1 General safety notes

■Read the operating instructions before commissioning.

■

Connection, mounting, and configuration may only be performed by trained

specialists.

■

Not a safety component in accordance with the EU Machinery Directive.

■

Do not install the sensor at locations that are exposed to direct sunlight

or other weather influences, unless this is expressly permitted in the operating

instructions.

■These operating instructions contain information required during the life cycle of

the sensor.

EN/IEC 60825-1:2014

IEC60825-1:2007

LASER CLASS 1

Laser

1

Maximum pulse power < 5.95 mW

Puls length: 2 µs

Wavelength: 670 - 690 nm

Complies with FDA performance

standards except for conformance with

IEC 60825-1 Ed. 3,

as described in Laser Notice No. 56,

dated May 8, 2019

ATTENTION

WARNING: Interruption, manipulation or incorrect use can lead to hazardous exposure

due to laser radiation.

2 Notes on UL approval

The device shall be supplied from an isolating transformer having a secondary overcur‐

rent protective device that complies with UL 248 to be installed in the field rated either:

a) max 5 amps for voltages 0 ~ 20 V (0 ~ 28.3 V peak), or

b) 100 / Vp for voltages of 20 ~ 30 V (28.3 ~ 42.4 V peak).

Alternatively, they can be supplied from a Class 2 power supply.

UL Environmental Rating: Enclosure type 1

3 Intended use

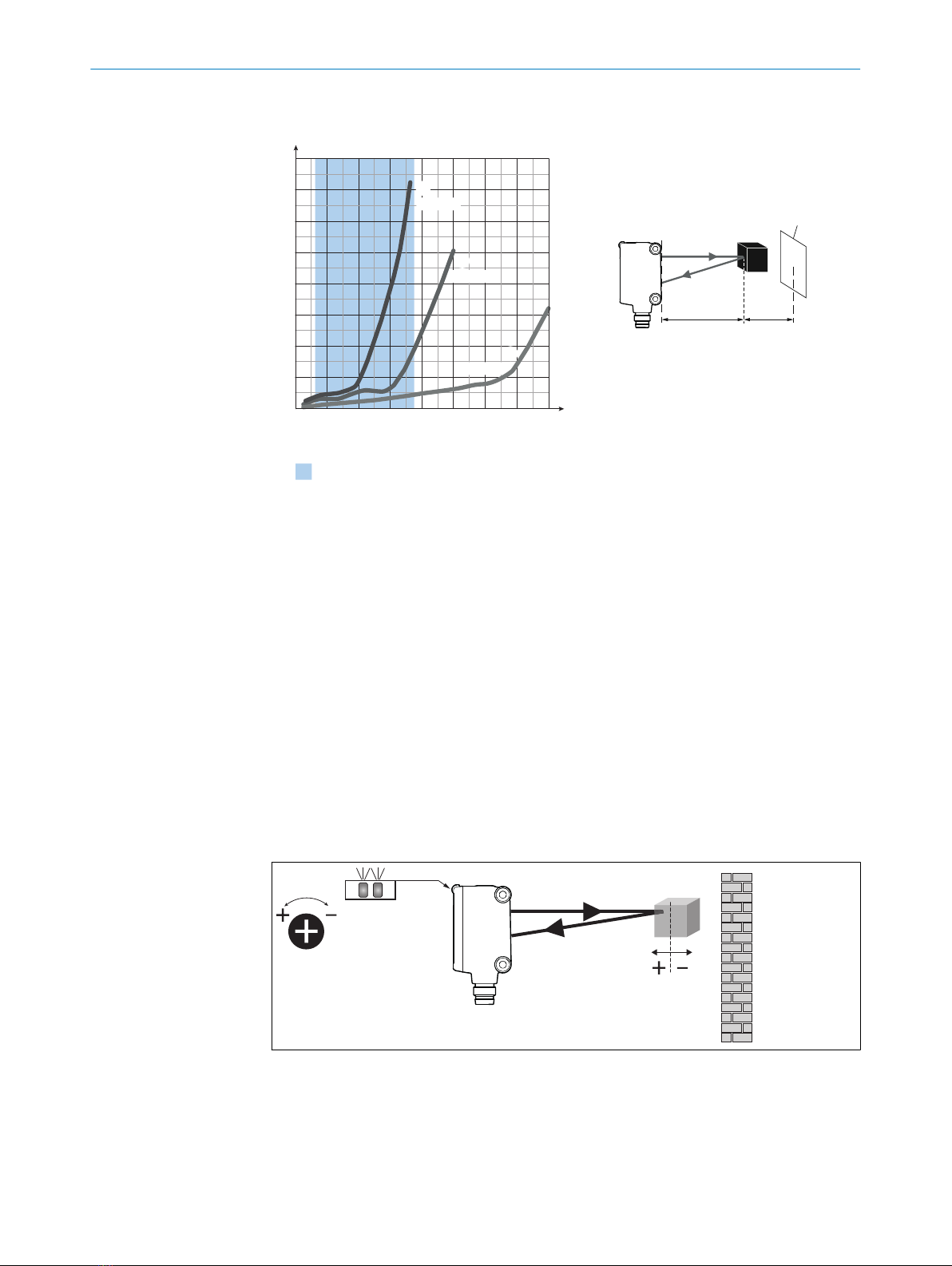

The GTB6L is an opto-electronic photoelectric proximity sensor (referred to as “sensor”

in the following) for the optical, non-contact detection of objects. If the product is used

for any other purpose or modified in any way, any warranty claim against SICK AG shall

become void.

GENERAL SAFETY NOTES 1

8025391.1AR6 / 21.02.2021 | SICK

Subject to change without notice 5