24”

Above

Tie-Off

Point.

36”

Tie-Off

Point

SUPER ANCHOR SAFETY®Page 4English Version

Inspection Record

Record annual and

semi-annual inspections

and date of first use.

No. 6180-LE Energy Absorber (EA)

SRL “B” end Snaphook

Work Surface

Fall Hazard Edge

60”

D-ring

Height

Above

Work

Surface.

Leading Edge

Length of Fall

Sample Plan

(LOF)

18”

Harness and

components

stretch

60”

Max F

ree Fall

54”

Max. SRL-LE

Deployment

Length

60”

Foot to

D-ring

Length

LOF

192”

16ft

To ground or

next lower level

below work

surface.

SAS Factory Service

SRLs requiring warranty or service work must be returned to the SAS factory.

Contact the sales office to request a Return Authorization Form (RAF).

Offsite annual and semi-annual inspections that do not require service or

repair may be performed by a “Competent” person using SAS inspection

forms. Replacement PID labels will be provided if the original label data is

available.

Casing Warning Label

Do not attempt to repair an SRL. There is an interior recoil spring

that poses a serious safety hazard.

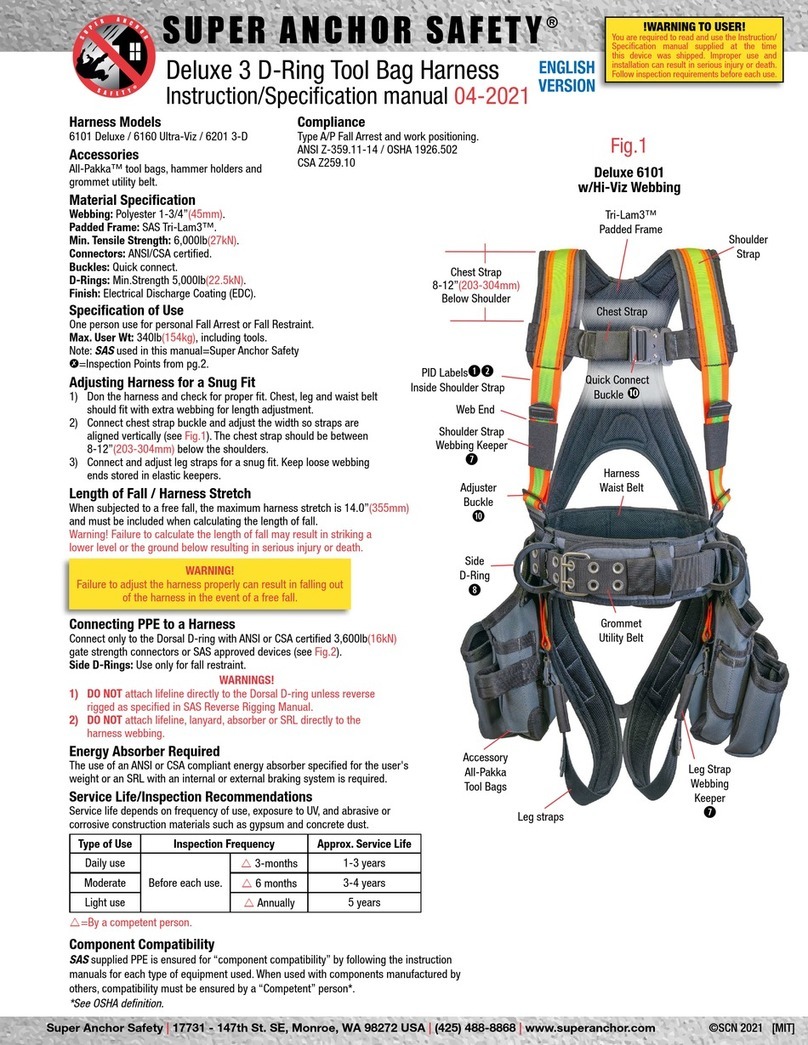

Fig.11b

Dorsal D-ring

24”

Side

D-ring

Fall Hazard

Fall Restraint Use

SRLs may be used for fall restraint when there is

no exposure to a free fall as shown in Fig. 11b. The

worker is prevented from moving close to the fall

hazard by a warning line or other guarding system.

The SRL connector “B” end may be attached to the

dorsal D-ring or side D-ring. Note: SRLs are not rated

for “work positioning” because the cable cannot be

set to a fixed length.

Fall Restraint Definition OSHA 1926.751

“A means of fall protection that prevents the user

from falling any distance.”

WARNING! Free falls over the edge of a fall hazard

can result in severing of the SRL cable. Safety

standards specify the use of an SRL with an external

E/A to prevent cable damage. Most deaths occur

from falls less than 8ft from the work surface.

Casing Marks

SRL model, cable length, serial no. and DOM ( date

of mfg.) are engraved at the time of shipping from

SAS factory.

Free Fall Hazard Warning

The following instructions apply only when a worker is exposed to a free fall hazard of more than 2ft.

Calculating the Free Fall Length:

The height of an SRL connection to the dorsal D-ring above the work surface determines the free fall length. As

shown at Fig.11b, the D-ring height above the work surface is 24”, the maximum free fall allowed Class A SRL’s.

Leading Edge (LE) Models Length of Fall

Shown at Fig.11a, the worker’s D-ring height is 5ft/60”above the work

surface the maximum free fall distance allowed for an LE model. The

maximum deployment length of the SRL internal braking system

combined with the external energy absorber

No. 6180-LE is 54”. The min. ground clearance is 16ft.

Fig.11a

SideWinder Manual 2020

Template SRL 3.0

SRL Label EE.1

©SCN 02-2020

[MIT]

!WARNING TO USER!

You are required to read

and use the Instruction/

Specification manual supplied

at the time this device was

shipped. Improper use and

installation can result in

serious injury or death. Follow

inspection requirements

before each use.

BEFORE EACH USE:

Perform locking and retraction

tests as specified in the

manual.

Mfg. Super Anchor Safety

Monroe, WA USA 98272

425-488-8868

Template SRL 3.1

SRL Label EE.2

©SCN 02-2020 [MIT]

BEFORE EACH USE:

Inspect and remove from

service if any of the following

conditions are present:

• Fall indicator on snaphook

swivel has been deployed.

• Cable has kinks, cuts or burs.

Storage, Maintenance, Use:

• Cable angle should not

exceed 40° from anchorage

point. See manual.

• Do not allow cable to retract

without tension serious

damage will result.

• Clean cable before storing.

• Store wet units vertically and

in a warm

Maintenance WARNING!

Do open the casing or attempt

repair. This device has an Internal

spring that can seriously injure a

person. Return to SAS factory for

service or repair

Template SRL 3.1

SRL Label EE.3

©SCN 02-2020 [MIT]

Compliance

ANSI Z359.14-2014 TYPE B

Cable: Galvanized steel

3/16”(4.8mm)d.

min.strength: 4,000lb(18kN)

Avg. Arrest force 900lb(4kN)

Max. Arrest distance: 42”(1.06m)

1-Person max wt: 310lb(140kg)

Including tools and equipment

Max. Free fall length: 54”(1.4m)

Temperature range-22°F(-30°C)

122°F (50°C)

! HAZARDS !

• DO NOT allow cable to come in

contact or wrap around sharp

or abrasive surfaces, equipment

tools or electrical sources.

• Do not use for fall restraint or

work positioning.

• Calcuate free fall length from

all leading edges.

Template SRL 3.0

SRL Label EE.1S

©SCN 02-2020

[MIT]

¡ADVERTENCIA AL USUARIO!

Se requiere leer y utilizar

el manual de Instrucción/

Especificación proveído en

el momento de envío de este

dispositivo. El uso e instalación

inadecuados puede resultar en

lesiones graves o la muerte.

Seguir los requisitos de

inspección antes de cada uso.

ANTES DE CADA USO:

• Efectuar las pruebas de

bloqueo y retracción cómo se

especifica en el manual.

Inspeccionar y sacar de servicio

si cualquiera d las siguientes

condiciones se presentan:

• El indicador de caída en

el rotador del gancho de

seguridad se ha desplegado.

• El cable tiene retorceduras,

cortadas o rebabas.

Template SRL 3.1

SRL Label Indicator

©SCN 02-2020 [MIT]

Fall Indicator is visible

Remove From Service!

Red Fall Indicator

Indicador de caída de

color rojo

El indicador de caída

esta visible.

Retirarlo de servicio

Template SRL 3.1

SRL Label EE.2S

©SCN 02-2020 [MIT]

Almacenamiento,

Mantenimiento, Uso:

• El ángulo del cable no debe

exceder 40° del punto de

anclaje. Ver el manual.

• No permitir que el cable se

retracte sin tensión resultara

en danos serios.

• Limpiar el cable antes de

almacenar.

• Almacenar unidades mojadas

verticalmente y en un área

tibia si han sido expuestas al

agua helada.

• Rango de Temperatura

-22°F(-30°C) 122°F (50°C)

¡ADVERTENCIA de Mantenimiento!

No abrir el revestimiento e intentar

reparar. Este dispositivo tiene un

resorte interno que puede lastimar

a una persona gravemente.

Regresarlo a la fábrica SAS para

servicio de reparacion.

Year: Month: By: Pass

Inspection Record

Date of First Use:

____________________

Property of: ______________

________________________

Template SRL 3.1

SRL Matrix

©SCN 02-2020 [MIT]

Template SRL 3.1

SRL Label EE.3S

©SCN 02-2020 [MIT]

Cable: Acero Galvanizado

3/16”(4.8mm)d.

Fuerza Mínima: 4,000lb(18kN)

Fuerza de Detención Promedio

900lb(4kN)

Distancia de Detención Máxima:

42”(1.06m)

1-Persona Peso Maximo:

310lb(140kg)

Incluyendo Equipo y Herramienta

Longitud de Caída Libre Máxima:

54”(1.4m)

¡PELIGROS!

• NO permitir que el cable tenga

contacto o se envuelva alrededor

de superficies afilados o abrasivos,

herramientas del equipo o fuentes

de electricidad.

• No utilizar para restricción de caída

o posicionamiento de trabajo.

• Calcular la longitud de la caída libre

de todos los bordes delanteros.

• Evitar peligros de caídas colgantes y

• Se requiere AMORTIGUADOR para

uso con este dispositivo.

SRL Label W.1.1S Eng-SP © SCN 03-2020 [MIT] Template SRL W.1

WARNING! Do not disassemble the casing. Return to

SAS factory for service or repair. Recoil spring inside is

extremely dangerous and can result in serious injury or death.

¡ADVERTENCIA! No desarmar oi retirar las tapas de un SRL. Para

reparaciones o servicio de mantenimiento, devolver la unidad a las

instalaciones de SAS. El resorte de retracción dentro de la unidad, es

extremadamente peligroso y podría ocasionar heridas serias o la muerte.

PID Labels

English and Spanish PID labels are attached to the SRL casing as

shown at Fig.2. Request replacement labels from SAS factory.

English Label Pack EE Spanish Label Pack EE.S

Model Length

Serial No. DOM