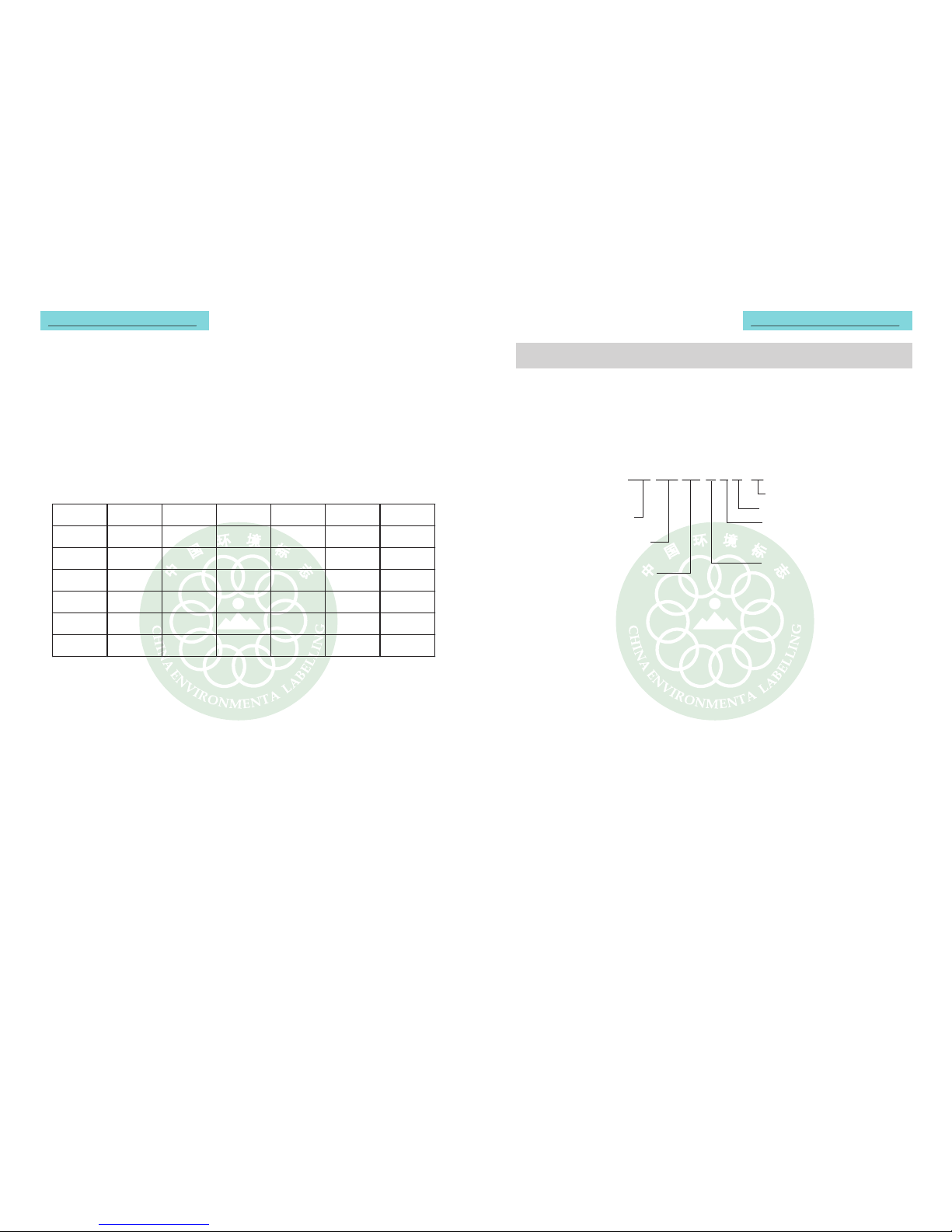

3.4 Connection accessories

Process pipeline

There are 2 inner thread interfaces for water pipe connection and water inlet

and outlet adapter is designed for connecting the accessories and working

pipeline.

In order to keep the working site clean and safe, please choose the right flexible

tube and accessories based on the liquid temperature and required temp.

Version information

4.3 Load factory default setting

4.4 Software version

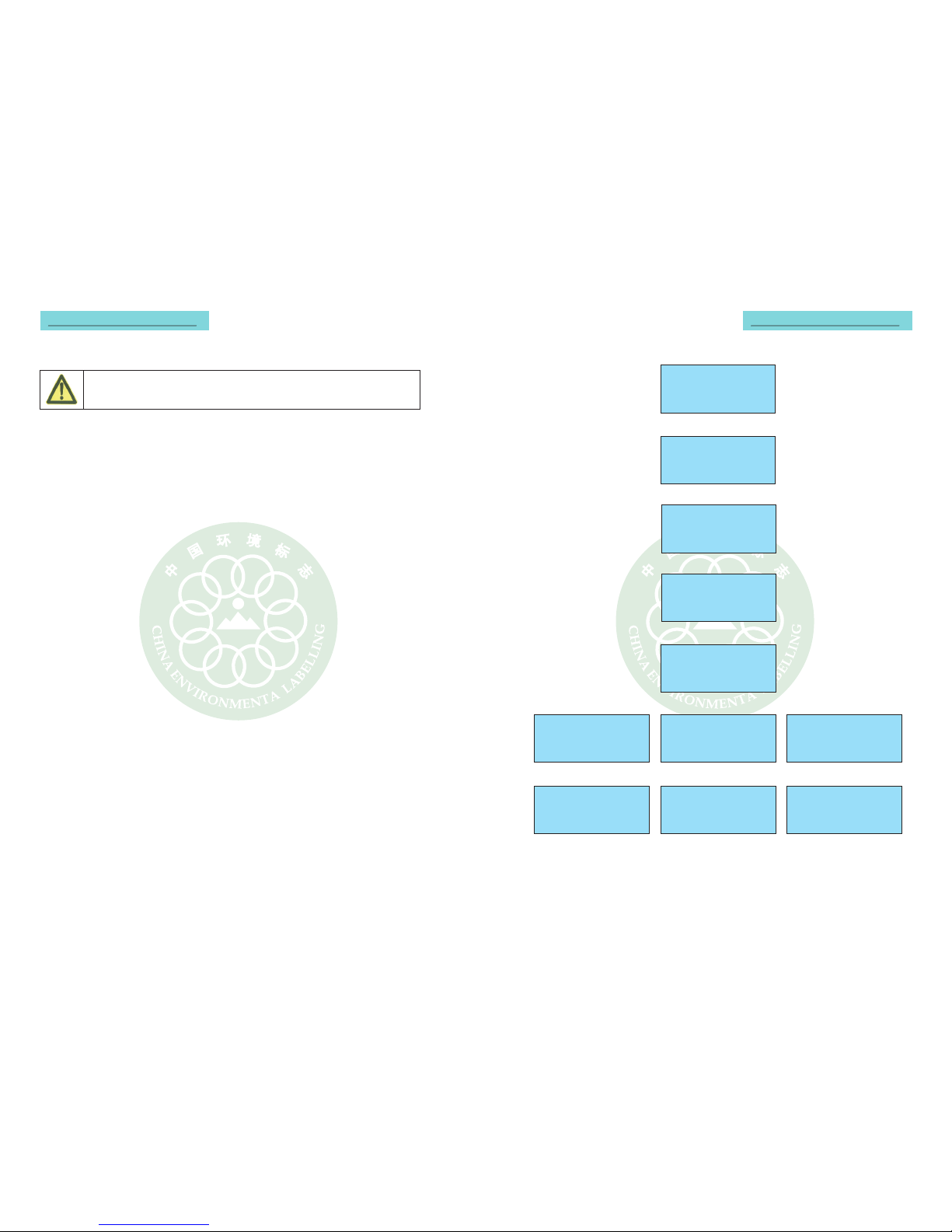

5 Alarm prompt, the LCD screen flashes when alarming,on & off every 1sec

DLY-619-V1.0-XX

Startup mode

Whet her aut omatical ly

startup when pow er on X

4.2.6 startup option, press up and down button to choose "yes" or "no"

System function view

cooling only (bypass)

Factory default setting

Please confirm to load factory

default setting?

Yes: kee p press ing set button for 5se c

No: press power button to exit

Phase reversal alarm

Change any two of three

live wires after power cut

off, please trouble shoot

and restart the system.

Liquid level alarm

Low liquid leve l or liquid leve l sw itch

mal func tion, fill more water or repl ace

liquid leve l sw itch; press ret urn/ pow er

butt on to rel ease al arm .

!High temp. alarm!

Water temp . exceeds the ma x.

setting va lue, fill cooling wa ter or

stop the system. pr ess return/power

button to release al arm.

Overload alarm!

Wire error or heavy load, please

let professional troubleshoot!

press return/power button to

release alarm.

Pressure alarm!

Refrigerating system leakage,

track down the leakage point and

recharge refrigerant. press return

/power button to release alarm.

Low temp. alarm!

Water temp. lower than min setting

value. Fill normal temp. water or

stop system! Press return/power

button to release alarm.

Water flow alarm!

Low wa ter flow or flow switch, wa ter

pump breakdown please check

water ci rcuit or replace co mp onent!

Press return/power button to release

alarm.