By SCN 6/10 | Pg.1

Instruction / Specification Manual 2010

ARS-Series Stainless Steel Anchor

MOVEABLE / I-JOIST/ WALL MOUNT / TILE ROOF / Z-PURLIN

Part Anchor SST Fits Fastener

No. Type Ga. Chord Pack

#2830 2x4 14 2x4

#2006

#2801 2x8 14 2x6-2x8

#2802 2x12 14 2x10-2x12

#2805 2x8 11 2x6-2x8

#2806 2x12 11 2x10-2x12

Tile Roof

#2820 2x8 14 2x4-2x12

I-Joist

#1003 I-Joist 14 1-3/4”-2-3/4” #2027

Moveable

#1014 * 2x8 11 2x4-2x8 Detent Pin

#2015

#1015 * 2x10 11 2x10-2x12

Wall Mount

#1004 Standard 11 2x4-2x8 #2014

#2014-A

#1004-A 45/o 11 2x4-2x8

Z-Purlin

#1016 Standard 14 9-1/2”-2-3/4” #2019

Flashing Systems: Roofing Base

#2001- Santoprene* All types 8x10”

#2003- 2.5lb Lead All types 16x16”

#2020- Alum/EPDM Tile 20x20”

#2018- EPDM/Alum Metal 8x8”

Sheathing:

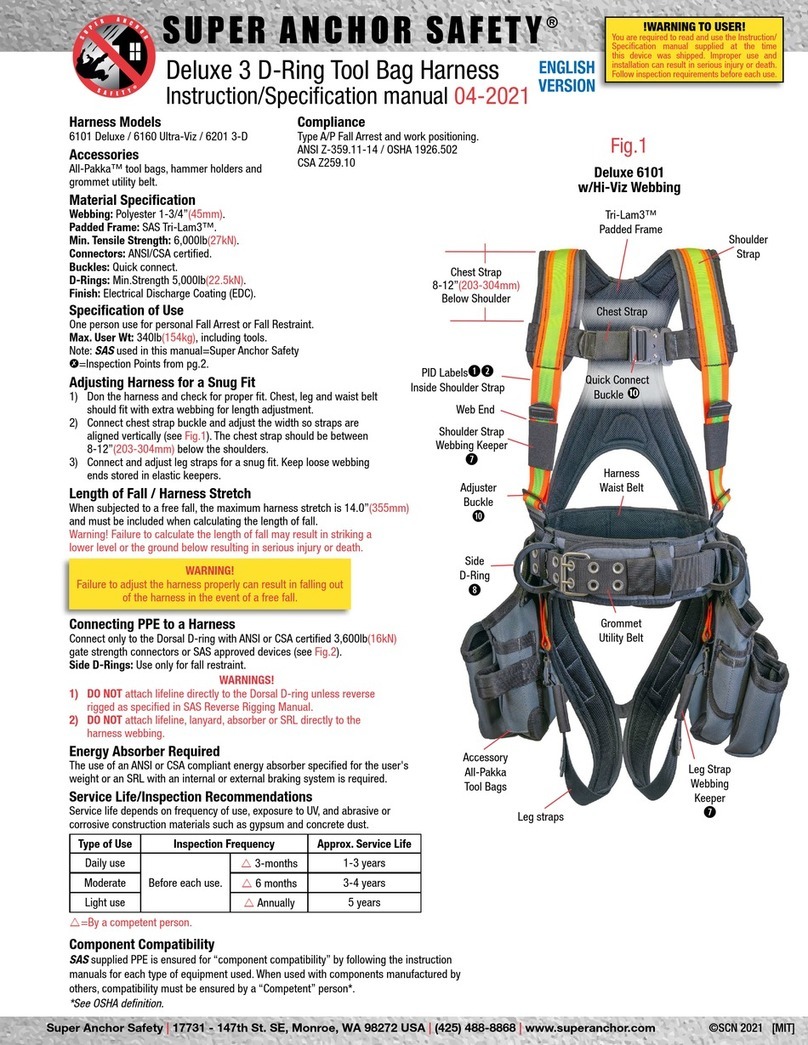

Sheathing over top chords must be a minimum of 7/16” OSB or plywood and installed

over the anchor shoulders as shown in Fig. 1 to allow the attachment bolt to be installed

under the top chord. If sheathing is already in place or if anchors are to be evacuated

after use, cut a 3”x 3” opening through the sheathing centered over the top chord.

Fig. 2

Fig. 1

Stem Cover

Tether

Strap

Santoprene®

8”x10” Base

Flashing

3”

Flashing

Riser

SAS Factory

Supplied

Attachment

Bolt/Nut

#2006

Drill Through

2x6, 2x8, 2x10,

2x12

Connector

Attachment

Hole

1-1/8”d.

Warning

Label

Stem

Shoulder

Teko Nails

3 ea. Leg

Leg

2x4

Grade 8

Attachment Bolt

2-1/4”x 5/16” d.

Tile Roof

Anchor

Stem Height

8.0”

2x4

2x8

2x12

Stem

Height

6-1/2”

2.0”

Fig. 3

Blocking Under

2x4 Top Chord

Ridge

2x4

2x4

12.0” min.

From Ridge

24.0” 2x4

Blocking

Attach

Blocking

to Top Chord

Connectors:

Connecting hardware must comply with current standards.

Attach only through the “Connector Attachment Hole” shown

at Fig. 2. See Fig. 10a,b pg.3 for connector types.

Cutting/Severing Hazard! Prevent lifelines/lanyards from

intersecting anchor stems.

Blocking 2x4 Top Chords:

2x8 anchors installed over 2x4 top chords or rafters

require a 24” length of 2x4 blocking. To prevent movement

attach blocking to the underside of the top chord as shown

in Fig. 3. 2x8 anchors will provide greater resistance

to force loads than a 2x4 anchor.

Personal Protection Equipment/PPE:

PPE refers to the common types of personal safety

equipment typically required for fall protection: Harness,

Lanyard, Lifeline, Shock Absorber, and Rope Grab. The

use of a shock or energy absorbing device is required

anytime there is exposure to a free fall when

using SAS anchorage devices.

Component Compatibility:

SAS anchorage devices are factory ensured for

compatibility with PPE manufactured by SAS. Users

must ensure component compatibility when using

equipment supplied by other manufacturers.

Framing Requirements:

Install onto top chords that are 2x4 or greater dimension.

Framing must be capable of supporting a 5,000lb (2,260kg)

load or 2 times the intended fall protection load.** Do not

install onto framing that is damaged or has spliced top chords.

11 Gauge and 14 Gauge:

14 ga. anchors have a strength test rating of

more than 6,000lb (2,721kg). 11 ga. anchors

have a strength test rating of more than 7,500lb

(3,400kg), to provide greater resistance to static

loading. Use for steep roofs or situations when

the anchor will be subjected to live loading.

Installation:

Anchors are supplied with (SAS) certified

grade 8 x 5/16” attachment bolts of sufficient

length to allow a lock nut to be installed as

shown in Fig. 3.Use 6 ea. 1-1/4” teko nails

to stabilize the anchor position and prevent

movement during use.

Drill Through Method:

2x4/2x8/2x12/ I-Joist and Wall anchors may

be installed by drilling through the top chord or

rafter as shown in Fig. 1. Use a 5/16” (9mm)

drill. DO NOT modify anchor by drilling additional

bolt holes and do not enlarge factory bolt or teko

nail holes.

Materials Specifications:

Fabricated from 304 grade stainless steel. Engineered to attach over wood truss top chords, rafters and

I-Joists with a single grade 8 bolt. Designed as a permanent or temporary fall protection anchorage

device and compatible with all flashing systems supplied by Super Anchor Safety(SAS)

Specification of Use:

Fall Arrest or Fall Restraint for one person with a maximum body weight of 340lb (154kg ) including

tools and equipment. Horizontal Lines or Multiple Users on a single anchor: use only ARS

2x8/2x12-11 ga. anchors, workers must not be exposed to a free fall, and the system designed by a

“Qualified Person”*.

* “Qualified Person” as defined by industrial safety standards. **As specified by OSHA 1926:502(d)(15)(i)(ii) or equal industrial standard.

WARNING TO USER:

Use Only Super Anchor Safety (SAS) Instruction/

Specification manuals for SAS equipment. You

must read this manual before you use this device.

Improper use can result in serious injury or

death. Consult SAS-07 or 2010 manual for more

information about fall protection.

Lock-nut