Super Anchor Safety (SAS) Phone | Téléphone: (425) 488-8868 www.superanchor.com

English |Français canadien Section English Page Page français

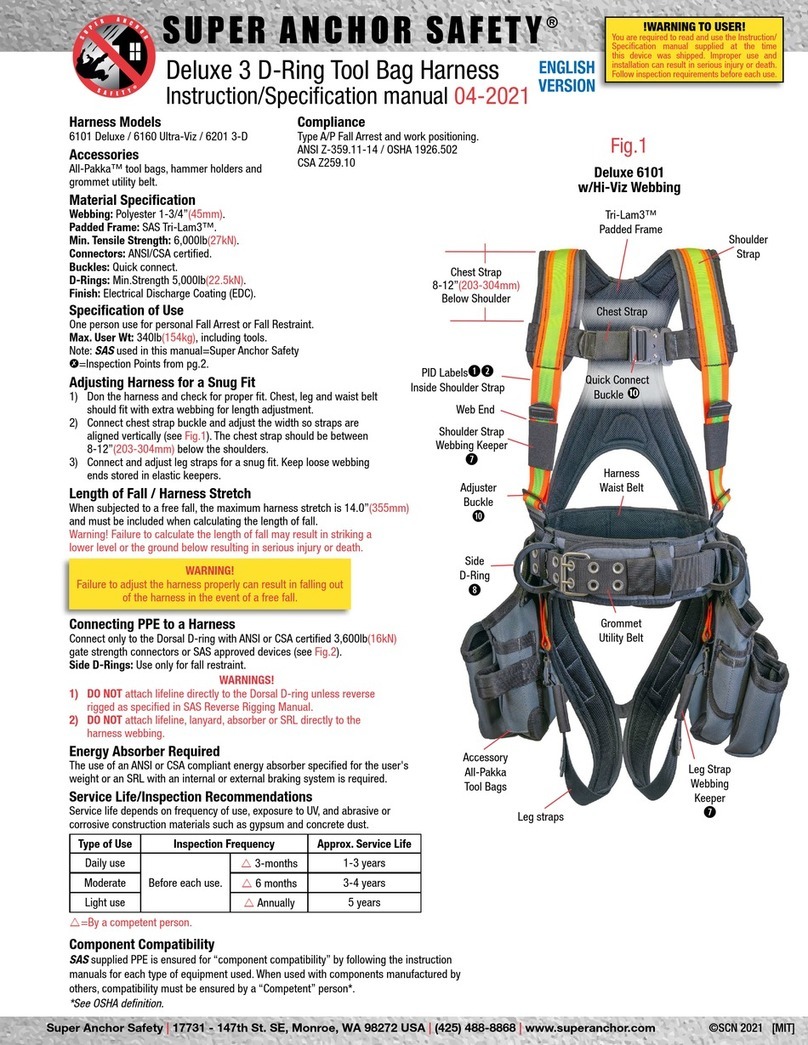

HARNESS ADJUSTMENT AND COMPONENT CONNECTIONS

AJUSTEMENT DU HARNAIS ET ACCESSOIRES DE FIXATION 12 12

INSPECTIONS: SHOCK ABSORBER / HARNESS

INSPECTIONS: ABSORBEUR D’ÉNERGIE/HARNAIS 23 13

ADJUSTING LIFELINE / ROPE GRAB TO LIMIT FREE FALL

AJUSTEMENT: LIGNE DE VIE/COULISSEAU DE SÉCURITÉ 34 14

ANCHOR SERVICE ZONES

SURFACE DESSERVIE PAR L’ANCRAGE 45 15

INSTALLING / MAINTAINING / INSPECTING ROPE GRAB

INSTALLATION/ENTRETIEN/INSPECTION : COULISSEAU DE SÉCURITÉ 5-A 6 16

INSPECTIONS: LIFELINE / SNAPHOOK

INSPECTIONS: LIGNE DE VIE/CROCHETS À RESSORTS 5-B 7 17

ANCHOR DEVICES: | DISPOSITIFS D’ANCRAGE

HINGED ANCHOR

ANCRAGE À CHARNIÈRES HINGED ANCHOR™ 6-A 8 18

QUICK-STRAP

COURROIE À ATTACHE RAPIDE QUICK-STRAP™ 6-B 9 19

COMPONENT COMPATIBILITY

COMPATIBILITÉ DES ACCESSOIRES 710 20

INSPECTION REPORT FORM

FORMULAIRE DE RAPPORT D’INSPECTION 11 21

USER TRAINING LOG

JOURNAL DE BORD 11 21

FALL HAZARDS

RISQUES DE CHUTES 822 22

FALL ARRESTER/VERTICAL LIFELINE

DISPOSITIF ANTICHUTE/LIGNE DE VIE VERTICALE 923 24

PRODUCT I.D./WARNING LABELS

ÉTIQUETTES D’AVERTISSEMENT/NUMÉRO DE SÉRIE 10 25 26

TABLE OF CONTENTS |TABLE DES MATIÈRES

CARACTÉRISTIQUES D’UTILISATION:

L’équipement de sécurité mentionné dans ce manuel est qualifié en tant que système

de protection contre les chutes et en tant que dispositif de positionnement pour un

ouvrier.Tel qu’il est mentionné à la section 7, l’équipement et les accessoires sont

compatibles. La compatibilité de l’équipement fabriqué par d’autres fournisseurs et

utilisé avec les produits SAS doit être garantie par un ingénieur*.

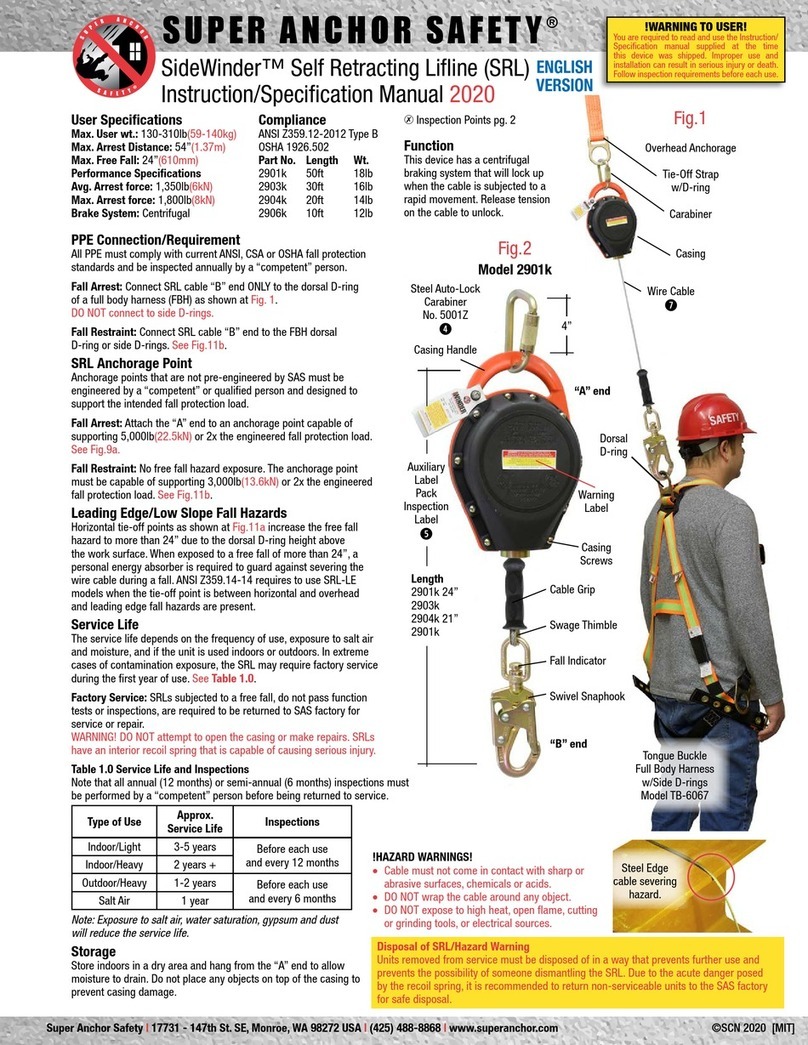

SPECIFICATIONS OF USE:

The equipment specified in this manual is rated for Fall Arrest and Fall Restraint/Work

Positioning for one person and is ensured for component compatibility as described

in section 7. Equipment mfg. by others and used with SAS equipment must have

compatibility ensured by“competent/qualified person”*.

HORIZONTAL LINES/MULTIPLE USERS:

The Quick Strap and Hinged Anchor are rated for two person use when there is no

exposure to a free fall. Not rated for Horizontal Lines.

ENERGY ABSORBER/ROPE GRAB: Maximum user wt. is 220lb(100kg).

E-4 model I6061k or I6061 energy absorber is fitted with a Snap-hook for connecting

to the harness D-Ring. Maximum arrest force (MAF) for a 6’(1.8m)free fall is 900lb(4kN).

The deployment length is 42”(1.06m). Rope grab Nº4015M is factory attached to the

energy absorber and is rated at 3,600lb(16kN). Complies with CSA Z259.11-05 / ANSI

Z359.1 /OSHA 1926:502

FULL BODY HARNESS: Maximum user wt. is 220lb(100kg).

6,000lb(27kN) rated polyester webbing fitted with a proof loaded 5,000lb(22kN) rated

di-chromate plated D-Ring, Fall Impact warning labels and serial number/date of mfg.

label. Complies with CSA Z259.10-06 Class A.

LIFELINE:

5/8”(16mm)dia. 3-strand, 9,300lb(4,200kg)strength polyester lifeline fitted with a

plastic thimble and locking type Snap-hook.The rope splice is encapsulated with clear

shrink tube. Fitted with specification and serial number labels. Complies with CSA

Z259.11-05 class F adjustable lanyard. Complies with ANSI Z359.1 as vertical lifeline.

LIGNES HORIZONTALES/UTILISATEURS MULTIPLES:

D’une capacité d’ancrage de 2 ouvriers, la Quick-Strap™ et le Hinged Anchor™ peuvent

être utilisés lorsqu’il n’y a pas risque de chute libre. Usage non compatible avec les

lignes horizontales.

ABSORBEUR D’ÉNERGIE/COULISSEAU DE SÉCURITÉ: Conçu pour un poids

maximal de 220lb(100kg), l’absorbeur d’énergie E-4 (modèle I6061k ou I6061) est

muni d’un crochet à ressort pour l’attacher à l’anneau en D du harnais. La force d’arrêt

maximale (FAM) lors d’une chute libre de 6pi(1.8m) est de 900lb(4kN). L’allongement

maximal est de 42”(1.06m). Le coulisseau de sécurité Nº4015M est fixé en usine à

l’absorbeur d’énergie. Il a une capacité de 3 600lb(16kN). Conformes à la norme CSA

Z259.11-05 / ANSI Z359.1 /OSHA 1926:502

HARNAIS DE SÉCURITÉ: Conçu pour un poids maximal de 220lb(100kg).

Fait de polyester d’une capacité de 6 000lb(2 721kg), le harnais est muni d’un anneau

en D bichromaté d’une capacité de 5 000lb(2 267kg), d’étiquettes d’avertissement

contre les chutes et d’une étiquette du fabricant (numéro de série/date de fabrication).

LIGNE DE VIE:

D’un diamètre de 5/8”(16mm), cette ligne de vie en polyester trois fils a une capacité

de 9 300lb(4 200kg) et est munie d’une cosse en plastique et d’un crochet à ressorts

verrouillable. L’épissure est encapsulée dans une gaine de protection transparente. La

gaine est munie d’une étiquette d’avertissement et du numéro de série. La ligne de vie

ajustable classe F est conforme à la norme CSA Z259.11-05.

*Qualified Person: According to the definition of the Industrial Safety Standards for your area. *Ingénieur: selon la définition des normes de sécurité industrielle régissant votre type de travail

Property of | Propriété de: Purchase Date | Date d’achat: