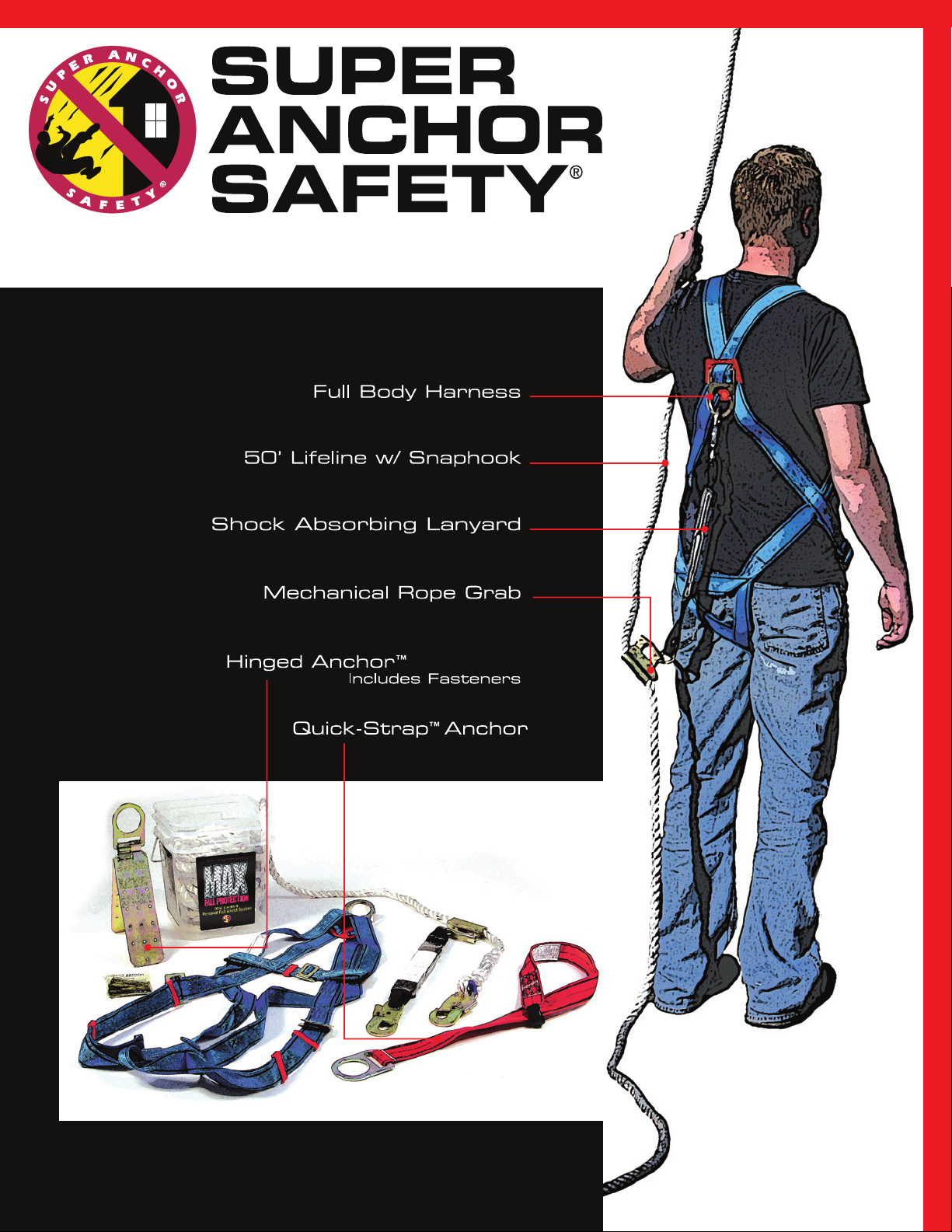

ADJUSTING A

NEW HARNESS:

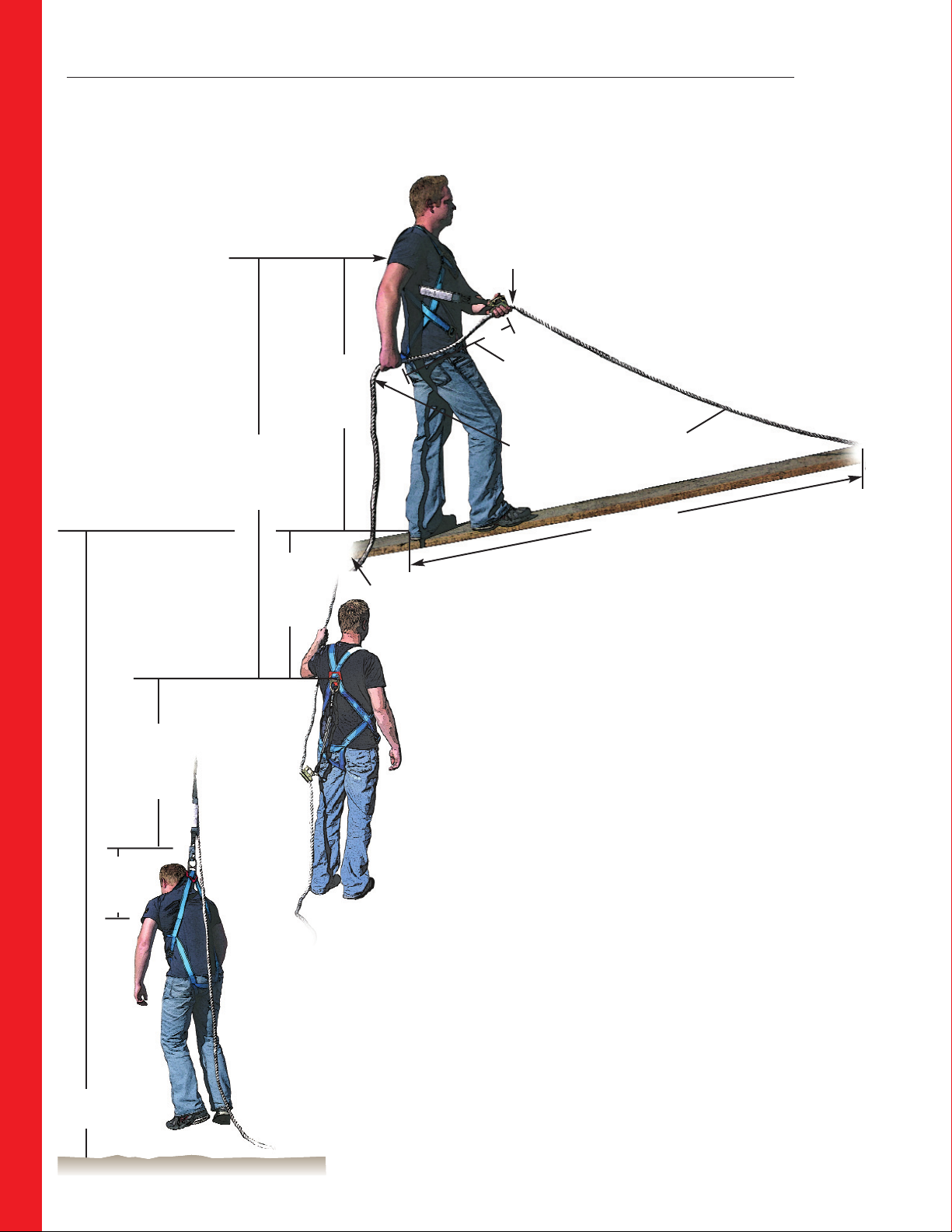

Hold the harness by the metal D-ring. Unbuckle the

chest strap and leg strap friction buckles. Remove any

twists in the webbing. Insert arms through the shoulder

straps so the D-ring is on your back and the arrow indi-

cator on the shoulder strap, shown in Fig. 3, is

pointing up toward your head. Leg straps should be

hanging down with no twists or tangles. Adjusting for

personal fit may require the harness to be put on and

taken off several times.

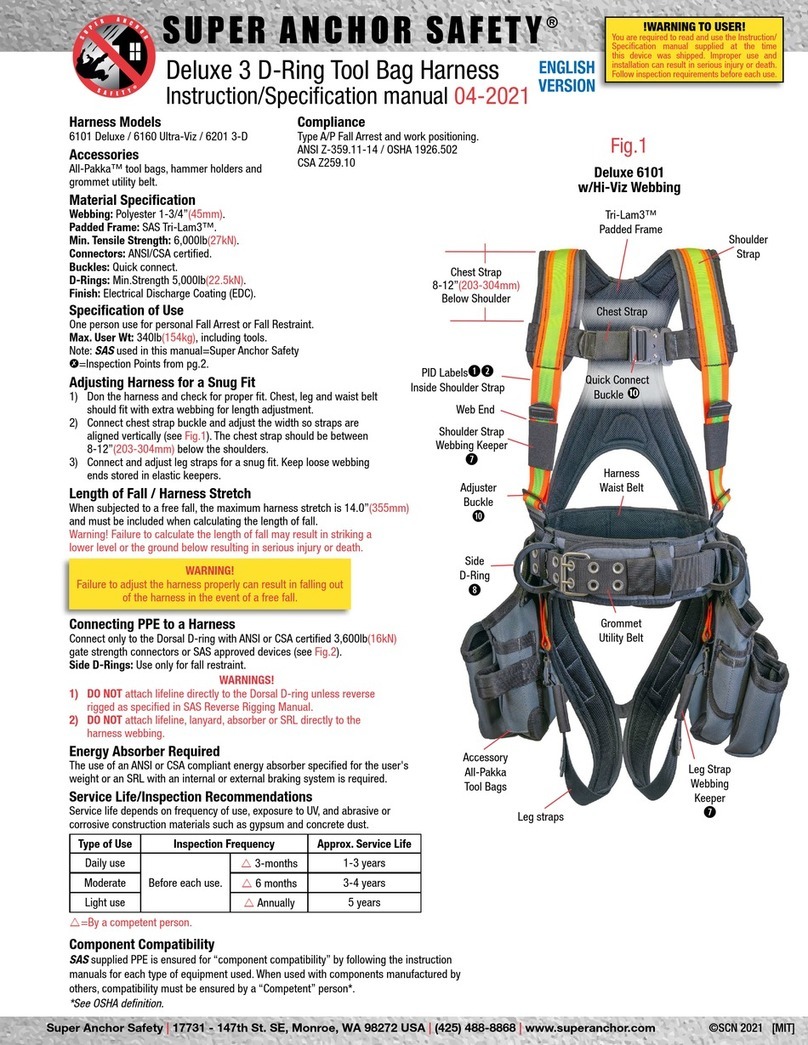

CHEST AND SHOULDER

STRAP ADJUSTMENT:

1. Align the shoulder straps so they are parallel to

each other as shown in Fig. 1. Buckle the chest strap

by inserting buckle "A" through buckle "B" as shown in

Figs. 5, 6 and 7below. Adjust the chest strap length by

moving the webbing through buckle "A" so the shoulder

straps do no extend past your armpits. For an average

size person the length between the shoulder straps

should be no more than 12". The chest strap should be

positioned at armpit level as shown in Fig. 1.

SECTION 1

HARNESS ADJUSTMENT AND COMPONENT CONNECTIONS

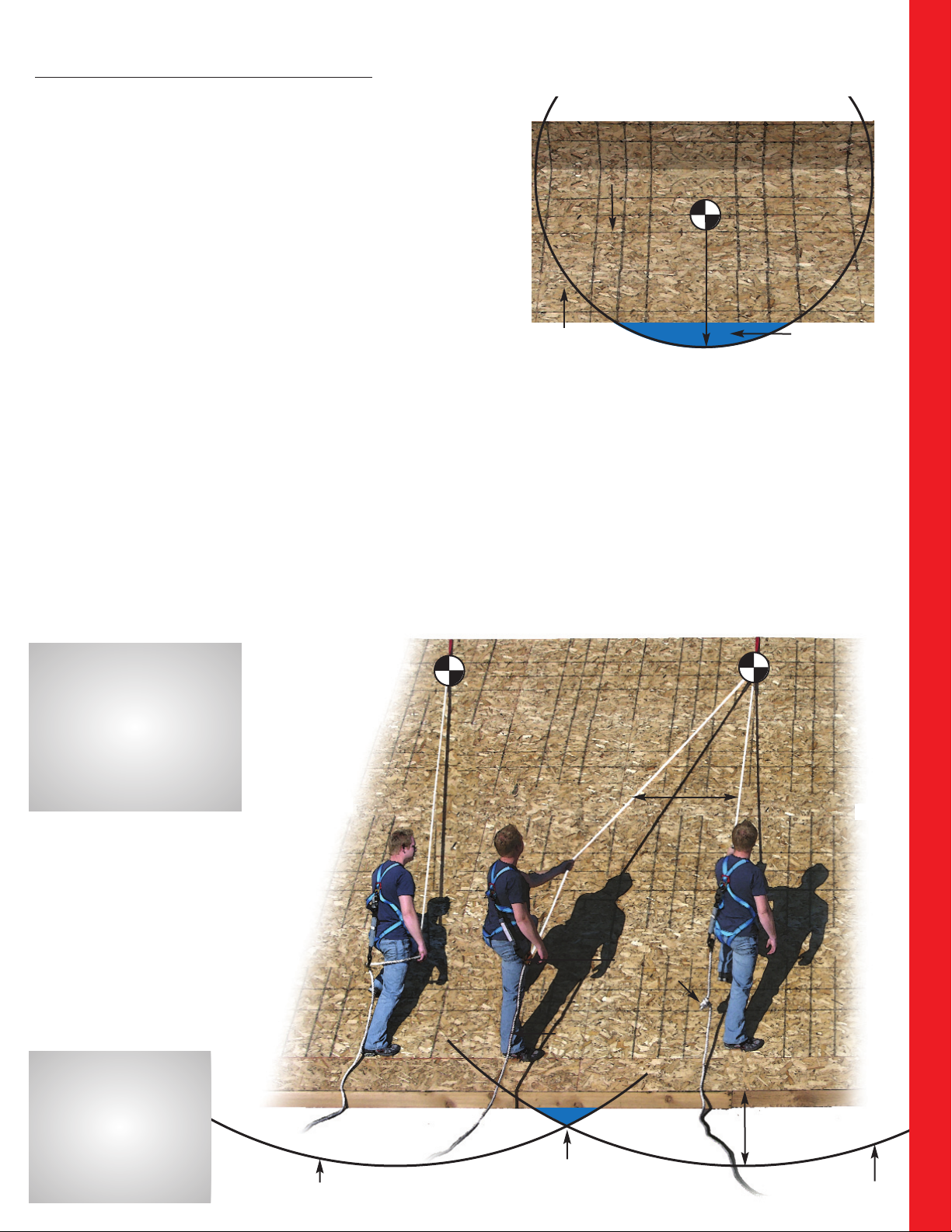

D-RING ADJUSTMENT:

3. The D-ring on harness back should position about the center of

the shoulder blades as shown in Fig. 2. Position the D-ring pad at

least 4" below the top of your shoulders but no more than 6". Adjust

the D-ring location by moving the webbing through the slots in the

D-ring pad (Fig. 3) and taking up excess webbing through the leg

strap friction buckles (Fig. 1). The chest strap position may have to be

adjusted after moving the D-ring pad.

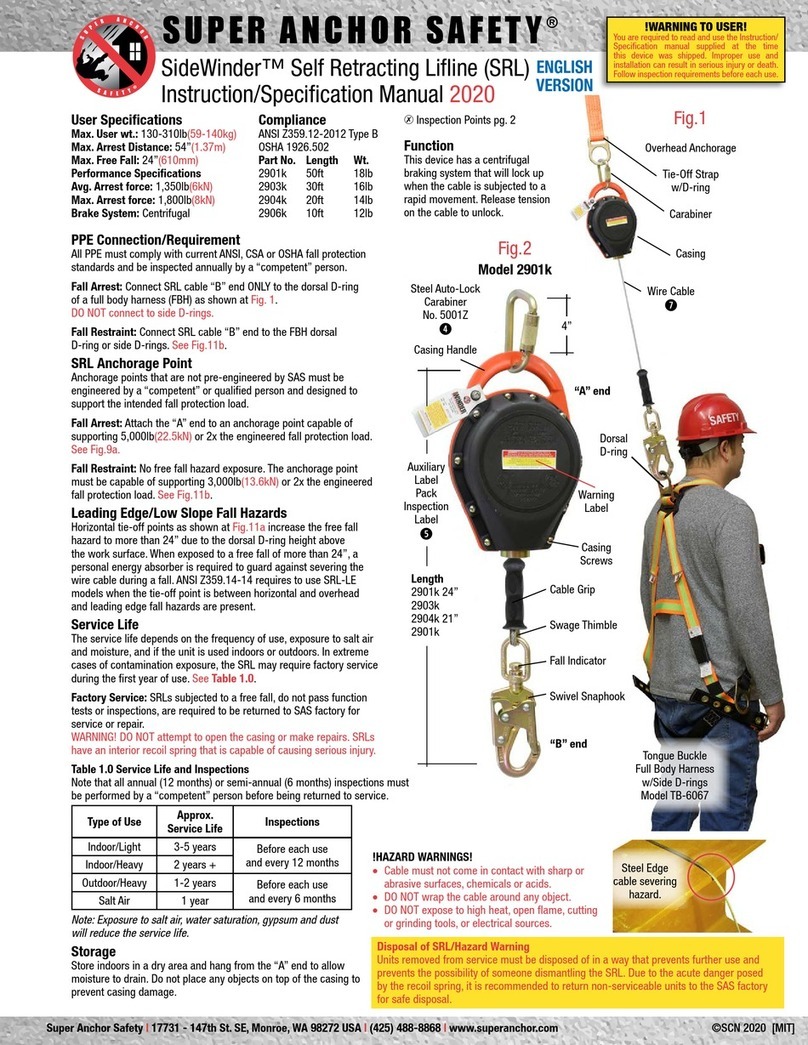

4. Connect shock absorber as shown in Fig. 3 to the back of the

D-ring on the harness with the snaphook. Make sure the snaphook

functions properly by following instructions in Section 5-B.

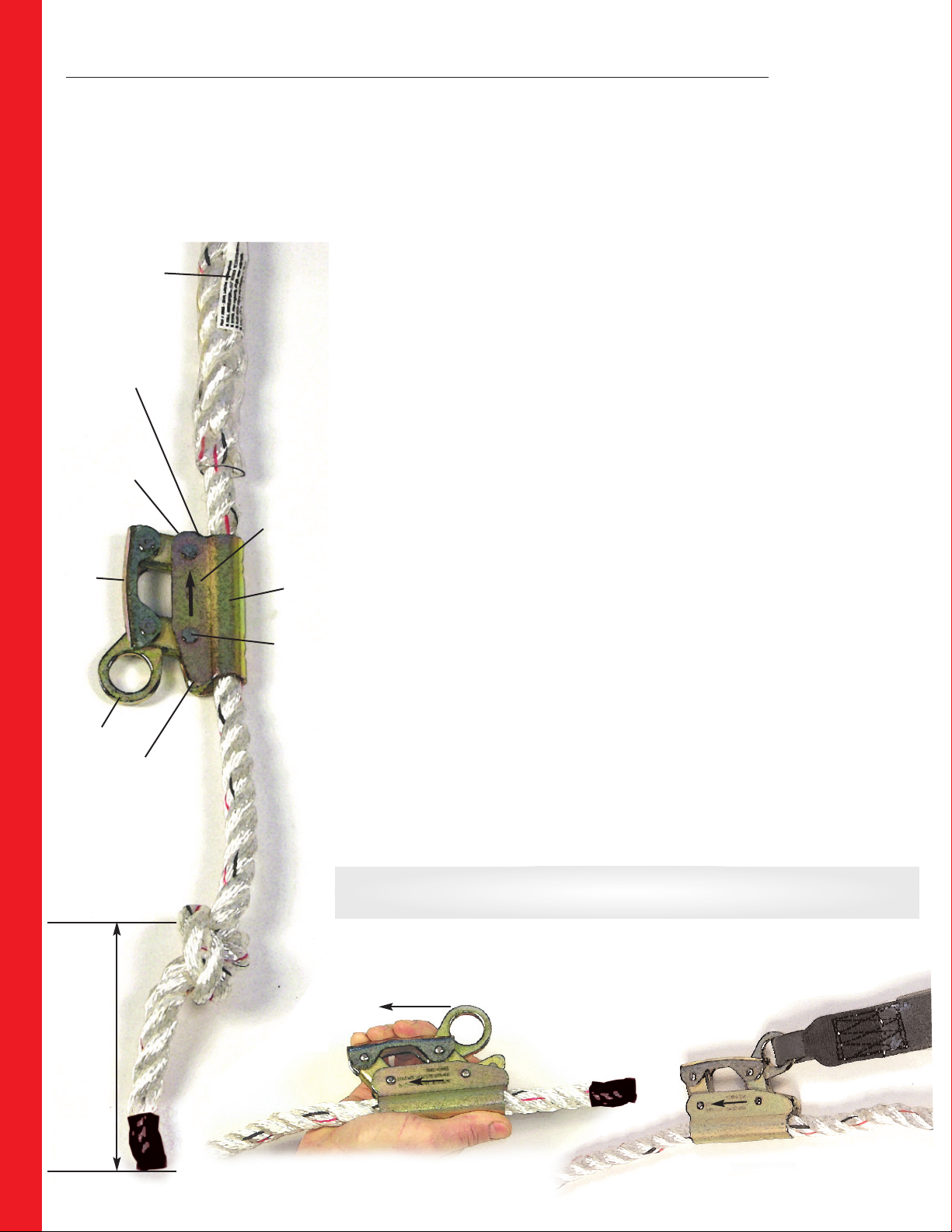

5. Lifeline should be installed through the rope grab with the arrow

indicator pointing toward the anchor-point end of the lifeline shown in

Fig. 4. Follow the instructions for the rope grab adjustment in

Section 3 before use.

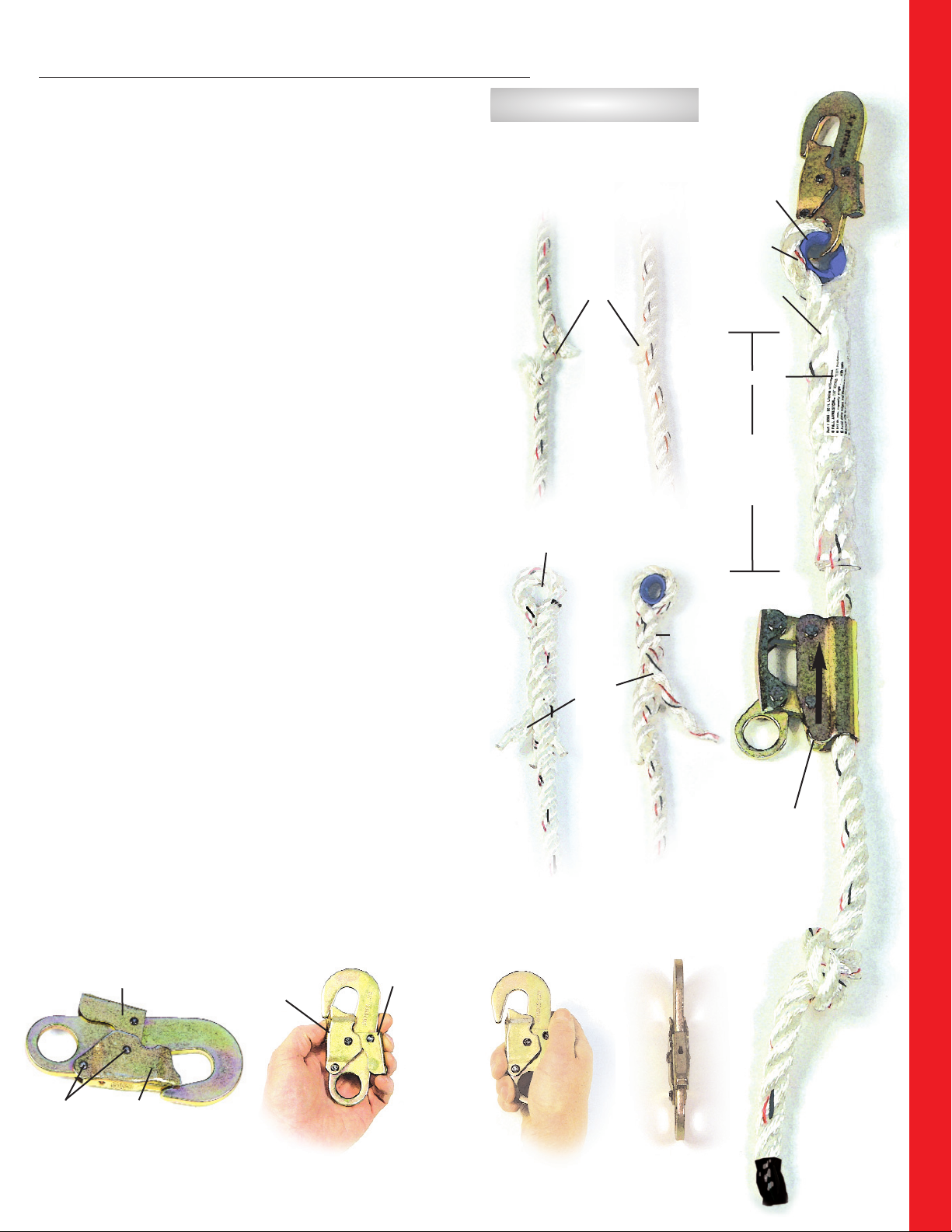

FRICTION BUCKLES:

7. Friction buckles are locked by inserting the smaller "A" buckle

through the larger "B" buckle (Fig. 5). Turn "A" buckle at an angle as

shown in Fig. 6 and slide through "B" buckle. The "A" buckle should

lay flat over the top of the "B" buckle as shown in Fig. 7.

LEG STRAP

ADJUSTMENT:

2. Buckle the leg straps and adjust for a snug

fit. Shorten or lengthen the strap by unbuck-

ling and moving the webbing through the "A"

buckle. Store excess webbing using keepers

shown in Fig. 7.

WEBBING KEEPERS:

8. Excess webbing from the chest and leg/shoulder straps are stored using the

plastic webbing keepers shown in Fig. 7. Webbing strap ends are terminated by

folding over and sewing in place. This prevents the webbing from sliding back

through the "A" buckle. For this reason, do not cut off excess webbing. If

termination overlap is missing do not use the harness.

WARNING:

IF THE HARNESS IS NOT ADJUSTED

FOR A SNUG FIT, IT IS POSSIBLE TO

COME OUT OF THE HARNESS IF YOU

FALL. THE CHEST STRAP MUST BE

CLOSED AND BUCKLED AT ALL

TIMES WHEN YOU ARE USING

THE HARNESS FOR FALL

PROTECTION.

Fig. 5 Fig. 6 Fig. 7

“A” “B”

Insert small buckle "A"

into large buckle "B" at an angle Buckle "A" lays over

the top of buckle "B"

Webbing

Keepers

"A" on top

Fig. 3

approx 12"

Adjust webbing

through D-ring

pad slots

D-ring pad

D-ring

Shoulder

strap arrow

Shock absorber

Fig. 1

Max length

below shoulder

6"

Harness

D-ring at

center of

back

Rope grab

Make sure "arrow" on

rope grab is pointed

toward anchorage point

6. Attach lifeline to anchorage device

with the snaphook. Ensure the snaphook

is locked and the lifeline is not twisted

or entangled.

Shoulder strap

Chest strap

position

(armpit height)

Leg strap

Friction buckles

NOTE: Shoulder strap webbing is adjusted by shortening

or lengthening the leg straps.

Fig. 4

Webbing overlap

Fig. 2

4