Pantone 1375 C

RGB: 255, 158, 27

CMYK: 0, 38, 89, 0

HEX: #FF9E1B

Gray 49%

Sunsation Instructions Manual 9

Repeat the same operation on the other side so that the front bar is absolutely leveled.

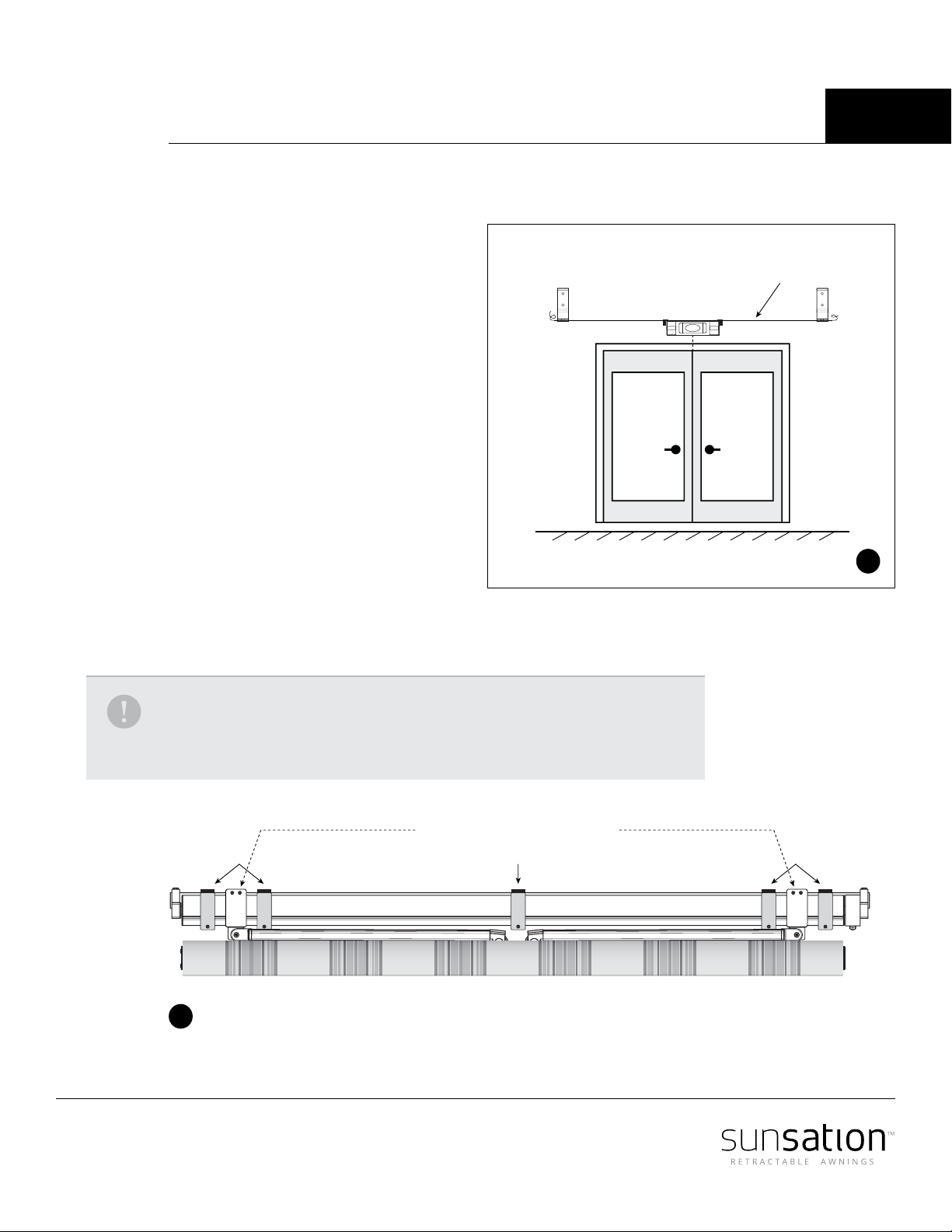

Standard arm control

1. Use the open-end wrench (13 mm)

to release the side bolt (Picture 3)

Do NOT unscrew bolts completely.

2. With the Allen key (6 mm), screw

or unscrew the bolt to the desired

angle (Picture 4).

3. Use the open-end wrench to lock

the side bolt (Picture 3).

Self-pitch arm control

1. Use the open-end wrench (13 mm)

to release the side bolt (Picture 1),

Do NOT unscrew bolts completely.

2. Use the self-pitch handle to adjust

to the desired angle (Picture 2).

3. Use the open-end wrench to lock

the side bolt (Picture 1).

Pitch adjustment (Arm control)

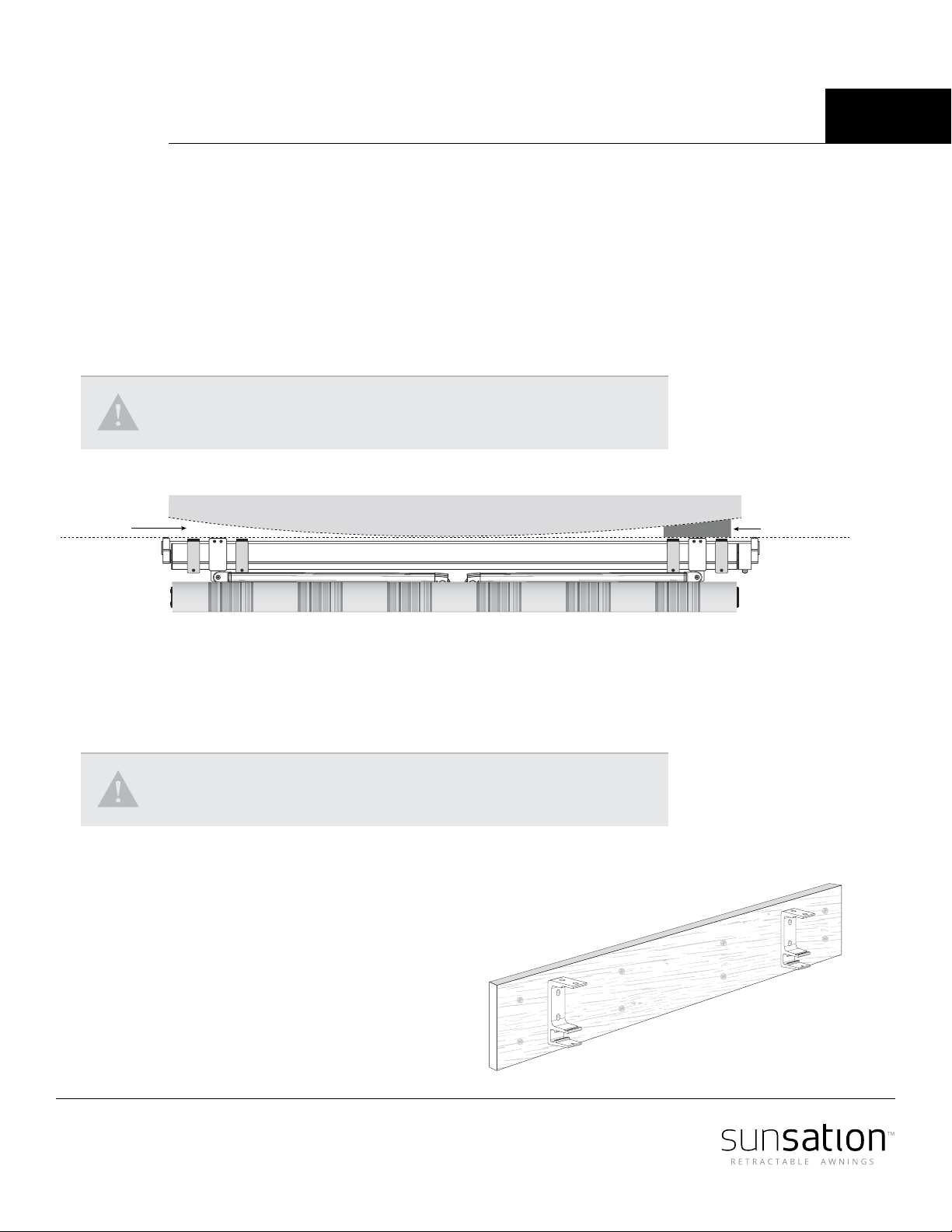

After the awning has been installed, making sure all bolts have been tightened and packing

materials removed, extend the awning to its full projection. The folding arms will still be

slightly angled. Hold the arm of the awning with one hand or shoulder to remove pressure

while doing the adjustment with the other hand.

A level is added to each arm where it is attached to the front prole, this unique addition

makes installing your awning easy and accurate within minutes.

Setting the correct pitch is one of the most important details to protect the

Awning from rain damage. The more that you pitch the awning, the less water

will gather on your awning.

2

4

1

3