WARNING!

Attach leg to framing with 3ea

2” length Super Anchor supplied WS

wood screws only. DO NOT substitute

with other fasteners.

DO NOT USE NAILS

¡ADVERTENCIA!

Sujete la pierna al enmarcado

con 3ea tornillos de series WS

para madera de 2” de longitud

suministrados por Super Anchor

solamente. NO sustituya con otros

sujetadores. NO USE CLAVOS.

Label: WS Truss Bar 1.1 Eng/SP ©SCN 01-2018 Template TRB 3.1

Super Anchor Safety®

Monroe, WA 98272 USA

WS Truss-Bar™ No. 2835

Material: 6mm 5052 grade Aluminum

Min. breaking strength: 5,000lb

Resistencia minima de rotura: (22.5kN)

Cross-Bar Bolts: 12mm X 1-1/4”-316sst

Compliance: Cumplimiento:

OSHA 1926:502/1910.66

ANSI Z359.1-07/A10.32-2012

WARNING: Before use read the instruction manual

included with this anchor at time of shipping.

User Specifications: One person max wt. 340lb

Max Free Fall Length: 6ft.Max Arrest Force:1,800lb

PPE Attachment: Personal energy absorber required.

2 Anchors May be used for a Horizontal Lifeline System.

FASTENERS: Use SAS factory supplied WS Screws only.

Do not substitute with others types. DO NOT USE nails.

Requires 3ea WS 2.0” length screws in each leg.

REMOVE FROM SERVICE: If anchor is subjected to a fall

or other force or evidence of damage to legs or cross-bar

Framing: Attach to fully sheathed min. 2x4 top chord that

is capable of withstanding 2x the max. fall arrest force.

ADVERTENCIA: Antes de usar, lea el manual

de instrucciones suministrado con el envío de esta ancla.

Especificaciones para el usuario: Una persona, peso máximo 340lb

Máxima longitud de caída libre: 6ft.Fuerza máxima de arresto:1,800lb

Equipo PPE: Se requiere componente de amortiguador personal.

Se pueden usar 2 anclas para el sistema de Cuerdas Salvavidas Horizontales (HLL).

SUJETADORES: Use solamente tornillos de series WS suministrados por la fábrica SAS.

No sustituya con otros tipos de tornillos. NO USE clavos.

Se requiere 3ea tornillos de series WS de 2.0” de longitud en cada pierna.

RETIRE DE SERVICIO: Si el ancla se somete a una caída

u otra fuerza o evidencia de daño a las piernas o la barra transversal.

ENMARCADO: Sujete a la cuerda superior completamente enfundada

de mín. 2x4 que es capaz de aguantar 2x la fuerza máxima de arresto de caída.

Label: WS Truss Bar 1.0 Eng/SP

©SCN 01-2018 mfg. China

Label Template TRB 3.0

Standard Installation

Attached to top chords.

Belay Rigging Wrong

DO NOT attach to angle web.

Angle Web

Belay Rigging Correct

RS-10

WS-Screws

Steel Carabiner

Vertical Web

Attach RS-10 or Hinge anchor

to the vertical web only with

6pc WS-2.0” or 2.5” screws.

Belay Rigging Example

Using an interim anchor point

attached to a truss web will

reduce the swing fall length.

Optional WS-TrussBar

attachment locations

Drywall Ceiling

Compatible Connection Examples

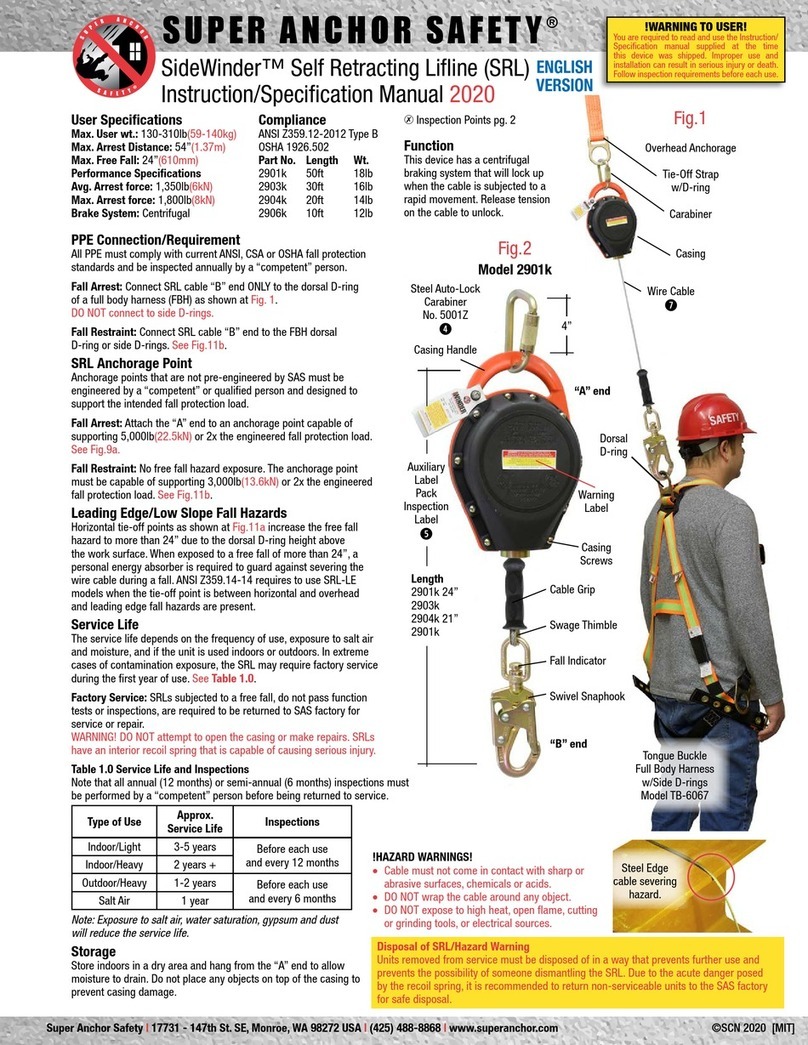

Single SRL w/Carabiner Single or Double HLL Single Lifeline Only No.1065-AC Coil Absorber

When 2 HLL are used in series only 1 person

may be attached to 1 leg of a HLL at one time

or 1 person each leg.

Leg 1 Leg 2 For use with 5º HLL systems,

1 absorber is required for each HLL leg.

Leg= 2 anchor ends with

a single cable.

Multiple Lifelines

2 lines may be attached if they are used

for relay by 1 person only.

Relay is when 1 person uses 2 lifelines or SRL’s to

facilitate movement without changing anchor points.

Truss Chord Butt Splice

DO NOT attach the WS-TrussBar

or belay anchors to chord splices.

Product I.D (PID) and Warning Labels

Warning Label attached to each leg.

PID Label

Maintenance/Inspection

Inspect before each use and remove from service

if any of the following conditions are present:

Friction washers or lock nuts are missing.

Request replacement parts.

Leg Flange weld is cracked. Cross-bar or legs

are damaged or deformed.

Connector hole is cracked, cut or deformed.

PID/Warning labels are missing.

Request replacement labels.

5ea WS screws in each anchor leg.

DO NOT store materials or tools on top of the

WS-TrussBar. Store inside when not in use.

DO NOT allow the bar to come in contact with

electrical lines.

Removal From Service: Dispose of in a way

that prevents further use. It is recommended to

cut off the connector hole and disassemble.

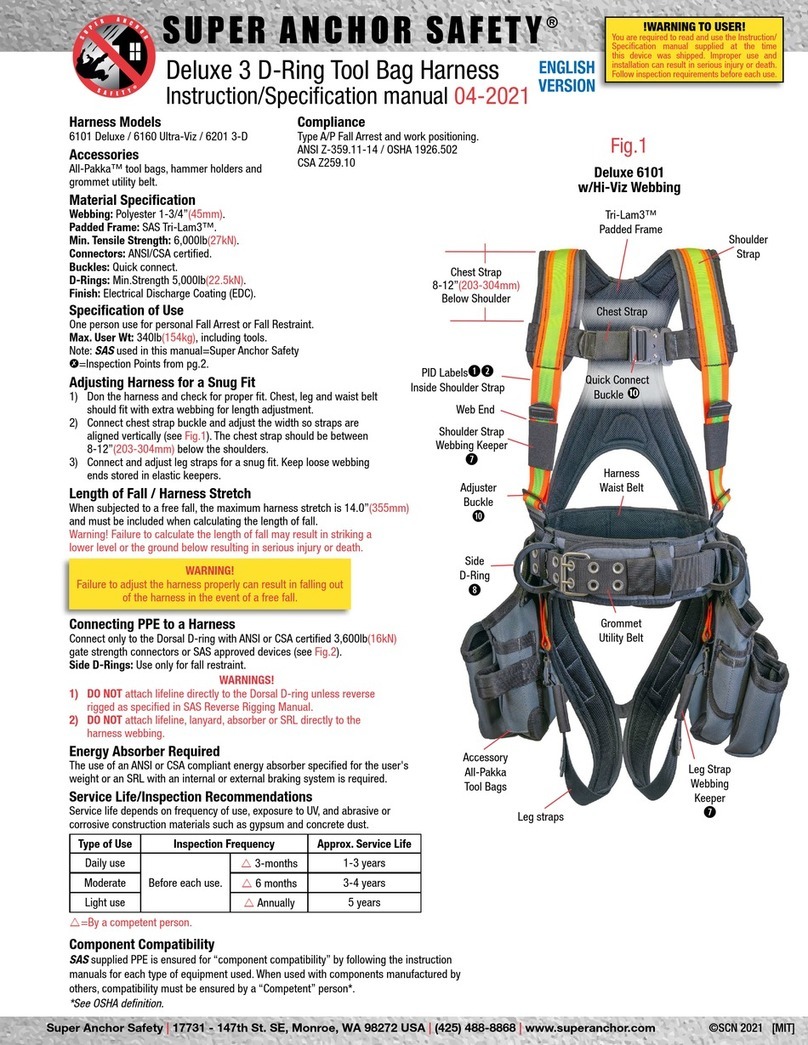

PPE Attachments

Harness Dorsal

D-Ring

Extender Lanyard

No. 6002

Extender Lanyard

No. 6002-C

w/Carabiner

SRL’s

Sidewinder™

Fig.13.0

Fig.15.0

Fig.16.0

Fig.17.0 Fig.17.1 Fig.17.2

Fig.16.1

Fig.16.2

Fig.15.1 Fig.15.2 Fig.15.3

Fig.14.0 Fig.14.1

Fig.14.2

WARNING!

DO NOT allow a lifeline, lanyard,

HLL or SRL cable to cross over

the top of the WS-TrussBar.

Vertical Web

SUPER ANCHOR SAFETY®Page 4English Version

©SCN 2022 [MIT]

WS-TrussBar English Manual 05-2022