14

+

-

N.C.

- FSW TX

N.C.

= +

= -

Fig. 10

After you have disaligned a device, the relevant LED

may flash for 2 or 3 seconds at realignment. This brief flashing

should not be considered as a discharged battery signal.

Fig. 11

Tab. 5

NOITISOPDEL NO FFO GNIHSALF

1DEL RETTIMSNARTPOT

DENGILA

RETTIMSNARTPOT

DENGILATON

RETTIMSNART HTIWTUBDENGILA

TSOMLASEIRETTAB

DEGRAHCSID

2DEL

LARTNEC RETTIMSNART

DENGILA

LARTNEC RETTIMSNART

DENGILATON

RETTIMSNART HTIWTUBDENGILA

TSOMLASEIRETTAB

DEGRAHCSID

3DEL

MOTTOB RETTIMSNART

DENGILA

MOTTOB RETTIMSNART

DENGILATON

RETTIMSNART HTIWTUBDENGILA

TSOMLASEIRETTAB

DEGRAHCSID

4DEL 1YALER EVITCA 1YALER EVITCATON ---

5DEL

DERARFNI LANGIS TNEICIFFUS

DERARFNI LANGIS TNEICIFFUSNI ---

6DEL 2YALER EVITCA 2YALER EVITCATON ---

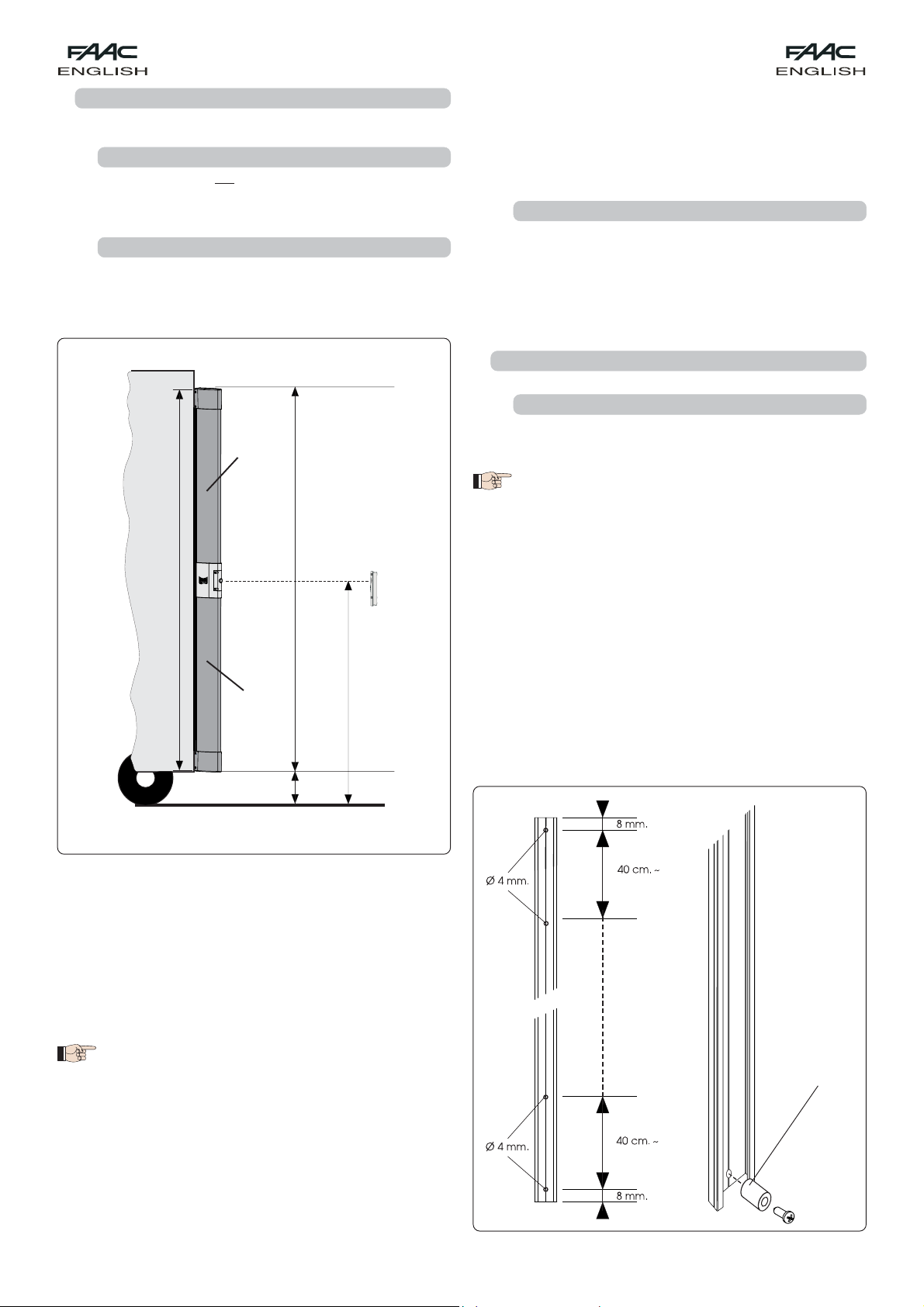

•If you use this profile to install the fixed receiver, you must cut

the front rubber element to create a niche for housing the

receiver at a height of 50 - 55 cm off the ground, using the

supplied drilling template (see Fig. 9).

•Drill a series of 4 mm diam. intermediate holes on the aluminium

profile, in steps of about 40 cm.

•Rest the aluminium profile on the pillar and, to secure it, use the

holes you drilled.

Move the gate manually and check if - in closed position

- the safety edge is positioned on the aluminium profile.

•Insert the rubber coupling profile downward in the aluminium

profile, until the niche reaches the height suitable for positioning

the fixed receiver.

•While moving the gate manually, check if - in closing position -

the edge penetrates inside the rubber coupling profile.

•Prepare the cables for the electrical connection, using the

niche made on the coupling profile (Fig.9).

•Place the electrical cables inside the coupling profile, and

make them exit from the lower part.

•Secure the fixed receiver (par. 4.3.4)

•Finish the installation by fitting the closing caps on the ends of

the coupling profile.

6. ELECTRICAL CONNECTIONS

Make the electrical connections on the terminal-board of the

fixed receiver, consulting the lay-outs in the instructions of the

control units, in the different configurations.

If using equipment without a FAIL SAFE input, you must

connect terminal

to terminal

of the fixed receiver.

7. OPERATING DIAGNOSTICS

The 6 LEDs on the fixed receiver make it possible to diagnose

installation and correct operation of all the devices of safety

edge MSE 110W.

Correct operation and installation is signalled by all 6 LEDs lighting

up on steady beam

For the meaning of each LED, refer to Tab.5.

•If the ray of the receiver-transmitter (Fig. 1 ref. ) is interrupted,

all 6 LEDs go OFF.

•If LED 5 goes OFF, this means:

- The distance between the fixed receiver (Fig.1 ref. ) and

the receiver-transmitter (Fig.1 ref. ) is too long.

- The fixed receiver and the receiver-transmitter are not

correctly aligned.

- The intensity of the signal is not sufficient for correct

operation.

If the MSE110W safety edge is triggered, it causes LEDS 4 and 6 to

go OFF simultaneously.

= Relay contact

= Relay contact

= Fail-Safe